Electrochemical Jet Machining of Surface Texture: Improving the Strength of Hot-Pressure-Welded AA6061-CF/PA66 Joints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. EJM of Textured Surfaces Using a Film Jet

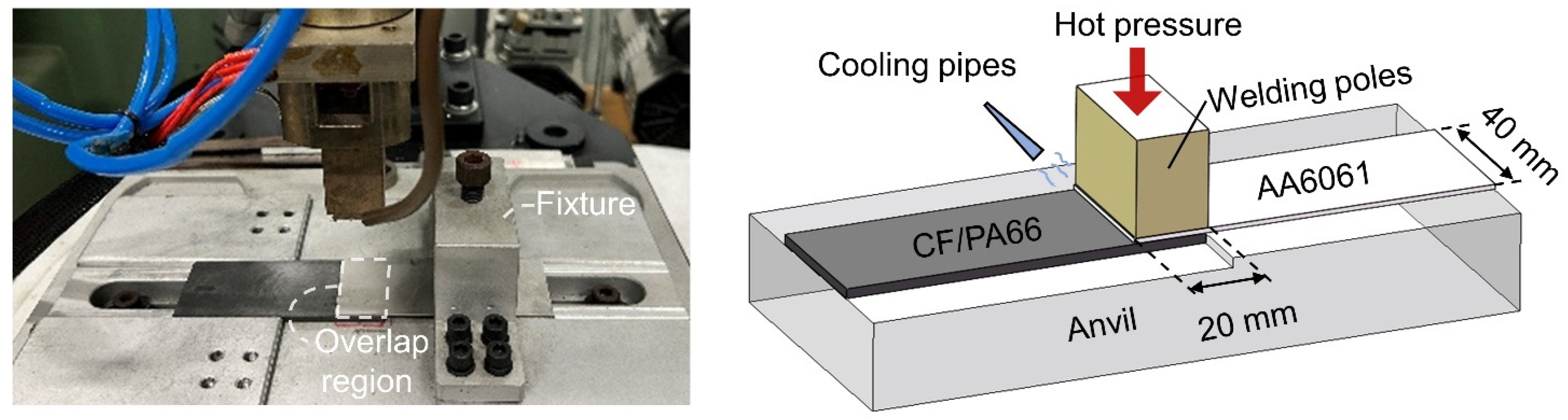

2.3. HPW of Textured AA6061 and CF/PA66

2.4. Characterization

3. Results and Discussion

3.1. Parametric Effects on Surface Texture Generated by EJM

3.1.1. Effect of Current Density on Surface Roughness and Morphology

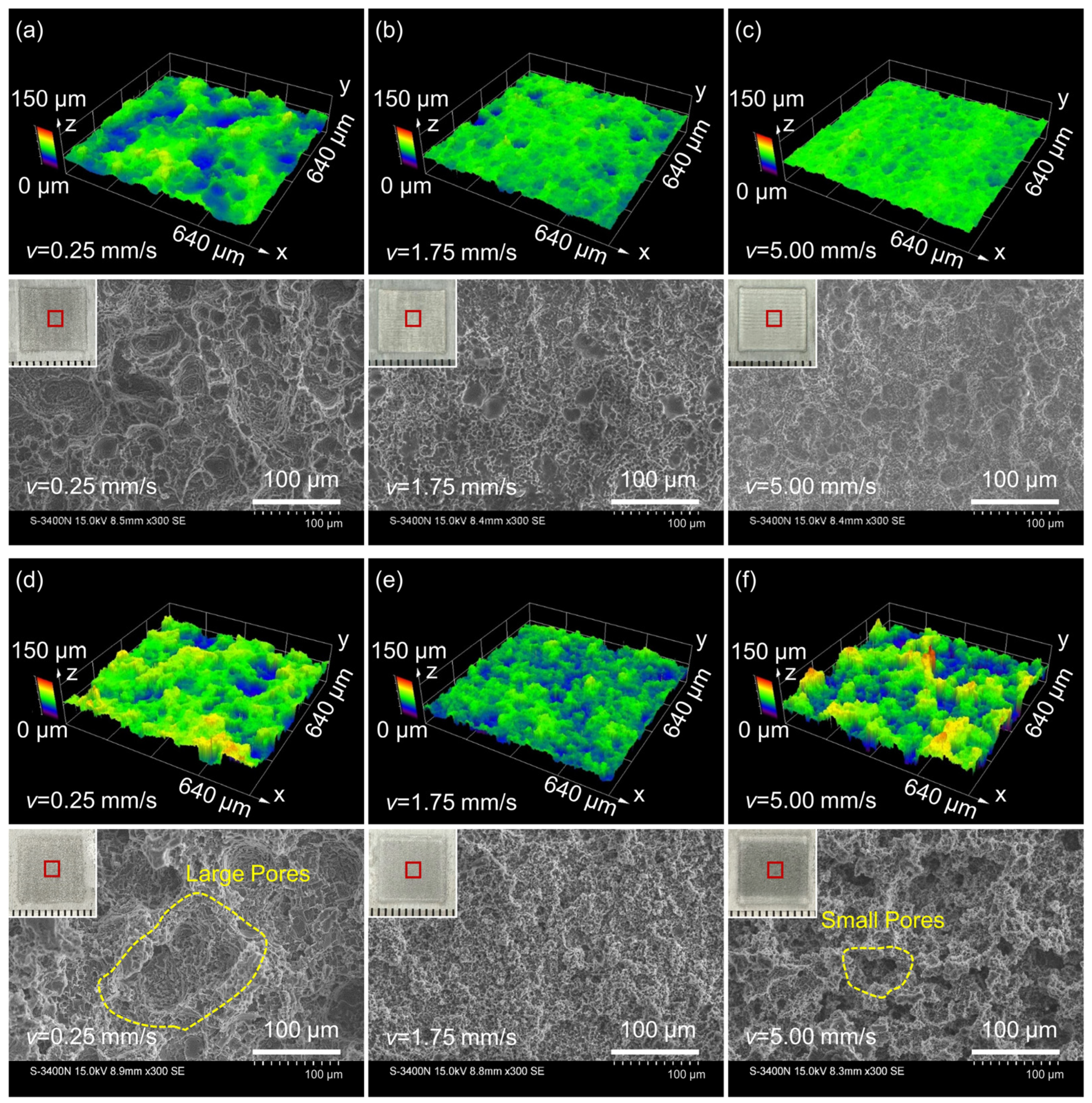

3.1.2. Effect of Jet Translational Speed on Surface Roughness and Morphology

3.2. Effect of Surface Texture Generated by EJM on AA6061-CF/PA66 HPW Joints

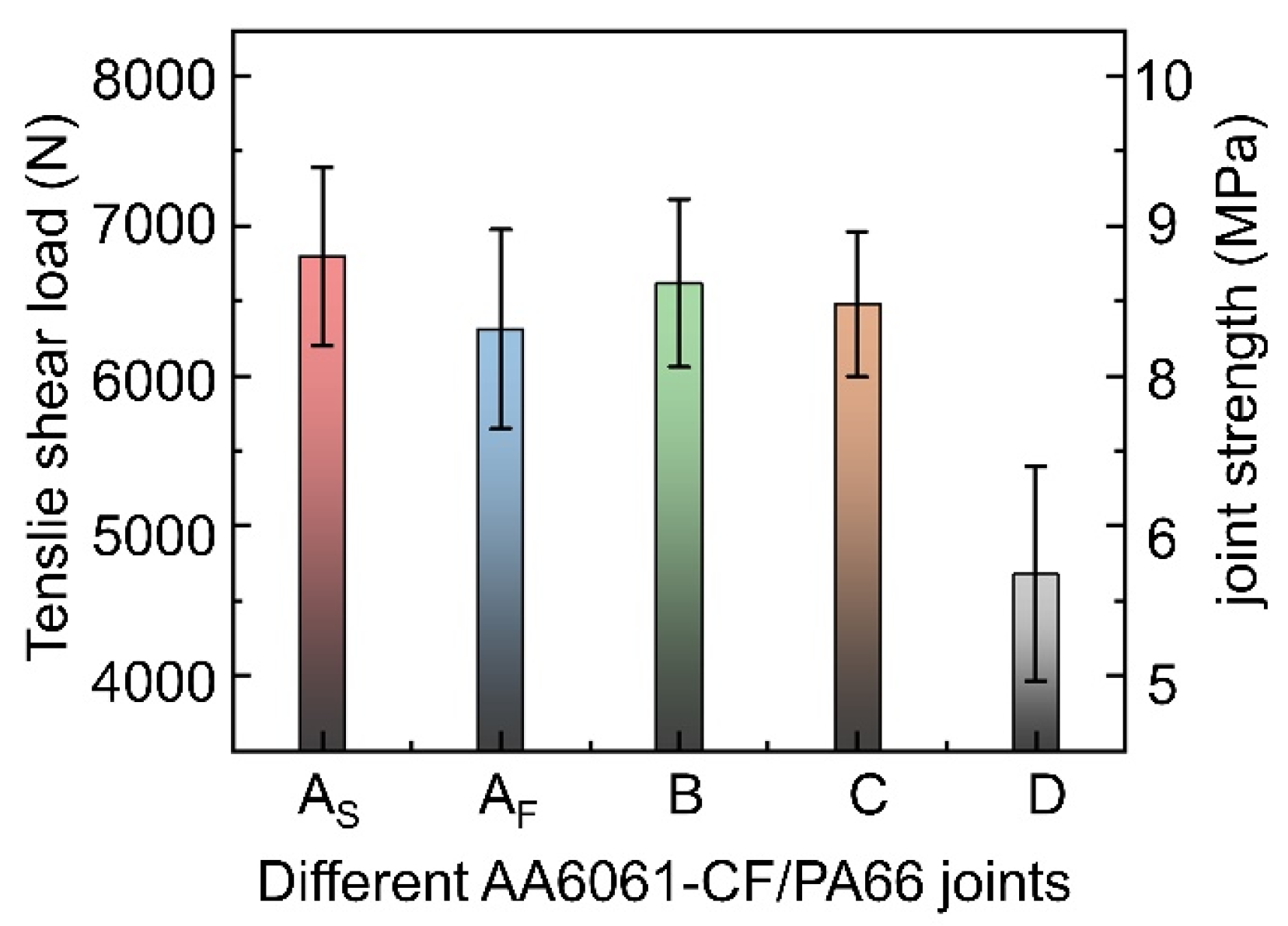

3.2.1. Mechanical Properties

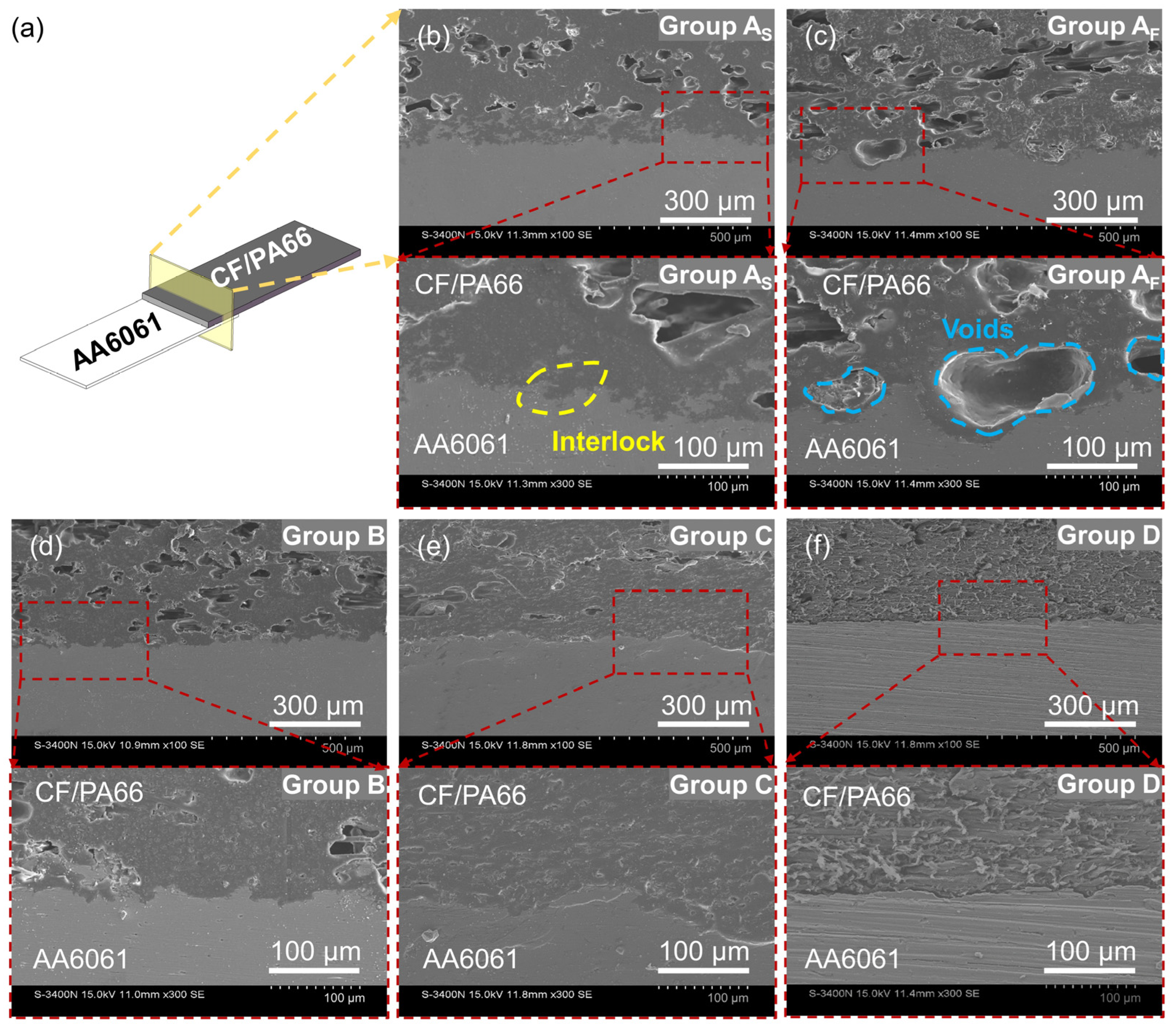

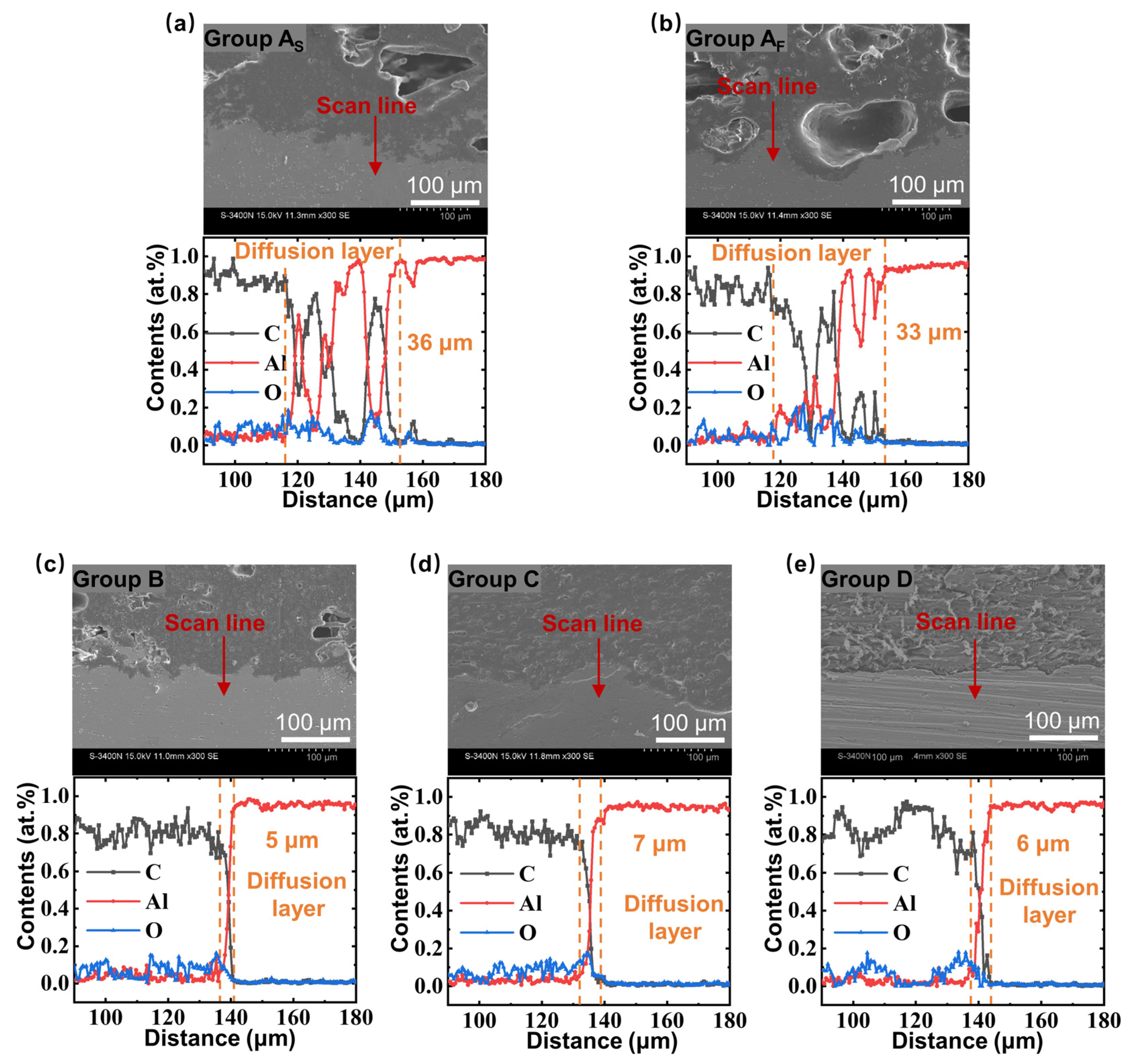

3.2.2. Interfacial Microstructure

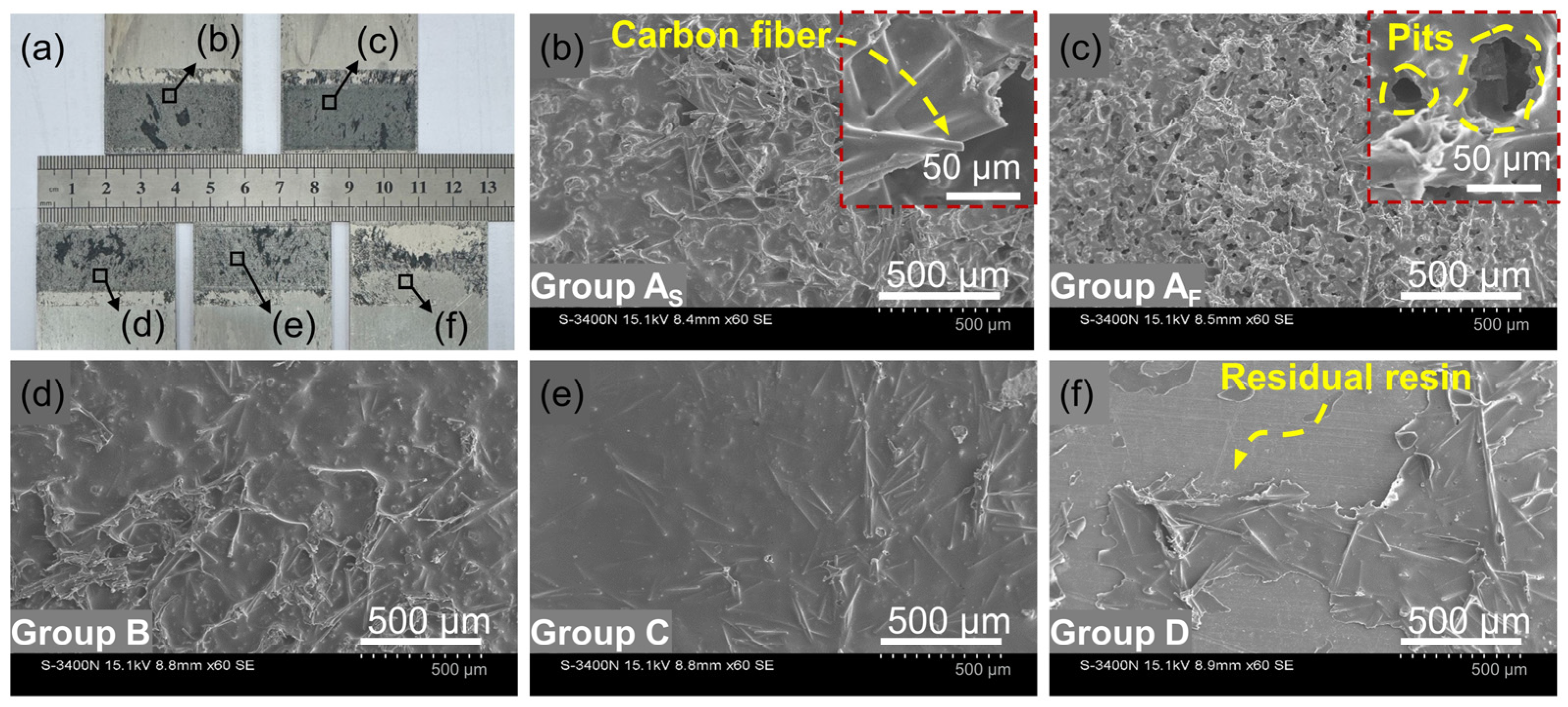

3.2.3. Fracture Morphology

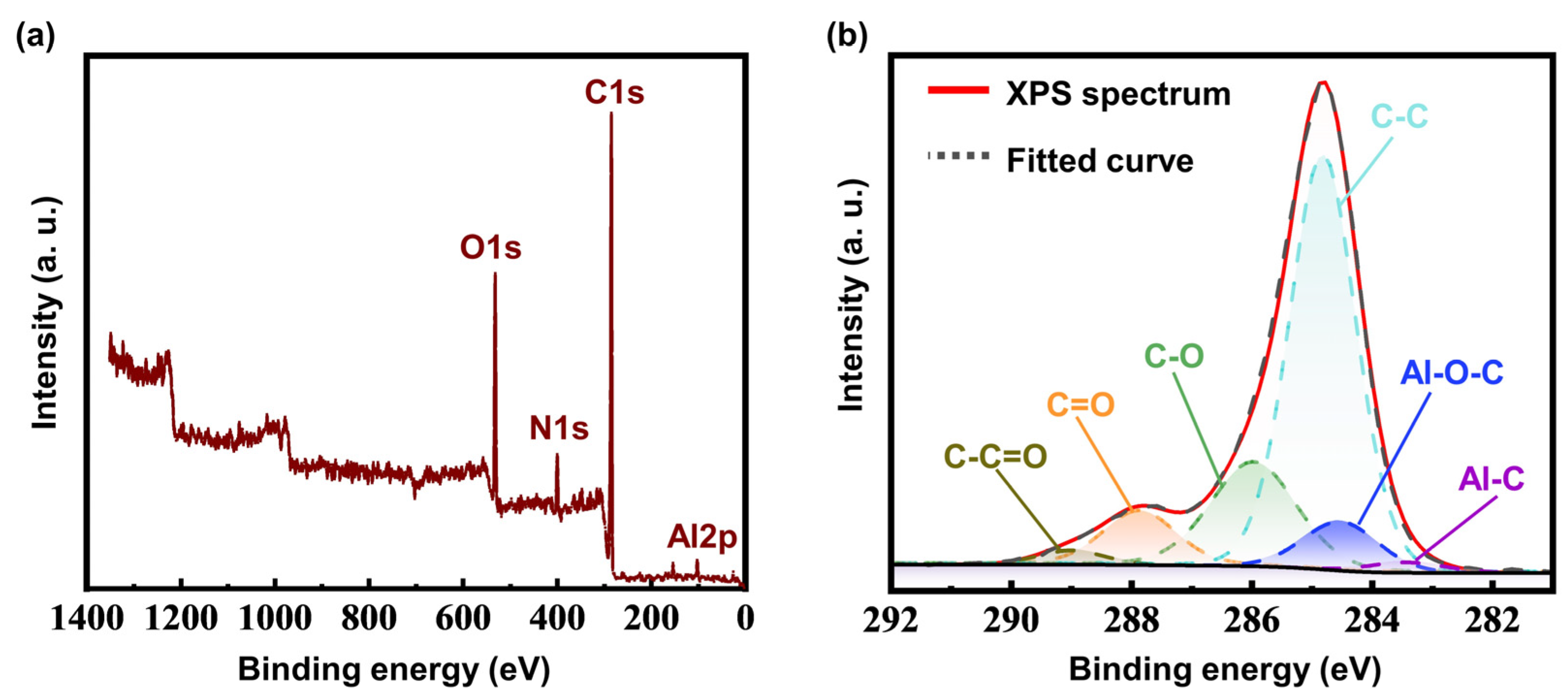

3.2.4. Interfacial Composition

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lambiase, F.; Scipioni, S.I.; Lee, C.J.; Ko, D.C.; Liu, F. A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures. Materials 2021, 14, 1890. [Google Scholar] [CrossRef] [PubMed]

- Almushaikeh, A.; Alaswad, S.; Alsuhybani, M. Manufacturing of carbon fiber reinforced thermoplastics and its recovery of carbon fiber: A review. Polym. Test. 2023, 122, 108029. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, Y.; Liu, Z.W.; Yang, Y.; Li, Y.; Luo, Z. Ultrasonic welding of metal to fiber-reinforced thermoplastic composites: A review. J. Manuf. Process. 2023, 85, 702–712. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, Y.; Liu, W.D.; Zhou, H.P.; Ao, S.S.; Luo, Z. Enhancing the ultrasonic plastic welding strength of Al/CFRTP joint via coated metal surface and structured composite surface. J. Manuf. Process. 2023, 108, 227–237. [Google Scholar] [CrossRef]

- Zhou, H.P.; Li, Y.; Liu, W.D.; Luo, Y.; Ao, S.S.; Luo, Z. Effect of Process Parameters on Joint Performance in Hot Pressure Welding of 6061 Aluminum Alloy to CF/PA66. Materials 2024, 17, 329. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.W.; Zhang, Q.; Fan, X.G.; Zhao, S.D. Review on Joining Process of Carbon Fiber-Reinforced Polymer and Metal: Methods and Joining Process. Rare Met. Mater. Eng. 2018, 47, 3689–3696. [Google Scholar]

- Faes, K.; Vermeersch, J.; Silva, R. Joining of Metal-Plastic Composites with Advanced Welding Processes. In Proceedings of the ASME 2021 16th International Manufacturing Science and Engineering Conference, Virtual, Online, 21–25 June 2021; V002T06A010; pp. 1–9. [Google Scholar]

- Li, Y.; Bu, H.C.; Yang, H.Y.; Liu, G.; Yao, J.A.; Zhan, X.H. Effect of laser heat input on the interface morphology during laser joining of CFRTP and 6061 aluminum alloy. J. Manuf. Process. 2020, 50, 366–379. [Google Scholar] [CrossRef]

- Jiao, J.; Xu, J.; Jing, C.; Cheng, X.; Wu, D.; Ru, H.; Zeng, K.; Sheng, L. Effect of Laser Micro-Texturing on Laser Joining of Carbon Fiber Reinforced Thermosetting Composites to TC4 Alloy. Materials 2022, 16, 270. [Google Scholar] [CrossRef] [PubMed]

- Nagatsuka, K.; Yoshida, S.; Tsuchiya, A.; Nakata, K. Direct joining of carbon-fiber-reinforced plastic to an aluminum alloy using friction lap joining. Compos. Part B Eng. 2015, 73, 82–88. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, H.B.; Ai, C.J.; Zhao, J.J.; Su, H.; Chen, J.; Zhao, G.Q. Parameter optimization of friction stir spot welded Al 6061 and CFRTP PA6 with surface treatment and interfacial adhesion. Thin-Walled Struct. 2024, 197, 111585. [Google Scholar] [CrossRef]

- Lionetto, F.; Mele, C.; Leo, P.; D’Ostuni, S.; Balle, F.; Maffezzoli, A. Ultrasonic spot welding of carbon fiber reinforced epoxy composites to aluminum: Mechanical and electrochemical characterization. Compos. Part B Eng. 2018, 144, 134–142. [Google Scholar] [CrossRef]

- Feistauer, E.E.; Santos, D.; Amancio, F. An investigation of the ultrasonic joining process parameters effect on the mechanical properties of metal-composite hybrid joints. Weld. World 2020, 64, 1481–1495. [Google Scholar] [CrossRef]

- Liu, Y.; Su, J.; Tan, C.W.; Feng, Z.; Zhang, H.; Wu, L.; Chen, B.; Song, X. Effect of laser texturing on mechanical strength and microstructural properties of hot-pressing joining of carbon fiber reinforced plastic to Ti6Al4V. J. Manuf. Process. 2021, 65, 30–41. [Google Scholar] [CrossRef]

- Li, W.; Geng, P.; Ma, N.; Chen, C. Effect of thermal-mechanical conditions on strength of silanized Al alloy/CFRTP hybrid joint made by thinning-controlled hot pressing. Mater. Today Commun. 2024, 38, 108507. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Su, J.H.; Feng, Z.W.; Liu, H.R.; Xia, H.B.; Zhang, Z.Q.; Tan, C.W.; Chen, B.; Song, X.G. Effect of laser textured patterns on the interfacial characteristics and mechanical properties of 6061Al/GFRTP joints via hot-pressing. Thin-Walled Struct. 2023, 189, 110916. [Google Scholar] [CrossRef]

- Sandeep, R.; Natarajan, A. Advances in joining technologies for the innovation of 21st century lightweight aluminium-CFRP hybrid structures. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 1239–1255. [Google Scholar] [CrossRef]

- Liu, Y.F.; Su, J.H.; Ma, G.L.; Han, X.H.; Tan, C.; Wu, L.J.; Chen, B.; Song, X.G. Effect of the laser texturing width on hot-pressing joining of AZ31B and CFRTP. Opt. Laser Technol. 2021, 143, 107350. [Google Scholar] [CrossRef]

- Abe, H.; Chung, J.C.; Mori, T.; Hosoi, A.; Jespersen, K.M.; Kawada, H. The effect of nanospike structures on direct bonding strength properties between aluminum and carbon fiber reinforced thermoplastics. Compos. Part B Eng. 2019, 172, 26–32. [Google Scholar] [CrossRef]

- Iwata, K.; Suzuki, A.; Kim, S.G.; Takata, N.; Kobashi, M. Enhancing the solid-state joinability of A5052 and CFRTP via an additively manufactured micro-structure. J. Mater. Process. Technol. 2022, 306, 117629. [Google Scholar] [CrossRef]

- Xia, H.B.; Yang, B.Y.; Su, J.H.; Liu, Y.F.; Su, X.; Wang, C.; Qiang, X.; Wu, T.; Tan, C.W. Improvement of laser welded TC4/CFRTP joint strength by combination of surface modification of MAO and laser texturing. Thin-Walled Struct. 2024, 196, 111409. [Google Scholar]

- Dong, H.G.; Tang, Z.Y.; Li, P.; Wu, B.S.; Hao, X.H.; Ma, C.Q. Friction stir spot welding of 5052 aluminum alloy to carbon fiber reinforced polyether ether ketone composites. Mater. Des. 2021, 201, 109495. [Google Scholar] [CrossRef]

- Speidel, A.; Bisterov, I.; Saxena, K.K.; Zubayr, M.; Reynaerts, D.; Natsu, W.; Clare, A.T. Electrochemical jet manufacturing technology: From fundamentals to application. Int. J. Mach. Tools Manuf. 2022, 180, 103931. [Google Scholar] [CrossRef]

- Yoneda, K.; Kunieda, M. Numerical analysis of cross sectional shape of micro-indents formed by the electrochemical jet machining. J. Jpn. Soc. Electr. Mach. Eng. 1995, 29, 1–8. [Google Scholar]

- Hackert-Oschätzchen, M.; Paul, R.; Martin, A.; Meichsner, G.; Lehnert, N.; Schubert, A. Study on the dynamic generation of the jet shape in jet electrochemical machining. J. Mater. Process. Technol. 2015, 223, 240–251. [Google Scholar] [CrossRef]

- Kunieda, M.; Mizugai, K.; Watanabe, S.; Shibuya, N.; Iwamoto, N. Electrochemical micromachining using flat electrolyte jet. CIRP Ann. 2011, 60, 251–254. [Google Scholar] [CrossRef]

- Lyu, X.; Kimura, F.; Zhao, Y.; Kunieda, M.; Kajihara, Y. Metal-polymer injection molded direct joining using electrolyte jet machining. In Proceedings of the 7th International Conference of Asian Society for Precision Engineering and Nanotechnology (ASPEN), Seoul, Republic of Korea, 14–17 November 2017. MFT–O–01. [Google Scholar]

- Lutey, A.H.A.; Jing, H.Y.; Romoli, L.; Kunieda, M. Electrolyte Jet Machining (EJM) of antibacterial surfaces. Precis. Eng. 2021, 70, 145–154. [Google Scholar] [CrossRef]

- Lutey, A.H.A.; Romoli, L.; Lee, J.; Kunieda, M. Tailoring microbial response to stainless steel surfaces via electrolyte jet machining and electrodeposition. J. Adv. Manuf. Technol. 2023, 129, 727–738. [Google Scholar] [CrossRef]

- Kawanaka, T.; Kunieda, M. Mirror-like finishing by electrolyte jet machining. CIRP Ann. 2015, 64, 237–240. [Google Scholar] [CrossRef]

- Kong, H.H.; Qu, N.S. Flat jet electrochemical milling of TC4 alloy with tailoring backward parallel flow. Chin. J. Aeronaut. 2023, 23, 574–592. [Google Scholar] [CrossRef]

- Liu, W.D.; Ao, S.S.; Li, Y.; Liu, Z.M.; Zhang, H.; Manladan, S.M.; Luo, Z.; Wang, Z.P. Effect of Anodic Behavior on Electrochemical Machining of TB6 Titanium Alloy. Electrochim. Acta 2017, 233, 190–200. [Google Scholar] [CrossRef]

- Feng, Z.W.; Zhao, H.Y.; Tan, C.W.; Zhang, X.Y.; Chen, B.; Song, X.G. Nanosecond laser ablation for improving the strength of CFRTP and aluminum alloy adhesively bonded joints. Compos. Struct. 2021, 274, 114369. [Google Scholar] [CrossRef]

- Yang, G.X.; Yang, T.; Yuan, W.H.; Du, Y. The influence of surface treatment on the tensile properties of carbon fiber-reinforced epoxy composites-bonded joints. Compos. Part B Eng. 2019, 160, 446–456. [Google Scholar] [CrossRef]

- Liu, F.C.; Dong, P.; Lu, W.; Sun, K. On formation of Al-O-C bonds at aluminum/polyamide joint interface. Appl. Surf. Sci. 2019, 466, 202–209. [Google Scholar] [CrossRef]

| Material | Elongation | Melting Point | Solid-Phase Line Temperature | Liquid-Phase Line Temperature | Elasticity Modulus | Tensile Strength |

|---|---|---|---|---|---|---|

| AA6061 | 12.5% | - | 582 °C | 650 °C | 68.7 GPa | 311 MPa |

| CF/PA66 | 1.4% | 260 °C | - | - | 29.5 GPa | 355 MPa |

| Parameters | Value |

|---|---|

| Electrolyte | 20 wt.% aq. NaCl |

| Slit nozzle length (l) | 38 (mm) |

| Slit nozzle width (b) | 0.1 (mm) |

| Flow velocity (f) | 4.28 (m/s) |

| Electric charge (Q) | 240 (C/cm2) |

| Current density (i) | 20, 50, 80, 120, 200, 300 (A/cm2) |

| Jet translational speed (v) | 0.25, 0.75, 1.25, 1.75, 3.5, 5 (mm/s) |

| Groups | EJM Parameters | Surface Roughness Ra | Surface Morphology |

|---|---|---|---|

| AS | i = 20 A/cm2; v = 0.25 mm/s | 13 μm | Shown in Figure 7d |

| AF | i = 20 A/cm2; v = 5 mm/s | 13 μm | Shown in Figure 7f |

| B | i = 50 A/cm2; v = 0.25 mm/s | 8 μm | Shown in Figure 7a |

| C | i = 80 A/cm2; v = 3.5 mm/s | 4 μm | Shown in Figure 9 |

| D | No treatment | 1 μm | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Luo, Y.; Zhao, Y.; Zhou, H.; Ao, S.; Li, Y. Electrochemical Jet Machining of Surface Texture: Improving the Strength of Hot-Pressure-Welded AA6061-CF/PA66 Joints. J. Compos. Sci. 2024, 8, 263. https://doi.org/10.3390/jcs8070263

Liu W, Luo Y, Zhao Y, Zhou H, Ao S, Li Y. Electrochemical Jet Machining of Surface Texture: Improving the Strength of Hot-Pressure-Welded AA6061-CF/PA66 Joints. Journal of Composites Science. 2024; 8(7):263. https://doi.org/10.3390/jcs8070263

Chicago/Turabian StyleLiu, Weidong, Yan Luo, Yonghua Zhao, Haipeng Zhou, Sansan Ao, and Yang Li. 2024. "Electrochemical Jet Machining of Surface Texture: Improving the Strength of Hot-Pressure-Welded AA6061-CF/PA66 Joints" Journal of Composites Science 8, no. 7: 263. https://doi.org/10.3390/jcs8070263

APA StyleLiu, W., Luo, Y., Zhao, Y., Zhou, H., Ao, S., & Li, Y. (2024). Electrochemical Jet Machining of Surface Texture: Improving the Strength of Hot-Pressure-Welded AA6061-CF/PA66 Joints. Journal of Composites Science, 8(7), 263. https://doi.org/10.3390/jcs8070263