A Unified Size-Dependent Theory for Analyzing the Free Vibration Behavior of an FG Microplate Under Fully Simply Supported Conditions and Magneto-Electro-Thermo-Mechanical Loads Considering Couple Stress and Thickness Stretching Effects

Abstract

:1. Introduction

2. Formulations

2.1. The Unified Kinematics Model and Relevant Equations

2.2. Generalized Constitutive Equations

2.3. Strong Form

3. Applications

4. Numerical Examples

4.1. Validation and Comparison

- (a)

- Open-circuit surface conditions

- (b)

- Closed-circuit surface conditions

4.1.1. FG Piezoelectric Microplates

4.1.2. FG-MEE Macroscale Plates

4.2. Parametric Studies

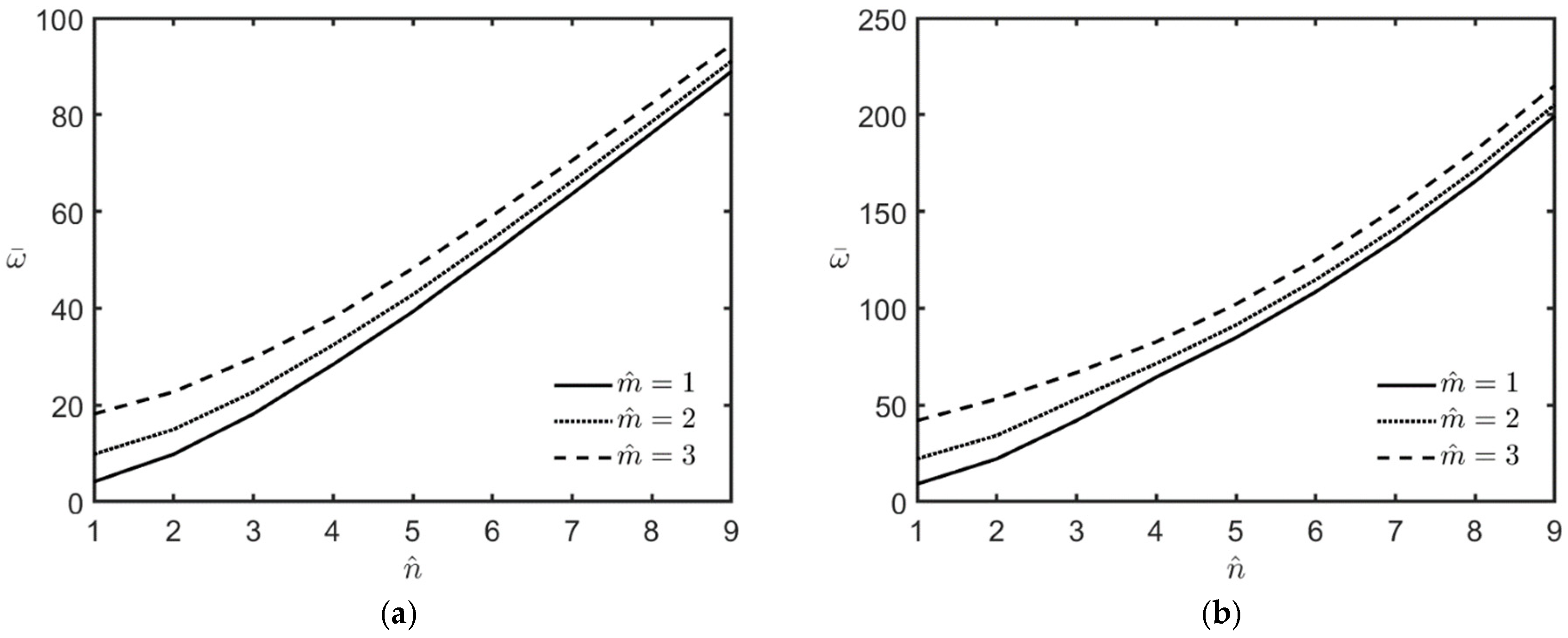

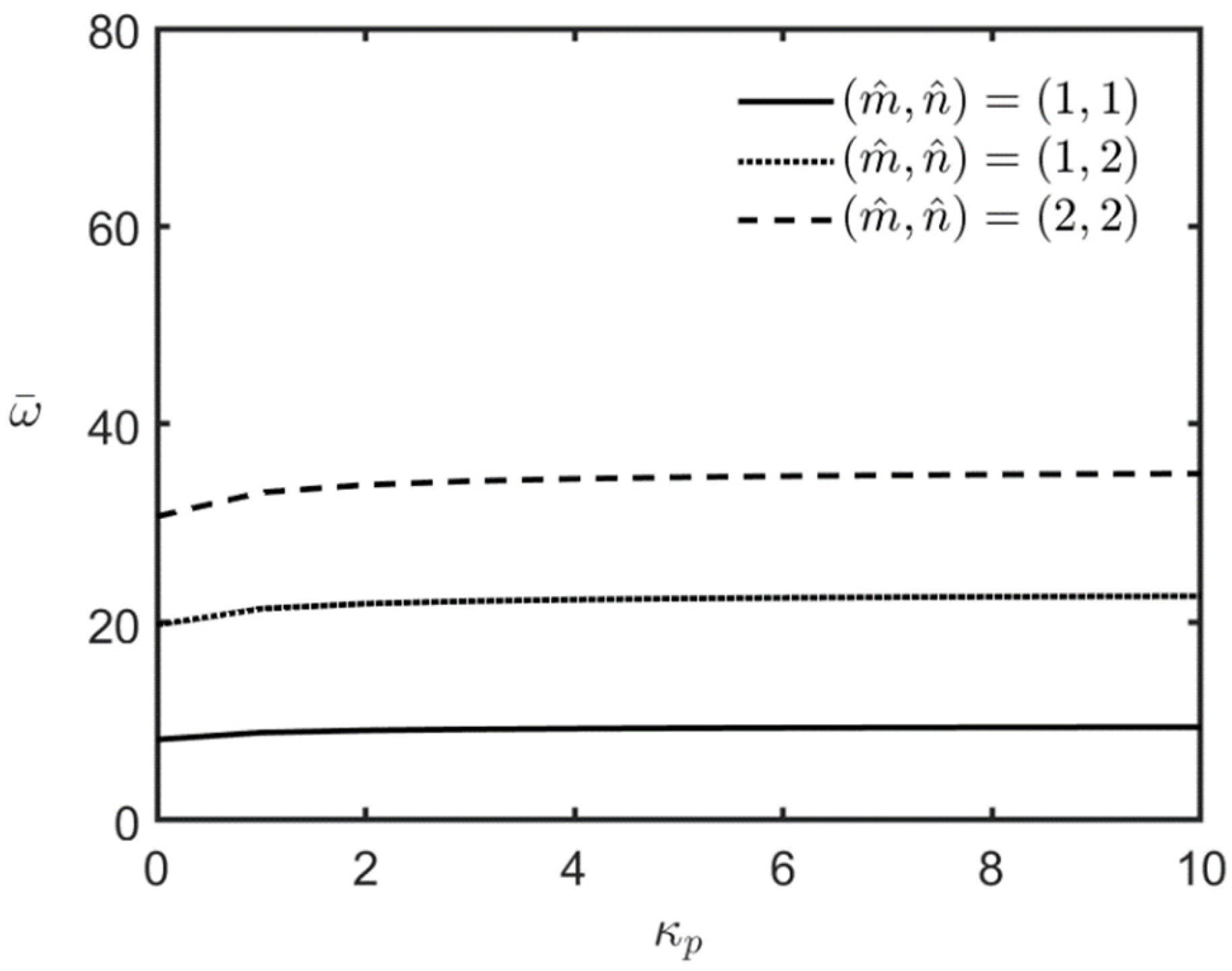

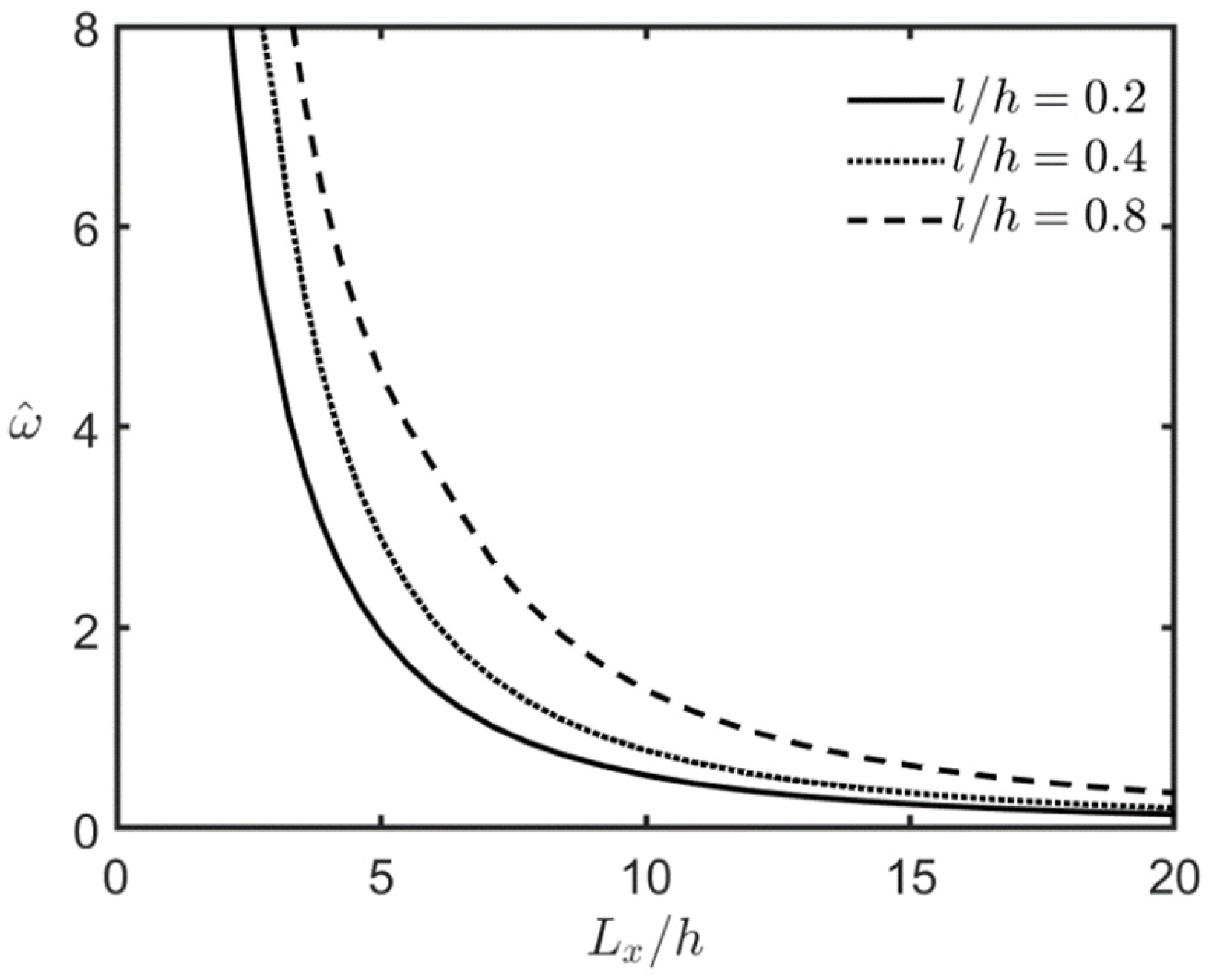

4.2.1. Unloaded FG-MEE Microplates Under Open-Circuit Surface Conditions

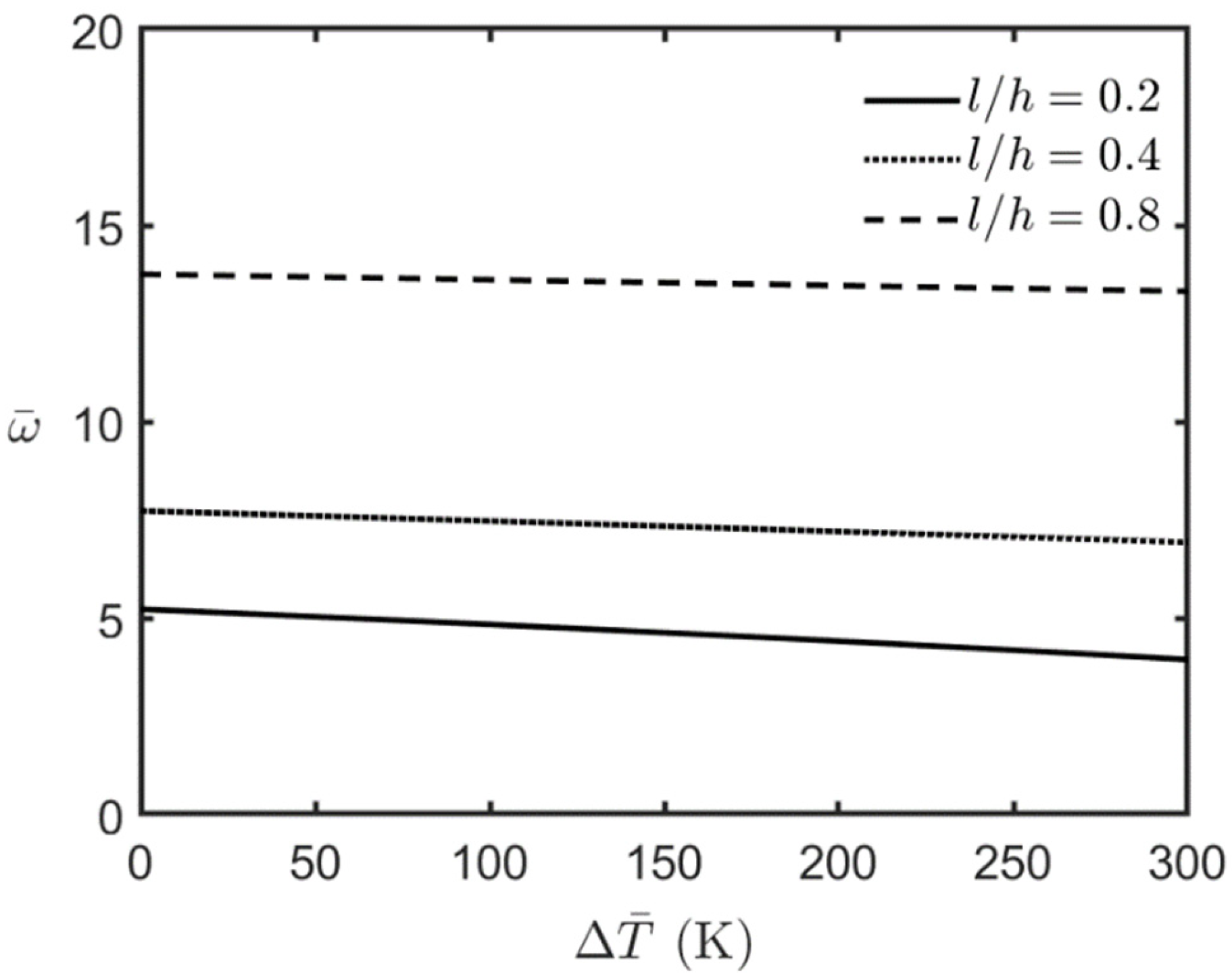

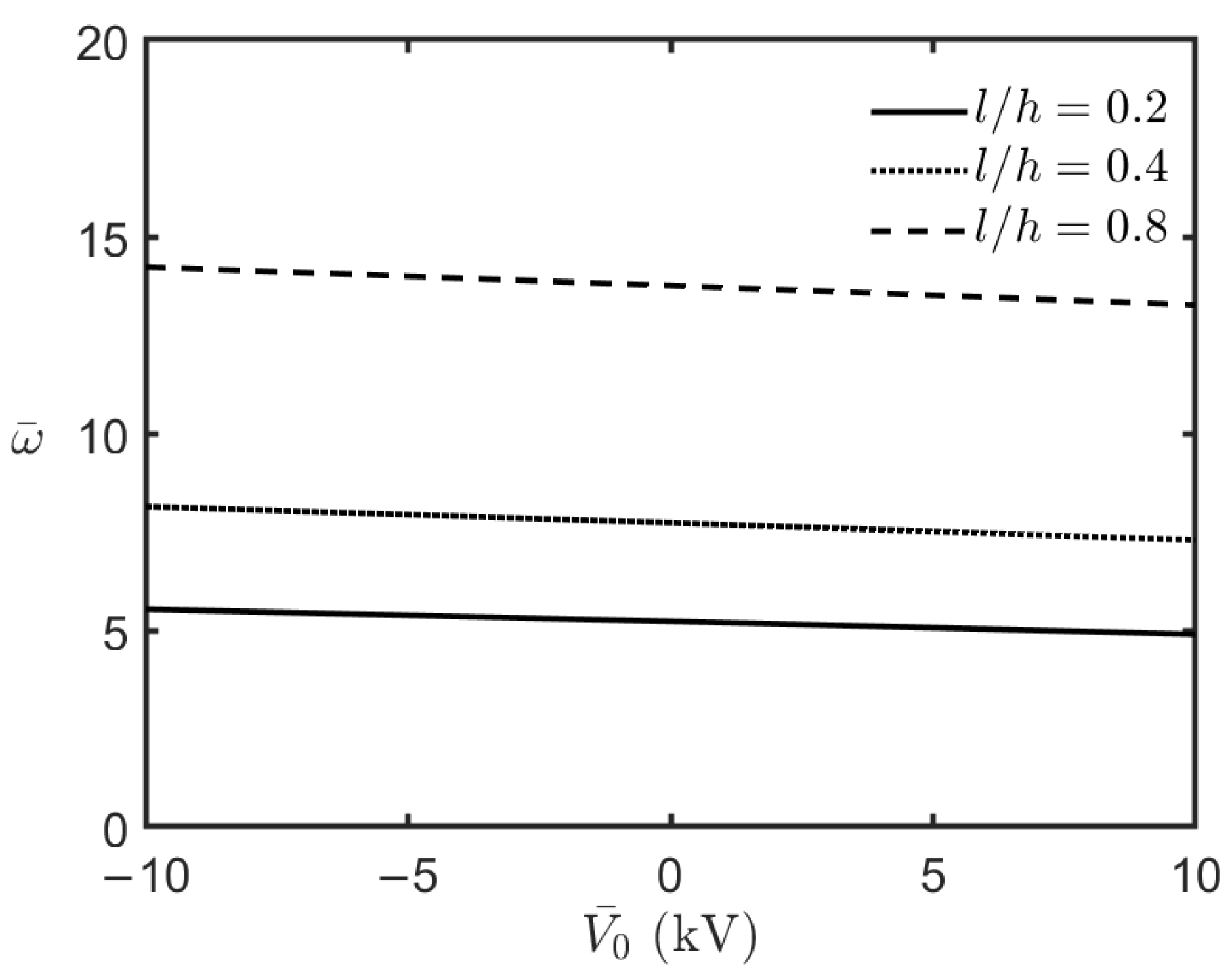

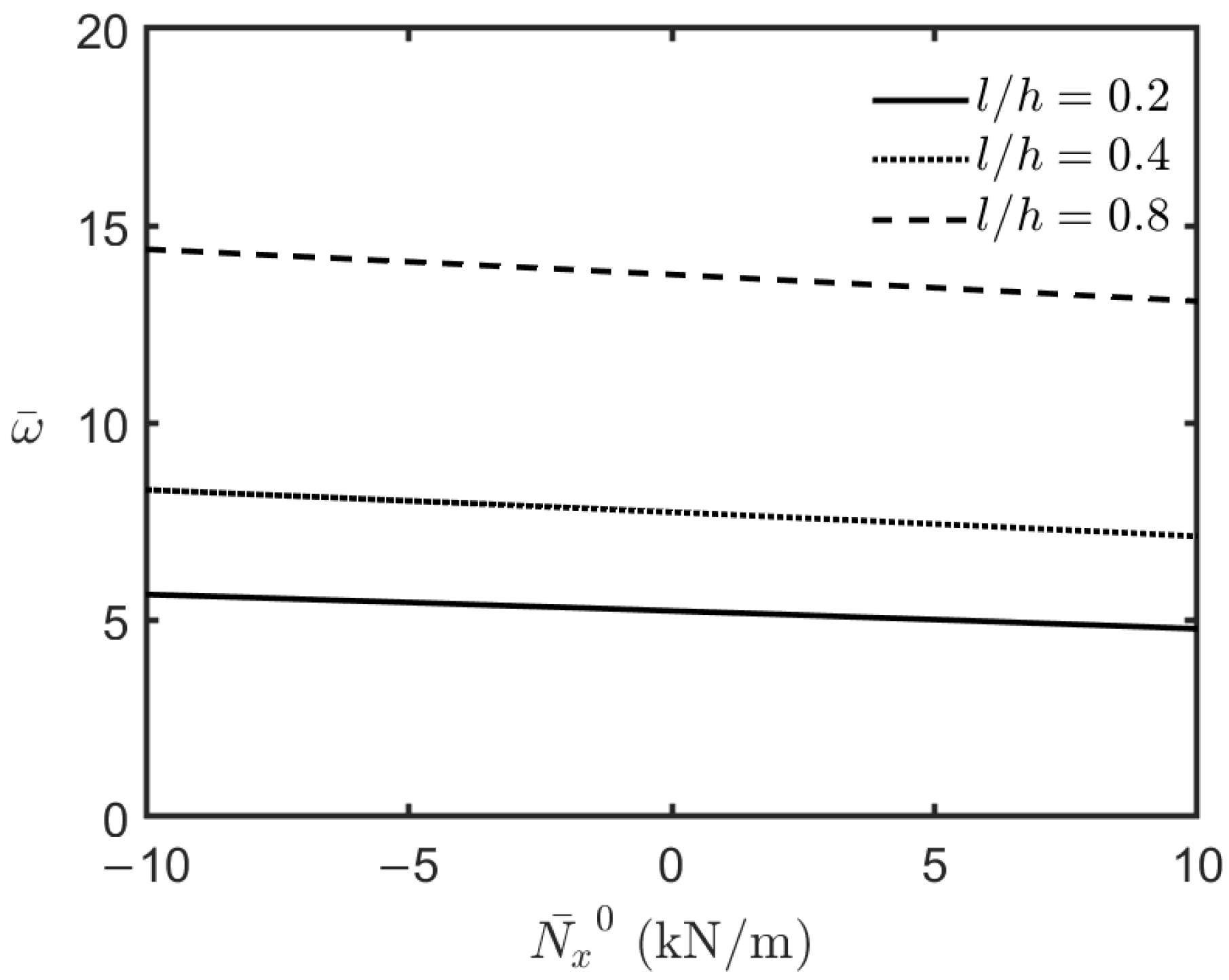

4.2.2. Loaded FG-MEE Microplates Under Closed-Circuit Surface Conditions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCM | Classical continuum mechanics |

| CCST | Consistent couple stress theory |

| CPT | Classical plate theory |

| SDSDT | Size-dependent shear deformation theory |

| SDT | Shear deformation theory |

| FG | Functionally graded |

| HOCM | Higher-order continuum mechanics |

| MCST | Modified couple stress theory |

| MEE | Magneto-electro-elastic |

| 2D | Two-dimensional |

| 3D | Three-dimensional |

Appendix A. The Generalized Force/Moment Resultants–Generalized Displacement Components Relationships

Appendix B. The Detailed Expressions of Generalized Initial In-Plane Force Resultants

Appendix C. The Detailed Expressions of Kij and Ik

Appendix D. The Detailed Expressions of kij, mij, and

References

- Koizumi, M. FGM activities in Japan. Compos. Part B Eng. 1997, 28, 1–4. [Google Scholar] [CrossRef]

- Koizumi, A. Recent progress of functionally graded materials in Japan. Cream. Eng. Sci. Proc. 1992, 13, 333–347. [Google Scholar]

- Ding, S.; Wu, C.P. Optimization of material composition to minimize the thermal stresses induced in FGM plates with temperature-dependent material properties. Int. J. Mech. Mater. Des. 2018, 14, 527–549. [Google Scholar] [CrossRef]

- Wu, C.P.; Li, K.W. Multi-objective optimization of functionally graded beams using a genetic algorithm with non-dominated sorting. J. Compos. Sci. 2021, 5, 92. [Google Scholar] [CrossRef]

- Bargatin, I.; Kozinsky, I.; Roukes, M. Efficient electrothermal actuation of multiple modes of high-frequency nanoelectromechanical resonators. Appl. Phys. Lett. 2007, 9, 093116. [Google Scholar] [CrossRef]

- Jalili, N.; Laxminarayana, K. A review of atomic force microscopy imaging systems: Application to molecular metrology and biological sciences. Mechatronics 2004, 14, 907–945. [Google Scholar] [CrossRef]

- Muller, E.; Drasar, C.; Schilz, J.; Kaysser, W.A. Functionally graded materials for sensors and energy applications. Mater. Sci. Eng. A 2003, 362, 17–39. [Google Scholar] [CrossRef]

- Kumar, S.; Murthy Reddy, K.V.V.S.; Kumar, A.; Rohini Devi, G. Development and characterization of polymer-ceramic continuous fiber reinforced functionally graded composites for aerospace application. Aerosp. Sci. Technol. 2013, 26, 185–191. [Google Scholar] [CrossRef]

- Thai, H.T.; Vo, T.P.; Nguyen, T.K.; Kim, S.E. A review of continuum mechanics models for size-dependent analysis of beams and plates. Compos. Struct. 2017, 177, 196–219. [Google Scholar] [CrossRef]

- Eltaher, M.A.; Khater, M.E.; Emam, S.A. A review on nonlocal elastic models for bending, buckling, vibrations, and wave propagation of nanoscale beams. Appl. Math. Modell. 2016, 40, 4109–4128. [Google Scholar] [CrossRef]

- Shariati, M.; Shishesaz, M.; Sahbafar, H.; Pourabdy, M.; Hosseini, M. A review on stress-driven nonlocal elasticity theory. J. Comput. Appl. Mech. 2021, 52, 535–552. [Google Scholar]

- Wu, C.P.; Yu, J.J. A review of mechanical analyses of rectangular nanobeams and single-, double-, and multi-walled carbon nanotubes using Eringen’s nonlocal elasticity theory. Arch. Appl. Mech. 2019, 89, 1761–1792. [Google Scholar] [CrossRef]

- Wu, C.P.; Hu, H.X. A review of dynamic analyses of single- and multi-layered graphene sheets/nanoplates using various nonlocal continuum mechanics-based plate theories. Acta Mech. 2021, 232, 4497–4531. [Google Scholar] [CrossRef]

- Kong, S. A review on the size-dependent models of micro-beam and micro-plate based on the modified couple stress theory. Arch. Comput. Methods Eng. 2022, 29, 1–31. [Google Scholar] [CrossRef]

- Nguyen, H.X.; Nguyen, T.N.; Abdel-Wahab, M.; Bordas, S.P.A.; Nguyen-Xuan, H.; Vo, T.P. A refined quasi-3D isogeometric analysis for functionally graded microplates based on the modified couple stress theory. Comput. Methods Appl. Mech. Eng. 2017, 313, 904–940. [Google Scholar] [CrossRef]

- Hadjesfandiari, A.R.; Dargush, G.F. Couple stress theory for solids. Int. J. Solids Struct. 2011, 48, 2496–2510. [Google Scholar] [CrossRef]

- Hadjesfandiari, A.R. Size-dependent piezoelectricity. Int. J. Solids Struct. 2013, 50, 2781–2791. [Google Scholar] [CrossRef]

- Wu, C.P.; Hu, H.X. A unified size-dependent plate theory for static bending and free vibration analyses of micro- and nano-scale plates based on the consistent couple stress theory. Mech. Mater. 2021, 162, 104085. [Google Scholar] [CrossRef]

- Wu, C.P.; Lin, E.L. Free vibration analysis of porous functionally graded piezoelectric microplates resting on an elastic medium subjected to electric voltages. Arch. Mech. 2022, 74, 463–511. [Google Scholar]

- Thai, S.; Thai, H.T.; Vo, T.P.; Patel, V.I. Size-dependent behavior of functionally graded microplates based on the modified strain gradient elasticity theory and isogeometric analysis. Comput. Struct. 2017, 190, 219–241. [Google Scholar] [CrossRef]

- Thai, C.H.; Hung, P.T.; Nguyen-Xuan, H.; Phung-Van, P. A size-dependent mesh-free approach for magneto-electro-elastic functionally graded nanoplates based on nonlocal strain gradient theory. Eng. Struct. 2023, 292, 116521. [Google Scholar] [CrossRef]

- Le, T.M.; Vo, D.; Rungamornrat, J.; Bui, T.Q. Strain-gradient theory for shear deformation free-form microshells: Governing equations of motion and general boundary conditions. Int. J. Solids Struct. 2022, 248, 111579. [Google Scholar] [CrossRef]

- Carrera, E.; Zozulya, V.V. Carrera unified formulation (CUF) for the micropolar plates and shells. I. Higher Order theory. Mech. Adv. Mater. Struct. 2022, 29, 773–795. [Google Scholar] [CrossRef]

- Carrera, E.; Zozulya, V.V. Carrera unified formulation (CUF) for the micropolar plates and shells. II. Complete Linear expansion case. Mech. Adv. Mater. Struct. 2022, 29, 796–815. [Google Scholar] [CrossRef]

- Zozulya, V.V. Higher order theory of micropolar plates and shells. ZAMM J. Appl. Math. Mech. 2018, 98, 886–918. [Google Scholar] [CrossRef]

- Hassanpour, S.; Heppler, G.R. Micropolar elasticity theory: A survey of linear isotropic equations, representative notations, and experimental investigations. Math. Mech. Solids 2015, 22, 224–242. [Google Scholar] [CrossRef]

- Gul, U.; Aydogdu, M. Structural modelling of nanorods and nanobeams using doublet mechanics theory. Int. J. Mech. Mater. Des. 2018, 14, 195–212. [Google Scholar] [CrossRef]

- Karamanli, A. Structural behaviours of zigzag and armchair nanobeams using finite element doublet mechanics. Eur. J. Mech. A/Solids 2021, 89, 104287. [Google Scholar] [CrossRef]

- Trinh, L.C.; Nguyen, H.X.; Vo, T.P.; Nguyen, T.K. Size-dependent behaviour of functionally graded microbeams using various shear deformation theories based on the modified couple stress theory. Compos. Struct. 2016, 154, 556–572. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q. Nonlinear dynamics of two-directional functionally graded microbeam with geometrical imperfection using unified shear deformable beam theory. Appl. Math. Model. 2021, 98, 783–800. [Google Scholar] [CrossRef]

- Simsek, M.; Reddy, J.N. A unified higher order beam theory for buckling of a functionally graded microbeam embedded in elastic medium using modified couple stress theory. Compos. Struct. 2013, 101, 47–58. [Google Scholar] [CrossRef]

- Li, Z.; Wang, H.; Zheng, S. Bending and free vibration of functionally graded piezoelectric microbeams based on the modified couple stress theory. Ann. Solid Struct. Mech. 2018, 10, 1–16. [Google Scholar] [CrossRef]

- Lou, J.; He, L.; Du, J. A unified higher order plate theory for functionally graded microplates based on the modified couple stress theory. Compos. Struct. 2015, 133, 1036–1047. [Google Scholar] [CrossRef]

- Tran, V.T.; Nguyen, T.K.; Nguyen, P.T.T.; Vo, T.P. Stochastic vibration and buckling analysis of functionally graded microplates with a unified higher-order shear deformation theory. Thin-Walled Struct. 2022, 177, 109473. [Google Scholar] [CrossRef]

- Wu, C.P.; Huang, Z. A unified consistent couple stress beam theory for functionally graded microscale beams. Steel Compos. Struct. 2024, 51, 103–116. [Google Scholar]

- Serpilli, M.; Rizzoni, R.; Ramos, R.R.; Lebon, F. A size-dependent model of strain gradient elastic laminated micro-beams with a weak adhesive layer. ZAMM J. Appl. Math. Mech. 2024, 105, e202400609. [Google Scholar] [CrossRef]

- Jedrysiak, J. On the tolerance modelling of thermoelasticity problems for transversally graded laminates. Arch. Civ. Mech. Eng. 2011, 11, 61–74. [Google Scholar] [CrossRef]

- Jedrysiak, J.; Kazmierczak-Sobinska, M. Dynamics of one-directional functionally graded plates with different sizes of microstructure: Theoretical tolerance modelling. Materials 2025, 18, 328. [Google Scholar] [CrossRef]

- Kazmierczak, M.; Jedrysiak, J. Tolerance modelling of vibrations of thin functionally graded plates. Thin-Walled Struct. 2011, 49, 1295–1303. [Google Scholar] [CrossRef]

- Jedrysiak, J. Free vibrations of thin functionally graded plates with microstructure. Eng. Struct. 2014, 75, 99–112. [Google Scholar] [CrossRef]

- Jedrysiak, J. Tolerance modelling of free vibrations of medium thickness functionally graded plates. Compos. Struct. 2018, 202, 1253–1262. [Google Scholar] [CrossRef]

- Tomczyk, B.; Szczerba, P. Tolerance and asymptotic modelling of dynamic problems for thin microstructured transversally graded shells. Compos. Struct. 2017, 162, 365–373. [Google Scholar] [CrossRef]

- Tomczyk, B.; Szczerba, P. A new asymptotic-tolerance model of dynamic and stability problems for longitudinally graded cylindrical shells. Compos. Struct. 2018, 202, 473–481. [Google Scholar] [CrossRef]

- Kazmierczak, M.; Jedrysiak, J. A new combined asymptotic-tolerance model of vibrations of thin transversally graded plates. Eng. Struct. 2013, 46, 322–331. [Google Scholar] [CrossRef]

- Vinyas, M. Computational analysis of smart magneto-electro-elastic materials and structures: Review and classification. Arch. Comput. Methods Eng. 2021, 28, 1205–1248. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Zhao, Y.F.; Wang, X.; Chen, M.; Schmidt, R. Static and dynamic analysis of functionally graded magneto-electro-elastic plates and shells. Compos. Struct. 2022, 281, 114950. [Google Scholar] [CrossRef]

- Garcia Lage, R.; Mota Soares, C.M.; Mota Soares, C.A.; Reddy, J.N. Layerwise partial mixed finite element analysis of magneto-electro-elastic plates. Comput. Struct. 2004, 82, 1293–1301. [Google Scholar] [CrossRef]

- Pan, E.; Han, F. Exact solution for functionally graded and layered magneto-electro-elastic plates. Int. J. Eng. Sci. 2005, 43, 321–339. [Google Scholar] [CrossRef]

- Ghadiri, M.; Safarpour, H. Free vibration analysis of embedded magneto-electro-thermo-elastic cylindrical nanoshell based on the modified couple stress theory. Appl. Phys. A 2016, 122, 833. [Google Scholar] [CrossRef]

- Qu, Y.L.; Li, P.; Zhang, G.Y.; Jin, F.; Gao, X.L. A microstructure-dependent anisotropic magneto-electro-elastic Mindlin plate model based on an extended modified couple stress theory. Acta Mech. 2020, 231, 4323–4350. [Google Scholar] [CrossRef]

- Guo, J.; Chen, J.; Pan, E. Static deformation of anisotropic layered magnetoelectroelastic plates based on modified couple stress theory. Compos. Part B Eng. 2016, 107, 84–96. [Google Scholar] [CrossRef]

- Zhong, Z.; Yu, T. Vibration of a simply supported functionally graded piezoelectric rectangular plate. Smart Mater. Struct. 2016, 15, 1404–1412. [Google Scholar] [CrossRef]

- Chen, J.; Chen, H.; Pan, E.; Heyliger, P.R. Modal analysis of magneto-electro-elastic plates using the state-vector approach. J. Sound Vibr. 2007, 304, 722–734. [Google Scholar] [CrossRef]

- Wu, C.P.; Lu, Y.A. A Hermite-family C1 finite layer method for the three-dimensional free vibration analysis of exponentially graded piezoelectric microplates based on the consistent couple stress theory. Int. J. Struct. Stab. Dyn. 2023, 23, 2350044. [Google Scholar] [CrossRef]

- Wu, C.P.; Lu, Y.C. A modified Pagano method for the 3D dynamic responses of functionally graded magneto-electro-elastic plates. Compos. Struct. 2009, 90, 363–372. [Google Scholar] [CrossRef]

- Tsai, Y.H.; Wu, C.P. Dynamic responses of functionally graded magneto-electro-elastic shells with open-circuit surface conditions. Int. J. Eng. Sci. 2008, 46, 843–857. [Google Scholar] [CrossRef]

- Ramirez, F.; Heyliger, P.R.; Pan, E. Discrete layer solution to free vibrations of functionally graded magneto-electro-elastic plates. Mech. Adv. Mater. Struct. 2006, 13, 249–266. [Google Scholar] [CrossRef]

| Material Properties | PZT-4 [52] | BaTiO3 [53] | CoFe2O4 [53] |

|---|---|---|---|

| 139 | 166.0 | 286.0 | |

| 77.8 | 77.0 | 173.0 | |

| 74.3 | 78.0 | 170.5 | |

| 115 | 162.0 | 269.5 | |

| 25.6 | 43.0 | 45.3 | |

| 30.6 | 44.5 | 56.5 | |

| −5.2 | −4.4 | 0.0 | |

| 15.1 | 18.6 | 0.0 | |

| 12.7 | 11.6 | 0.0 | |

| 0.0 | 0.0 | 580.3 | |

| 0.0 | 0.0 | 699.7 | |

| 0.0 | 0.0 | 550.0 | |

| 6.46 × 10−9 | 11.2 × 10−9 | 0.08 × 10−9 | |

| 5.62 × 10−9 | 12.6 × 10−9 | 0.093 × 10−9 | |

| 0.0 | 5.0 × 10−6 | −590.0 × 10−6 | |

| 0.0 | 10.0 × 10−6 | 157.0 × 10−6 | |

| NA | 15.7 × 10−6 | 10 × 10−6 | |

| NA | 6.4 × 10−6 | 10 × 10−6 | |

| 0.0 | 0.0 | 0.0 | |

| 7500 | 5800.0 | 5300.0 | |

| l for the CCST (m) | 8.8 × 10−6 | 8.8 × 10−6 | 8.8 × 10−6 |

| for the MCST (m) | 17.6 × 10−6 | 17.6 × 10−6 | 17.6 × 10−6 |

| Surface Conditions | 2D and 3D Size-Dependent Theories Based on the CCST | |||||||

|---|---|---|---|---|---|---|---|---|

| (1, 1) | (1, 2) | (1, 3) | (2, 2) | |||||

| Open-circuit | 0.5 | 5 | 1 | CPT | 0.28716 | 0.68609 | 1.02396 | 0.90005 |

| First-order SDT | 0.24919 | 0.53777 | 0.93294 | 0.78305 | ||||

| Reddy’s refined SDT | 0.25378 | 0.57257 | 1.02396 | 0.85218 | ||||

| Sinusoidal SDT | 0.25428 | 0.57416 | 1.02396 | 0.85510 | ||||

| Exponential SDT | 0.25515 | 0.57665 | 1.02396 | 0.85940 | ||||

| Hyperbolic SDT | 0.25375 | 0.57248 | 1.02396 | 0.85199 | ||||

| 3D CCST [54] | 0.25922 | 0.58043 | 1.02476 | 0.85664 | ||||

| Open-circuit | 0.5 | 5 | 10 | CPT | 0.26847 | 0.64749 | 1.02396 | 0.90005 |

| First-order SDT | 0.23724 | 0.51880 | 0.90777 | 0.75996 | ||||

| Reddy’s refined SDT | 0.24438 | 0.55881 | 1.01260 | 0.83852 | ||||

| Sinusoidal SDT | 0.24467 | 0.55973 | 1.01381 | 0.84039 | ||||

| Exponential SDT | 0.24525 | 0.56146 | 1.01411 | 0.84359 | ||||

| Hyperbolic SDT | 0.24437 | 0.55876 | 1.01244 | 0.83842 | ||||

| 3D CCST [54] | 0.24681 | 0.55954 | 0.99989 | 0.83247 | ||||

| Open-circuit | 0.5 | 10 | 10 | CPT | 0.06840 | 0.16938 | 0.33352 | 0.26847 |

| First-order SDT | 0.06580 | 0.15542 | 0.28852 | 0.23724 | ||||

| Reddy’s refined SDT | 0.06499 | 0.15721 | 0.30019 | 0.24438 | ||||

| Sinusoidal SDT | 0.06506 | 0.15739 | 0.30057 | 0.24467 | ||||

| Exponential SDT | 0.06520 | 0.15774 | 0.30132 | 0.24525 | ||||

| Hyperbolic SDT | 0.06498 | 0.15720 | 0.30018 | 0.24437 | ||||

| 3D CCST [54] | 0.06588 | 0.15909 | 0.30276 | 0.24681 | ||||

| Open-circuit | 1 | 10 | 10 | CPT | 0.10503 | 0.26009 | 0.51198 | 0.41227 |

| First-order SDT | 0.09903 | 0.22931 | 0.41720 | 0.34536 | ||||

| Reddy’s refined SDT | 0.10219 | 0.24859 | 0.47793 | 0.38813 | ||||

| Sinusoidal SDT | 0.10224 | 0.24873 | 0.47833 | 0.38841 | ||||

| Exponential SDT | 0.10234 | 0.24907 | 0.47926 | 0.38908 | ||||

| Hyperbolic SDT | 0.10218 | 0.24858 | 0.47792 | 0.38812 | ||||

| 3D CCST [54] | 0.10423 | 0.24862 | 0.46589 | 0.38193 | ||||

| Surface Conditions | 2D and 3D Size-Dependent Theories Based on the CCST | |||||||

|---|---|---|---|---|---|---|---|---|

| (1, 1) | (1, 2) | (1, 3) | (2, 2) | |||||

| Closed-circuit | 0.5 | 5 | 1 | CPT | 0.28449 | 0.68043 | 1.02396 | 0.90005 |

| First-order SDT | 0.24181 | 0.50913 | 0.85945 | 0.72805 | ||||

| Reddy’s refined SDT | 0.23337 | 0.52092 | 0.92233 | 0.76963 | ||||

| Sinusoidal SDT | 0.23405 | 0.52302 | 0.92721 | 0.77338 | ||||

| Exponential SDT | 0.23560 | 0.52702 | 0.93528 | 0.77983 | ||||

| Hyperbolic SDT | 0.23335 | 0.52082 | 0.92205 | 0.76943 | ||||

| 3D CCST [54] | 0.24803 | 0.54884 | 0.96382 | 0.80666 | ||||

| Closed-circuit | 0.5 | 5 | 10 | CPT | 0.26695 | 0.64416 | 1.02396 | 0.90005 |

| First-order SDT | 0.23260 | 0.49907 | 0.85288 | 0.71996 | ||||

| Reddy’s refined SDT | 0.23018 | 0.52034 | 0.93044 | 0.77407 | ||||

| Sinusoidal SDT | 0.23070 | 0.52197 | 0.93454 | 0.77712 | ||||

| Exponential SDT | 0.23191 | 0.52527 | 0.94176 | 0.78274 | ||||

| Hyperbolic SDT | 0.23016 | 0.52028 | 0.93022 | 0.77393 | ||||

| 3D CCST [54] | 0.22395 | 0.50170 | 0.89103 | 0.74291 | ||||

| Closed-circuit | 0.5 | 10 | 10 | CPT | 0.06800 | 0.16840 | 0.33167 | 0.26695 |

| First-order SDT | 0.06518 | 0.15318 | 0.28192 | 0.23260 | ||||

| Reddy’s refined SDT | 0.06165 | 0.14859 | 0.28214 | 0.23018 | ||||

| Sinusoidal SDT | 0.06177 | 0.14890 | 0.28282 | 0.23070 | ||||

| Exponential SDT | 0.06206 | 0.14964 | 0.28436 | 0.23191 | ||||

| Hyperbolic SDT | 0.06165 | 0.14858 | 0.28212 | 0.23016 | ||||

| 3D CCST [54] | 0.06054 | 0.14514 | 0.27393 | 0.22395 | ||||

| Closed-circuit | 1 | 10 | 10 | CPT | 0.10476 | 0.25945 | 0.51099 | 0.41129 |

| First-order SDT | 0.09850 | 0.22703 | 0.40979 | 0.34030 | ||||

| Reddy’s refined SDT | 0.09987 | 0.24188 | 0.46179 | 0.37605 | ||||

| Sinusoidal SDT | 0.09995 | 0.24210 | 0.46236 | 0.37646 | ||||

| Exponential SDT | 0.10016 | 0.24273 | 0.46394 | 0.37763 | ||||

| Hyperbolic SDT | 0.09987 | 0.24188 | 0.46179 | 0.37605 | ||||

| 3D CCST [54] | 0.09646 | 0.22651 | 0.41729 | 0.34410 | ||||

| Surface Conditions | Theories | Lowest | Second Lowest | ||

|---|---|---|---|---|---|

| Open-circuit | 10 | 1 | CPT | 12.1415 | 28.8462 |

| First-order SDT | 10.9389 | 28.8444 | |||

| Reddy’s refined SDT | 9.5951 | 28.8444 | |||

| Sinusoidal SDT | 9.6308 | 28.8444 | |||

| Exponential SDT | 9.7097 | 28.8444 | |||

| Hyperbolic SDT | 9.5941 | 28.8444 | |||

| State space sols [55] | 9.5543 | 28.8389 | |||

| Asymptotic sols [56] | 9.5545 | 28.8389 | |||

| Discrete sols [57] | 9.525 | 28.762 | |||

| Open-circuit | 10 | 3 | CPT | 13.3624 | 30.4768 |

| First-order SDT | 11.8391 | 30.4757 | |||

| Reddy’s refined SDT | 9.9926 | 30.4757 | |||

| Sinusoidal SDT | 10.0351 | 30.4757 | |||

| Exponential SDT | 10.1411 | 30.4757 | |||

| Hyperbolic SDT | 9.9920 | 30.4757 | |||

| State space sols [55] | 9.7730 | 30.0246 | |||

| Asymptotic sols [56] | 9.7730 | 30.0246 | |||

| Discrete sols [57] | 9.747 | 29.975 | |||

| Closed-circuit | 10 | 1 | CPT | 12.0904 | 28.8462 |

| First-order SDT | 10.8868 | 28.8444 | |||

| Reddy’s refined SDT | 9.3344 | 28.8444 | |||

| Sinusoidal SDT | 9.3720 | 28.8444 | |||

| Exponential SDT | 9.4627 | 28.8444 | |||

| Hyperbolic SDT | 9.3338 | 28.8444 | |||

| State space sols [55] | 9.5289 | 28.8390 | |||

| Closed-circuit | 10 | 3 | CPT | 13.3030 | 30.4768 |

| First-order SDT | 11.8082 | 30.4757 | |||

| Reddy’s refined SDT | 9.8945 | 30.4757 | |||

| Sinusoidal SDT | 9.9400 | 30.4757 | |||

| Exponential SDT | 10.0527 | 30.4757 | |||

| Hyperbolic SDT | 9.8939 | 30.4757 | |||

| State space sols [55] | 9.7667 | 30.0246 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.-P.; Hsu, C.-D. A Unified Size-Dependent Theory for Analyzing the Free Vibration Behavior of an FG Microplate Under Fully Simply Supported Conditions and Magneto-Electro-Thermo-Mechanical Loads Considering Couple Stress and Thickness Stretching Effects. J. Compos. Sci. 2025, 9, 201. https://doi.org/10.3390/jcs9050201

Wu C-P, Hsu C-D. A Unified Size-Dependent Theory for Analyzing the Free Vibration Behavior of an FG Microplate Under Fully Simply Supported Conditions and Magneto-Electro-Thermo-Mechanical Loads Considering Couple Stress and Thickness Stretching Effects. Journal of Composites Science. 2025; 9(5):201. https://doi.org/10.3390/jcs9050201

Chicago/Turabian StyleWu, Chih-Ping, and Cheng-Dao Hsu. 2025. "A Unified Size-Dependent Theory for Analyzing the Free Vibration Behavior of an FG Microplate Under Fully Simply Supported Conditions and Magneto-Electro-Thermo-Mechanical Loads Considering Couple Stress and Thickness Stretching Effects" Journal of Composites Science 9, no. 5: 201. https://doi.org/10.3390/jcs9050201

APA StyleWu, C.-P., & Hsu, C.-D. (2025). A Unified Size-Dependent Theory for Analyzing the Free Vibration Behavior of an FG Microplate Under Fully Simply Supported Conditions and Magneto-Electro-Thermo-Mechanical Loads Considering Couple Stress and Thickness Stretching Effects. Journal of Composites Science, 9(5), 201. https://doi.org/10.3390/jcs9050201