Dynamic Mechanical Analysis and Optimization of Vibration Damping in Epoxy-Based Nano Cement Composite Dampers for Sustainable Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used in the Study

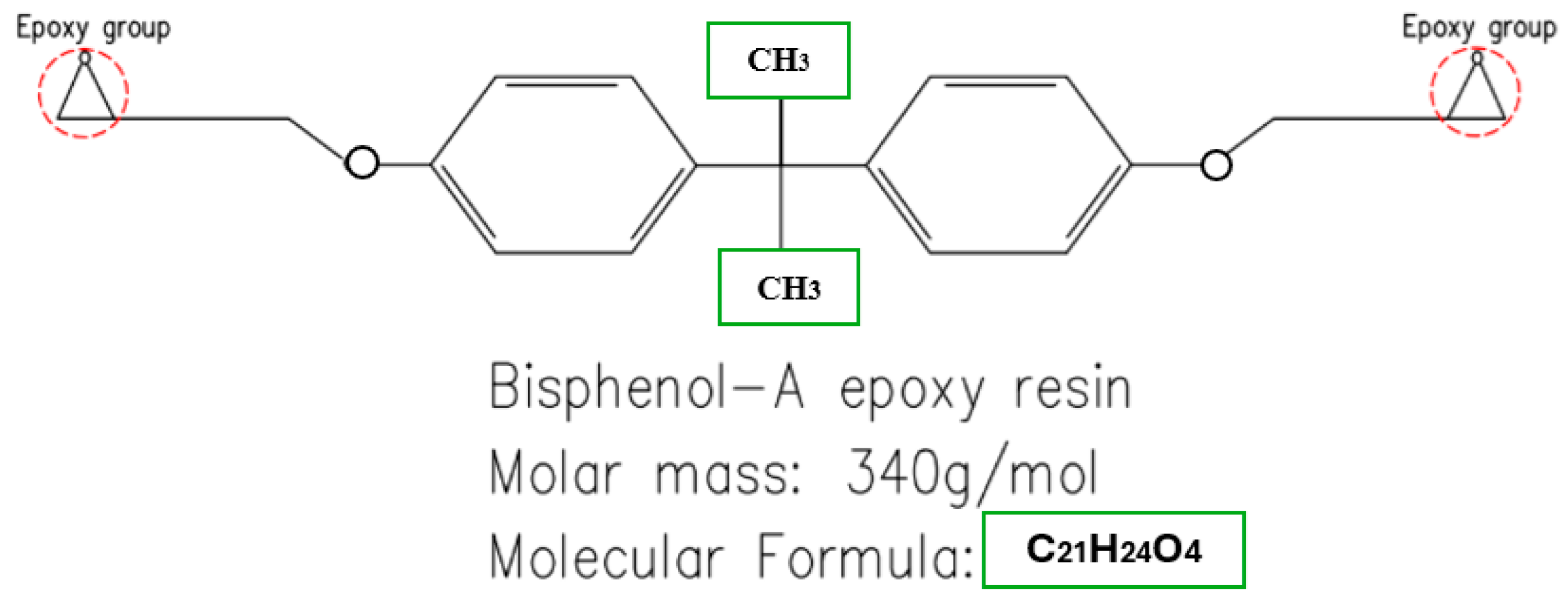

2.2. Characteristics of Resin

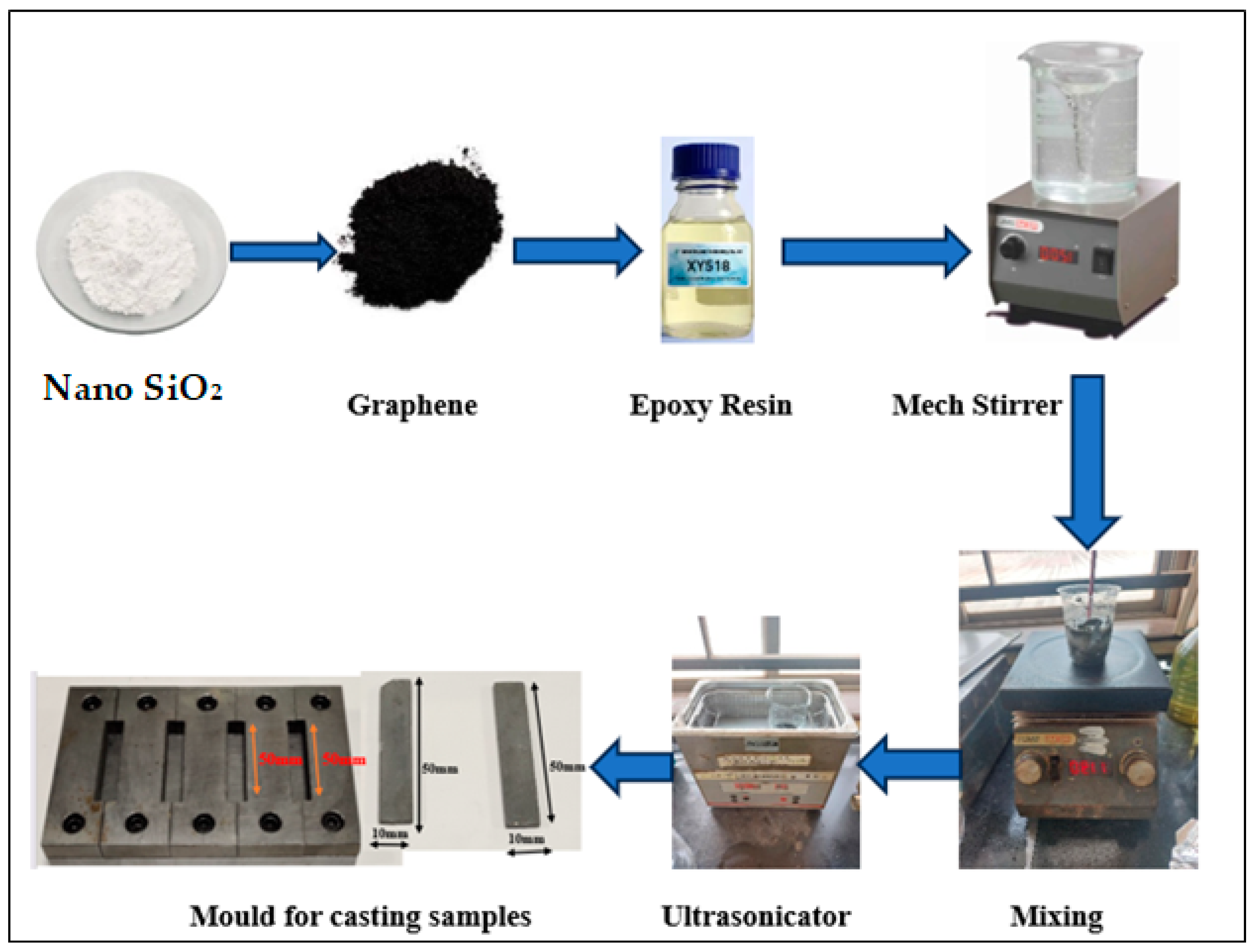

2.3. Preparation of Epoxy-Based Nano SiO2 and Graphene Nano Powder Mortar Composites

2.3.1. Material Mixing and Composite Preparation

2.3.2. Casting and Curing of Specimens

2.4. Testing Methods

2.4.1. Flexural and Compressive Strength

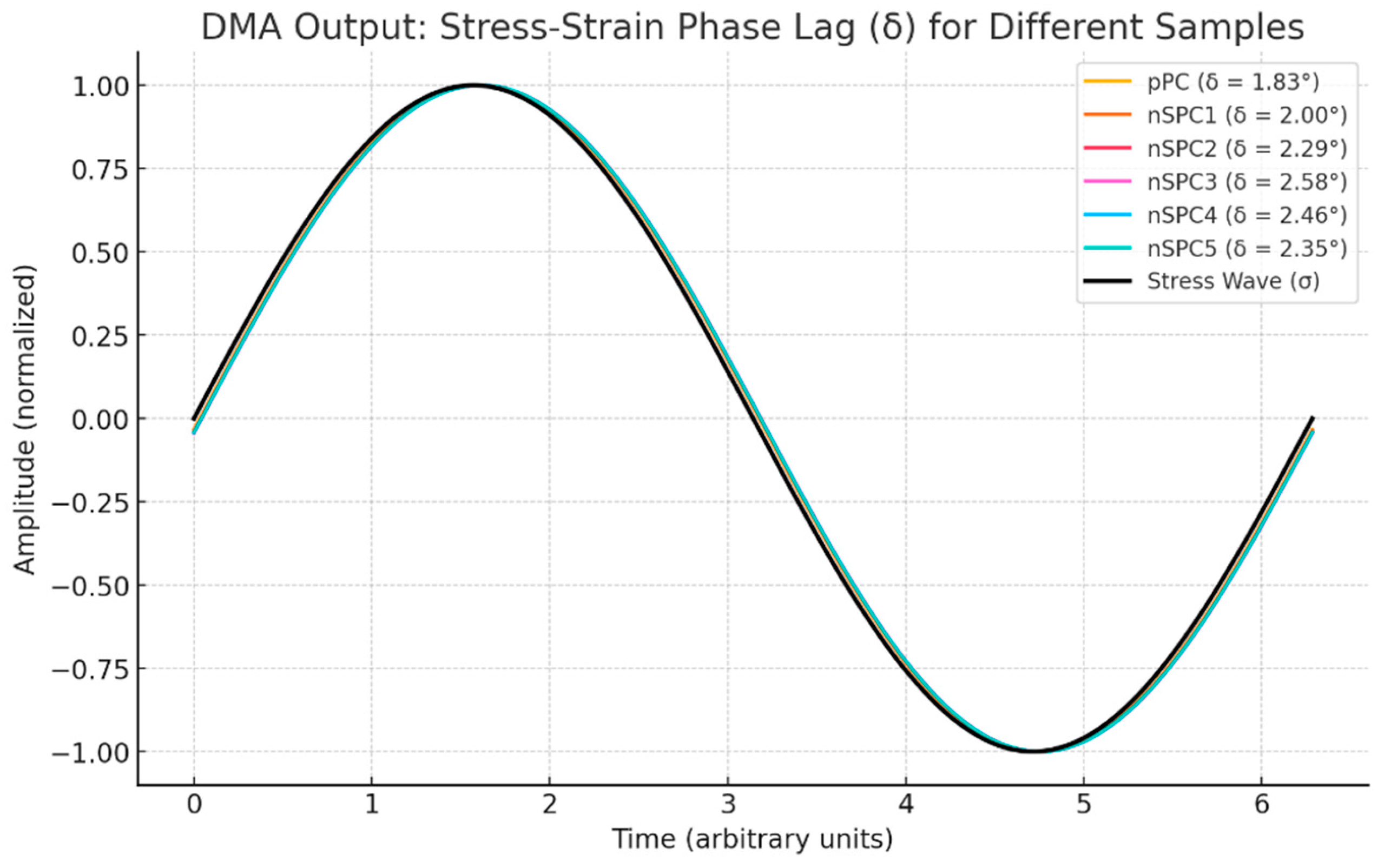

2.4.2. Damping Property Evaluation

2.4.3. Microstructural and Elemental Analysis

2.5. Viscoelastic Damping Model for Epoxy-Based Composites

2.5.1. Effect of Nano-SiO2 and Graphene on Damping Ratio

2.5.2. Frequency-Dependent Modulus and Damping Behavior

3. Results and Discussion

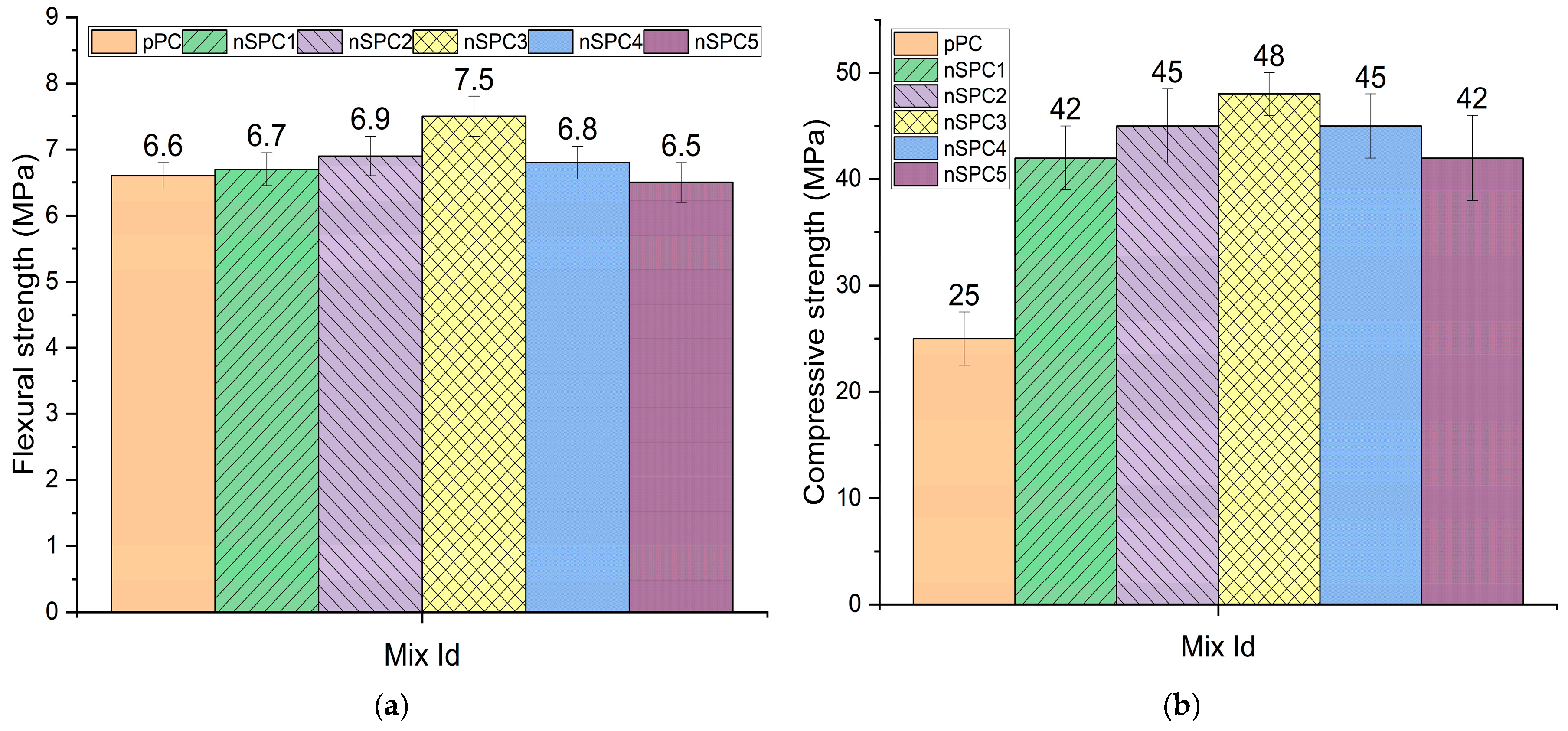

3.1. Flexural and Compressive Strength

3.2. Damping Characteristics

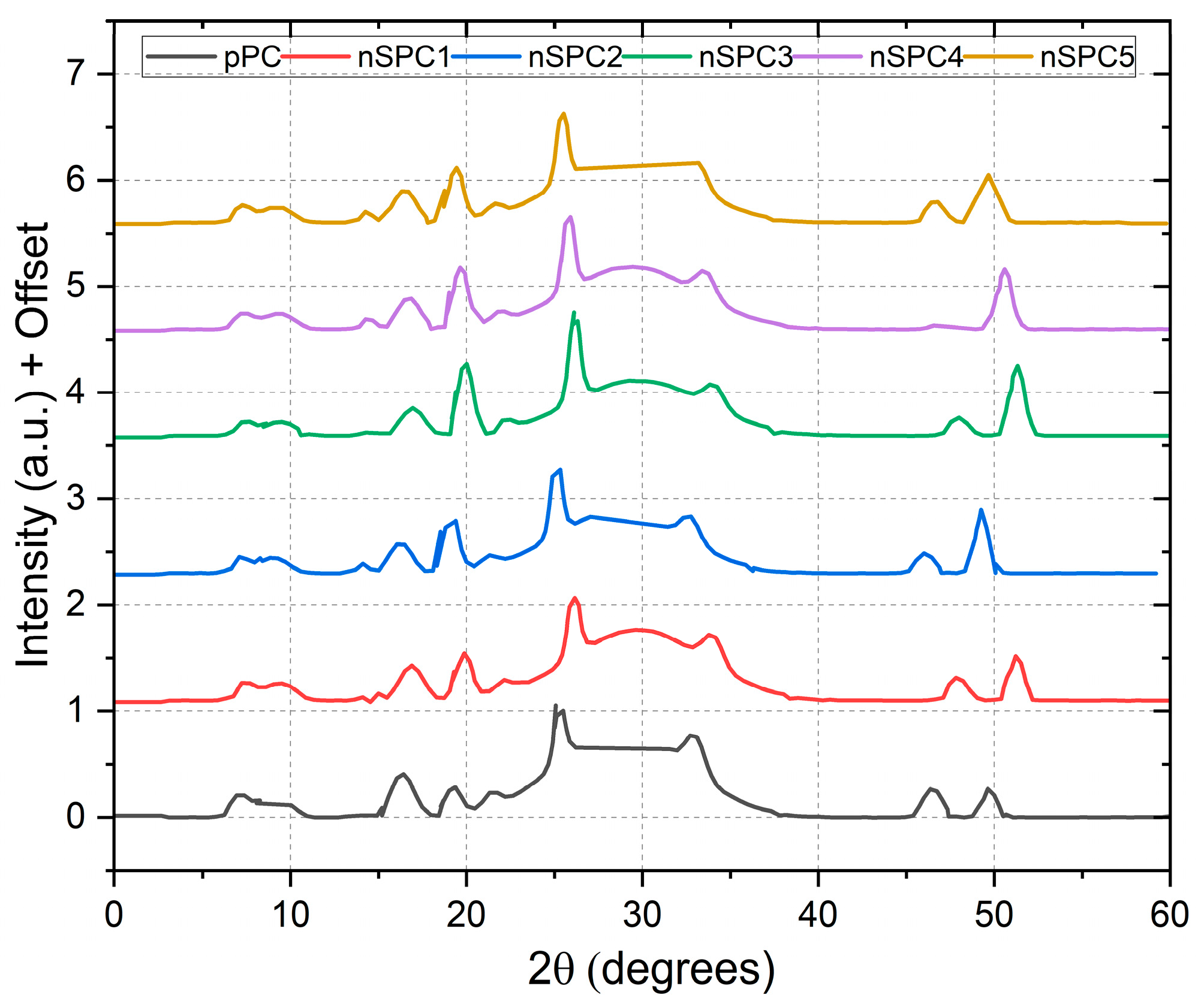

3.3. Energy Dispersive X-Ray Spectroscopy, X-Ray Diffraction, and Transmission Electron Microscopy

3.4. Comparison of Experimental and Modeled Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, X.; Yan, X. A review on the damping properties of fiber reinforced polymer composites. J. Ind. Text. 2020, 49, 693–721. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent applications of carbon-based composites in defence industry: A review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Cavalcanti, M.; Torres, S.M.; Lima Filho, M.R.F.; dos Santos, A.J.V. Evaluation of rheological models for concrete submitted to alkali-aggregate reaction based on numerical analysis of damping–free expansion. Rev. IBRACON Estrut. Mater. 2021, 14, e14205. [Google Scholar] [CrossRef]

- Ghernaout, D.; Belaadi, A.; Boumaaza, M.; Chai, B.X.; Jawaid, M.; Abdullah, M.M.S.; Krishnasamy, P.; Al-Khawlani, A. Effects of incorporating cellulose fibers from Yucca treculeana L. on the thermal characteristics of green composites based on high-density poly-ethylene: An eco-friendly material for cleaner production. J. Mater. Res. Technol. 2024, 31, 787–798. [Google Scholar] [CrossRef]

- Sadeghi, P.; Karimi, A.; Torbatifard, S.; Goli, A. A comprehensive evaluation of damping, vibration, and dynamic modulus in reclaimed asphalt pavement: The role of rejuvenators, polymer, temperature, and aging. Case Stud. Constr. Mater. 2024, 21, e03366. [Google Scholar] [CrossRef]

- Zhong, S.; Nsengiyumva, W. Application of Acoustic Emission for the Inspection of Fiber-Reinforced Composite Materials. In Nondestructive Testing and Evaluation of Fiber-Reinforced Composite Structures; Springer Nature: Singapore, 2022; pp. 315–354. [Google Scholar]

- Li, C.; Zhang, W.; Sun, G.; Li, Y.; Zhang, Y. Research on damping properties and microscopic mechanism of polyurethane cement-based composites. Constr. Build. Mater. 2023, 365, 130137. [Google Scholar] [CrossRef]

- Chi, L.; Lu, S.; Yao, Y. Damping additives used in cement-matrix composites: A review. Compos. Part B Eng. 2019, 164, 26–36. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Jin, C. Effect of multi-walled carbon nanotubes on the damping property of cement mortar and mechanism analysis. Arch. Civ. Mech. Eng. 2021, 21, 102. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, J.; Liang, C. Study on nonlinear damping behavior of damaged recycled aggregate concrete beams. Struct. Concr. 2021, 22, 1429–1444. [Google Scholar] [CrossRef]

- Bahari-Sambran, F.; Eslami-Farsani, R.; Arbab Chirani, S. The flexural and impact behavior of the laminated aluminum-epoxy/basalt fibers composites containing nanoclay: An experimental investigation. J. Sandw. Struct. Mater. 2020, 22, 1931–1951. [Google Scholar] [CrossRef]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-Art Review of Capabilities and Limitations of Polymer and Glass Fibers Used for Fiber-Reinforced Concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef] [PubMed]

- Vilar, Z.T.; Grassi, E.N.D.; de Oliveira, H.M.R.; de Araujo, C.J. Use of Dynamic Mechanical Analysers to Characterize Shape Memory Alloys: Cautions and Considerations from an Experimental Analysis. Int. J. Thermophys. 2023, 44, 142. [Google Scholar] [CrossRef]

- Genovese, A.; Pastore, S.R. Development of a portable instrument for non-destructive characterization of the polymers viscoelastic properties. Mech. Syst. Signal Process. 2021, 150, 107259. [Google Scholar] [CrossRef]

- Misrak, A.; Chauhan, T.; Bhandari, R.; Chowdhury, A.S.M.R.; Lakshminarayana, A.; Mirza, F.; Bazehhour, B.G.; Vujosevic, M.; Agonafer, D. Impact of Die Attach Sample Preparation on Its Measured Mechanical Properties for MEMS Sensor Applications. J. Microelectron. Electron. Packag. 2021, 18, 21–28. [Google Scholar] [CrossRef]

- Du, M.; Jing, H.; Gao, Y.; Su, H.; Fang, H. Carbon nanomaterials enhanced cement-based composites: Advances and challenges. Nanotechnol. Rev. 2020, 9, 115–135. [Google Scholar] [CrossRef]

- Li, W.; Dong, W.; Guo, Y.; Wang, K.; Shah, S.P. Advances in multifunctional cementitious composites with conductive carbon nanomaterials for smart infrastructure. Cem. Concr. Compos. 2022, 128, 104454. [Google Scholar] [CrossRef]

- Leonavičius, D.; Pundienė, I.; Pranckevičienė, J.; Kligys, M. Selection of superplasticisers for improving the rheological and mechanical properties of cement paste with CNTs. Constr. Build. Mater. 2020, 253, 119182. [Google Scholar] [CrossRef]

- An, S.H.; Kim, K.Y.; Chung, C.W.; Lee, J.U. Development of cement nanocomposites reinforced by carbon nanotube dispersion using superplasticizers. Carbon Lett. 2024, 34, 1481–1494. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr. Build. Mater. 2019, 198, 70–81. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Properties of concrete with addition carbon nanotubes: A review. Constr. Build. Mater. 2023, 393, 132066. [Google Scholar] [CrossRef]

- Hong, S.-H.; Choi, J.-S.; Yoo, S.-J.; Yoo, D.-Y.; Yoon, Y.-S. Reinforcing effect of CNT on the microstructure and creep properties of high-strength lightweight concrete. Constr. Build. Mater. 2024, 428, 136294. [Google Scholar] [CrossRef]

- Assi, L.; Alsalman, A.; Bianco, D.; Ziehl, P.; El-Khatib, J.; Bayat, M.; Hussein, F.H. Multiwall carbon nanotubes (MWCNTs) dispersion & mechanical effects in OPC mortar & paste: A review. J. Build. Eng. 2021, 43, 102512. [Google Scholar] [CrossRef]

- Pan, S.; Feng, J.; Safaei, B.; Qin, Z.; Chu, F.; Hui, D. A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets. Nanotechnol. Rev. 2022, 11, 1658–1669. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, M.; Gong, L.; Li, L.; Zhou, H.; Mai, Y.W. Three-dimensional nano-structural design for enhanced damping performance of carbon fiber reinforced polymer composites with balanced mechanical performance. Compos. Part B Eng. 2025, 298, 112351. [Google Scholar] [CrossRef]

- Wang, X.; Chen, D.; Zhong, W.; Zhang, L.; Fan, X.; Cai, Z.; Zhu, M. Experimental and theoretical evaluations of the interfacial interaction between carbon nanotubes and carboxylated butadiene nitrile rubber: Mechanical and damping properties. Mater. Des. 2020, 186, 108318. [Google Scholar] [CrossRef]

- Luo, Q.; Wu, Y.-Y.; Qiu, W.; Huang, H.; Pei, S.; Lambert, P.; Hui, D. Improving flexural strength of UHPC with sustainably synthesized graphene oxide. Nanotechnol. Rev. 2021, 10, 754–767. [Google Scholar] [CrossRef]

- Wang, Z.; Bai, E.; Liang, L.; Du, Y.; Liu, C. Comparison of dynamic mechanical properties of carbon fiber and graphene oxide grafted carbon fiber modified concrete. J. Build. Eng. 2024, 94, 109989. [Google Scholar] [CrossRef]

- Avil, E.; Kadioglu, F.; Kaynak, C. Contribution of carbon nanotubes to vibration damping behavior of epoxy and its carbon fiber composites. J. Reinf. Plast. Compos. 2020, 39, 311–323. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, L.; Zhao, L.-C. Vibration analysis of a hybrid nanocomposite saturated porous plate reinforced with carbon nanotubes and graphene nanoplatelets. Mech. Adv. Mater. Struct. 2025, 1–17. [Google Scholar] [CrossRef]

- V.S., S.; B., R.; Xavier, J.R. Effects of nanomaterials on mechanical properties in cementitious construction materials for high-strength concrete applications: A review. J. Adhes. Sci. Technol. 2024, 38, 3737–3768. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Yang, J.; Jindal, B.B.; Ariyachandra, E. Influence of nano-TiO2, nano-Fe2O3, nanoclay and nano-CaCO3 on the properties of cement/geopolymer concrete. Clean. Mater. 2022, 4, 100061. [Google Scholar] [CrossRef]

- Fakhri, M.; Kianfar, A. Comparison of BBR results of EVA polymer and nano-CaCO3-modified bitumen using burger model, relaxation modulus, dissipation energy ratio, ANOVA, and artificial neural networks. Int. J. Pavement Res. Technol. 2021, 14, 85–97. [Google Scholar] [CrossRef]

- Balaji, D. Finite Deformation of Polymer Nanocomposites. In Mechanics of Nanomaterials and Polymer Nanocomposites; Springer: Singapore, 2023; pp. 175–191. [Google Scholar]

- Mistry, M.; Prajapati, V.; Dholakiya, B.Z. Redefining Construction: An In-Depth Review of Sustainable Polyurethane Applications. J. Polym. Environ. 2024, 32, 3448–3489. [Google Scholar] [CrossRef]

- Jamshidi, A.; White, G.; Kurumisawa, K. Rheological characteristics of epoxy asphalt binders and engineering properties of epoxy asphalt mixtures–state-of-the-art. Road Mater. Pavement Des. 2022, 23, 1957–1980. [Google Scholar] [CrossRef]

- Singh, S.; Anand, V. Innovative enhancement of self-compacting concrete using varying percentages of steel slag: An experimental investigation into fresh, mechanical, durability, and microstructural properties. Asian J. Civ. Eng. 2024, 25, 6073–6090. [Google Scholar] [CrossRef]

- Banstola, R.; GC, S.; Shrestha, B.; Koirala, S.; Gauchan, M. Experimental Analysis on Quality of Coarse and Fine Aggregate Produce from Crusher Plants of Syangja District of Nepal. Tech. J. 2024, 4, 39–49. [Google Scholar] [CrossRef]

- Gouse Mohiuddin, M.D.; Malagavelli, V.; kumar Balguri, P. Influence of wollastonite–GGBS on properties of ternary blended self compacting concrete. Mater. Today Proc. 2022, 62, 3027–3032. [Google Scholar] [CrossRef]

- Isarn, I.; Collado, I.; Jiménez-Suárez, A.; Prolongo, S.G. Analysis of bio-based epoxy resins: Impact of amine hardeners on thermal, thermomechanical, optical and electrical properties of epoxidized resveratrol with high Tg. React. Funct. Polym. 2024, 205, 106080. [Google Scholar] [CrossRef]

- Sun, Q.; Feng, Y.; Guo, J.; Wang, C. High performance epoxy resin with ultralow coefficient of thermal expansion cured by conformation-switchable multi-functional agent. Chem. Eng. J. 2022, 450, 138295. [Google Scholar] [CrossRef]

- Syamsunur, D.; Wei, L.; Hisyam, M.N.; Memon, Z.A.; Sultan, B. Research on performance monitoring of binary nano modified concrete based on temperature variation. Case Stud. Constr. Mater. 2023, 19, e02373. [Google Scholar] [CrossRef]

- Atiq Orakzai, M. Hybrid effect of nano-alumina and nano-titanium dioxide on Mechanical properties of concrete. Case Stud. Constr. Mater. 2021, 14, e00483. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Hutchison, W.; Hossain, M.M. Performance of amine cured epoxy and silica fume modified cement mortar under military airbase operating conditions. Constr. Build. Mater. 2020, 232, 117280. [Google Scholar] [CrossRef]

- Kothari, C.; Garg, N. Quantitative phase analysis of anhydrous Portland cement via combined X-ray diffraction and Raman imaging: Synergy and impact of analysis parameters. Cem. Concr. Res. 2024, 186, 107662. [Google Scholar] [CrossRef]

- Tüfekci, M.; Baytak, T.; Bulut, O.; Pir, İ.; Acarer Arat, S.; Özkal, B.; Liu, H.; Dear, J.P.; Salles, L. Nonlinear behaviour of epoxy and epoxy-based nanocomposites: An integrated experimental and computational analysis. Mech. Based Des. Struct. Mach. 2024, 52, 6858–6888. [Google Scholar] [CrossRef]

- Shah, N.; Bhattacharya, B.; Kanchwala, H. Development of a Novel Viscoelastic Nanocomposite and Investigation of Its Damping Capacity for Large Frequency Band. In Advances in Structural Vibration; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 233–252. [Google Scholar]

- Tüfekci, M.; Özkal, B.; Maharaj, C.; Liu, H.; Dear, J.P.; Salles, L. Strain-rate-dependent mechanics and impact performance of epoxy-based nanocomposites. Compos. Sci. Technol. 2023, 233, 109870. [Google Scholar] [CrossRef]

- Surendran, A.; Joy, J.; Parameswaranpillai, J.; Anas, S.; Thomas, S. An overview of viscoelastic phase separation in epoxy based blends. Soft Matter 2020, 16, 3363–3377. [Google Scholar] [CrossRef]

- Uchida, M.; Kamimura, K.; Yoshida, T.; Kaneko, Y. Viscoelastic-viscoplastic modeling of epoxy based on transient network theory. Int. J. Plast. 2022, 153, 103262. [Google Scholar] [CrossRef]

- Orlandini, L.R.; Henriques, I.R.; Castello, D.A.; Borges, L.A.; Soares, B.G. Dynamic mechanical characterization of epoxy-based thermosetting materials loaded with lignin. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 394. [Google Scholar] [CrossRef]

- Turan, F.; Guclu, M.; Gurkan, K.; Durmus, A.; Taskin, Y. The effect of carbon nanotubes loading and processing parameters on the electrical, mechanical, and viscoelastic properties of epoxy-based composites. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 93. [Google Scholar] [CrossRef]

- Gao, Y.; Cheng, Z.; Yu, J.; Guo, X.; Liu, Y.; Chen, W. Mechanical performance enhancement of UHPC via ITZ improvement using graphene oxide-coated steel fibers. Cem. Concr. Compos. 2025, 157, 105931. [Google Scholar] [CrossRef]

- Alkhaza’leh, H.; Rahbeh, M.; Hamadneh, I.; AL-Mashakbeh, H.; Albalawna, Z. Nanoparticles in Soil Reclamation: A Review of Their Role in Reducing Soil Compaction. Air Soil Water Res. 2025, 18. [Google Scholar] [CrossRef]

- Khajeh Kulaki, A.; Hosseini-Nasab, S.M.; Hormozi, F. Low-salinity water flooding by a novel hybrid of nano γ-Al2O3/SiO2 modified with a green surfactant for enhanced oil recovery. Sci. Rep. 2024, 14, 14033. [Google Scholar] [CrossRef]

- Wang, R.; Sun, R.; Zhao, L.; Zhang, T.; Kong, X.; Fu, Y. Investigation of the dispersion of reduced graphene oxide in cementitious composites under different mixing strategies. J. Build. Eng. 2023, 77, 107447. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Mechanical and damping properties of CNT-reinforced cementitious composites. Compos. Struct. 2017, 160, 81–88. [Google Scholar] [CrossRef]

- Li, C.; Zhong, J.; Sun, Y. Novel approach to enhance the damping performance of cement-based materials through polymer/carbon nanotube composite coating and gradation of aggregates. Constr. Build. Mater. 2025, 471, 140708. [Google Scholar] [CrossRef]

| Product Description | Silicon Dioxide Nano Powder Properties |

|---|---|

| Purity | 99.9% |

| Average Size of Particles | 60–70 nm |

| Molecular Formula | SiO2 |

| Molecular Weight | 60.08 g/mol |

| Form | Powder |

| Color | White |

| Density | 2.4 g/cm |

| Bulk Density | 0.10 g/cm3 |

| Specific Surface Area (SSA) | 190–600 m2/g |

| Melting Point | 1600 °C |

| Solubility | Insoluble in Water |

| Product Description | Graphene Oxide Nano Powder Properties |

|---|---|

| Purity | 99.99% |

| Lateral size | 10 µm |

| Thickness | 1.6 nm |

| Molecular Weight | 12.01 g/mol |

| Form | Powder |

| Color | Black |

| Density | 1.9–2.2 g/cm3 |

| Boiling Point | 4830 °C |

| Specific Surface Area (SSA) | 550–580 m2/g |

| Melting Point | 3452–3697 °C |

| Solubility | Slightly soluble in Water |

| Sl No | Designation | Filler wt.% (nSiO2) | Filler wt.% (Graphene) | Filler wt.% (Epoxy) |

|---|---|---|---|---|

| 1 | pPC | -- | -- | |

| 2 | nSPC1 | 1.0 | 0.05 | 10 |

| 3 | nSPC2 | 1.5 | 0.05 | 10 |

| 4 | nSPC3 | 2.0 | 0.05 | 10 |

| 5 | nSPC4 | 2.5 | 0.05 | 10 |

| 6 | nSPC5 | 3.0 | 0.05 | 10 |

| Mix Id | Ingredient(g) | FOR Cement Mortar 1:1 | ||||

|---|---|---|---|---|---|---|

| Cement | Sand | Nano SiO2 | Graphene | W/C | Epoxy | |

| pPC | 43.87 | 49.28 | 0 | 0 | 0.45 | 0 |

| nSPC1 | 43.87 | 49.28 | 0.44 (1%) | 0.0044 (0.01%) | 0.45 | 4.387 |

| nSPC2 | 43.87 | 49.28 | 0.66 (1.5%) | 0.0044 (0.01%) | 0.45 | 4.387 |

| nSPC3 | 43.87 | 49.28 | 0.88 (2.0%) | 0.0044 (0.01%) | 0.45 | 4.387 |

| nSPC4 | 43.87 | 49.28 | 1.108 (2.5%) | 0.0044 (0.01%) | 0.45 | 4.387 |

| nSPC5 | 43.87 | 49.28 | 1.32 (3.0%) | 0.0044 (0.01%) | 0.45 | 4.387 |

| Sample | Storage Modulus (Exp.) (GPa) | Storage Modulus (Model) (GPa) | Loss Modulus (Exp.) (GPa) | Loss Modulus (Model) (GPa) | Loss Factor (Exp.) (tan δ) | Loss Factor (Model) (tan δ) |

|---|---|---|---|---|---|---|

| pPC | 6.5 | 6.4 | 0.75 | 0.73 | 0.0325 | 0.031 |

| nSPC1 | 6 | 6.6 | 0.78 | 0.77 | 0.035 | 0.034 |

| nSPC2 | 6.2 | 6.8 | 0.82 | 0.81 | 0.038 | 0.037 |

| nSPC3 | 7.2 | 7.1 | 0.88 | 0.87 | 0.045 | 0.044 |

| nSPC4 | 6.1 | 7 | 0.86 | 0.85 | 0.043 | 0.042 |

| nSPC5 | 6 | 6.9 | 0.85 | 0.84 | 0.042 | 0.041 |

| Study | Nano-Additive (wt.%) | Compressive Strength | Flexural Strength | Damping Factor | Processing and Modeling Notes |

|---|---|---|---|---|---|

| Khajeh et al. [55] | MWCNT (0.1–0.3%) + Nano-SiO2 (up to 7.5%) | ↑25% (to ~84 MPa) | ↑53% | ↑24% | Surfactant-assisted CNT dispersion; no modeling. |

| Wang et al. [56] | Graphene Oxide (0.01–0.1%) | ↑15–33% | ↑41–59% | Qualitative ↑ | Conventional mixing; free vibration damping. |

| Li et al. [9] | MWCNT (0–0.07%) | ↑2–3% | ↑5% | ↑15–20% | DMA-based damping; no modeling. |

| Liew et al. [57] | MWCNT (0–0.1%) | ≈same | ↑5% | ↑44% | Viscoelastic matrix + CNT; high damping. |

| Li et al. [58] | CNT in polymer emulsion (~0.1%) | ≈same | Not Reported | ↑148% | Surface damping via coated aggregates. |

| Present Study (Epoxy–Cement Hybrid) | Nano-SiO2 (2.0%) + Graphene (0.05%) | ↑92% (48 MPa) | ↑13.6% (7.5 MPa) | ↑38% (tan δ = 0.045) | Epoxy–cement hybrid; DMA tested; validated viscoelastic model used. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jalgar, S.R.; Hunashyal, A.M.; Prabhu, U.S.; Gurumurthy, B.M.; Hiremath, P.; Naik, N. Dynamic Mechanical Analysis and Optimization of Vibration Damping in Epoxy-Based Nano Cement Composite Dampers for Sustainable Structures. J. Compos. Sci. 2025, 9, 202. https://doi.org/10.3390/jcs9050202

Jalgar SR, Hunashyal AM, Prabhu US, Gurumurthy BM, Hiremath P, Naik N. Dynamic Mechanical Analysis and Optimization of Vibration Damping in Epoxy-Based Nano Cement Composite Dampers for Sustainable Structures. Journal of Composites Science. 2025; 9(5):202. https://doi.org/10.3390/jcs9050202

Chicago/Turabian StyleJalgar, Sandhya R., Anand M. Hunashyal, U. Satisha Prabhu, B. M. Gurumurthy, Pavan Hiremath, and Nithesh Naik. 2025. "Dynamic Mechanical Analysis and Optimization of Vibration Damping in Epoxy-Based Nano Cement Composite Dampers for Sustainable Structures" Journal of Composites Science 9, no. 5: 202. https://doi.org/10.3390/jcs9050202

APA StyleJalgar, S. R., Hunashyal, A. M., Prabhu, U. S., Gurumurthy, B. M., Hiremath, P., & Naik, N. (2025). Dynamic Mechanical Analysis and Optimization of Vibration Damping in Epoxy-Based Nano Cement Composite Dampers for Sustainable Structures. Journal of Composites Science, 9(5), 202. https://doi.org/10.3390/jcs9050202