Composite Building Materials Prepared from Bioresources: Use of Rice Husk for Autoclaved Lightweight Concrete Production

Abstract

1. Introduction

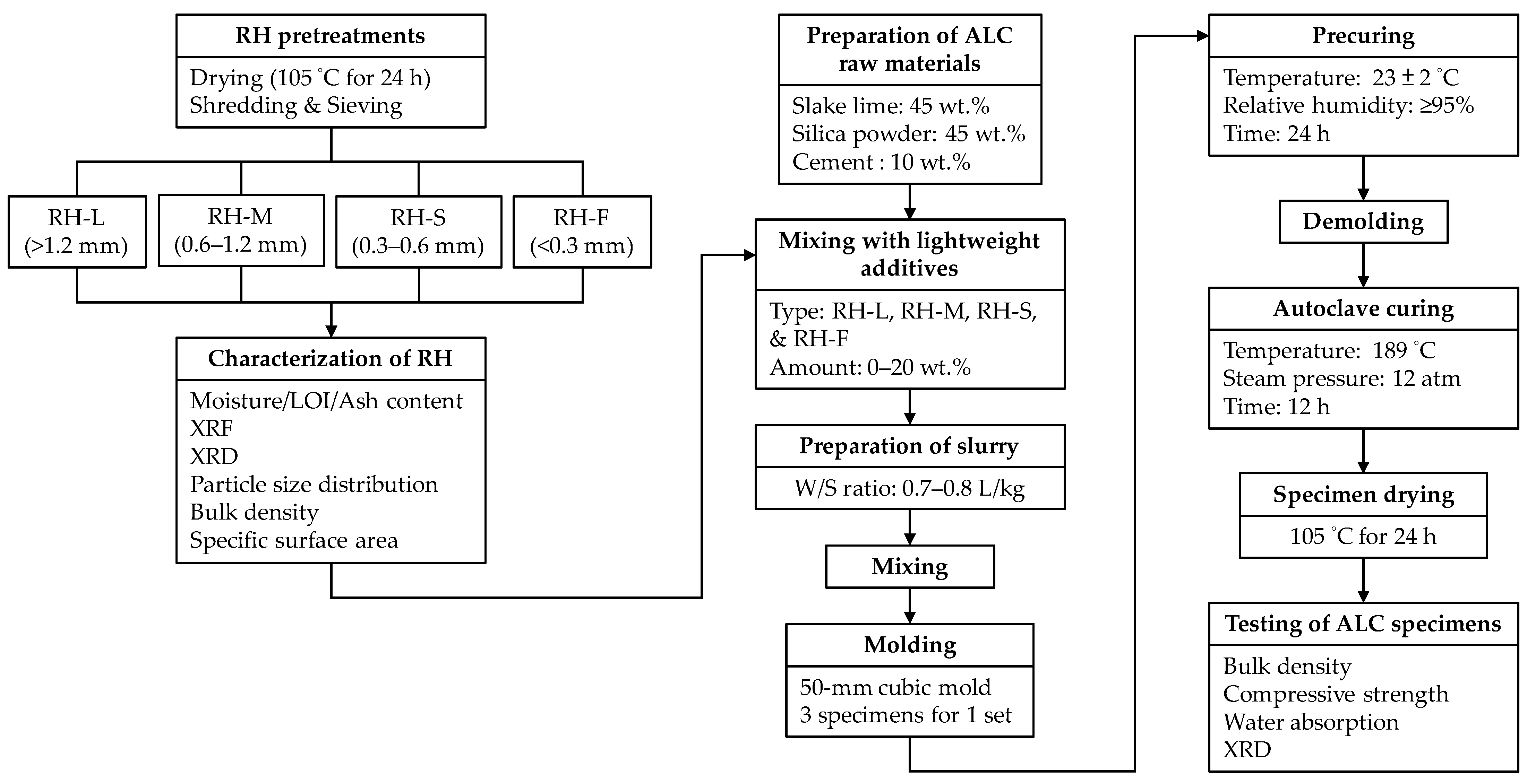

2. Materials and Methods

3. Results and Discussion

3.1. Characterization of RH

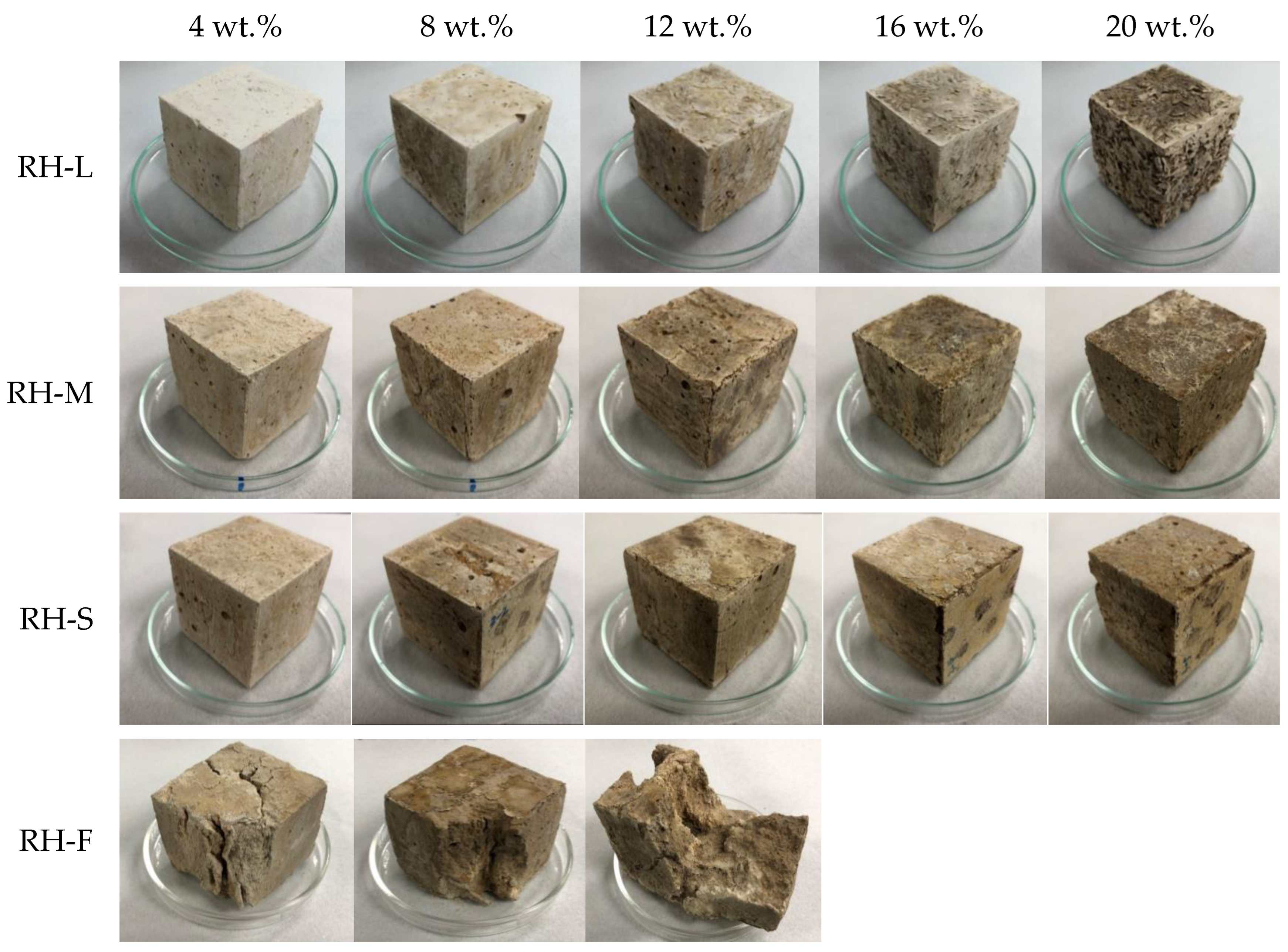

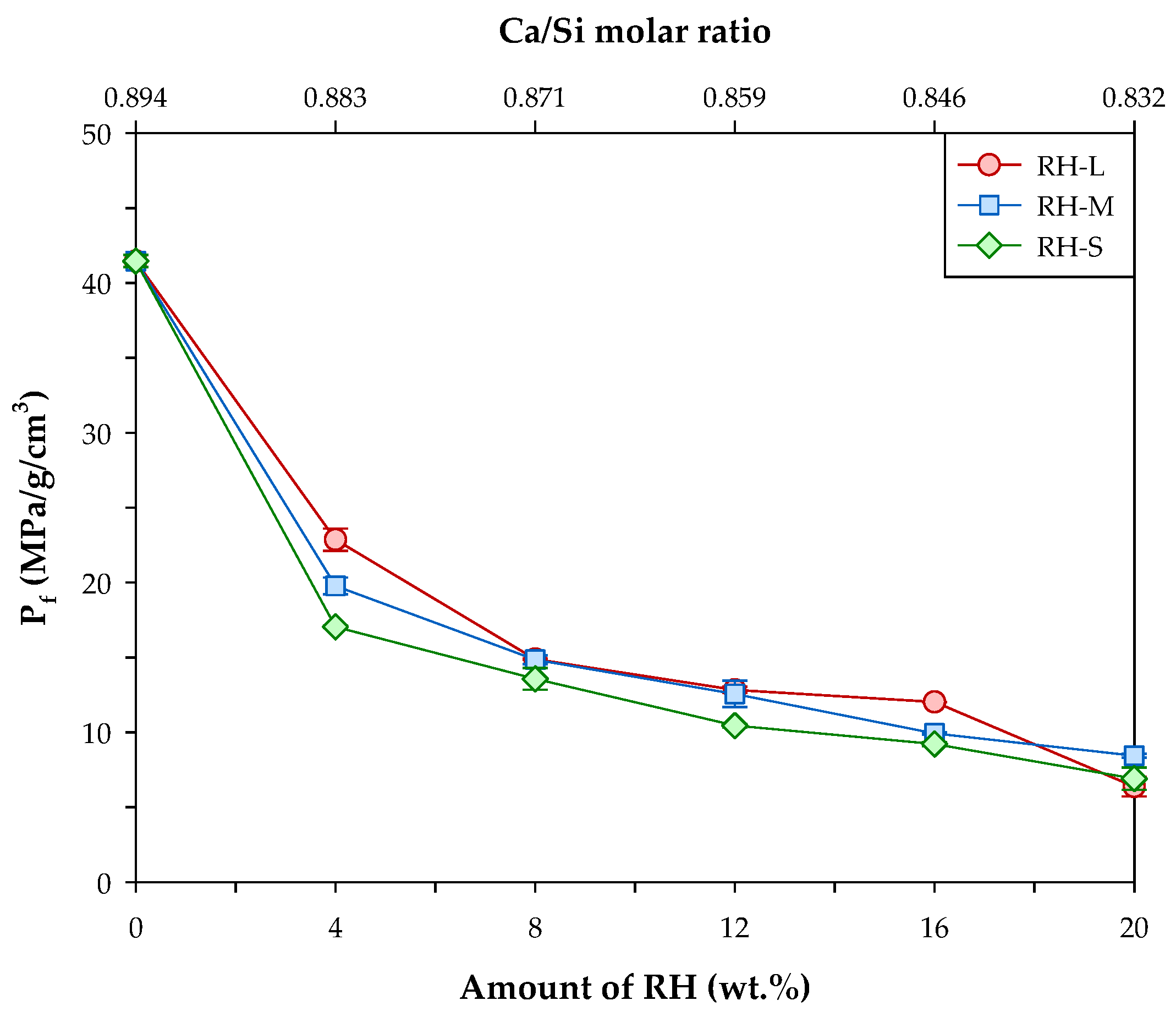

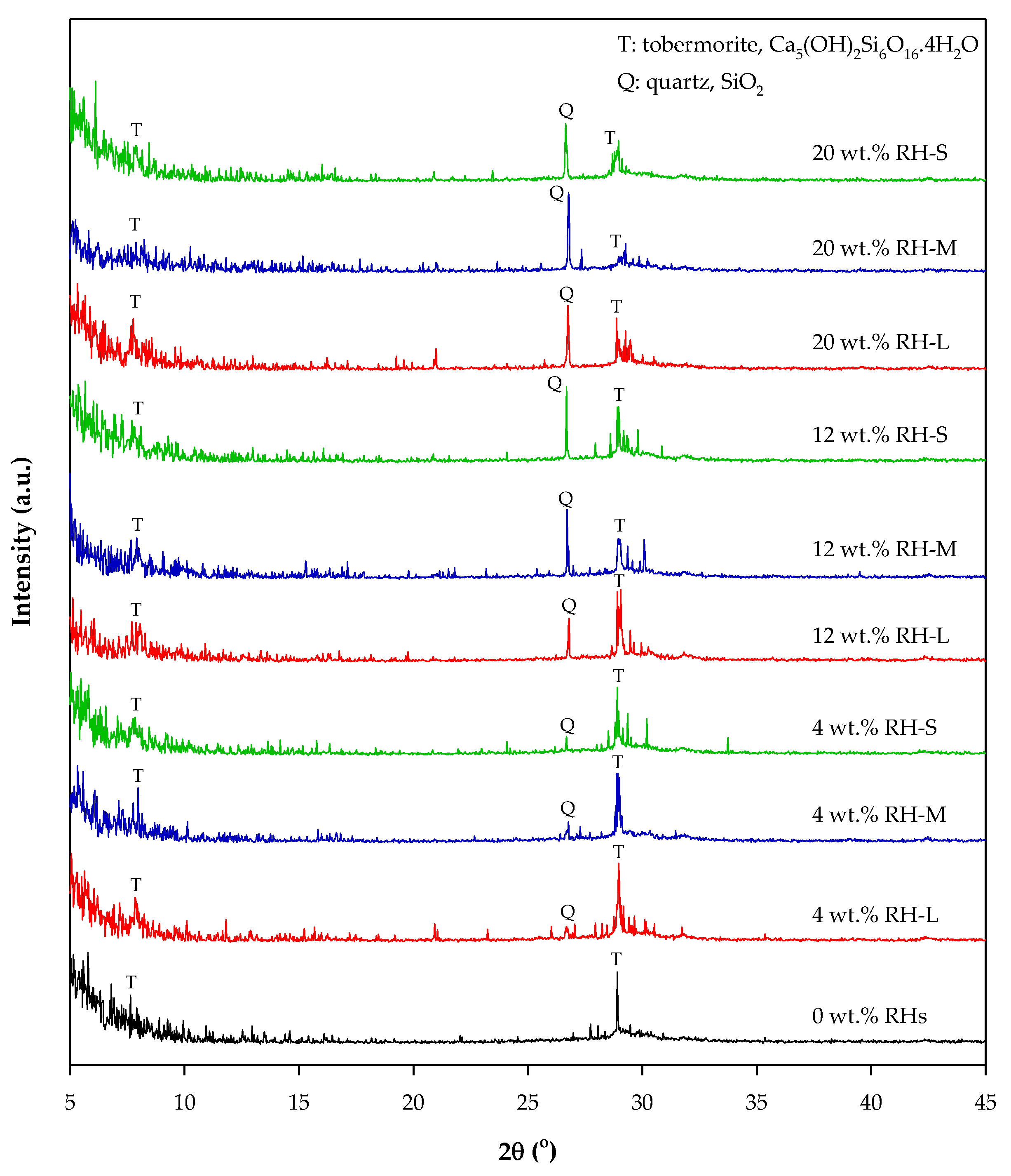

3.2. Properties of ALC Prepared with RHs

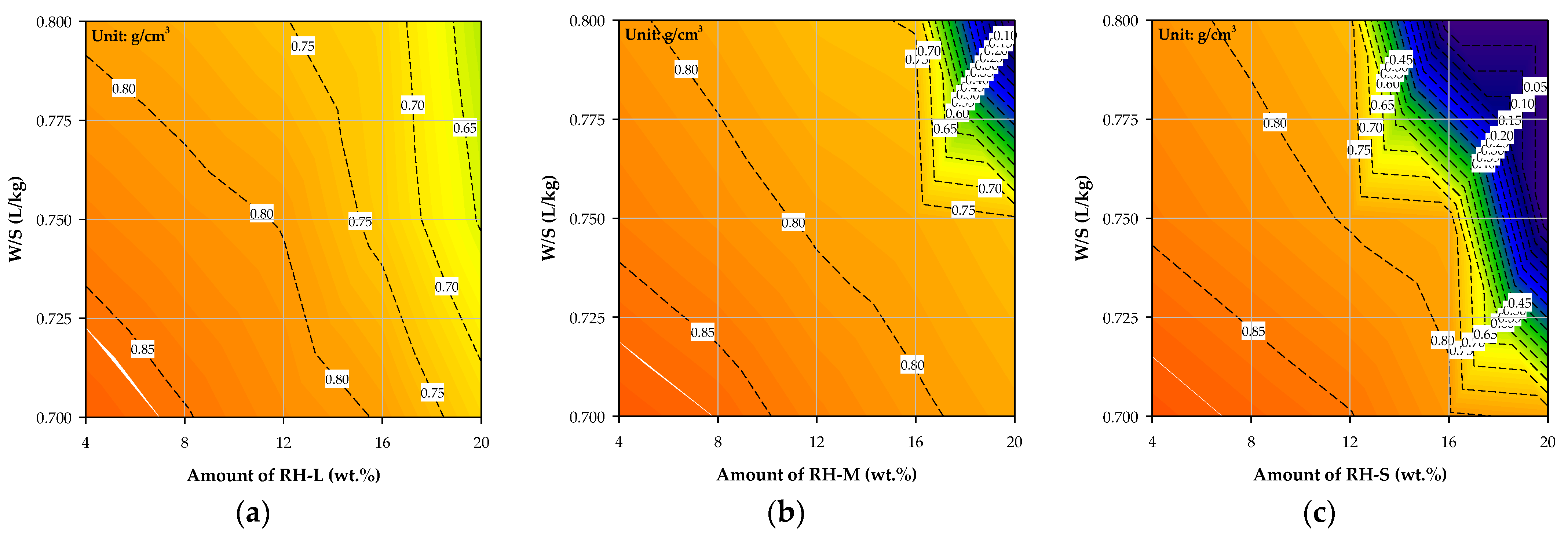

3.3. Effects of the W/S Ratio on the Physical Properties of the ALC Specimens

4. Conclusions

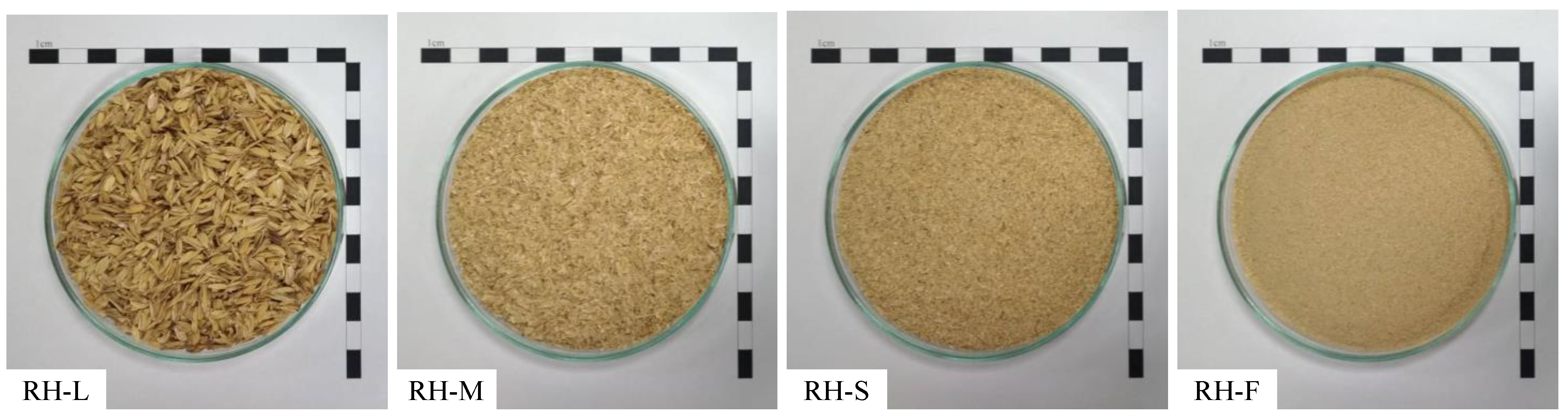

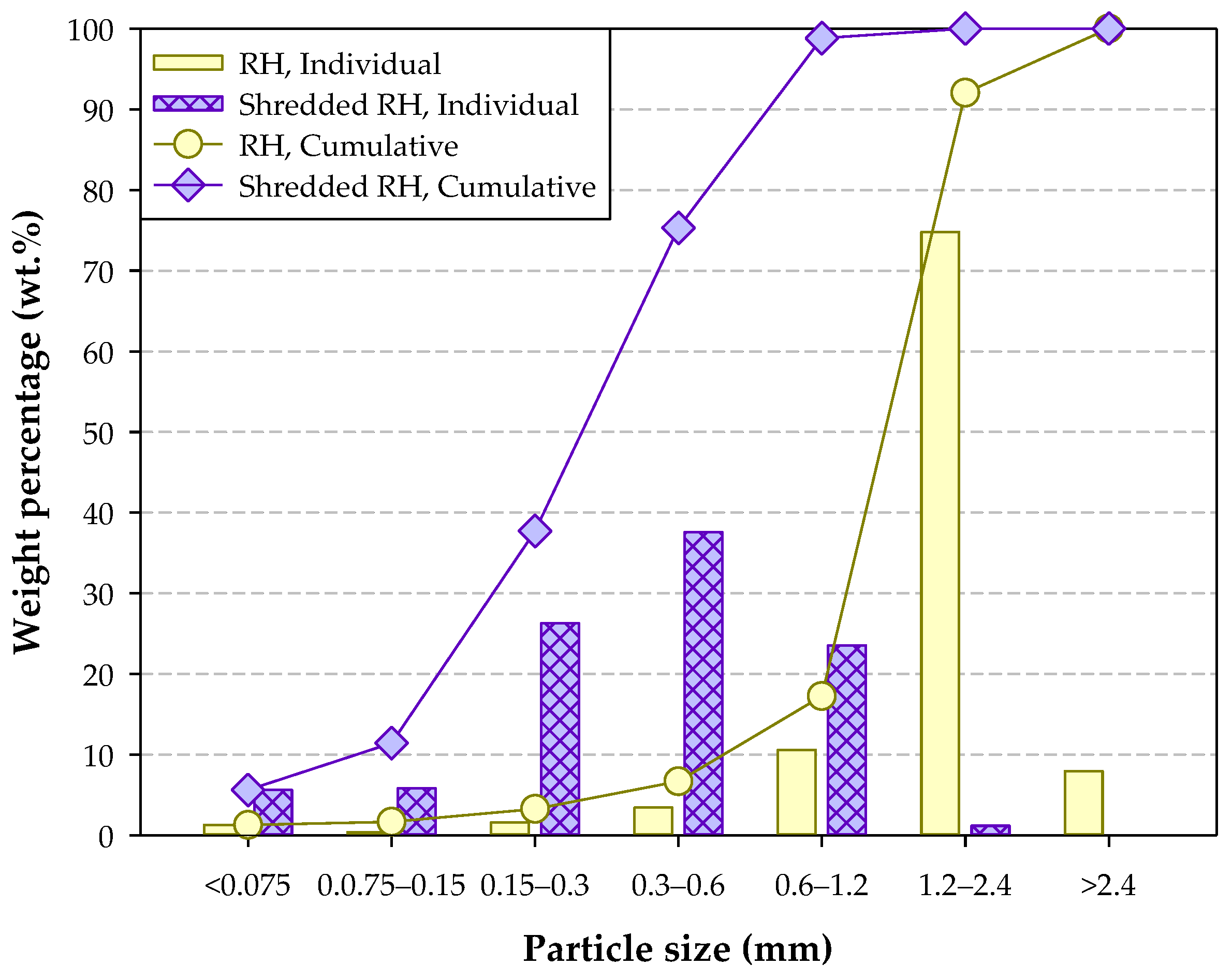

- The dried RH had a high LOI (~86 wt.%), which should be attributed to organic substances, and contained ~14 wt.% ash (mostly composed of silica). The particles larger than 1.2 mm accounted for >82 wt.% of the RH and most of these particles were intact RHs. Four RHs with different particle sizes, namely RH-L (>1.2 mm), RH-M (0.6–1.2 mm), RH-S (0.3–0.6 mm), and RH-F (<0.3 mm), were investigated, and it was found that both the bulk density and the specific surface area increased with the increase in the particle size of the RHs.

- When RHs were used as lightweight additives for ALC production, the use of RH-F (<0.3 mm) failed to produce ALC specimens. This shows that the decomposition of RHs will occur during the preparation of ALC specimens, and the influence is more significant for RHs with fine particle sizes. Generally, the ALC specimens prepared with RH-L (>1.2 mm) had lower bulk density and higher compressive strength than those prepared with RH-M or RH-S. The bulk density and compressive strength of the ALC specimens simultaneously decreased with increasing RH size. When the amounts of RHs increased, the Ca/Si molar ratio decreased and more SiO2 remained in the ALC specimens. The formation of tobermorite was thus retarded, causing a reduction in the compressive strength of ALC.

- The amount of RH may be restricted to a level in order to control the water absorption of the ALC specimens. The effect of the W/S ratio on the bulk density of ALC specimens seems more significant than that on the compressive strength. By appropriately controlling the W/S ratio and the amounts of RHs added, the resulting ALC specimens can meet the requirements of some strength classes for qualified commercial products (CNS 13480: G6, G8, and G10).

- The above findings prove the feasibility of using RH in the production of ALC. The hydrolysis reactions of cellulose and hemicellulose under autoclaving conditions may be studied in future work to reveal the effects of the hydrolysis products on tobermorite formation and ALC properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Agriculture. 2023 Basic Agriculture Statistics; Ministry of Agriculture: Taipei, Taiwan, 2024. [Google Scholar]

- Ma’ruf, A.; Pramudono, B.; Aryanti, N. Lignin isolation process from rice husk by alkaline hydrogen peroxide: Lignin and silica extracted. In Proceedings of the 14th International Symposium on Therapeutic Ultrasound, Las Vegas, NV, USA, 2–5 April 2014; p. 020013. [Google Scholar]

- Moayedi, H.; Aghel, B.; Abdullahi, M.a.M.; Nguyen, H.; Rashid, A.S.A. Applications of rice husk ash as green and sustainable biomass. J. Clean. Prod. 2019, 237, 117851. [Google Scholar] [CrossRef]

- Moraes, C.A.M.; Fernandes, I.J.; Calheiro, D.; Kieling, A.G.; Brehm, F.A.; Rigon, M.R.; Berwanger Filho, J.A.; Schneider, I.A.H.; Osorio, E. Review of the rice production cycle: By-products and the main applications focusing on rice husk combustion and ash recycling. Waste Manag. Res. 2014, 32, 1034–1048. [Google Scholar] [CrossRef] [PubMed]

- Satbaev, B.; Yefremova, S.; Zharmenov, A.; Kablanbekov, A.; Yermishin, S.; Shalabaev, N.; Satbaev, A.; Khen, V. Rice husk research: From environmental pollutant to a promising source of organo-mineral raw materials. Materials 2021, 14, 4119. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-F. Study of the earth composition of adobe walls and bamboo-daub walls―A case study of traditional buildings, Yunlin County and Chiayi County. J. Cult. Herit. Conserv. 2020, 52, 7–26. [Google Scholar]

- Rodríguez de Sensale, G. Strength development of concrete with rice-husk ash. Cem. Concr. Compos. 2006, 28, 158–160. [Google Scholar] [CrossRef]

- Ramasamy, V. Compressive strength and durability properties of Rice Husk Ash concrete. KSCE J. Civ. Eng. 2012, 16, 93–102. [Google Scholar] [CrossRef]

- Sandhu, R.K.; Siddique, R. Influence of rice husk ash (RHA) on the properties of self-compacting concrete: A review. Constr. Build. Mater. 2017, 153, 751–764. [Google Scholar] [CrossRef]

- Madandoust, R.; Ranjbar, M.M.; Moghadam, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Anh-Tuan, B.L.; Chun-Tsun, C. Effect of rice husk ash on the strength and durability characteristics of concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Chandrasekhar, S.; Satyanarayana, K.G.; Pramada, P.N.; Raghavan, P.; Gupta, T.N. Review processing, properties and applications of reactive silica from rice husk—An overview. J. Mater. Sci. 2003, 38, 3159–3168. [Google Scholar] [CrossRef]

- Abah, E.O.; Ahamed, T.; Noguchi, R. Catalytic temperature effects on conversion efficiency of PM2.5 and gaseous emissions from rice husk combustion. Energies 2021, 14, 6131. [Google Scholar] [CrossRef]

- Duan, F.; Chyang, C.; Chin, Y.; Tso, J. Pollutant emission characteristics of rice husk combustion in a vortexing fluidized bed incinerator. J. Environ. Sci. 2013, 25, 335–339. [Google Scholar] [CrossRef] [PubMed]

- Ataie, F. Influence of rice straw fibers on concrete strength and drying shrinkage. Sustainability 2018, 10, 2445. [Google Scholar] [CrossRef]

- Pachla, E.C.; Silva, D.B.; Stein, K.J.; Marangon, E.; Chong, W. Sustainable application of rice husk and rice straw in cellular concrete composites. Constr. Build. Mater. 2021, 283, 122770. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Gupta, S.; Kua, H.W. Application of rice husk biochar and thermally treated low silica rice husk ash to improve physical properties of cement mortar. Theor. Appl. Fract. Mech. 2019, 104, 102376. [Google Scholar] [CrossRef]

- Ministry of Agriculture. Taiwan’s Pathway to Net-Zero Emissions in 2050-Carbon Sink; Ministry of Agriculture: Taipei, Taiwan, 2023. [Google Scholar]

- Chinnu, S.N.; Minnu, S.N.; Bahurudeen, A.; Senthilkumar, R. Reuse of industrial and agricultural by-products as pozzolan and aggregates in lightweight concrete. Constr. Build. Mater. 2021, 302, 124172. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar]

- Thienel, K.-C.; Haller, T.; Beuntner, N. Lightweight concrete—From basics to innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef]

- Hamad, A.J. Materials, production, properties and application of aerated lightweight concrete: Review. Int. J. Mater. Sci. Eng. 2014, 2, 152–157. [Google Scholar] [CrossRef]

- Kalpana, M.; Mohith, S. Study on autoclaved aerated concrete: Review. Mater. Today Proc. 2020, 22, 894–896. [Google Scholar]

- Rahman, R.A.; Fazlizan, A.; Asim, N.; Thongtha, A. Utilization of waste material for aerated autoclaved concrete production: A preliminary review. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012035. [Google Scholar] [CrossRef]

- Jauberthie, R.; Rendell, F.; Tamba, S.; Cisse, I. Origin of the pozzolanic effect of rice husks. Constr. Build. Mater. 2000, 14, 419–423. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Asavapisit, S.; Sombatsompop, K. Properties of autoclaved aerated concrete incorporating rice husk ash as partial replacement for fine aggregate. Cem. Concr. Compos. 2015, 55, 11–16. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Asawapisit, S.; Sombatsompop, K. The effect of rice husk ash on properties of aerated concrete. Adv. Mater. Res. 2013, 747, 420–423. [Google Scholar] [CrossRef]

- Qin, L.; Gao, X.; Chen, T. Recycling of raw rice husk to manufacture magnesium oxysulfate cement based lightweight building materials. J. Clean. Prod. 2018, 191, 220–232. [Google Scholar] [CrossRef]

- Winarno, S. Comparative Strength and cost of rice husk concrete block. MATEC Web Conf. 2019, 280, 04002. [Google Scholar] [CrossRef]

- Akinyemi, B.; Omoniyi, T.E.; Elemile, O.; Arowofila, O. Innovative husk-crete building materials from rice chaff and modified cement mortars. Acta Technol. Agric. 2020, 23, 67–72. [Google Scholar] [CrossRef]

- Akinwumi, I.I.; Awoyera, P.O.; Olofinnade, O.M.; Busari, A.A.; Okotie, M. Rice husk as a concrete constituent: Workability, water absorption and strength of the concrete. Asian J. Civil Eng. 2016, 17, 887–898. [Google Scholar]

- Doumongue, B.; Limam, K.; Dany, A.Y.M.X.; Mastouri, H.; Bahi, H.; El bouazouli, A. Analysis of rice husk concrete samples observed by scanning electron microscopy. Mater. Today Proc. 2023, 72, 3850–3856. [Google Scholar] [CrossRef]

- Chabannes, M.; Bénézet, J.-C.; Clerc, L.; Garcia-Diaz, E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: An innovative application. Constr. Build. Mater. 2014, 70, 428–438. [Google Scholar] [CrossRef]

- Saeed, A.A.H.; Yub Harun, N.; Bilad, M.R.; Afzal, M.T.; Parvez, A.M.; Roslan, F.A.S.; Abdul Rahim, S.; Vinayagam, V.D.; Afolabi, H.K. Moisture content impact on properties of briquette produced from rice husk waste. Sustainability 2021, 13, 3069. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, M.N.N.; Karim, M.R.; Kaish, A.B.M.A.; Zain, M.F.M. Physical and chemical contributions of Rice Husk Ash on the properties of mortar. Constr. Build. Mater. 2016, 128, 185–198. [Google Scholar] [CrossRef]

- Hossain, S.S.; Mathur, L.; Roy, P.K. Rice husk/rice husk ash as an alternative source of silica in ceramics: A review. J. Asian Ceram. Soc. 2018, 6, 299–313. [Google Scholar] [CrossRef]

- Jittin, V.; Bahurudeen, A.; Ajinkya, S.D. Utilisation of rice husk ash for cleaner production of different construction products. J. Clean. Prod. 2020, 263, 121578. [Google Scholar] [CrossRef]

- Liu, K.; Shen, C.; Wang, Y.; Rong, N.; Ma, J.; Wang, A.; Sun, D. The performance of autoclaved aerated concrete prepared by arenaceous rock coal gangue powder instead of fly ash: The effect of Ca/Si ratio. Constr. Build. Mater. 2024, 441, 137495. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, Y.; Zhan, B.; Xu, G. Preparation of autoclaved aerated concrete by using graphite tailings as an alternative silica source. Constr. Build. Mater. 2021, 267, 121792. [Google Scholar] [CrossRef]

- Kumar, R. Effects of high volume dolomite sludge on the properties of eco-efficient lightweight concrete: Microstructure, statistical modeling, multi-attribute optimization through Derringer’s desirability function, and life cycle assessment. J. Clean Prod. 2021, 307, 127107. [Google Scholar] [CrossRef]

- Kurama, H.; Topçu, İ.B.; Karakurt, C. Properties of the autoclaved aerated concrete produced from coal bottom ash. J. Mater. Process. Technol. 2009, 209, 767–773. [Google Scholar] [CrossRef]

- Lim, S.K.; Tan, C.S.; Lim, O.Y.; Lee, Y.L. Fresh and hardened properties of lightweight foamed concrete with palm oil fuel ash as filler. Constr. Build. Mater. 2013, 46, 39–47. [Google Scholar] [CrossRef]

- Rahman, R.A.; Fazlizan, A.; Asim, N.; Thongtha, A. A review on the utilization of waste material for autoclaved aerated concrete production. J. Renew. Mater. 2021, 9, 61–72. [Google Scholar] [CrossRef]

- Chen, Y.-L.; Chang, J.-E.; Lai, Y.-C.; Chou, M.-I.M. A comprehensive study on the production of autoclaved aerated concrete: Effects of silica-lime-cement composition and autoclaving conditions. Constr. Build. Mater. 2017, 153, 622–629. [Google Scholar] [CrossRef]

- Qu, X.; Zhao, X. Previous and present investigations on the components, microstructure and main properties of autoclaved aerated concrete—A review. Constr. Build. Mater. 2017, 135, 505–516. [Google Scholar] [CrossRef]

- Dong, M.; Ma, R.; Sun, G.; Pan, C.; Zhan, S.; Qian, X.; Chen, R.; Ruan, S. Size distribution of pores and their geometric analysis in red mud-based autoclaved aerated concrete (AAC) using regression neural network and elastic mechanics. Constr. Build. Mater. 2022, 359, 129420. [Google Scholar] [CrossRef]

- CNS 13480; Autoclaved Lightweight Aerated Concrete Blocks. Bureau of Standards Metrology and Inspection: Taipei, Taiwan, 1995.

| Chemical Composition | Slaked Lime 1 | Silica Powder 1 | Cement 1 |

|---|---|---|---|

| Mg (wt.%) | 0.36 | 0.004 | 1.61 |

| Al (wt.%) | 0.04 | 0.470 | 2.56 |

| Si (wt.%) | 0.06 | 46.51 | 14.47 |

| P (wt.%) | NA 2 | NA 2 | NA 2 |

| S (wt.%) | 0.01 | NA 2 | 0.89 |

| Cl (wt.%) | NA 2 | NA 2 | NA 2 |

| K (wt.%) | NA 2 | NA 2 | 0.29 |

| Ca (wt.%) | 52.91 | 0.001 | 42.12 |

| Fe (wt.%) | 0.03 | 0.029 | 2.46 |

| Percentage | Moisture Content | LOI 1 | Ash Content |

|---|---|---|---|

| wt.% | 11.19 | 76.73 | 12.08 |

| wt.% (dry basis) | – | 86.39 | 13.61 |

| Chemical Composition | RH | |

|---|---|---|

| Major Element (wt.%) | Mg | <0.50 |

| Al | <0.01 | |

| Si | 11.79 | |

| P | 0.29 | |

| S | 0.20 | |

| Cl | 0.20 | |

| K | 1.54 | |

| Ca | 0.23 | |

| Fe | 0.03 | |

| Trace Metal (mg/kg) | Ti | 24 |

| Mn | 126 | |

| Ni | 11 | |

| Zn | 22 | |

| Ba | 40 | |

| Characteristic | RH-L | RH-M | RH-S | RH-F |

|---|---|---|---|---|

| Particle size (mm) | >1.2 | 0.6–1.2 | 0.3–0.6 | <0.3 |

| Bulk density (g/cm3) | 0.102 | 0.276 | 0.354 | 0.456 |

| Specific surface area (m2/kg) | 43.4 | 91.1 | 139.3 | 768.5 |

| Amount of RH (wt.%) | Water Absorption (wt.%) | ||

|---|---|---|---|

| RH-L | RH-M | RH-S | |

| 4 | 76.2 | 70.9 | 71.7 |

| 8 | 78.6 | 72.9 | 73.9 |

| 12 | 78.2 | 76.7 | 77.5 |

| 16 | 85.5 | 79.4 | 83.7 |

| 20 | 96.0 | 82.5 | 84.0 |

| Strength Class | Compressive Strength (MPa) 1 | Bulk Density (g/cm3) 2 |

|---|---|---|

| G2 | 2.5 | 0.50 |

| G4 | 5.0 | 0.60 |

| G6 | 7.5 | 0.80 |

| G8 | 10.0 | 1.00 |

| G10 | 12.5 | 1.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, S.-L.; Chen, Y.-L.; Dai, Y.-S. Composite Building Materials Prepared from Bioresources: Use of Rice Husk for Autoclaved Lightweight Concrete Production. J. Compos. Sci. 2024, 8, 359. https://doi.org/10.3390/jcs8090359

Peng S-L, Chen Y-L, Dai Y-S. Composite Building Materials Prepared from Bioresources: Use of Rice Husk for Autoclaved Lightweight Concrete Production. Journal of Composites Science. 2024; 8(9):359. https://doi.org/10.3390/jcs8090359

Chicago/Turabian StylePeng, Shao-Lin, Ying-Liang Chen, and Yu-Sheng Dai. 2024. "Composite Building Materials Prepared from Bioresources: Use of Rice Husk for Autoclaved Lightweight Concrete Production" Journal of Composites Science 8, no. 9: 359. https://doi.org/10.3390/jcs8090359

APA StylePeng, S.-L., Chen, Y.-L., & Dai, Y.-S. (2024). Composite Building Materials Prepared from Bioresources: Use of Rice Husk for Autoclaved Lightweight Concrete Production. Journal of Composites Science, 8(9), 359. https://doi.org/10.3390/jcs8090359