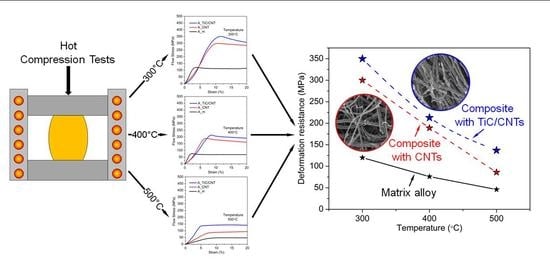

Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Poletti, C.; Balog, M.; Simancik, F.; Degischer, H.P. High-temperature strength of compacted sub-micrometer aluminium powder. Acta Mater. 2010, 58, 3781–3789. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Deev, V.B.; Prusov, E.S.; Ri, E.H. Physical Methods of Processing the Melts of Metal Matrix Composites: Current State and Prospects. Russ. J. Non-Ferr. Met. 2022, 63, 292–304. [Google Scholar] [CrossRef]

- Grilo, J.; Carneiro, V.H.; Teixeira, J.C.; Puga, H. Manufacturing Methodology on Casting-Based Aluminium Matrix Composites: Systematic Review. Metals 2021, 11, 436. [Google Scholar] [CrossRef]

- Jendrzejewski, R.; Łubiński, J.; Śliwiński, G. Wear Resistance Enhancement of Al6061 Alloy Surface Layer by Laser Dispersed Carbide Powders. Materials 2020, 13, 3683. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.; Zhao, Y. Research Status and Prospect of Friction Stir Processing Technology. Coatings 2019, 9, 129. [Google Scholar] [CrossRef]

- Jendrzejewski, R.; Van Acker, K.; Vanhoyweghen, D.; Śliwiński, G. Metal matrix composite production by means of laser dispersing of SiC and WC powder in Al alloy. Appl. Surf. Sci. 2009, 255, 5584–5587. [Google Scholar] [CrossRef]

- Li, W.; Assadi, H.; Gaertner, F.; Yin, S. A review of advanced composite and nanostructured coatings by solid-state cold spraying process. Crit. Rev. Solid State Mater. Sci. 2019, 44, 109–156. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Alymov, M.I.; Arkhipov, V.E.; Khrenov, D.S. Formation of heterogeneous powder coatings with a two-level micro-and nanocomposite structure under gas-dynamic spraying conditions. Dokl. Phys. 2018, 63, 50–54. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold Spray Coating: Review of Material Systems and Future Perspectives. Surf. Eng. 2014, 36, 369–395. [Google Scholar] [CrossRef]

- Liu, J.; Huang, X.; Zhao, K.; Zhu, Z.; Zhu, X.; An, L. Effect of reinforcement particle size on quasistatic and dynamic mechanical properties of Al-Al2O3 composites. J. Alloy. Compd. 2019, 797, 1367–1371. [Google Scholar] [CrossRef]

- Kang, Y.C.; Chan, S.L.I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- Prabhu, B.; Suryanarayana, C.; An, L.; Vaidyanathan, R. Synthesis and characterization of high volume fraction Al-Al2O3 nanocomposite powders by high-energy milling. Mater. Sci. Eng. A 2006, 425, 192–200. [Google Scholar] [CrossRef]

- Saravanan, L.; Senthilvelan, T. Investigations on the hot workability characteristics and deformation mechanisms of aluminium alloy-Al2O3 nanocomposite. Mater. Des. 2015, 79, 6–14. [Google Scholar] [CrossRef]

- Kashyap, K.T.; Patil, R.G. On Young’s modulus of multi-walled carbon nanotubes. Bull. Mater. Sci. 2008, 31, 185–187. [Google Scholar] [CrossRef]

- Wong, E.W.; Sheehan, P.E.; Lieber, C.M. Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes. Science 1997, 277, 1971–1975. [Google Scholar] [CrossRef]

- Lourie, O.; Wagner, H.D. Evaluation of Young’s modulus of carbon nanotubes by micro-Raman spectroscopy. J. Mater. Res. 1998, 13, 2418–2422. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef]

- Peng, B.; Locascio, M.; Zapol, P.; Li, S.; Mielke, S.L.; Schatz, G.C.; Espinosa, H.D. Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat. Nanotechnol. 2008, 3, 626–631. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Elevated temperature tensile properties and thermal expansion of CNT/2009Al composites. Compos. Sci. Technol. 2012, 72, 1826–1833. [Google Scholar] [CrossRef]

- Lee, W.S.; Sue, W.C.; Lin, C.F. The effects of temperature and strain rate on the properties of carbon-fiber-reinforced 7075 aluminum alloy metal-matrix composite. Compos. Sci. Technol. 2000, 60, 1975–1983. [Google Scholar] [CrossRef]

- Cao, L.; Chen, B.; Wan, J.; Kondoh, K.; Guo, B.; Shen, J.; Li, J.S. Superior high-temperature tensile properties of aluminum matrix composites reinforced with carbon nanotubes. Carbon 2022, 191, 403–414. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Khor’kov, K.S.; Ob’edkov, A.M.; Kremlev, K.V.; Izobello, A.Y.; Volochko, A.T.; Alymov, M.I. Evolution of Multiwalled Carbon Nanotubes and Related Nanostructures during the Formation of Alumomatrix Composite Materials. Tech. Phys. Lett. 2019, 45, 20–23. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Babin, D.M.; Zalesnov, A.I.; Prusov, E.S.; Ob’edkov, A.M.; Alymov, M.I. Effect of ceramic coating on carbon nanotubes interaction with matrix material and mechanical properties of aluminum matrix nanocomposite. Ceram. Int. 2020, 46, 19256–19263. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Khorkov, K.S.; Prusov, E.S.; Ob’edkov, A.M.; Kremlev, K.V.; Perezhogin, I.A.; Alymov, M.I. Effect of Increasing the Strength of Aluminum Matrix Nanocomposites Reinforced with Microadditions of Multiwalled Carbon Nanotubes Coated with TiC Nanoparticles. Nanomaterials 2019, 9, 1596. [Google Scholar] [CrossRef] [PubMed]

- Kremlev, K.V.; Ob’edkov, A.M.; Semenov, N.M.; Kaverin, B.S.; Ketkov, S.Y.; Vilkov, I.V.; Andreev, P.V.; Gusev, S.A.; Aborkin, A.V. Synthesis of Hybrid Materials Based on Multiwalled Carbon Nanotubes Decorated with WC1–x Nanocoatings of Various Morphologies. Tech. Phys. Lett. 2019, 45, 348–351. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Elkin, A.I.; Reshetniak, V.V.; Ob’edkov, A.M.; Sytschev, A.E.; Leontiev, V.G.; Titov, D.D.; Alymov, M.I. Thermal expansion of aluminum matrix composites reinforced by carbon nanotubes with in-situ and ex-situ designed interfaces ceramics layers. J. Alloy. Compd. 2021, 872, 159593. [Google Scholar] [CrossRef]

- Guo, B.; Luo, S.; Wu, Y.; Song, M.; Chen, B.; Yu, Z.; Li, W. Regulating the interfacial reaction between carbon nanotubes and aluminum via copper nano decoration. Mater. Sci. Eng. A 2021, 821, 141576. [Google Scholar] [CrossRef]

- Contreras, A. Wetting of TiC by Al-Cu alloys and interfacial characterization. J. Colloid Interface Sci. 2007, 311, 159–170. [Google Scholar] [CrossRef]

- Huang, C.C.; Qi, L.; Chen, J.; Guan, R.; Ojo, O.A.; Wang, Z.G. Effect of TiC nanoparticles on the hot deformation behavior of AA7075 aluminum alloy. Mater. Charact. 2021, 181, 111508. [Google Scholar] [CrossRef]

- Jagannatham, M.; Chandran, P.; Sankaran, S.; Haridoss, P.; Nayan, N.; Bakshi, S.R. Tensile properties of carbon nanotubes reinforced aluminum matrix composites: A review. Carbon 2020, 160, 14–44. [Google Scholar] [CrossRef]

- Obiedkov, A.M.; Kaverin, B.S.; Egorov, V.A.; Semenov, N.M.; Ketkov, S.Y.; Domrachev, G.A.; Kremlev, K.V.; Gusev, S.A.; Perevezentsev, V.N.; Moskvichev, A.N.; et al. Macroscopic cylinders on the basis of radial-oriented multiwall carbon nanotubes. Lett. Mater. 2012, 3, 152–156. [Google Scholar] [CrossRef]

- Vilkov, I.V.; Kaverin, B.S.; Ob’edkov, A.M.; Semenov, N.M.; Ketkov, S.Y.; Rychagova, E.A.; Gusev, S.A.; Tatarskiy, D.A.; Andreev, P.V.; Aborkin, A.V. Single-step synthesis of tic mesocrystals on the mwcnts surface by the pyrolysis of Cp2TiCl2. Mater. Today Chem. 2022, 24, 100830. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Alymov, M.I.; Sobol’kov, A.V.; Khor’kov, K.S.; Babin, D.M. Effect of the Thermomechanical Treatment Conditions on the Consolidation, the Structure, and the Mechanical Properties of Bulk Al–Mg–C Nanocomposites. Russ. Metall. 2018, 2018, 625–632. [Google Scholar] [CrossRef]

- Ou, L.; Zheng, Z.; Nie, Y.; Jian, H. Hot deformation behavior of 2060 alloy. J. Alloys Compd. 2015, 648, 681–689. [Google Scholar] [CrossRef]

- Avramovic-Cingara, G.; McQueen, H.J.; Perovic, D.D. Comparison of torsion and compression constitutive analyses for elevated temperature deformation of Al–Li–Cu–Mn alloy. Mater. Sci. Technol. 2014, 19, 11–19. [Google Scholar] [CrossRef]

- Rajamuthamilselvan, M.; Rajakumar, S.; Kavitha, S. Effect of Different SiCp Particle Sizes on the Behavior of AA 7075 Hot Deformation Composites Using Processing Maps. Springer Proc. Mater. 2021, 5, 1233–1244. [Google Scholar]

- Lin, H.B. Dynamic recrystallization behavior of 6082 aluminum alloy during hot deformation. Adv. Mech. Eng. 2021, 13, 11. [Google Scholar] [CrossRef]

- Ding, S.; Khan, S.A.; Yanagimoto, J. Constitutive descriptions and microstructure evolution of extruded A5083 aluminum alloy during hot compression. Mater. Sci. Eng. A 2018, 728, 133–143. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aborkin, A.V.; Bokaryov, D.V.; Pankratov, S.A.; Elkin, A.I. Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs. Ceramics 2023, 6, 231-240. https://doi.org/10.3390/ceramics6010013

Aborkin AV, Bokaryov DV, Pankratov SA, Elkin AI. Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs. Ceramics. 2023; 6(1):231-240. https://doi.org/10.3390/ceramics6010013

Chicago/Turabian StyleAborkin, Artemiy V., Dmitriy V. Bokaryov, Sergey A. Pankratov, and Alexey I. Elkin. 2023. "Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs" Ceramics 6, no. 1: 231-240. https://doi.org/10.3390/ceramics6010013

APA StyleAborkin, A. V., Bokaryov, D. V., Pankratov, S. A., & Elkin, A. I. (2023). Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs. Ceramics, 6(1), 231-240. https://doi.org/10.3390/ceramics6010013