Advances in Conductive Polymer-Based Flexible Electronics for Multifunctional Applications

Abstract

:1. Introduction

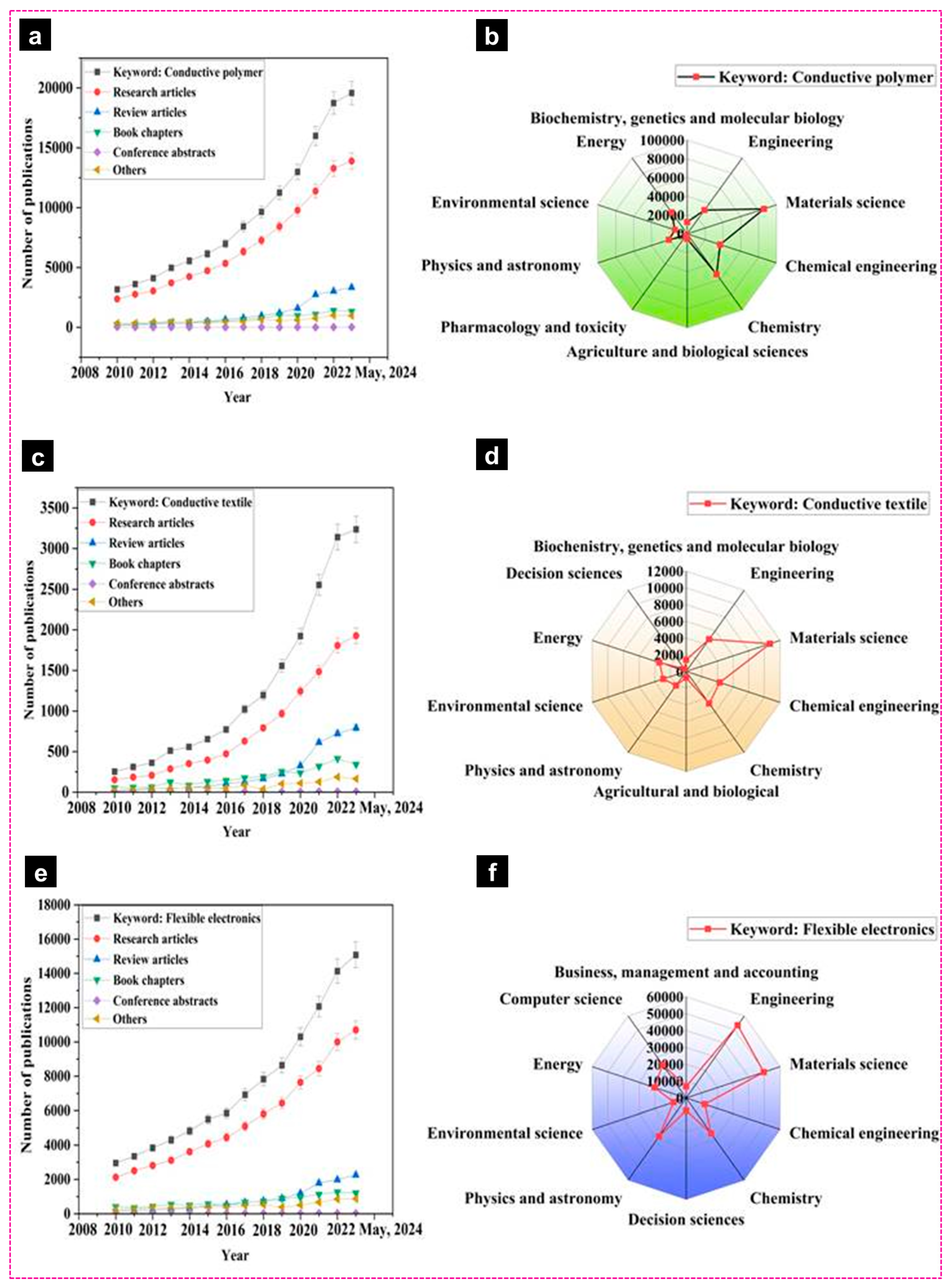

2. Methodology of Bibliometric Analysis

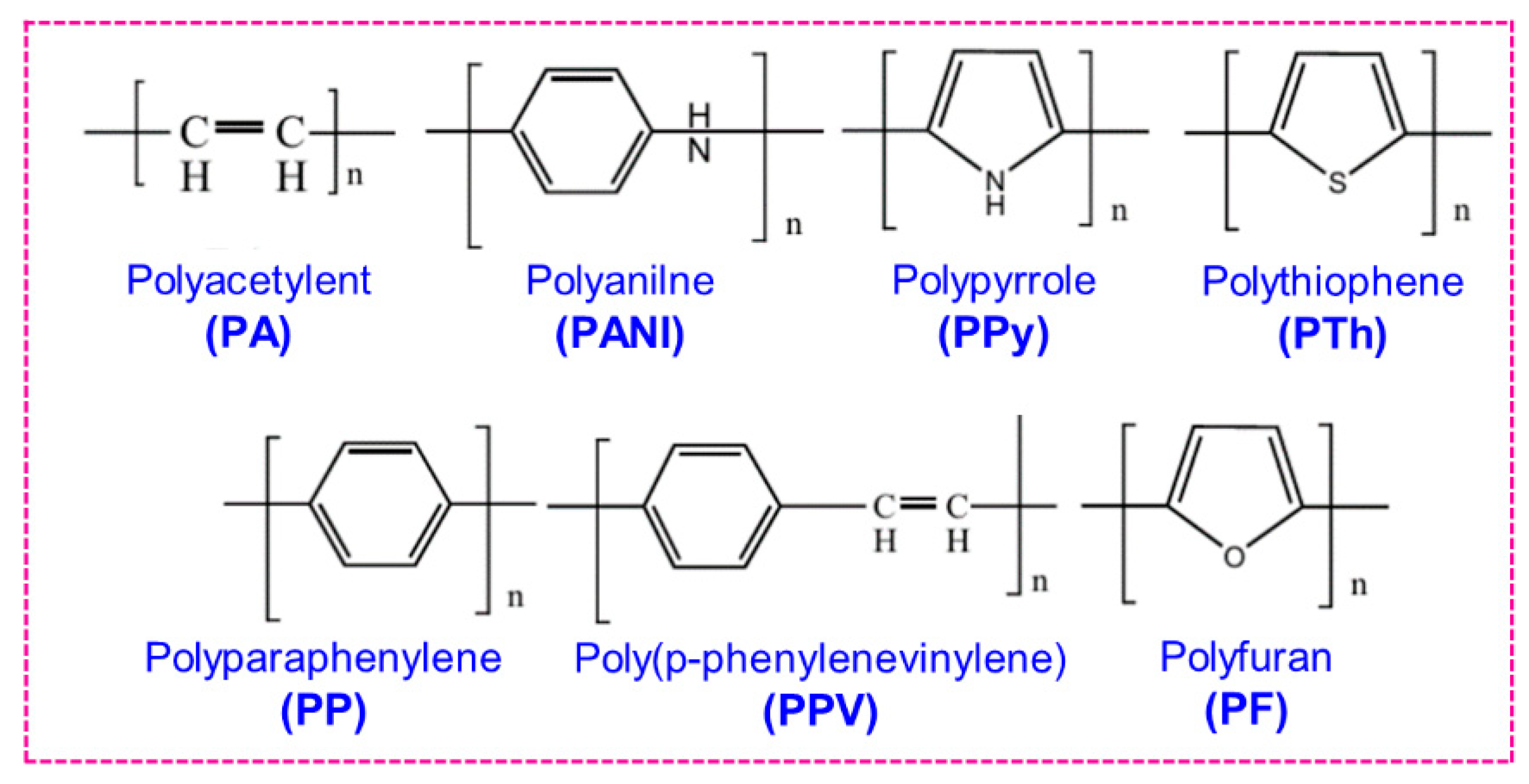

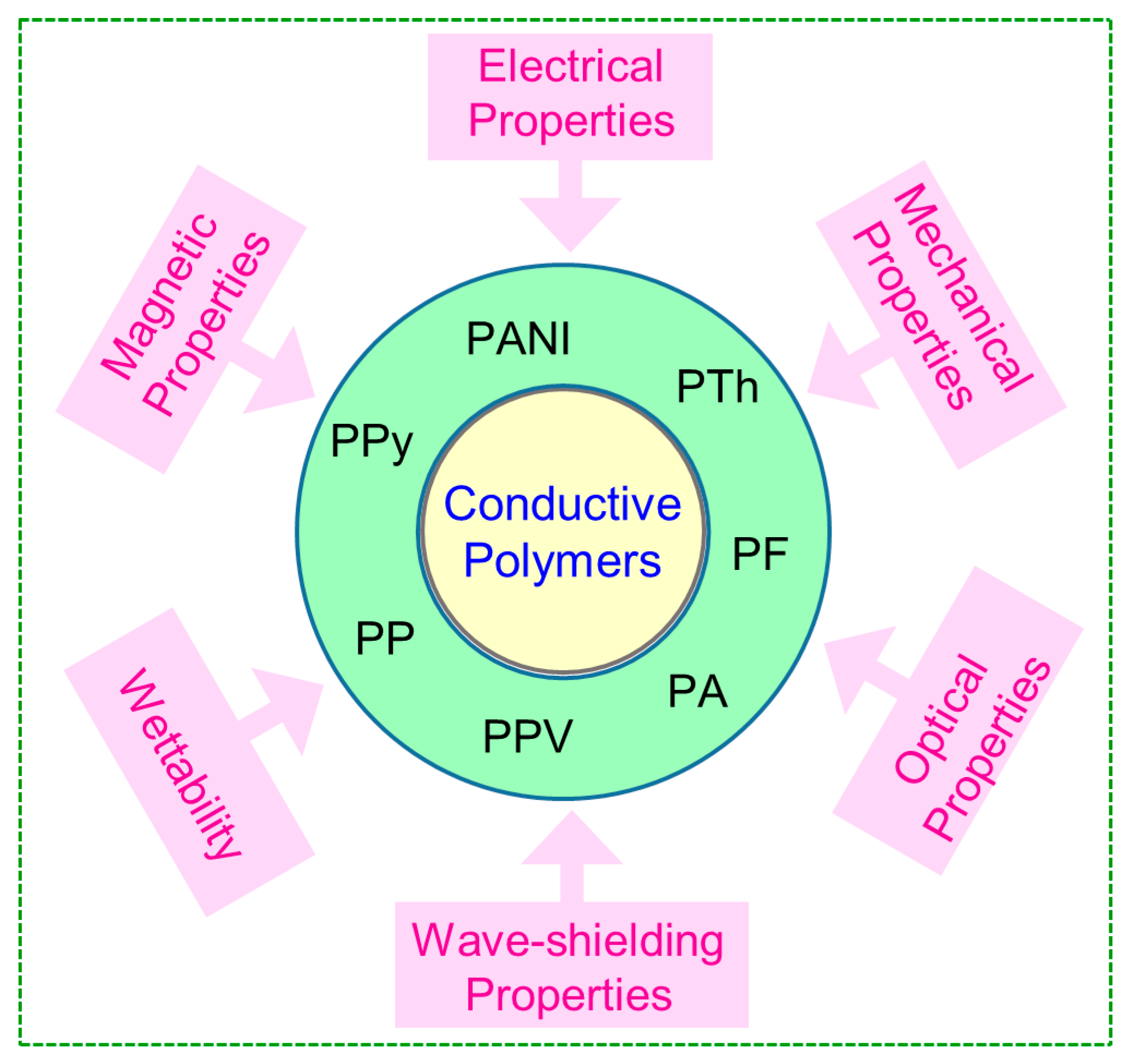

3. Properties of Conductive Polymers

| Conducting Polymer | Electrical Conductivity (S/cm) | Applications | Ref. |

|---|---|---|---|

| Polyacetylene (PA) | 4.4 × 10−5 |

| [23,24] |

| Polypyrrole (PPy) | 1 × 10−8 |

| [24,25] |

| Polyaniline (PANI) | 1 × 10−7 |

| [20] |

| Polythiophene (PTh) | 1 × 10−7 |

| [16] |

| PANI/PANI blends | 1.9 × 10−4 |

| [20] |

| Polyfluorenes (PFs) | 1 × 10−10 |

| [21,26] |

| Polyparaphenylene (PPV) | 1 × 10−12 |

| [19,24] |

3.1. Electrical-Conducting Properties

3.2. Magnetic Properties

3.3. Optical Properties

3.4. Wettability

3.5. Mechanical Properties

3.6. Microwave-Absorbing Properties

3.7. Electron Percolation Network

3.8. Frequency Domain Conductivity Spectra

3.9. Multiple (Accelerated) Aging Conditions/Effects

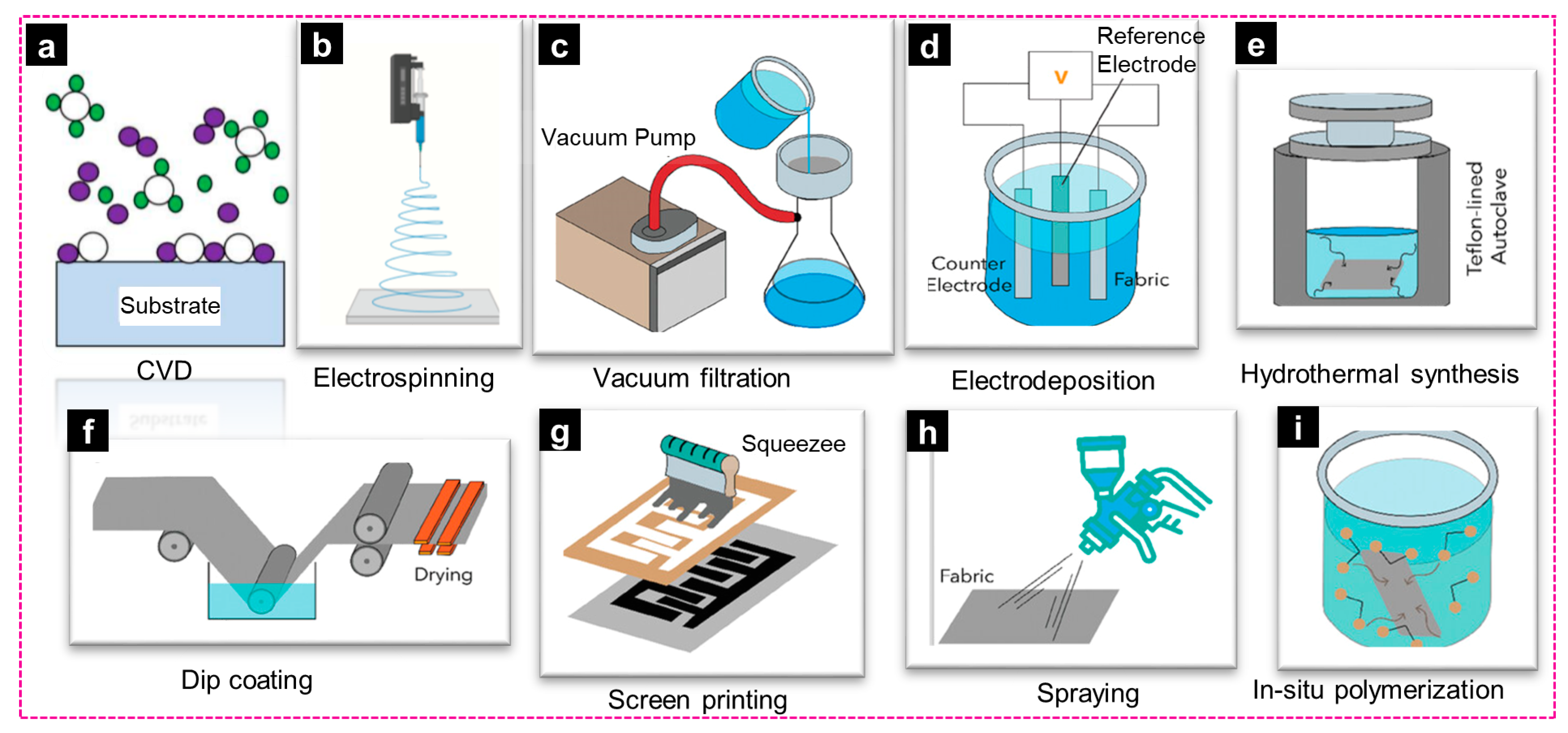

4. Fabrication Techniques for Conductive Polymer-Based Textiles

4.1. Chemical Vapor Deposition (CVD)

4.2. In Situ Polymerization

4.3. Electrochemical Polymerization

4.4. Dip Coating

4.5. Spray Coating

4.6. Electrospinning

4.7. Vacuum Filtration

4.8. Hydrothermal Synthesis

4.9. Screen Printing

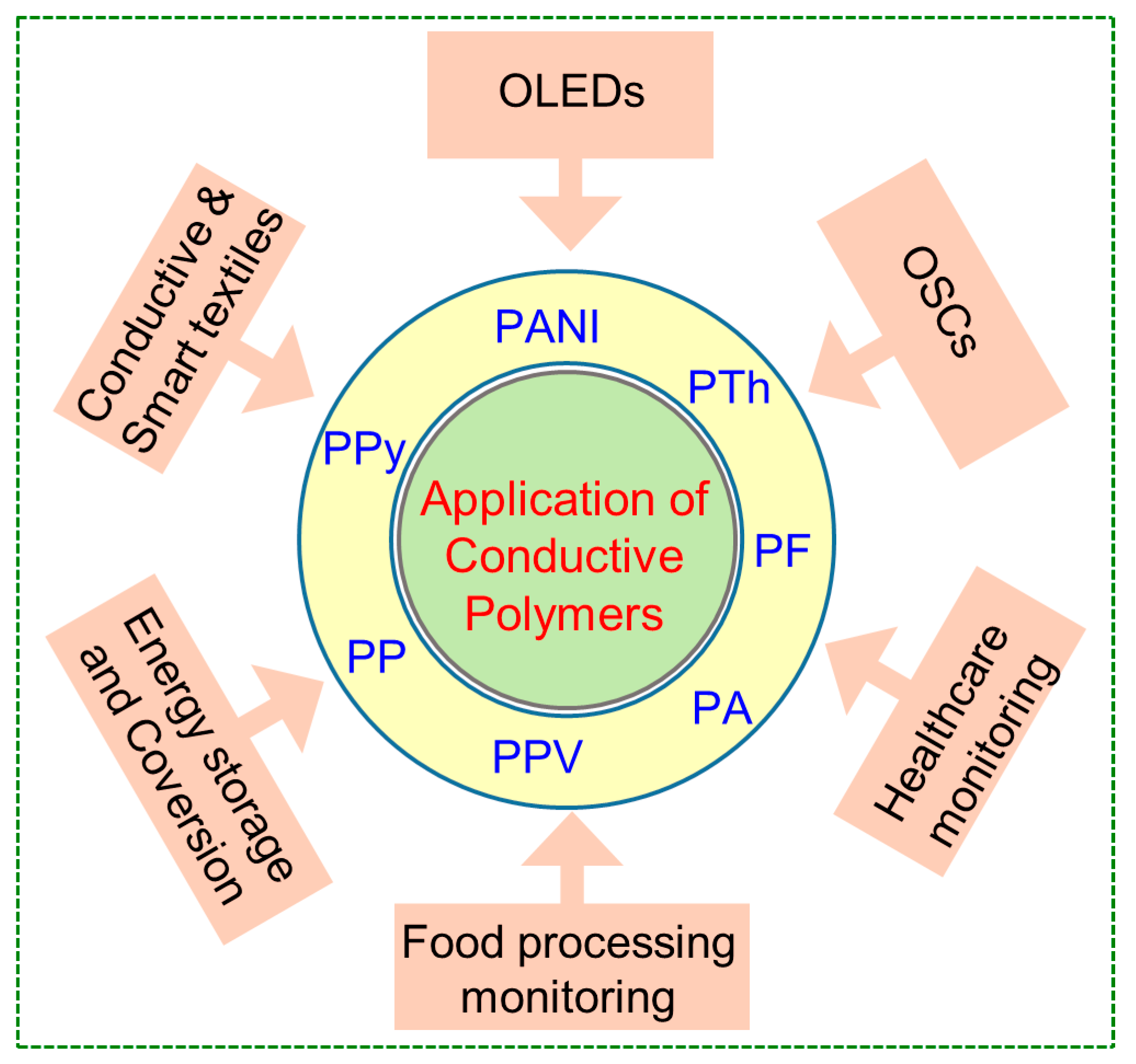

5. Application of Conductive Polymers

5.1. Energy Storage and Conversion

5.1.1. Supercapacitors

5.1.2. Lithium-Ion Batteries

5.1.3. Sodium-Ion Batteries

5.2. OLEDs

| Name of Polymer | Type | Characterizations | Key Findings | Limitations | Applications | Ref |

|---|---|---|---|---|---|---|

| PPy | Intrinsically | XRD, TGA, DSC | Easy synthesis, High conductivity | Brittle nature | Flexible sensors, actuators, wearable electronics, | [108] |

| PEDOT | Intrinsically | Raman, EIS, AFM | High stability, Good conductivity | Expensive monomers | Transparent electrodes, flexible OLEDs, stretchable electronic devices, bioelectronics | [109] |

| PA | Intrinsically | XPS, ESR, NMR | High conductivity | Instability in air | Molecular electronics, flexible transistors | [3] |

| PT | Intrinsically | FTIR, SEM, CV | Flexible, Moderate conductivity | Poor processability | Solar cells, flexible sensors | [108] |

| Poly(3-hexylthiophene) | Intrinsically | UV-Vis, GPC, AFM | High mobility, Good film-forming ability | Limited environmental stability | Organic transistors, photovoltaics, flexible electronic circuits | [110] |

| Poly(para-phenylene) | Intrinsically | UV-Vis, TGA, DSC | High thermal stability | Difficult synthesis | LEDs, field-effect transistors | [111] |

| Poly(para-phenylene vinylene) | Intrinsically | Raman, AFM, CV | High fluorescence | Low conductivity | OLEDs, solar cells | [112] |

| Polyfluorene | Intrinsically | UV-Vis, PL, GPC | High photoluminescence | Limited solubility | Blue LEDs, photodetectors, bioelectronics | [113] |

| Polycarbazole | Intrinsically | FTIR, CV, AFM | High thermal stability | Limited conductivity | Sensors, photovoltaics | [4,114] |

| PPy-DBSA | Conductive blend | XRD, TGA, DSC | Improved processability | Lower conductivity | Actuators, batteries | [108] |

| PEDOT-PSS | Conductive blend | Raman, EIS, AFM | High conductivity, Processable | High cost | Transparent electrodes, solar cells | [109] |

| Poly(thiophene-co-pyrrole) (PT-PPy) | Copolymer | UV-Vis, FTIR, SEM | Enhanced conductivity | Stability issues | Solar cells, actuators | [111] |

| PANI-PSSA | Conductive blend | UV-Vis, FTIR, SEM | Improved solubility | Reduced conductivity | Antistatic coatings, sensors | [115] |

| PPy-DBSA | Conductive blend | XRD, TGA, DSC | Improved process ability | Lower conductivity | Actuators, batteries | [116] |

| PEDOT-dodecylbenzene sulfonate | Conductive blend | UV-Vis, FTIR, SEM | Improved solubility | Expensive monomers | Antistatic coatings, sensors | [117] |

| Poly(aniline-co-pyrrole) | Copolymer | XRD, TGA, DSC | Combined properties | Complex synthesis | Flexible sensors, batteries | [118] |

| Poly(para-phenylene)-polystyrene | Copolymer | Raman, EIS, AFM | Improved film forming | Lower conductivity | LEDs, photovoltaics | [119] |

| Poly(3-hexylthiophene)-polyethylene glycol | Copolymer | FTIR, SEM, CV | Enhanced solubility | Lower thermal stability | Organic transistors, flexible sensors | [120] |

| Polyfluorene-polyvinyl alcohol | Copolymer | UV-Vis, TGA, DSC | Improved film forming | Limited conductivity | Blue LEDs, photodetector, flexible electronics | [121] |

5.3. Organic Solar Cells (OSCs)

5.4. Strain Sensors with Intrinsically Conducting Polymers (ICPs) for Healthcare Monitoring

5.5. Strain Sensors with ICPs for Food Processing Monitoring

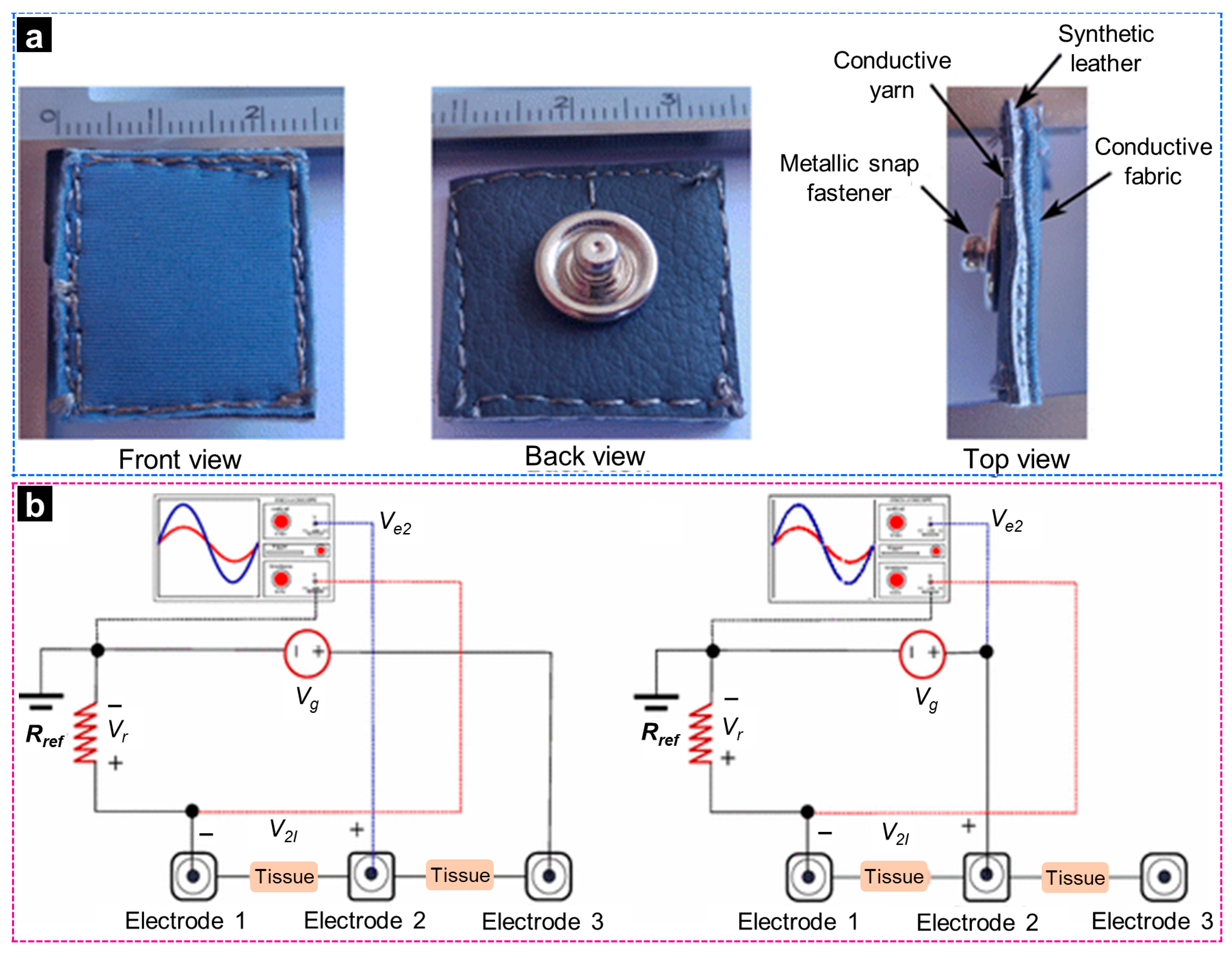

5.6. Electrically Conductive Textiles and Smart Textiles Applications

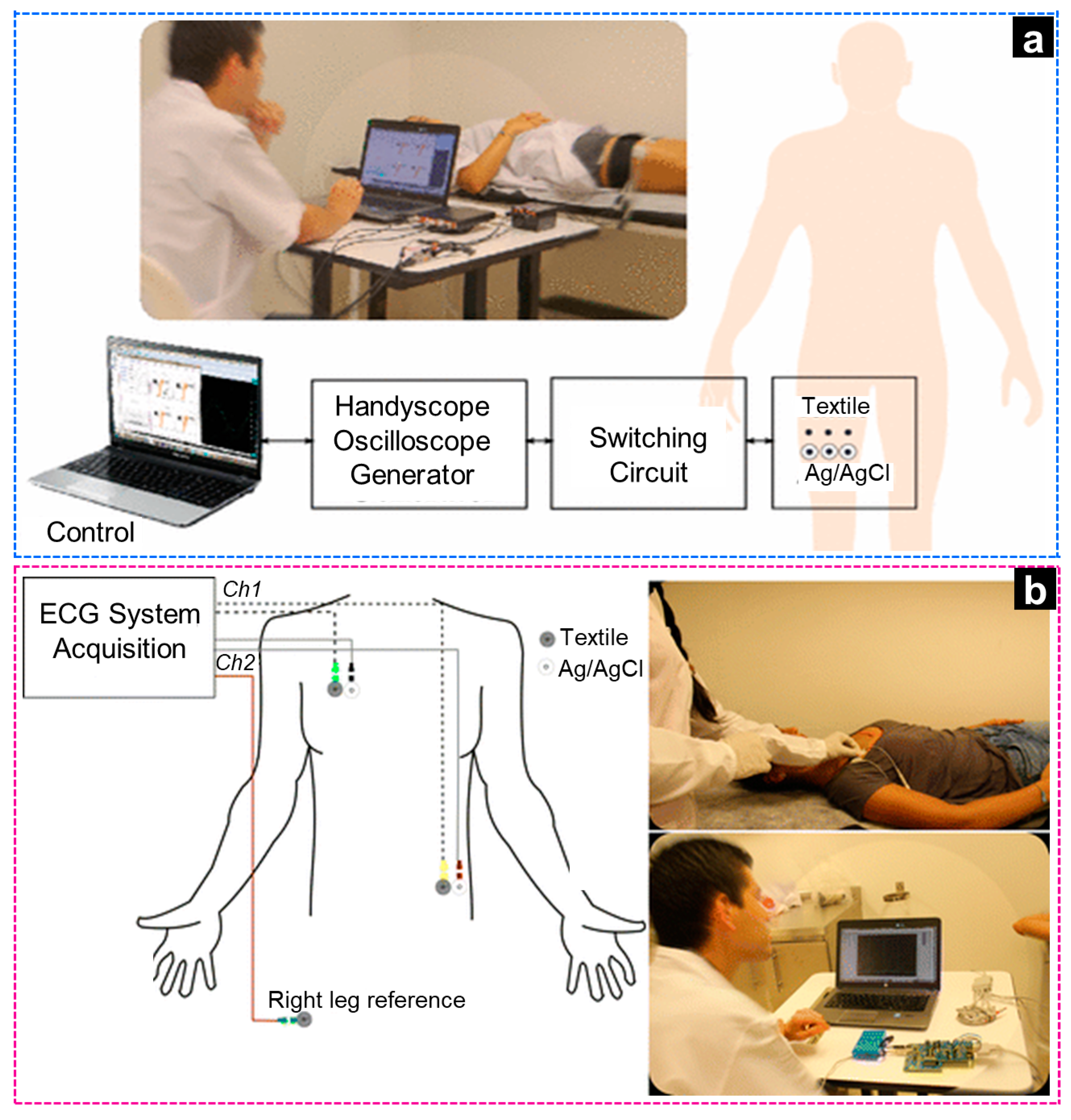

5.7. Health, Sport, and Fitness Applications

| Flexible Electronics | Manufacturing Elements | Ref. |

|---|---|---|

| OLEDs |

| [66] |

| OSCs |

| [66] |

| Healthcare monitoring |

| [133] |

| Food processing monitoring |

| [67,68,69,70] |

| Flexible super capacitors |

| [11,122,126,127,128,134,135] |

| Textiles and smart textiles applications |

| [91,123,130,136,137,138,139,140] |

6. Challenges and Limitations

7. Future Directions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.-I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef]

- Shirakawa, H.; Louis, E.J.; MacDiarmid, A.G.; Chiang, C.K.; Heeger, A.J. Synthesis of electrically conducting organic polymers: Halogen derivatives of polyacetylene, (CH)x. J. Chem. Soc. Chem. Commun. 1977, 578–580. [Google Scholar] [CrossRef]

- Jiang, C.; Chen, G.; Wang, X. High-conversion synthesis of poly (3, 4-ethylenedioxythiophene) by chemical oxidative polymerization. Synth. Met. 2012, 162, 1968–1971. [Google Scholar] [CrossRef]

- Dubey, N.; Kushwaha, C.S.; Shukla, S.K. A review on electrically conducting polymer bionanocomposites for biomedical and other applications. Int. J. Polym. Mater. Polym. Biomater. 2019, 69, 709–727. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Habib, A.; Rana, M.M.; Khan, S.A.; Hossain, M.D. Research and application of polypropylene: A review. Discov. Nano 2024, 19, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Lou, Z.; Shen, G. Flexible photodetectors based on 1D inorganic nanostructures. Adv. Sci. 2016, 3, 1500287. [Google Scholar] [CrossRef]

- Niu, X.Z.; Peng, S.L.; Liu, L.Y.; Wen, W.J.; Sheng, P. Characterizing and patterning of PDMS-based conducting composites. Adv. Mater. 2007, 19, 2682–2686. [Google Scholar] [CrossRef]

- Xiao, X.; Yuan, L.; Zhong, J.; Ding, T.; Liu, Y.; Cai, Z.; Rong, Y.; Han, H.; Zhou, J.; Wang, Z.L. High-strain sensors based on ZnO nanowire/polystyrene hybridized flexible films. Adv. Mater. 2011, 23, 5440–5444. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Wang, J.; Kang, W.; Cui, M.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Highly stretchable piezoresistive graphene–nanocellulose nanopaper for strain sensors. Adv. Mater. 2014, 26, 2022–2027. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Darda, M.A.; Samad, A.B. Techniques, applications, and prospects of recycled polyethylene terephthalate bottle: A review. J. Thermoplast. Compos. Mater. 2024, 37, 1268–1286. [Google Scholar] [CrossRef]

- Ouyang, J. Application of intrinsically conducting polymers in flexible electronics. SmartMat 2021, 2, 263–285. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Q.; Zou, W.; Zhang, X.; Sun, Y.; Kan, Y.; Cai, P.; Gao, K. Recent Progress in All-Solution-Processed Organic Solar Cells. Chin. J. Chem. 2024, 42, 190–198. [Google Scholar] [CrossRef]

- Shahid, M.A.; Hossain, M.T.; Hossain, I.; Limon, M.G.M.; Rabbani, M.; Rahim, A. Research and development on phase change material-integrated cloth: A review. J. Ind. Text. 2024, 54, 15280837241262518. [Google Scholar] [CrossRef]

- Awuzie, C. Conducting polymers. Mater. Today Proc. 2017, 4, 5721–5726. [Google Scholar] [CrossRef]

- Namsheer, K.; Rout, C.S. Conducting polymers: A comprehensive review on recent advances in synthesis, properties and applications. RSC Adv. 2021, 11, 5659–5697. [Google Scholar]

- Wallace, D.S.; Stoneham, A.M.; Hayes, W.; Fisher, A.J.; Testa, A. Theory of defects in conducting polymers. II. Application to polyacetylene. J. Phys. Condens. Matter 1991, 3, 3905. [Google Scholar] [CrossRef]

- Waghuley, S.A.; Yenorkar, S.M.; Yawale, S.S.; Yawale, S.P. Application of chemically synthesized conducting polymer-polypyrrole as a carbon dioxide gas sensor. Sens. Actuators B Chem. 2008, 128, 366–373. [Google Scholar] [CrossRef]

- Baker, C.O.; Huang, X.; Nelson, W.; Kaner, R.B. Polyaniline nanofibers: Broadening applications for conducting polymers. Chem. Soc. Rev. 2017, 46, 1510–1525. [Google Scholar] [CrossRef]

- Ates, M.; Karazehir, T.; Sezai Sarac, A. Conducting polymers and their applications. Curr. Phys. Chem. 2012, 2, 224–240. [Google Scholar] [CrossRef]

- Bhadra, J.; Alkareem, A.; Al-Thani, N. A review of advances in the preparation and application of polyaniline based thermoset blends and composites. J. Polym. Res. 2020, 27, 122. [Google Scholar] [CrossRef]

- Chakraborty, C.; Layek, A.; Ray, P.P.; Malik, S. Star-shaped polyfluorene: Design, synthesis, characterization and application towards solar cells. Eur. Polym. J. 2014, 52, 181–192. [Google Scholar] [CrossRef]

- Hossaın, M.T.; Repon, M.R.; Shahid, M.A.; Ali, A.; Islam, T. Progress, prospects and challenges of MXene integrated optoelectronics devices. ChemElectroChem 2024, 11, e202400008. [Google Scholar] [CrossRef]

- Petrach, E.; Abu-Isa, I.; Wang, X. Percolation threshold study of a plastic–elastomeric matrix based composite material for bipolar plates in proton exchange membrane fuel cells. J. Compos. Mater. 2012, 46, 2959–2971. [Google Scholar] [CrossRef]

- Maiti, S. Recent trends in conducting polymers: Problems and promises. Indian J. Chem. 1994, 33A, 524–539. [Google Scholar]

- Dweiri, R.; Sahari, J. Electrical properties of carbon-based polypropylene composites for bipolar plates in polymer electrolyte membrane fuel cell (PEMFC). J. Power Sources 2007, 171, 424–432. [Google Scholar] [CrossRef]

- Ranger, M.; Leclerc, M. New base-doped polyfluorene derivatives. Macromolecules 1999, 32, 3306–3313. [Google Scholar] [CrossRef]

- Timp, G.; Howard, R.E.; Mankiewich, P.M. Nano-electronics for advanced computation and communication. In Nanotechnology; Springer: New York, NY, USA, 1999; pp. 7–87. [Google Scholar]

- Xia, Y.; Yang, P.; Sun, Y.; Wu, Y.; Mayers, B.; Gates, B.; Yin, Y.; Kim, F.; Yan, H. One-dimensional nanostructures: Synthesis, characterization, and applications. Adv. Mater. 2003, 15, 353–389. [Google Scholar] [CrossRef]

- Hu, J.; Odom, T.W.; Lieber, C.M. Chemistry and physics in one dimension: Synthesis and properties of nanowires and nanotubes. Acc. Chem. Res. 1999, 32, 435–445. [Google Scholar] [CrossRef]

- Wang, Z.L. Characterizing the structure and properties of individual wire-like nanoentities. Adv. Mater. 2000, 12, 1295–1298. [Google Scholar] [CrossRef]

- Kuchibhatla, S.V.N.T.; Karakoti, A.S.; Bera, D.; Seal, S. One dimensional nanostructured materials. Prog. Mater. Sci. 2007, 52, 699–913. [Google Scholar] [CrossRef]

- Akkerman, H.B.; Blom, P.W.M.; De Leeuw, D.M.; De Boer, B. Towards molecular electronics with large-area molecular junctions. Nature 2006, 441, 69–72. [Google Scholar] [CrossRef]

- Heeger, A.J. Semiconducting and metallic polymers: The fourth generation of polymeric materials. J. Phys. Chem. B 2001, 105, 8475–8491. [Google Scholar] [CrossRef]

- Stejskal, J.; Sapurina, I.; Trchová, M. Polyaniline nanostructures and the role of aniline oligomers in their formation. Prog. Polym. Sci. 2010, 35, 1420–1481. [Google Scholar] [CrossRef]

- Li, C.; Bai, H.; Shi, G. Conducting polymer nanomaterials: Electrosynthesis and applications. Chem. Soc. Rev. 2009, 38, 2397–2409. [Google Scholar] [CrossRef]

- Lupu, N. Nanowires: Science and Technology; BoD–Books on Demand; INTECH: London, UK, 2010. [Google Scholar]

- Long, Y.; Chen, Z.; Wang, N.; Zhang, Z.; Wan, M. Resistivity study of polyaniline doped with protonic acids. Phys. B Condens. Matter 2003, 325, 208–213. [Google Scholar] [CrossRef]

- Kim, B.-H.; Jung, J.-H.; Hong, S.-H.; Joo, J.; Epstein, A.J.; Mizoguchi, K.; Kim, J.W.; Choi, H.J. Nanocomposite of polyaniline and Na+–montmorillonite clay. Macromolecules 2002, 35, 1419–1423. [Google Scholar] [CrossRef]

- Norris, I.D.; Shaker, M.M.; Ko, F.K.; MacDiarmid, A.G. Electrostatic fabrication of ultrafine conducting fibers: Polyaniline/polyethylene oxide blends. Synth. Met. 2000, 114, 109–114. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, J.; Shen, J.; Wan, M.; Chen, Z. Chemical one step method to prepare polyaniline nanofibers with electromagnetic function. Macromol. Rapid Commun. 2007, 28, 585–590. [Google Scholar] [CrossRef]

- Lu, X.; Chao, D.; Zheng, J.; Chen, J.; Zhang, W.; Wei, Y. Preparation and characterization of polydiphenylamine/multi-walled carbon nanotube composites. Polym. Int. 2006, 55, 945–950. [Google Scholar] [CrossRef]

- Su, C.; Wang, G.; Huang, F. Preparation and characterization of composites of polyaniline nanorods and multiwalled carbon nanotubes coated with polyaniline. J. Appl. Polym. Sci. 2007, 106, 4241–4247. [Google Scholar] [CrossRef]

- Lu, X.; Zheng, J.; Chao, D.; Chen, J.; Zhang, W.; Wei, Y. Poly (N-methylaniline)/multi-walled carbon nanotube composites—Synthesis, characterization, and electrical properties. J. Appl. Polym. Sci. 2006, 100, 2356–2361. [Google Scholar] [CrossRef]

- Feng, W.; Bai, X.D.; Lian, Y.Q.; Liang, J.; Wang, X.G.; Yoshino, K. Well-aligned polyaniline/carbon-nanotube composite films grown by in-situ aniline polymerization. Carbon 2003, 41, 1551–1557. [Google Scholar] [CrossRef]

- Pillalamarri, S.K.; Blum, F.D.; Tokuhiro, A.T.; Bertino, M.F. One-pot synthesis of polyaniline−metal nanocomposites. Chem. Mater. 2005, 17, 5941–5944. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, Y.; Long, Y.; Yuan, J.; Han, D.; Wang, Z.; Niu, L.; Chen, Z. Preparation of highly conductive, self-assembled gold/polyaniline nanocables and polyaniline nanotubes. Chem.–A Eur. J. 2006, 12, 5314–5319. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.; Huang, K.; Yuan, J.; Han, D.; Niu, L.; Chen, Z.; Gu, C.; Jin, A.; Duvail, J.L. Electrical conductivity of a single Au/polyaniline microfiber. Appl. Phys. Lett. 2006, 88, 162113. [Google Scholar] [CrossRef]

- Lu, X.; Mao, H.; Chao, D.; Zhang, W.; Wei, Y. Ultrasonic synthesis of polyaniline nanotubes containing Fe3O4 nanoparticles. J. Solid State Chem. 2006, 179, 2609–2615. [Google Scholar] [CrossRef]

- Nalwa, H.S. Phase transitions in polypyrrole and polythiophene conducting polymers demonstrated by magnetic susceptibility measurements. Phys. Rev. B 1989, 39, 5964. [Google Scholar] [CrossRef]

- Weinberger, B.R.; Kaufer, J.; Heeger, A.J.; Pron, A.; MacDiarmid, A.G. Magnetic susceptibility of doped polyacetylene. Phys. Rev. B 1979, 20, 223. [Google Scholar] [CrossRef]

- Long, Y.; Chen, Z.; Duvail, J.L.; Zhang, Z.; Wan, M. Electrical and magnetic properties of polyaniline/Fe3O4 nanostructures. Phys. B Condens. Matter 2005, 370, 121–130. [Google Scholar] [CrossRef]

- Xiao, H.-M.; Fu, S.-Y. Synthesis and physical properties of electromagnetic polypyrrole composites via addition of magnetic crystals. CrystEngComm 2014, 16, 2097–2112. [Google Scholar] [CrossRef]

- Cao, H.Q.; Xu, Z.; Sang, H.; Sheng, D.; Tie, C.Y. Template synthesis and magnetic behavior of an array of cobalt nanowires encapsulated in polyaniline nanotubules. Adv. Mater. 2001, 13, 121–123. [Google Scholar] [CrossRef]

- Cao, H.; Tie, C.; Xu, Z.; Hong, J.; Sang, H. Array of nickel nanowires enveloped in polyaniline nanotubules and its magnetic behavior. Appl. Phys. Lett. 2001, 78, 1592–1594. [Google Scholar] [CrossRef]

- Huang, M.H.; Mao, S.; Feick, H.; Yan, H.; Wu, Y.; Kind, H.; Weber, E.; Russo, R.; Yang, P. Room-temperature ultraviolet nanowire nanolasers. Science 2001, 292, 1897–1899. [Google Scholar] [CrossRef]

- Law, M.; Kind, H.; Messer, B.; Kim, F.; Yang, P. Photochemical sensing of NO2 with SnO2 nanoribbon nanosensors at room temperature. Angew. Chem. Int. Ed. 2002, 41, 2405–2408. [Google Scholar] [CrossRef]

- Xi, Y.; Zhou, J.; Guo, H.; Cai, C.; Lin, Z. Enhanced photoluminescence in core-sheath CdS–PANI coaxial nanocables: A charge transfer mechanism. Chem. Phys. Lett. 2005, 412, 60–64. [Google Scholar] [CrossRef]

- Turac, E.; Sahmetlioglu, E.; Toppare, L.; Yuruk, H. Synthesis, Characterization and Optoelectrochemical Properties of Poly (2, 5-di (thiophen-2-yl-) 1-(4-(thiophen-3-yl) phenyl)-1H-pyrrole-co-EDOT). Des. Monomers Polym. 2010, 13, 261–275. [Google Scholar] [CrossRef]

- Zhong, W.; Chen, X.; Liu, S.; Wang, Y.; Yang, W. Synthesis of highly hydrophilic polyaniline nanowires and sub-micro/nanostructured dendrites on poly (propylene) film surfaces. Macromol. Rapid Commun. 2006, 27, 563–569. [Google Scholar] [CrossRef]

- Zhu, Y.; Hu, D.; Wan, M.X.; Jiang, L.; Wei, Y. Conducting and superhydrophobic rambutan-like hollow spheres of polyaniline. Adv. Mater. 2007, 19, 2092. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, J.; Wan, M.; Jiang, L. Superhydrophobic 3D microstructures assembled from 1D nanofibers of polyaniline. Macromol. Rapid Commun. 2008, 29, 239–243. [Google Scholar] [CrossRef]

- Xu, L.; Chen, W.; Mulchandani, A.; Yan, Y. Reversible conversion of conducting polymer films from superhydrophobic to superhydrophilic. Angew. Chem. Int. Ed. 2005, 44, 6009–6012. [Google Scholar] [CrossRef]

- Zhu, Y.; Feng, L.; Xia, F.; Zhai, J.; Wan, M.; Jiang, L. Chemical dual-responsive wettability of superhydrophobic PANI-PAN coaxial nanofibers. Macromol. Rapid Commun. 2007, 28, 1135–1141. [Google Scholar] [CrossRef]

- Villafiorita-Monteleone, F.; Canale, C.; Caputo, G.; Cozzoli, P.D.; Cingolani, R.; Fragouli, D.; Athanassiou, A. Controlled swapping of nanocomposite surface wettability by multilayer photopolymerization. Langmuir 2011, 27, 8522–8529. [Google Scholar] [CrossRef] [PubMed]

- Cuenot, S.; Demoustier-Champagne, S.; Nysten, B. Elastic modulus of polypyrrole nanotubes. Phys. Rev. Lett. 2000, 85, 1690. [Google Scholar] [CrossRef] [PubMed]

- Cuenot, S.; Frétigny, C.; Demoustier-Champagne, S.; Nysten, B. Surface tension effect on the mechanical properties of nanomaterials measured by atomic force microscopy. Phys. Rev. B 2004, 69, 165410. [Google Scholar] [CrossRef]

- Park, J.G.; Lee, S.H.; Kim, B.; Park, Y.W. Electrical resistivity of polypyrrole nanotube measured by conductive scanning probe microscope: The role of contact force. Appl. Phys. Lett. 2002, 81, 4625–4627. [Google Scholar] [CrossRef]

- Guo, J.-G.; Zhao, Y.-P. The size-dependent bending elastic properties of nanobeams with surface effects. Nanotechnology 2007, 18, 295701. [Google Scholar] [CrossRef]

- Wan, M.; Li, J.; Li, S. Microtubules of polyaniline as new microwave absorbent materials. Polym. Adv. Technol. 2001, 12, 651–657. [Google Scholar] [CrossRef]

- Muraoka, M.; Tobe, R. Mechanical characterization of nanowires based on optical diffraction images of the bent shape. J. Nanosci. Nanotechnol. 2009, 9, 4566–4574. [Google Scholar] [CrossRef]

- Murugappan, K.; Castell, M.R. Bridging electrode gaps with conducting polymers around the electrical percolation threshold. Electrochem. Commun. 2018, 87, 40–43. [Google Scholar] [CrossRef]

- Armitage, B.I.; Murugappan, K.; Lefferts, M.J.; Cowsik, A.; Castell, M.R. Conducting polymer percolation gas sensor on a flexible substrate. J. Mater. Chem. C 2020, 8, 12669–12676. [Google Scholar] [CrossRef]

- Bruck, H.A.; Yang, M.; Kostov, Y.; Rasooly, A. Electrical percolation based biosensors. Methods 2013, 63, 282–289. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Li, Z.; Du, Y.; Zhang, L.; Huang, Y.; Sun, J.; Coates, P.; Gao, X. Compression-induced electrical percolation and enhanced mechanical properties of polydimethylsiloxane-based nanocomposites. J. Mater. Sci. 2020, 55, 10611–10625. [Google Scholar] [CrossRef]

- Chang, I.; Park, T.; Lee, J.; Lee, M.H.; Ko, S.H.; Cha, S.W. Bendable polymer electrolyte fuel cell using highly flexible Ag nanowire percolation network current collectors. J. Mater. Chem. A 2013, 1, 8541–8546. [Google Scholar] [CrossRef]

- Guerchouche, K.; Herth, E.; Calvet, L.E.; Roland, N.; Loyez, C. Conductive polymer based antenna for wireless green sensors applications. Microelectron. Eng. 2017, 182, 46–52. [Google Scholar] [CrossRef]

- Das, S.; Kumar, A.; Narayan, K. Confinement highlights the different electrical transport mechanisms prevailing in conducting polymers. Phys. Rev. Mater. 2022, 6, 025602. [Google Scholar] [CrossRef]

- Verma, A.; Fumeaux, C.; Truong, V.-T.; Bates, B.D. Effect of film thickness on the radiation efficiency of a 4.5 GHz polypyrrole conducting polymer patch antenna. In Proceedings of the 2010 Asia-Pacific Microwave Conference, Yokohama, Japan, 7–10 December 2010; pp. 95–98. [Google Scholar]

- Palsaniya, S.; Mukherji, S. Enhanced dielectric and electrostatic energy density of electronic conductive organic-metal oxide frameworks at ultra-high frequency. Carbon 2022, 196, 749–762. [Google Scholar] [CrossRef]

- Xia, X.; Weng, G.J.; Hou, D.; Wen, W. Tailoring the frequency-dependent electrical conductivity and dielectric permittivity of CNT-polymer nanocomposites with nanosized particles. Int. J. Eng. Sci. 2019, 142, 1–19. [Google Scholar] [CrossRef]

- Khanna, V.K. Extreme-Temperature and Harsh-Environment Electronics: Physics, Technology and Applications; IOP Publishing: Bristol, UK, 2023. [Google Scholar]

- Boehler, C.; Oberueber, F.; Schlabach, S.; Stieglitz, T.; Asplund, M. Long-term stable adhesion for conducting polymers in biomedical applications: IrOx and nanostructured platinum solve the chronic challenge. ACS Appl. Mater. Interfaces 2017, 9, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Jiang, C.; Li, L. Hierarchical structures on platinum–iridium substrates enhancing conducting polymer adhesion. Bio-Des. Manuf. 2024, 7, 889–898. [Google Scholar] [CrossRef]

- Mandal, H.S.; Knaack, G.L.; Charkhkar, H.; McHail, D.G.; Kastee, J.S.; Dumas, T.C.; Peixoto, N.; Rubinson, J.F.; Pancrazio, J.J. Improving the performance of poly (3, 4-ethylenedioxythiophene) for brain–machine interface applications. Acta Biomater. 2014, 10, 2446–2454. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Abidian, M.R.; Ahn, J.-H.; Akinwande, D.; Andrews, A.M.; Antonietti, M.; Bao, Z.; Berggren, M.; Berkey, C.A.; Bettinger, C.J. Technology roadmap for flexible sensors. ACS Nano 2023, 17, 5211–5295. [Google Scholar] [CrossRef] [PubMed]

- Momber, A.W.; Irmer, M.; Glück, N. Investigation into the performance of a dual-layer thin-film organic coating during accelerated low-temperature offshore testing. J. Offshore Mech. Arct. Eng. 2017, 139, 041402. [Google Scholar] [CrossRef]

- Bashir, T. Conjugated Polymer-Based Conductive Fibers for Smart Textile Applications; Chalmers Tekniska Hogskola: Göteborg, Sweden, 2013. [Google Scholar]

- Roslan, N.C.; Aizamddin, M.F.; Ruzaidi, D.A.A.; Ayub, A.N.; Asri, N.A.N.; Jani, N.A.; Mahat, M.M. Conducting polymer-based textile materials. In Conjugated Polymers for Next-Generation Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 325–359. [Google Scholar]

- Maity, S.; Chatterjee, A. Conductive polymer based electro-conductive textiles for novel applications. Tech. Text. 2015, 1, E16–E18. [Google Scholar]

- Ojstršek, A.; Jug, L.; Plohl, O. A review of electro conductive textiles utilizing the dip-coating technique: Their functionality, durability and sustainability. Polymers 2022, 14, 4713. [Google Scholar] [CrossRef]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Ali, A. Development of nanofibrous membrane from recycled polyethene terephthalate bottle by electrospinning. OpenNano 2022, 8, 100089. [Google Scholar] [CrossRef]

- Maity, S.; Chatterjee, A. Conductive polymer-based electro-conductive textile composites for electromagnetic interference shielding: A review. J. Ind. Text. 2018, 47, 2228–2252. [Google Scholar] [CrossRef]

- Rajesh, M.; Raj, C.J.; Manikandan, R.; Kim, B.C.; Park, S.Y.; Yu, K.H. A high performance PEDOT/PEDOT symmetric supercapacitor by facile in-situ hydrothermal polymerization of PEDOT nanostructures on flexible carbon fibre cloth electrodes. Mater. Today Energy 2017, 6, 96–104. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Ali, M.Y.; Saha, S.; Jamal, M.S.I.; Habib, A. Fabrications, classifications, and environmental impact of PCM-incorporated textiles: Current state and future outlook. ACS Omega 2023, 8, 45164–45176. [Google Scholar] [CrossRef]

- Nezakati, T.; Seifalian, A.; Tan, A.; Seifalian, A.M. Conductive polymers: Opportunities and challenges in biomedical applications. Chem. Rev. 2018, 118, 6766–6843. [Google Scholar] [CrossRef]

- Shahid, M.A.; Saha, C.; Miah, M.S.; Hossain, M.T. Incorporation of MPCM on cotton fabric for potential application in hospital bed sheet. Heliyon 2023, 9, e16412. [Google Scholar] [CrossRef]

- Hoque, M.I.U.; Donne, S.W.; Holze, R. Graphene Nanocomposite Materials for Supercapacitor Electrodes. Encyclopedia 2024, 4, 101–116. [Google Scholar] [CrossRef]

- Hoque, M.I.U.; Holze, R. Intrinsically conducting polymer composites as active masses in supercapacitors. Polymers 2023, 15, 730. [Google Scholar] [CrossRef]

- Ge, Y.; Hoque, M.I.U.; Qu, Q. 1D Hematite-[α-Fe2O3]-nanorods prepared by green fabrication for supercapacitor electrodes. Electrochem. Energy Technol. 2019, 5, 1–6. [Google Scholar] [CrossRef]

- Hoque, M.I.U.; Gibson, A.; Donne, S. SnO2-QDs/RGO Nanocomposites for Lithium Ion Battery Anodes. In Proceedings of the Electrochemical Society Meeting Abstracts 242, Atlanta, GA, USA, 9–13 October 2022; The Electrochemical Society, Inc.: Pennington, NJ, USA, 2022; p. 2519. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, S.; Wang, Y.; Zhang, T.; Yue, H.; Li, T.; Li, W.; Li, H.; Hao, Y.; Gao, Y. Fabrication of polypyrrole-coated silicon nanoparticle composite electrode for lithium-ion battery. Ionics 2024, 30, 7869–7879. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, C.; Huang, X.; Wang, T.; Gu, C.; Joo, S.W.; Huang, J. Polyaniline-coated flower-like iron oxide served as anode material for superior-performance lithium-ion batteries. J. Electroanal. Chem. 2024, 967, 118484. [Google Scholar] [CrossRef]

- Zhao, W.; Zhou, H.; Li, Y.; Yi, X.; Wang, G.; Ma, X. Synergistic engineering of heteroatomic N-doping and PPy modification in flower-like vanadium sulfide anode enables stable sodium storage. Chem. Eng. J. 2024, 500, 156999. [Google Scholar]

- Ma, D.; Yin, X.; Li, X.; Qin, X.; Qi, M. Study on the Performance of Aniline Electrodeposited on MnO2 Nanowire as an Anode for Sodium-Ion Batteries. Polymers 2024, 16, 1856. [Google Scholar] [CrossRef]

- Han, L.; Li, Y.; Miao, R.; Liu, L.; Lu, Z.; Zhang, N. Redox Active Lignosulfonate Functionalized Polyaniline-Based Hydrogel Electrodes for Wide Temperature Tolerant Flexible Supercapacitors. ACS Sustain. Chem. Eng. 2024, 12, 13220–13230. [Google Scholar] [CrossRef]

- Dang, F.; Cai, Y.; Yang, P. Electrodeposition of Graphene/Polypyrrole Electrode for Flexible Supercapacitor with Large Areal Capacitance. ACS Appl. Energy Mater. 2024, 7, 5832–5838. [Google Scholar] [CrossRef]

- Hao, L.; Dong, C.; Zhang, L.; Zhu, K.; Yu, D. Polypyrrole nanomaterials: Structure, preparation and application. Polymers 2022, 14, 5139. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, Z.; Azman, A.W.; Buys, Y.F.; Sarifuddin, N. Mechanisms for doped PEDOT: PSS electrical conductivity improvement. Mater. Adv. 2021, 2, 7118–7138. [Google Scholar]

- Duc, C.; Stoclet, G.; Soulestin, J.; Samuel, C. Poly (ethylene oxide)/poly (3, 4-ethylenedioxythiophene): Poly (styrene sulfonate) (PEDOT: PSS) Blends: An efficient route to highly conductive thermoplastic materials for melt-state extrusion processing? ACS Appl. Polym. Mater. 2020, 2, 2366–2379. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive nanomaterials for 2D and 3D printed flexible electronics. Chem. Soc. Rev. 2019, 48, 1712–1740. [Google Scholar] [CrossRef]

- Choi, S.; Han, S.I.; Kim, D.; Hyeon, T.; Kim, D.-H. High-performance stretchable conductive nanocomposites: Materials, processes, and device applications. Chem. Soc. Rev. 2019, 48, 1566–1595. [Google Scholar] [CrossRef]

- Someya, T.; Bao, Z.; Malliaras, G.G. The rise of plastic bioelectronics. Nature 2016, 540, 379–385. [Google Scholar] [CrossRef]

- Saha, C.; Shahid, M.A.; Prasad, R.K. Evaluation of Thermal and Moisture Management Properties of PCM Treated Denim Fabrics. J. Text. Appar. Technol. Manag. (JTATM) 2021, 12, 1–6. [Google Scholar]

- Bae, S.; Lee, J.U.; Park, H.-s.; Jung, E.H.; Jung, J.W.; Jo, W.H. Enhanced performance of polymer solar cells with PSSA–g–PANI/Graphene oxide composite as hole transport layer. Sol. Energy Mater. Sol. Cells 2014, 130, 599–604. [Google Scholar] [CrossRef]

- Merdj, F.; Mekki, A.; Guettiche, D.; Mettai, B.; Sayah, Z.B.D.; Safidine, Z.; Abdi, A.; Mahmoud, R.; Chehimi, M.M. Highly ammonia sensing using direct in situ electro-deposited polypyrrole-dodecylbenzene sulfonic acid film on ITO coated flexible substrates. Macromol. Res. 2018, 26, 511–520. [Google Scholar] [CrossRef]

- Tumová, Š.; Malečková, R.; Kubáč, L.; Akrman, J.; Enev, V.; Kalina, L.; Vojtková, E.; Pešková, M.; Víteček, J.; Vala, M.; et al. Novel highly stable conductive polymer composite PEDOT: DBSA for bioelectronic applications. Polym. J. 2023, 55, 983–995. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Zhang, D.; Tang, Y.; Cang, H. Electrosynthesis of PAni/PPy coatings doped by phosphotungstate on mild steel and their corrosion resistances. Prog. Org. Coat. 2015, 88, 84–91. [Google Scholar] [CrossRef]

- Chen, J.; Jia, S.; Ji, X.; Nourrein, M.; Xiang, H.; Zhou, Z.; Wang, C.-L.; Sun, B.; Zhu, M. The morphologies and fluorescence quantum yields of perylene diimide dye-doped PS and PHVB microspheres. RSC Adv. 2018, 8, 35534–35538. [Google Scholar] [CrossRef] [PubMed]

- Soga, T.; Kato, S.; Kato, S.; Kishi, N. Role of polyethylene glycol addition on the improvement of P3HT: PCBM organic solar cells. J. Mater. Sci. Mater. Electron. 2019, 30, 3332–3337. [Google Scholar] [CrossRef]

- Ma, C.; Song, Y.; Shi, J.; Zhang, D.; Zhai, X.; Zhong, M.; Guo, Q.; Liu, L. Preparation and one-step activation of microporous carbon nanofibers for use as supercapacitor electrodes. Carbon 2013, 51, 290–300. [Google Scholar] [CrossRef]

- Zhan, Z.; Lin, R.; Tran, V.-T.; An, J.; Wei, Y.; Du, H.; Tran, T.; Lu, W. Paper/carbon nanotube-based wearable pressure sensor for physiological signal acquisition and soft robotic skin. ACS Appl. Mater. Interfaces 2017, 9, 37921–37928. [Google Scholar] [CrossRef]

- Tyler, N. While smart textiles for wearables remains in its infancy, its potential is huge. Newelectron. Site Electron. Des. Eng. 2016, 14–16. Available online: https://www.newelectronics.co.uk/content/features/while-smart-textiles-for-wearables-remains-in-its-infancy-its-potential-is-huge/ (accessed on 1 January 2025).

- Fan, X.; Nie, W.; Tsai, H.; Wang, N.; Huang, H.; Cheng, Y.; Wen, R.; Ma, L.; Yan, F.; Xia, Y. PEDOT: PSS for flexible and stretchable electronics: Modifications, strategies, and applications. Adv. Sci. 2019, 6, 1900813. [Google Scholar] [CrossRef]

- Castrillón, R.; Pérez, J.J.; Andrade-Caicedo, H. Electrical performance of PEDOT: PSS-based textile electrodes for wearable ECG monitoring: A comparative study. Biomed. Eng. Online 2018, 17, 1–23. [Google Scholar] [CrossRef]

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Tucci, V.; Russo, S. Piezoresistive properties of resin reinforced with carbon nanotubes for health-monitoring of aircraft primary structures. Compos. Part B Eng. 2016, 107, 192–202. [Google Scholar] [CrossRef]

- Zha, J.-W.; Zhang, B.; Li, R.K.Y.; Dang, Z.-M. High-performance strain sensors based on functionalized graphene nanoplates for damage monitoring. Compos. Sci. Technol. 2016, 123, 32–38. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Yue, S.; He, H.; Ouyang, J. Biocompatible blends of an intrinsically conducting polymer as stretchable strain sensors for real-time monitoring of starch-based food processing. Adv. Funct. Mater. 2021, 31, 2102745. [Google Scholar] [CrossRef]

- Naysmith, A.; Mian, N.S.; Rana, S. Development of conductive textile fabric using Plackett–Burman optimized green synthesized silver nanoparticles and in situ polymerized polypyrrole. Green Chem. Lett. Rev. 2023, 16, 2158690. [Google Scholar] [CrossRef]

- Takamatsu, S.; Lonjaret, T.; Crisp, D.; Badier, J.-M.; Malliaras, G.G.; Ismailova, E. Direct patterning of organic conductors on knitted textiles for long-term electrocardiography. Sci. Rep. 2015, 5, 15003. [Google Scholar] [CrossRef]

- Paul, G.; Torah, R.; Beeby, S.; Tudor, J. The development of screen printed conductive networks on textiles for biopotential monitoring applications. Sens. Actuators A Phys. 2014, 206, 35–41. [Google Scholar] [CrossRef]

- Carvalho, H.; Catarino, A.P.; Rocha, A.; Postolache, O. Health monitoring using textile sensors and electrodes: An overview and integration of technologies. In Proceedings of the 2014 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Lisboa, Portugal, 11–12 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Sun, L.; Han, R.P.S.; Wang, J.; Lim, C.T. Modeling the size-dependent elastic properties of polymeric nanofibers. Nanotechnology 2008, 19, 455706. [Google Scholar] [CrossRef] [PubMed]

- Ryu, K.S.; Kim, K.M.; Park, N.-G.; Park, Y.J.; Chang, S.H. Symmetric redox supercapacitor with conducting polyaniline electrodes. J. Power Sources 2002, 103, 305–309. [Google Scholar] [CrossRef]

- Burke, A. R&D considerations for the performance and application of electrochemical capacitors. Electrochim. Acta 2007, 53, 1083–1091. [Google Scholar]

- Rudge, A.; Raistrick, I.; Gottesfeld, S.; Ferraris, J.P. A study of the electrochemical properties of conducting polymers for application in electrochemical capacitors. Electrochim. Acta 1994, 39, 273–287. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Kim, K.H.; Kim, K.B. Fabrication and electrochemical properties of carbon nanotube/polypyrrole composite film electrodes with controlled pore size. J. Power Sources 2008, 176, 396–402. [Google Scholar] [CrossRef]

- Lota, K.; Khomenko, V.; Frackowiak, E. Capacitance properties of poly (3, 4-ethylenedioxythiophene)/carbon nanotubes composites. J. Phys. Chem. Solids 2004, 65, 295–301. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, L.; Zhang, J. A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 2012, 41, 797–828. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Wu, H.; Meng, Y.; Wei, Z. Conducting polymer nanowire arrays for high performance supercapacitors. Small 2014, 10, 14–31. [Google Scholar] [CrossRef]

- Yan, Y.; Jiang, Y.; Ng, E.L.L.; Zhang, Y.; Owh, C.; Wang, F.; Song, Q.; Feng, T.; Zhang, B.; Li, P. Progress and opportunities in additive manufacturing of electrically conductive polymer composites. Mater. Today Adv. 2023, 17, 100333. [Google Scholar] [CrossRef]

- Cavaliere, S.; Subianto, S.; Savych, I.; Jones, D.J.; Rozière, J. Electrospinning: Designed architectures for energy conversion and storage devices. Energy Environ. Sci. 2011, 4, 4761–4785. [Google Scholar] [CrossRef]

- Zhang, L.; Du, W.; Nautiyal, A.; Liu, Z.; Zhang, X. Recent progress on nanostructured conducting polymers and composites: Synthesis, application and future aspects. Sci. China Mater. 2018, 61, 303–352. [Google Scholar] [CrossRef]

- Nandee, R.; Chowdhury, M.A.; Shahid, A.; Hossain, N.; Rana, M. Band gap formation of 2D materialin graphene: Future prospect and challenges. Results Eng. 2022, 15, 100474. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahid, M.A.; Rahman, M.M.; Hossain, M.T.; Hossain, I.; Sheikh, M.S.; Rahman, M.S.; Uddin, N.; Donne, S.W.; Hoque, M.I.U. Advances in Conductive Polymer-Based Flexible Electronics for Multifunctional Applications. J. Compos. Sci. 2025, 9, 42. https://doi.org/10.3390/jcs9010042

Shahid MA, Rahman MM, Hossain MT, Hossain I, Sheikh MS, Rahman MS, Uddin N, Donne SW, Hoque MIU. Advances in Conductive Polymer-Based Flexible Electronics for Multifunctional Applications. Journal of Composites Science. 2025; 9(1):42. https://doi.org/10.3390/jcs9010042

Chicago/Turabian StyleShahid, Md. Abdus, Md. Mostafizur Rahman, Md. Tanvir Hossain, Imam Hossain, Md. Sohan Sheikh, Md. Sunjidur Rahman, Nasir Uddin, Scott W. Donne, and Md. Ikram Ul Hoque. 2025. "Advances in Conductive Polymer-Based Flexible Electronics for Multifunctional Applications" Journal of Composites Science 9, no. 1: 42. https://doi.org/10.3390/jcs9010042

APA StyleShahid, M. A., Rahman, M. M., Hossain, M. T., Hossain, I., Sheikh, M. S., Rahman, M. S., Uddin, N., Donne, S. W., & Hoque, M. I. U. (2025). Advances in Conductive Polymer-Based Flexible Electronics for Multifunctional Applications. Journal of Composites Science, 9(1), 42. https://doi.org/10.3390/jcs9010042