Preliminary Experimental and Numerical Study of the Tensile Behavior of a Composite Based on Sycamore Bark Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber’s Extraction

2.3. Fabrication of Sycamore Bark Fiber-Reinforced Composite

2.4. Tensile Tests

2.5. Microstructural Observations

3. Finite Element Modeling

3.1. Modeling Hypotheses

3.2. Simulation Setup

4. Results and Discussion

4.1. Experimental Results of Tensile Tests

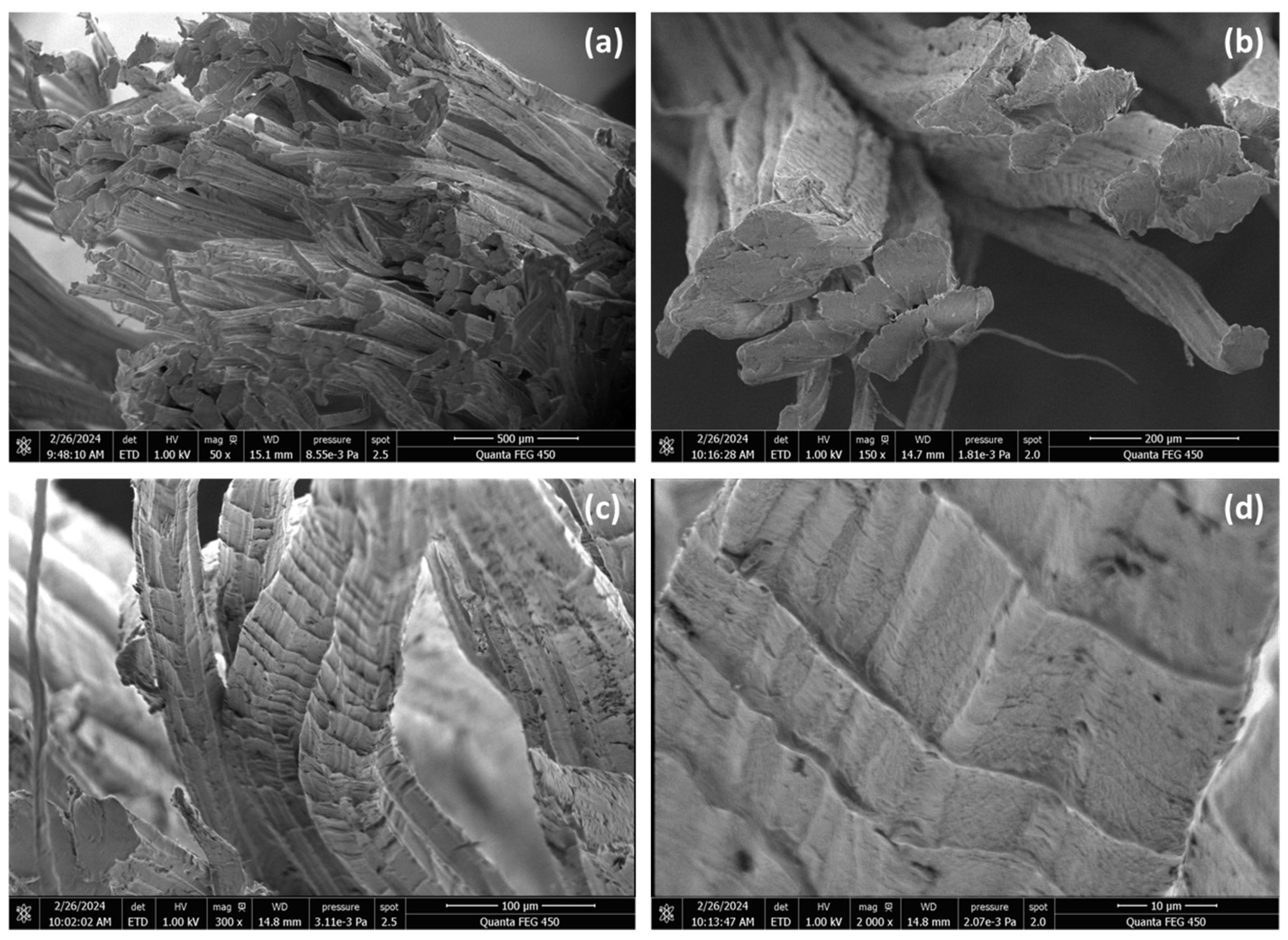

4.2. Microstructural Analysis

4.3. Finite Element Simulation Results

5. Conclusions

- The experimental tensile tests using DIC strain field measurements show that the addition of sycamore bark fibers to the polyester matrix significantly incremented the elastic modulus from 1916.1 to 4788.4 MPa up to 18 vol.% of reinforcement, corresponding to an increment of 150%.

- Additionally, the tensile strength of the polyester resin increased by approximately 90% when reinforced with sycamore bark fibers, attaining a tensile strength of 64.5 MPa.

- The strain at break decreased from 2.1% to 1.4% after the addition of sycamore bark fibers to the polyester matrix. This reduction indicates that the composite material becomes stronger and more rigid due to the fiber reinforcement; it also becomes less ductile.

- The microstructural analysis revealed that the fiber cells are almost cylindrical in shape and compactly arranged, and the transverse section of the structural fibers is found in a semi elongated circular shape. The diameter distribution of the bundles shows a normal distribution with a mean diameter of 84.9 μm and a standard deviation of 18.8 μm.

- From experimental tensile tests on composite specimens, an inverse problem was solved to evaluate the elastic modulus of the fibers. The models delivered an average elastic modulus of 17,763 ± 6051 MPa, which were found in the same order of magnitude as other existing natural fibers despite the observed variability inherent to the natural fibers.

- Prior to industrial applications, supplementary research should be performed to assess the materials’ long-term durability performance and degradation behavior under various aging environments (thermo-oxidative aging, accelerated weathering (ultraviolet aging), hydrolytic degradation, fatigue, and creep, etc.).

- The potential of sycamore bark fiber should be analyzed considering its mechanical performance along with its sustainability aspects. For this assessment, life cycle assessment (LCA) can be deployed to evaluate the environmental aspects and potential impacts of the entire product’s life cycle.

- Advanced approaches, such as cohesive zone modeling (CZM), can be investigated in future work to model the fiber-matrix interface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Natural Fiber Composites Market—By Type (Wood Fiber Composites, Hemp Fiber Composites, Flax Fiber Composites, Jute Fiber Composites), by Matrix (Inorganic Compound, Natural Polymer, Synthetic Polymer), by End-Use & Forecast, 2023–2032. Global Market Insights Inc. Available online: https://www.gminsights.com/industry-analysis/natural-fiber-composites-market (accessed on 6 June 2024).

- Thakur, V.K.; Thakur, M.K.; Gupta, R.K. Synthesis of lignocellulosic polymer with improved chemical resistance through free radical polymerization. Int. J. Biol. Macromol. 2013, 61, 121–126. [Google Scholar] [CrossRef]

- Saha, P.; Chowdhury, S.; Roy, D.; Adhikari, B.; Kim, J.K.; Thomas, S. A brief review on the chemical modifications of lignocellulosic fibers for durable engineering composites. Polym. Bull. 2016, 73, 587–620. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Brosius, D. Natural fiber composites slowly take root. Compos. Technol. 2006, 12, 32–37. [Google Scholar]

- Dujardin, N. Un matériau biosourcé de choix: Les fibres naturelles. Caractérisations et applications. In 25èmes Journées Scientifiques de l’Environnement-L’économie Verte en Question (No. 01). 2014. Available online: https://hal.science/hal-00978360 (accessed on 4 June 2024).

- Correia, J.R.; Cabral-Fonseca, S.; Branco, F.A.; Ferreira, J.G.; Eusébio, M.I.; Rodrigues, M.P. Durability of pultruded glass-fiber-reinforced polyester profiles for structural applications. Mech. Compos. Mater. 2006, 42, 325–338. [Google Scholar] [CrossRef]

- Panaitescu, I.; Koch, T.; Archodoulaki, V.M. Accelerated aging of a glass fiber/polyurethane composite for automotive applications. Polym. Test. 2019, 74, 245–256. [Google Scholar] [CrossRef]

- Dong, Z.; Ji, J.H.; Liu, Z.Q.; Wu, C.; Wu, G.; Zhu, H.; Zhang, P. I-shaped ECC/UHPC composite beams reinforced with steel bars and BFRP sheets. Sustain. Struct. 2023, 3, 000022. [Google Scholar] [CrossRef]

- Ke, L.; Li, Y.; Li, C.; Cheng, Z.; Ma, K.; Zeng, J. Bond behavior of CFRP-strengthened steel structures and its environmental influence factors: A critical review. Sustain. Struct. 2024, 4, 000038. [Google Scholar] [CrossRef]

- Xian, G.; Zhou, P.; Bai, Y.; Wang, J.; Li, C.; Dong, S.; Guo, R.; Li, J.; Du, H.; Zhong, J. Design, preparation and mechanical properties of novel glass fiber reinforced polypropylene bending bars. Constr. Build. Mater. 2024, 429, 136455. [Google Scholar] [CrossRef]

- Alam, L.; Piezel, B.; Sicot, O.; Aivazzadeh, S.; Moscardelli, S.; Van-Schoors, L. UV accelerated aging of unidirectional flax composites: Comparative study between recycled and virgin polypropylene matrix. Polym. Degrad. Stab. 2023, 208, 110268. [Google Scholar] [CrossRef]

- Abbès, F.; Xu, S.; Abbès, B. Characterization of Mechanical and Damping Properties of Nettle and Glass Fiber Reinforced Hybrid Composites. J. Compos. Sci. 2022, 6, 238. [Google Scholar] [CrossRef]

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2022, 35, 1169–1209. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Sun, S.; Li, X. Physicochemical Properties and Fatty Acid Profile of Phoenix Tree Seed and its Oil. J. Am. Oil. Chem. Soc. 2016, 93, 1111–1114. [Google Scholar] [CrossRef]

- Gan, S.-R.; Guo, J.-C.; Zhang, Y.-X.; Wang, X.-F.; Huang, L.-J. “Phoenix in Flight”: A unique fruit morphology ensures wind dispersal of seeds of the phoenix tree (Firmiana simplex (L.) W. Wight). BMC Plant Biol. 2022, 22, 113. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A review on natural fiber reinforced composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Huda, M.K.; Widiastuti, I. Natural fiber reinforced polymer in automotive application: A systematic literature review. J. Phys. Conf. Ser. 2021, 1808, 012015. [Google Scholar] [CrossRef]

- Abdollahiparsa, H.; Shahmirzaloo, A.; Teuffel, P.; Blok, R. A review of recent developments in structural applications of natural fiber-Reinforced composites (NFRCs). Compos. Adv. Mater. 2023, 32, 26349833221147540. [Google Scholar] [CrossRef]

- Choudhary, S.; Haloi, J.; Sain, M.K.; Saraswat, P. Advantages and Applications of Natural Fiber Reinforced Hybrid Polymer Composites in Automobiles: A Literature Review. In Advances in Modelling and Optimization of Manufacturing and Industrial Systems. Lecture Notes in Mechanical Engineering; Singh, R.P., Tyagi, M., Walia, R.S., Davim, J.P., Eds.; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Ladaci, N.; Saadia, A.; Belaadi, A.; Boumaaza, M.; Chai, B.X.; Abdullah, M.M.; Al-Khawlani, A.; Ghernaout, D. ANN and RSM Prediction of Water Uptake of Recycled HDPE Biocomposite Reinforced with Treated Palm Waste W. filifera. J. Nat. Fibers 2024, 21, 2356697. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Assarar, M.; Sabhi, H.; Ayad, R. Hybridisation effect on diffusion kinetic and tensile mechanical behaviour of epoxy based flax–glass composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 153–160. [Google Scholar] [CrossRef]

- Roe, P.J.; Ansell, M.P. Jute-reinforced polyester composites. J. Mater. Sci. 1985, 20, 4015–4020. [Google Scholar] [CrossRef]

- De Albuquerque, A.C.; Joseph, K.; de Carvalho, L.H.; d’Almeida, J.R.M. Effect of wettability and ageing conditions on the physical and mechanical properties of uniaxially oriented jute-roving-reinforced polyester composites. Compos. Sci. Technol. 2000, 60, 833–844. [Google Scholar] [CrossRef]

- Pal, S.K.; Mukhopadhyay, D.; Sanyal, S.K.; Mukherjea, R.N. Studies on process variables for natural fiber composites—Effect of polyesteramide polyol as interfacial agent. J. Appl. Polym. Sci. 1988, 35, 973–985. [Google Scholar] [CrossRef]

- Owolabi, O.; Czvikovszky, T.; Kovacs, I. Coconut-fiber-reinforced thermosetting plastics. J. Appl. Polym. Sci. 1985, 30, 1827–1836. [Google Scholar] [CrossRef]

- White, N.M.; Ansell, M.P. Straw-reinforced polyester composites. J. Mater. Sci. 1983, 18, 1549–1556. [Google Scholar] [CrossRef]

- Sohn, J.S.; Cha, S.W. Enhanced interfacial adhesion of polypropylene and waste wood from roadside trees composite materials. Int. J. Precis. Eng. Manuf. 2015, 16, 2389–2393. [Google Scholar] [CrossRef]

- Pirayesh, H.; Moradpour, P.; Sepahvand, S. Particleboard from wood particles and sycamore leaves. Eng. Agric. Environ. Food 2015, 8, 38–43. [Google Scholar] [CrossRef]

- Aghakhani, M.; Enayati, S.H.; Nadalizadeh, H.; Pirayesh, H. The potential for using the sycamore (Platus orientalis) leaves in manufacturing particleboard. Int. J. Environ. Sci. Technol. 2014, 11, 417–422. [Google Scholar] [CrossRef]

- Cu Lao Cham Field Corn Hammock Weaving is a National Heritage. Available online: https://www.vietnam.vn/en/nghe-dan-vong-ngo-dong-cu-lao-cham-la-di-san-quoc-gia/ (accessed on 20 June 2024).

- ISO 527-5; Plastics—Determination of Tensile Properties—Part 5: Test Conditions for Unidirectional Fibre-Reinforced Plastic Composites. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- Aramis—User Manual Software; Version 6.1; GOM mbH: Braunschweig, Germany, 2009.

- Jerabek, M.; Major, Z.; Lang, R.W. Strain determination of polymeric materials using digital image correlation. Polym. Test. 2010, 29, 407–416. [Google Scholar] [CrossRef]

- Quanjin, M.; Rejab, M.R.M.; Halim, Q.; Merzuki, M.N.M.; Darus, M.A.H. Experimental investigation of the tensile test using digital image correlation (DIC) method. Mater. Today Proc. 2020, 27, 757–763. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Abida, M.; Baklouti, A.; Gehring, F.; Vivet, A.; Bouvet, C. Inverse approach for flax yarns mechanical properties identification from statistical mechanical characterization of the fabric. Mech. Mater. 2020, 151, 103638. [Google Scholar] [CrossRef]

- Singh, D.K.; Vaidya, A.; Thomas, V.; Theodore, M.; Kore, S.; Vaidya, U. Finite Element Modeling of the Fiber-Matrix Interface in Polymer Composites. J. Compos. Sci. 2020, 4, 58. [Google Scholar] [CrossRef]

- Inglis, H.M.; Geubelle, P.H.; Matouš, K.; Tan, H.; Huang, Y. Cohesive modeling of dewetting in particulate composites: Micromechanics vs. multiscale finite element analysis. Mech. Mater. 2007, 39, 580–595. [Google Scholar] [CrossRef]

- Simulia; Abaqus Documentations; Dassault Systemes: Vélizy-Villacoublay, France, 2019.

- Baldi, A.; Santucci, P.M.; Bertolino, F. Experimental assessment of noise robustness of the forward-additive, symmetric-additive and the inverse-compositional Gauss-Newton algorithm in digital image correlation. Opt. Lasers Eng. 2022, 154, 107012. [Google Scholar] [CrossRef]

- Baldi, A.; Santucci, P.M.; Bertolino, F. Experimental image dataset for validation of the noise-induced bias that affects Digital Image Correlation. Data Brief 2022, 42, 108156. [Google Scholar] [CrossRef]

- Amraish, N.; Reisinger, A.; Pahr, D.H. Robust Filtering Options for Higher-Order Strain Fields Generated by Digital Image Correlation. Appl. Mech. 2020, 1, 174–192. [Google Scholar] [CrossRef]

- Amraish, N.; Reisinger, A.; Pahr, D. A novel specimen shape for measurement of linear strain fields by means of digital image correlation. Sci. Rep. 2021, 11, 17515. [Google Scholar] [CrossRef]

- Haghdan, S.; Smith, G.D. Natural fiber reinforced polyester composites: A literature review. J. Reinf. Plast. Compos. 2015, 34, 1179–1190. [Google Scholar] [CrossRef]

- Muthukumar, V.; Venkatasamy, R.; Mariselvam, V.; Sureshbabu, A.; Senthilkumar, N.; Fernando, A.A.G. Comparative Investigation on Mechanical Properties of Natural Fiber Reinforced Polyester Composites. Appl. Mech. Mater. 2014, 592–594, 92–96. [Google Scholar] [CrossRef]

- Reddy, S.S.K.; Hussain, S.A. Development and testing of natural fiber reinforced composites with polyester resin. Int. J. Eng. Sci. Res. Technol. 2013, 2, 2701–2706. [Google Scholar]

- El-Wazery, M.S.; El-Elamy, M.I.; Zoalfakar, S.H. Mechanical properties of glass fiber reinforced polyester composites. Int. J. Appl. Sci. Eng. 2017, 14, 121–131. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

- Dhir, D.K.; Rashidi, A.; Bogyo, G.; Ryde, R.; Pakpour, S.; Milani, A.S. Environmental Durability Enhancement of Natural Fibres Using Plastination: A Feasibility Investigation on Bamboo. Molecules 2020, 25, 474. [Google Scholar] [CrossRef]

- Sinha, E.; Panigrahi, S. Effect of plasma treatment on structure, wettability of jute fiber and flexural strength of its composite. J. Compos. Mater. 2009, 43, 1791–1802. [Google Scholar] [CrossRef]

- Huber, T.; Biedermann, U.; Müssig, J. Enhancing the fibre matrix adhesion of natural fibre reinforced polypropylene by electron radiation analyzed with the single fibre fragmentation test. Compos. Interfaces 2010, 17, 371–381. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Engineering and evaluation of hemp fibre reinforced polypropylene composites: Fibre treatment and matrix modification. Compos. Part A Appl. Sci. Manuf. 2008, 39, 979–988. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind. Crops Prod. 2020, 145, 111984. [Google Scholar] [CrossRef]

- Peyrache, T.; Chabbert, B.; Aguié-Béghin, V.; Delattre, F.; Kurek, B.; Gainvors-Claisse, A. Multiscale assessment of the heterogeneity of scutched flax fibers. Ind. Crops Prod. 2024, 220, 119260. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Hariharan, V.; Sathishkumar, T. Characterization of Phoenix sp. natural fiber as potential reinforcement of polymer composites. J. Ind. Text. 2016, 46, 667–683. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef]

- Belouadah, Z.; Ati, A.; Rokbi, M. Characterization of new natural cellulosic fiber from Lygeum spartum L. Carbohydr. Polym. 2015, 134, 429–437. [Google Scholar] [CrossRef]

- Belaadi, A.; Bourchak, M.; Aouici, H. Mechanical properties of vegetal yarn: Statistical approach. Compos. B Eng. 2016, 106, 139–153. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Chawla, N.; de Toledo Filho, R.D. Tensile behavior of high performance natural (sisal) fibers. Compos. Sci. Technol. 2008, 68, 3438–3443. [Google Scholar] [CrossRef]

- Kim, J.T.; Netravali, A.N. Development of aligned-hemp yarn-reinforced green composites with soy protein resin: Effect of pH on mechanical and interfacial properties. Compos. Sci. Technol. 2011, 71, 541–547. [Google Scholar] [CrossRef]

- Blanchard, J.M.F.A.; Sobey, A.J.; Blake, J.I.R. Multi-scale investigation into the mechanical behaviour of flax in yarn, cloth and laminate form. Compos. Part B Eng. 2016, 84, 228–235. [Google Scholar] [CrossRef]

| Samples | Resin | Composite | ||||||

|---|---|---|---|---|---|---|---|---|

| Modulus (MPa) | Poisson Ratio (-) | Max. Stress (MPa) | Max. Strain (-) | Modulus (MPa) | Poisson Ratio (-) | Max. Stress (MPa) | Max. Strain (-) | |

| 1 | 1848.3 | 0.42 | 35.9 | 2.33% | 4878.4 | 0.31 | 83.8 | 1.63% |

| 2 | 1973.1 | 0.39 | 35.4 | 2.08% | 4013.6 | 0.29 | 59.2 | 1.65% |

| 3 | 1988.4 | 0.40 | 34.2 | 2.06% | 5690.7 | 0.34 | 76.3 | 1.41% |

| 4 | 1949.8 | 0.41 | 33.0 | 1.80% | 5652.4 | 0.39 | 70.8 | 1.23% |

| 5 | 1823.4 | 0.39 | 33.9 | 2.01% | 6124.2 | 0.45 | 76.0 | 1.16% |

| 6 | 4363.0 | 0.43 | 55.4 | 1.24% | ||||

| 7 | 3608.2 | 0.45 | 43.9 | 1.21% | ||||

| 8 | 3976.4 | 0.41 | 58.1 | 1.57% | ||||

| Mean | 1916.6 | 0.40 | 34.5 | 2.06% | 4788.4 | 0.38 | 65.4 | 1.39% |

| Std. Dev. | 75.5 | 0.01 | 1.2 | 0.19% | 940.1 | 0.06 | 13.4 | 0.19% |

| Samples | Modulus (MPa) |

|---|---|

| 1 | 19,500 |

| 2 | 11,200 |

| 3 | 22,400 |

| 4 | 22,600 |

| 5 | 27,200 |

| 6 | 15,600 |

| 7 | 11,300 |

| 8 | 12,300 |

| Mean | 17,763 |

| Std. Dev. | 6051 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoury Moussa, H.; Lestriez, P.; Bui, H.T.; Nguyen, P.T.N.; Michaud, P.; Lucas-Roper, R.; Antou, G.; Luong, V.D.; Duong, P.T.M.; Abbès, F.; et al. Preliminary Experimental and Numerical Study of the Tensile Behavior of a Composite Based on Sycamore Bark Fibers. J. Compos. Sci. 2024, 8, 333. https://doi.org/10.3390/jcs8090333

Khoury Moussa H, Lestriez P, Bui HT, Nguyen PTN, Michaud P, Lucas-Roper R, Antou G, Luong VD, Duong PTM, Abbès F, et al. Preliminary Experimental and Numerical Study of the Tensile Behavior of a Composite Based on Sycamore Bark Fibers. Journal of Composites Science. 2024; 8(9):333. https://doi.org/10.3390/jcs8090333

Chicago/Turabian StyleKhoury Moussa, Helena, Philippe Lestriez, He Thong Bui, Pham The Nhan Nguyen, Philippe Michaud, Romain Lucas-Roper, Guy Antou, Viet Dung Luong, Pham Tuong Minh Duong, Fazilay Abbès, and et al. 2024. "Preliminary Experimental and Numerical Study of the Tensile Behavior of a Composite Based on Sycamore Bark Fibers" Journal of Composites Science 8, no. 9: 333. https://doi.org/10.3390/jcs8090333

APA StyleKhoury Moussa, H., Lestriez, P., Bui, H. T., Nguyen, P. T. N., Michaud, P., Lucas-Roper, R., Antou, G., Luong, V. D., Duong, P. T. M., Abbès, F., & Abbès, B. (2024). Preliminary Experimental and Numerical Study of the Tensile Behavior of a Composite Based on Sycamore Bark Fibers. Journal of Composites Science, 8(9), 333. https://doi.org/10.3390/jcs8090333