In Situ Microscopy of Fatigue-Loaded Embedded Transverse Layers of Cross-Ply Laminates: The Role of an Inhomogeneous Fiber Distribution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.3. In Situ Microscopy

2.4. Fatigue Loading

2.5. Strain Amplification

2.6. Homogenization

3. Results

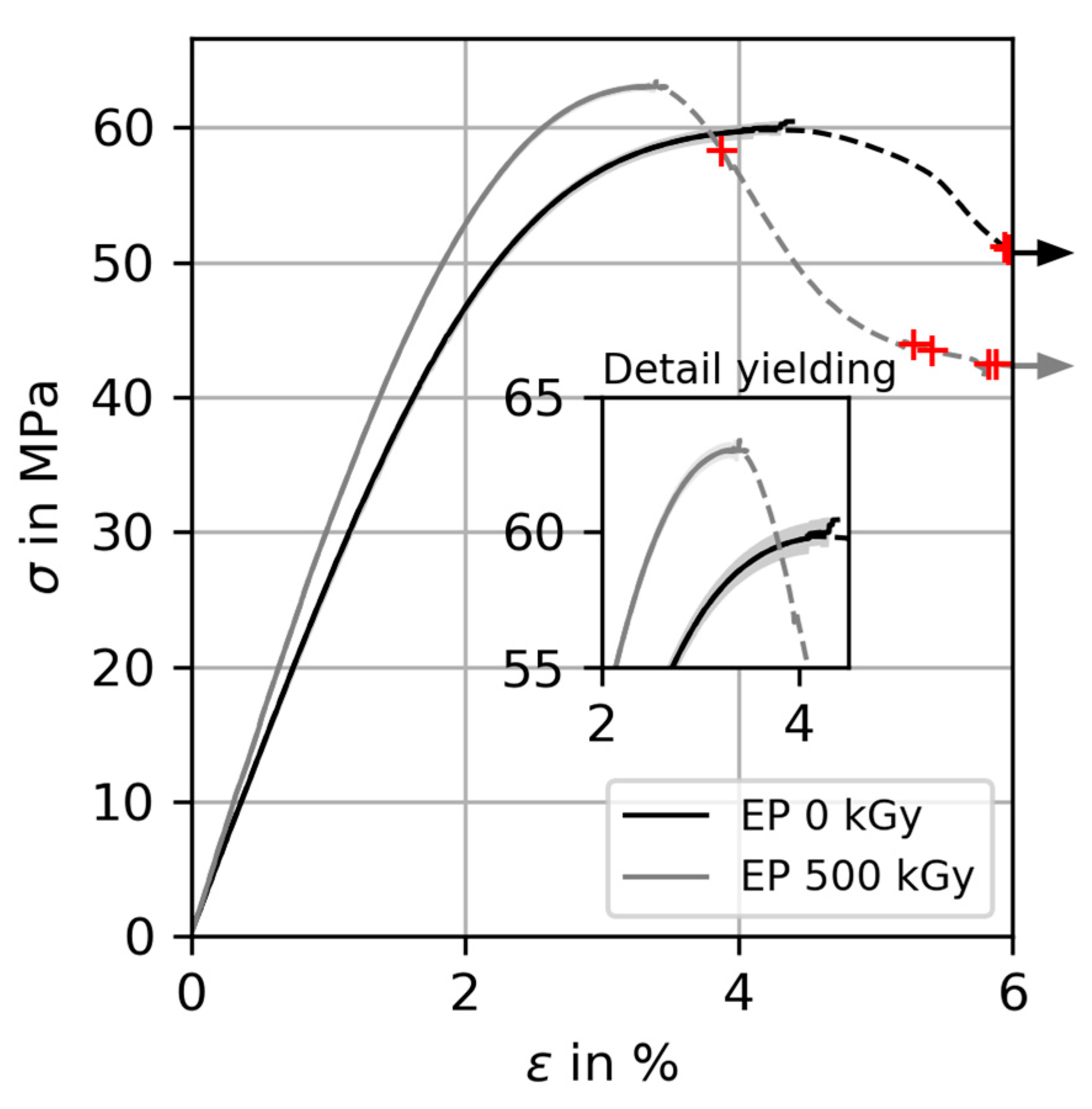

3.1. Neat Epoxy Specimens

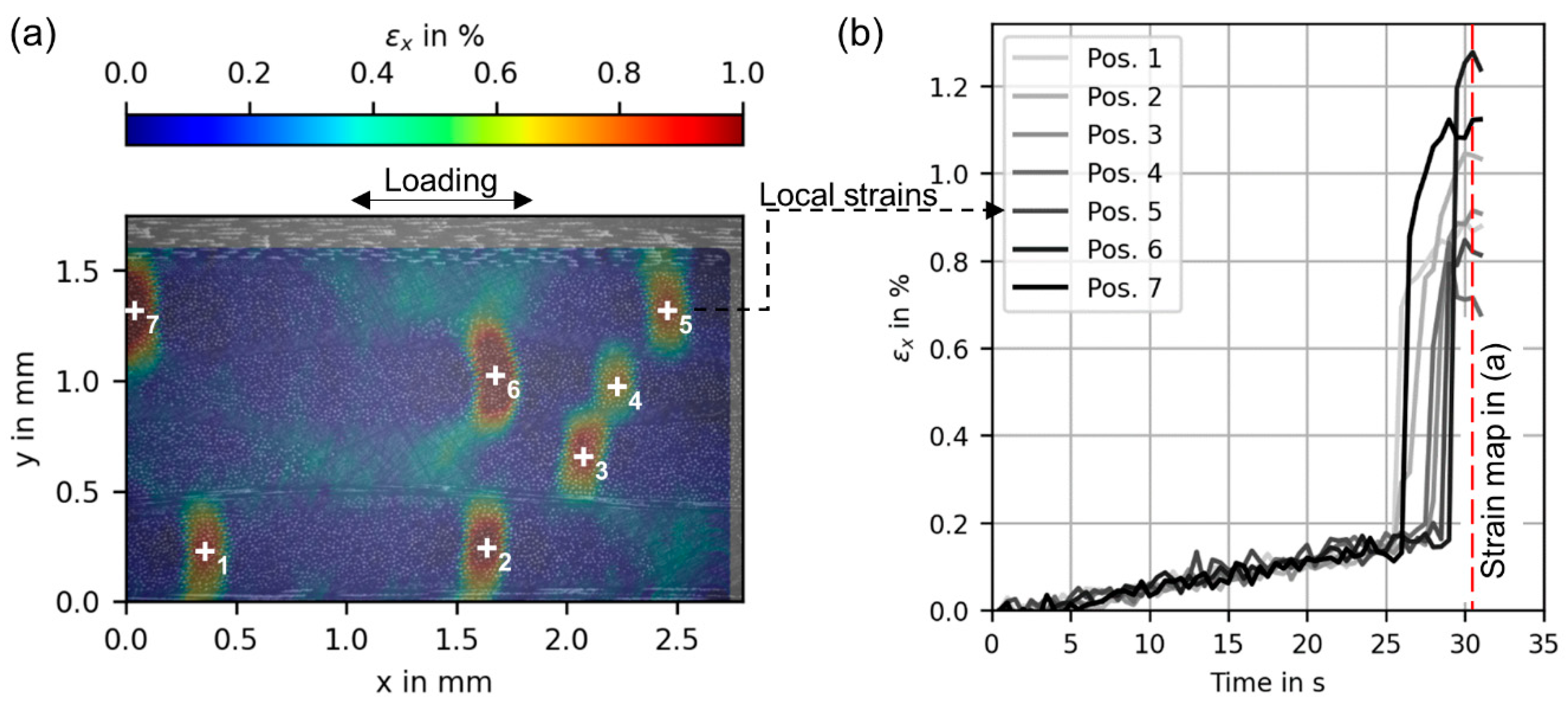

3.2. Glass Fiber-Reinforced Epoxy Laminates

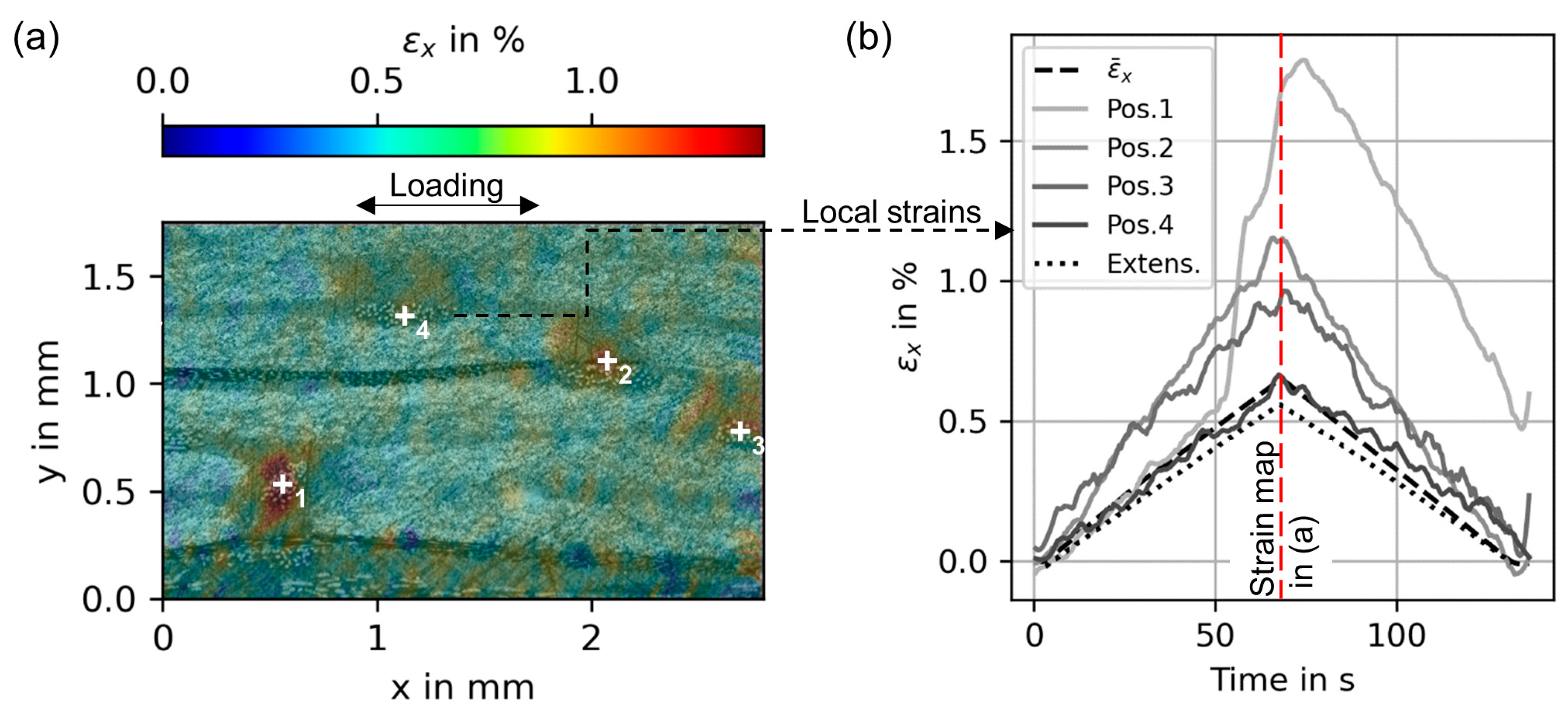

3.3. Carbon Fiber-Reinforced Epoxy Laminates

4. Discussion

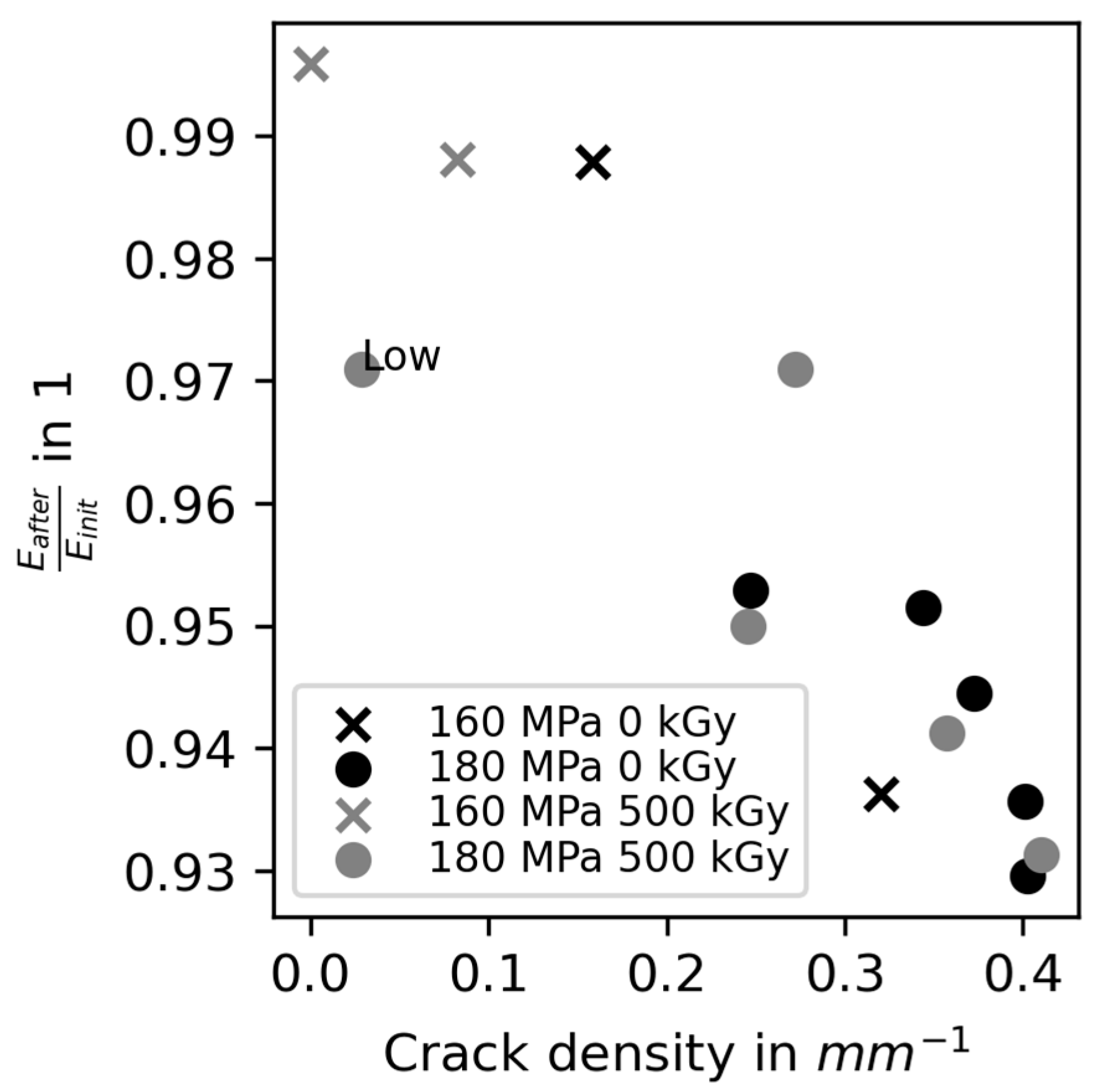

4.1. Damage Evolution

4.2. Strain Evaluation from Microscopic Images

4.3. Potential Application of In Situ Failure Strains

4.3.1. Optimization Potential by a Homogenous Fiber Distribution

4.3.2. Incorporating Inhomogeneity into the Failure Analysis

5. Conclusions

- The following mechanism can overcome the trade-off between field of view, depth of view, and magnification in edge observation, which enables DIC based on microscopic images of composites.

- Cracking sites are insensitive to moderate changes in polymer properties (elastic modulus +17.4% and yield stress +5.4%) and are mainly controlled by inhomogeneity induced by spatial fiber volume content variations and stitching fibers.

- Potential applications of the strains to local onset cracking are proposed either as optimization targets for a more homogenous FVF distribution or as knock-down factors extending to existing failure criteria.

- Cracking can be present early in the fatigue life and might be introduced during the first loading cycle, emphasizing the importance of fracture mechanical concepts.

- For both EP-CF and EP-GF laminates, the fiber–matrix interface initiates failure by debonding, although, in the case of EP-CF, it is not the interface of the reinforcement fibers but that of the stitching fibers that initiates failure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vallons, K.; Adolphs, G.; Lucas, P.; Lomov, S.V.; Verpoest, I. Quasi-UD Glass Fibre NCF Composites for Wind Energy Applications: A Review of Requirements and Existing Fatigue Data for Blade Materials. Mech. Ind. 2013, 14, 175–189. [Google Scholar] [CrossRef]

- Gamstedt, E.K.; Talreja, R. Fatigue Damage Mechanisms in Unidirectional Carbon-Fibre-Reinforced Plastics. J. Mater. Sci. 1999, 34, 2535–2546. [Google Scholar] [CrossRef]

- Soden, P.D.; Kaddour, A.S.; Hinton, M.J. Recommendations for Designers and Researchers Resulting from the World-Wide Failure Exercise. Compos. Sci. Technol. 2004, 64, 589–604. [Google Scholar] [CrossRef]

- Cuntze, R.G.; Freund, A. The Predictive Capability of Failure Mode Concept-Based Strength Criteria for Multidirectional Laminates. Compos. Sci. Technol. 2004, 64, 343–377. [Google Scholar] [CrossRef]

- Koch, I.; Zscheyge, M.; Tittmann, K.; Gude, M. Numerical Fatigue Analysis of CFRP Components. Compos. Struct. 2017, 168, 392–401. [Google Scholar] [CrossRef]

- Camanho, P.P.; Dávila, C.G.; Pinho, S.T.; Iannucci, L.; Robinson, P. Prediction of in Situ Strengths and Matrix Cracking in Composites under Transverse Tension and In-Plane Shear. Compos. Part A Appl. Sci. Manuf. 2006, 37, 165–176. [Google Scholar] [CrossRef]

- Endruweit, A.; Gommer, F.; Long, A.C. Stochastic Analysis of Fibre Volume Fraction and Permeability in Fibre Bundles with Random Filament Arrangement. Compos. Part A Appl. Sci. Manuf. 2013, 49, 109–118. [Google Scholar] [CrossRef]

- Zaami, A.; Baran, I.; Bor, T.C.; Akkerman, R. Optical Characterization of Fiber-Reinforced Thermoplastic Tapes for Laser-Based Composite Manufacturing. Compos. Part A Appl. Sci. Manuf. 2021, 146, 106402. [Google Scholar] [CrossRef]

- Brunbauer, J.; Pinter, G. Effects of Mean Stress and Fibre Volume Content on the Fatigue-Induced Damage Mechanisms in CFRP. Int. J. Fatigue 2015, 75, 28–38. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of Stress Level and Fibre Volume Fraction on Fatigue Performance of Glass Fibre-Reinforced Polyester Composites. Polymers 2022, 14, 2662. [Google Scholar] [CrossRef]

- Mortensen, U.A.; Rasmussen, S.; Mikkelsen, L.P.; Fraisse, A.; Andersen, T.L. The Impact of the Fiber Volume Fraction on the Fatigue Performance of Glass Fiber Composites. Compos. Part A Appl. Sci. Manuf. 2023, 169, 107493. [Google Scholar] [CrossRef]

- Brunbauer, J.; Pinter, G. (Eds.) Fatigue-Induced Damage Mechanisms in Carbon/Epoxy Laminates Influenced by Mean Stress and Fibre Volume Content. In Proceedings of the ICCM20—20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015; ICCM-Central: Belfast, UK, 2015. [Google Scholar]

- Dharan, C.K.H. Fatigue Failure in Graphite Fibre and Glass Fibre-Polymer Composites. J. Mater. Sci. 1975, 10, 1665–1670. [Google Scholar] [CrossRef]

- Schommer, D.; Duhovic, M.; Hoffmann, T.; Ernst, J.; Schladitz, K.; Moghiseh, A.; Gortner, F.; Hausmann, J.; Mitschang, P.; Steiner, K. Polarization Imaging for Surface Fiber Orientation Measurements of Carbon Fiber Sheet Molding Compounds. Compos. Commun. 2023, 37, 101456. [Google Scholar] [CrossRef]

- Drvoderic, M.; Gfrerrer, M.; Wiener, J.; Pinter, G.; Pletz, M.; Schuecker, C. Comparing Crack Density and Dissipated Energy as Measures for Off-Axis Damage in Composite Laminates. Int. J. Fatigue 2023, 169, 107486. [Google Scholar] [CrossRef]

- Maragoni, L.; Carraro, P.A.; Peron, M.; Quaresimin, M. Fatigue Behaviour of Glass/Epoxy Laminates in the Presence of Voids. Int. J. Fatigue 2017, 95, 18–28. [Google Scholar] [CrossRef]

- Pakkam Gabriel, V.R.; Loukil, M.S.; Varna, J. Analysis of Intralaminar Cracking in 90-Plies of GF/EP Laminates with Distributed Ply Strength. J. Compos. Mater. 2021, 55, 3925–3942. [Google Scholar] [CrossRef]

- Shen, H.; Yao, W.; Qi, W.; Zong, J. Experimental Investigation on Damage Evolution in Cross-Ply Laminates Subjected to Quasi-Static and Fatigue Loading. Compos. Part B Eng. 2017, 120, 10–26. [Google Scholar] [CrossRef]

- Lafarie-Frenot, M.C.; Hénaff-Gardin, C. Formation and Growth of 90° Ply Fatigue Cracks in Carbon/Epoxy Laminates. Compos. Sci. Technol. 1991, 40, 307–324. [Google Scholar] [CrossRef]

- Li, X.; Benedictus, R.; Zarouchas, D. Analysis of Stochastic Matrix Crack Evolution in CFRP Cross-Ply Laminates under Fatigue Loading. Eng. Fail. Anal. 2023, 150, 107277. [Google Scholar] [CrossRef]

- Li, X.; Kupski, J.; Teixeira De Freitas, S.; Benedictus, R.; Zarouchas, D. Unfolding the Early Fatigue Damage Process for CFRP Cross-Ply Laminates. Int. J. Fatigue 2020, 140, 105820. [Google Scholar] [CrossRef]

- Van Paepegem, W.; De Baere, I.; Lamkanfi, E.; Degrieck, J. Poisson’s Ratio as a Sensitive Indicator of (Fatigue) Damage in Fibre-reinforced Plastics. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 269–276. [Google Scholar] [CrossRef]

- Wharmby, A. Observations on Damage Development in Fibre Reinforced Polymer Laminates under Cyclic Loading. Int. J. Fatigue 2003, 25, 437–446. [Google Scholar] [CrossRef]

- Reifsnider, K.; Jamison, R. Fracture of Fatigue-Loaded Composite Laminates. Int. J. Fatigue 1982, 4, 187–197. [Google Scholar] [CrossRef]

- Carraro, P.A.; Quaresimin, M. A Damage Based Model for Crack Initiation in Unidirectional Composites under Multiaxial Cyclic Loading. Compos. Sci. Technol. 2014, 99, 154–163. [Google Scholar] [CrossRef]

- Baar, S.; Pavlov, L.; Kassapoglou, C. Consistent Approach to Onset Theory. J. Compos. Mater. 2022, 56, 3495–3507. [Google Scholar] [CrossRef]

- Zhuang, L.; Talreja, R.; Maragoni, L. Crack Deflection Near a Ply Interface in a Composite Laminate. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, Online, 16–19 November 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 4, p. V004T04A023. [Google Scholar]

- Baumann, A.; Hausmann, J. Effect of High Energy Radiation on Technical Polymers; ilmedia: Ilmenau, Germany, 2023. [Google Scholar]

- Aratama, S.; Hashizume, R.; Takenaka, K.; Koga, K.; Tsumura, Y.; Miyake, T.; Nishikawa, M.; Hojo, M. Microscopic Observation of Voids and Transverse Crack Initiation in CFRP Laminates. Adv. Compos. Mater. 2016, 25, 115–130. [Google Scholar] [CrossRef]

- Sutton, M.A.; Yan, J.H.; Tiwari, V.; Schreier, H.W.; Orteu, J.J. The Effect of Out-of-Plane Motion on 2D and 3D Digital Image Correlation Measurements. Opt. Lasers Eng. 2008, 46, 746–757. [Google Scholar] [CrossRef]

- ISO 13003:2003; Fibre-Reinforced Plastics—Determination of Fatigue Properties under Cyclic Loading Conditions. International Organization for Standardization: Geneva, Switzerland, 2003.

- Sommer, J.; Hajikazemi, M.; De Baere, I.; Van Paepegem, W. Fatigue Behaviour of Thermoplastic Glass/Polypropylene Composite Cross-Ply Laminates: An Experimental Study with in-Situ Damage Observations and Numerical Validation. Compos. Part B Eng. 2023, 252, 110494. [Google Scholar] [CrossRef]

- Sommer, J.; Hajikazemi, M.; De Baere, I.; Van Paepegem, W. Experimental and Numerical Damage Characterization of Glass/Polypropylene Multidirectional Laminates under Quasi-Static Loading Condition. Compos. Sci. Technol. 2022, 227, 109569. [Google Scholar] [CrossRef]

- Luo, Y. Improved Voigt and Reuss Formulas with the Poisson Effect. Materials 2022, 15, 5656. [Google Scholar] [CrossRef]

- Schürmann, H. Konstruieren Mit Faser-Kunststoff-Verbunden, 2nd ed.; VDI-Buch; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-72189-5. [Google Scholar]

- Aboudi, J. Mechanics of Composite Materials: A Unified Micromechanical Approach; Studies in applied mechanics; Elsevier: Amsterdam, The Netherlands; New York, NY, USA, 1991; Volume 29, ISBN 0-444-88452-1. [Google Scholar]

- Baumann, A.; Hausmann, J. Effect of High-Energy Radiation on the Relaxation of Residual Stresses in Polycarbonate and Epoxy Resin by Stress Optics. Radiat. Phys. Chem. 2024. accepted. [Google Scholar]

- Kody, R.S.; Lesser, A.J. Deformation and Yield of Epoxy Networks in Constrained States of Stress. J. Mater. Sci. 1997, 32, 5637–5643. [Google Scholar] [CrossRef]

- Asp, L.E.; Berglund, L.A.; Gudmundson, P. Effects of a Composite-like Stress State on the Fracture of Epoxies. Compos. Sci. Technol. 1995, 53, 27–37. [Google Scholar] [CrossRef]

- Asp, L.E.; Berglund, L.A.; Talreja, R. Prediction of Matrix-Initiated Transverse Failure in Polymer Composites. Compos. Sci. Technol. 1996, 56, 1089–1097. [Google Scholar] [CrossRef]

| Material and Irradiation Level | Elastic Modulus in GPa | Poisson’s Ratio |

|---|---|---|

| EP 0 kGy | 2.70 | 0.4 |

| EP 500 kGy | 3.17 | 0.4 |

| E-glass [35] | 73 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baumann, A.; Duhovic, M.; Hausmann, J. In Situ Microscopy of Fatigue-Loaded Embedded Transverse Layers of Cross-Ply Laminates: The Role of an Inhomogeneous Fiber Distribution. J. Compos. Sci. 2024, 8, 366. https://doi.org/10.3390/jcs8090366

Baumann A, Duhovic M, Hausmann J. In Situ Microscopy of Fatigue-Loaded Embedded Transverse Layers of Cross-Ply Laminates: The Role of an Inhomogeneous Fiber Distribution. Journal of Composites Science. 2024; 8(9):366. https://doi.org/10.3390/jcs8090366

Chicago/Turabian StyleBaumann, Andreas, Miro Duhovic, and Joachim Hausmann. 2024. "In Situ Microscopy of Fatigue-Loaded Embedded Transverse Layers of Cross-Ply Laminates: The Role of an Inhomogeneous Fiber Distribution" Journal of Composites Science 8, no. 9: 366. https://doi.org/10.3390/jcs8090366