Sustainable Approaches for the Additive Manufacturing of Ceramic Materials

Abstract

1. Introduction

2. Additive Manufacturing of Ceramics

2.1. Slurry-Based Technologies

2.1.1. Stereolithography (SL)

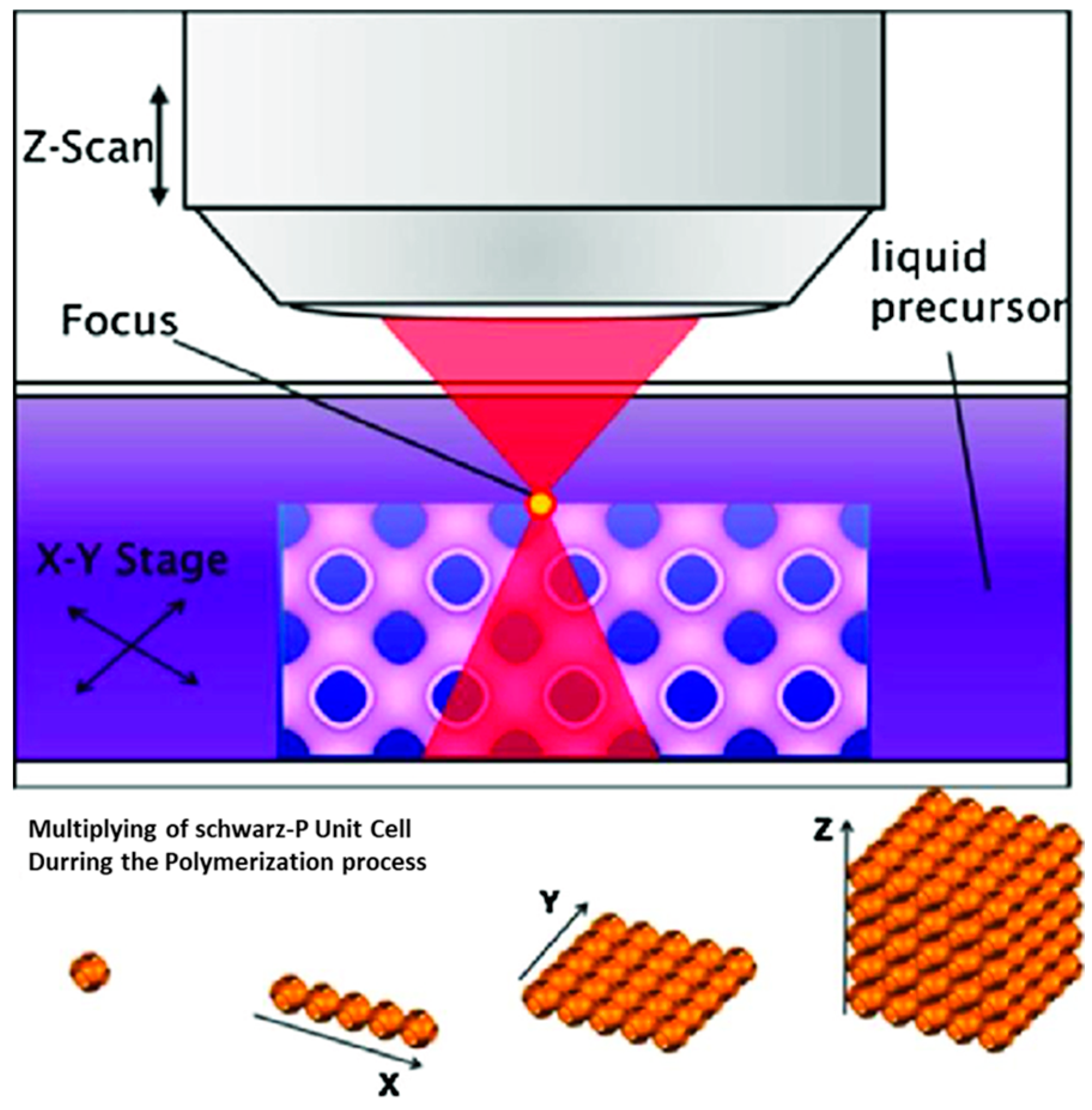

2.1.2. Two-Photon Polymerisation (TPP)

2.1.3. Inkjet Printing (IJP)

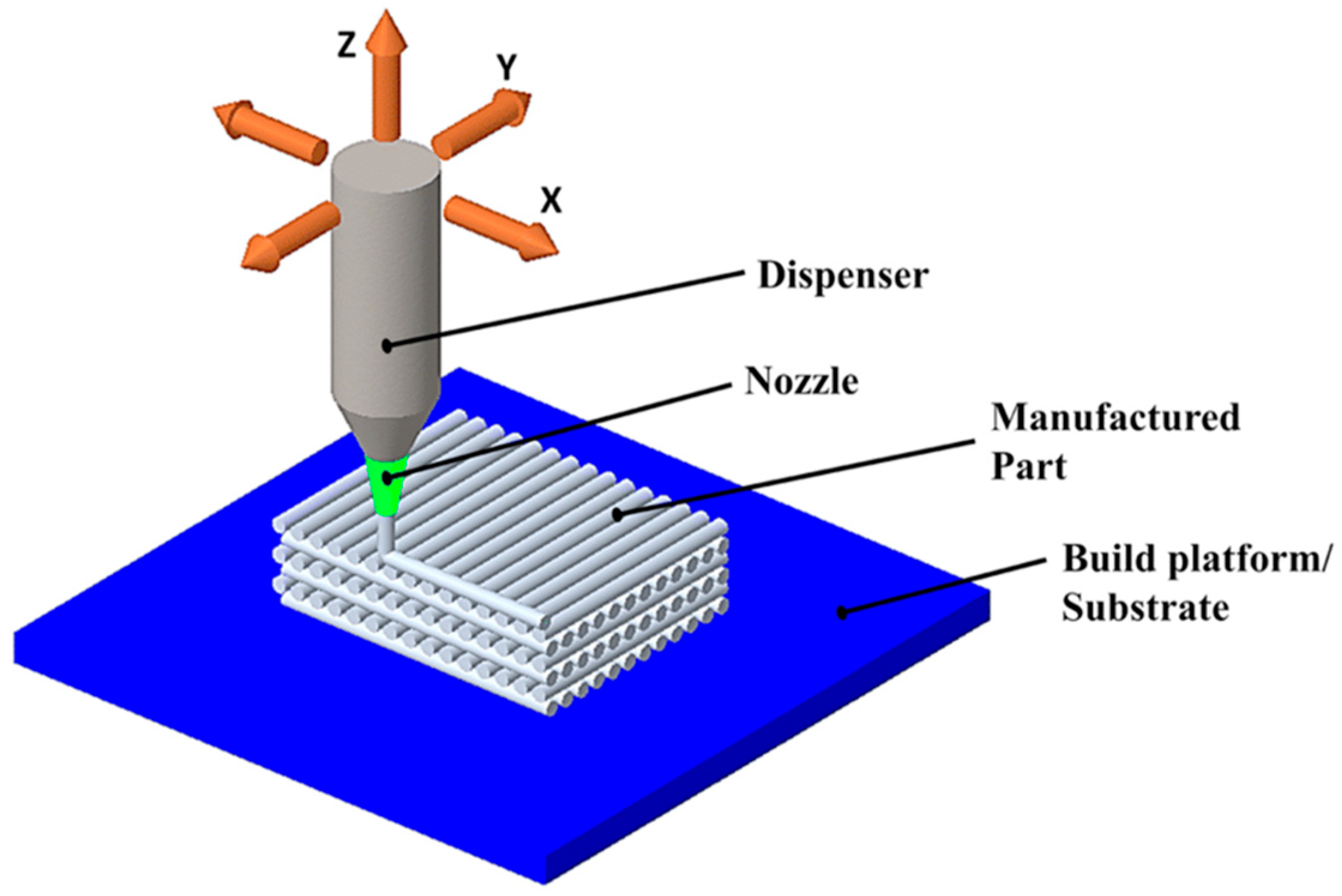

2.1.4. Robocasting

2.2. Powder-Based Technologies

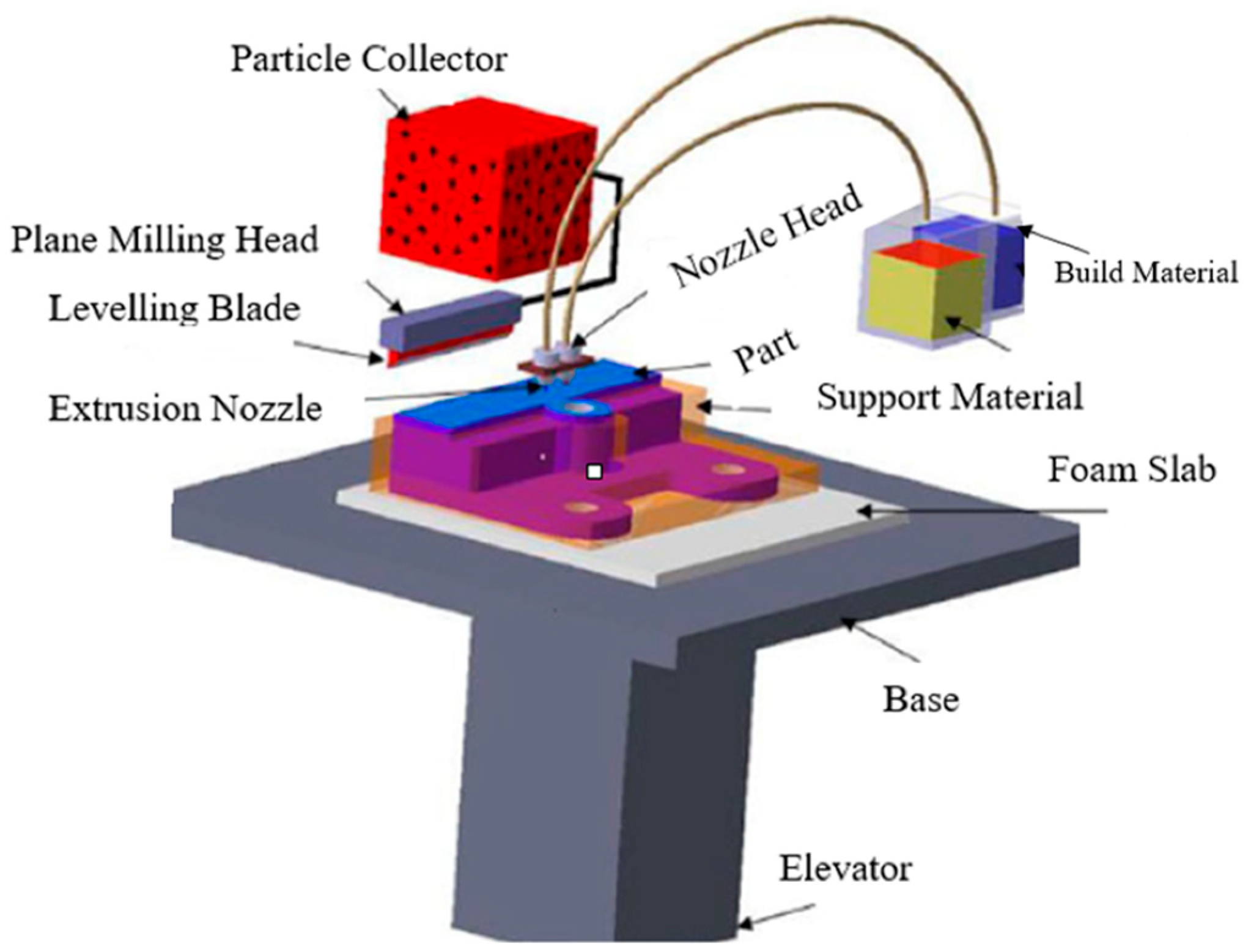

2.2.1. Three-Dimensional Printing (3DP)

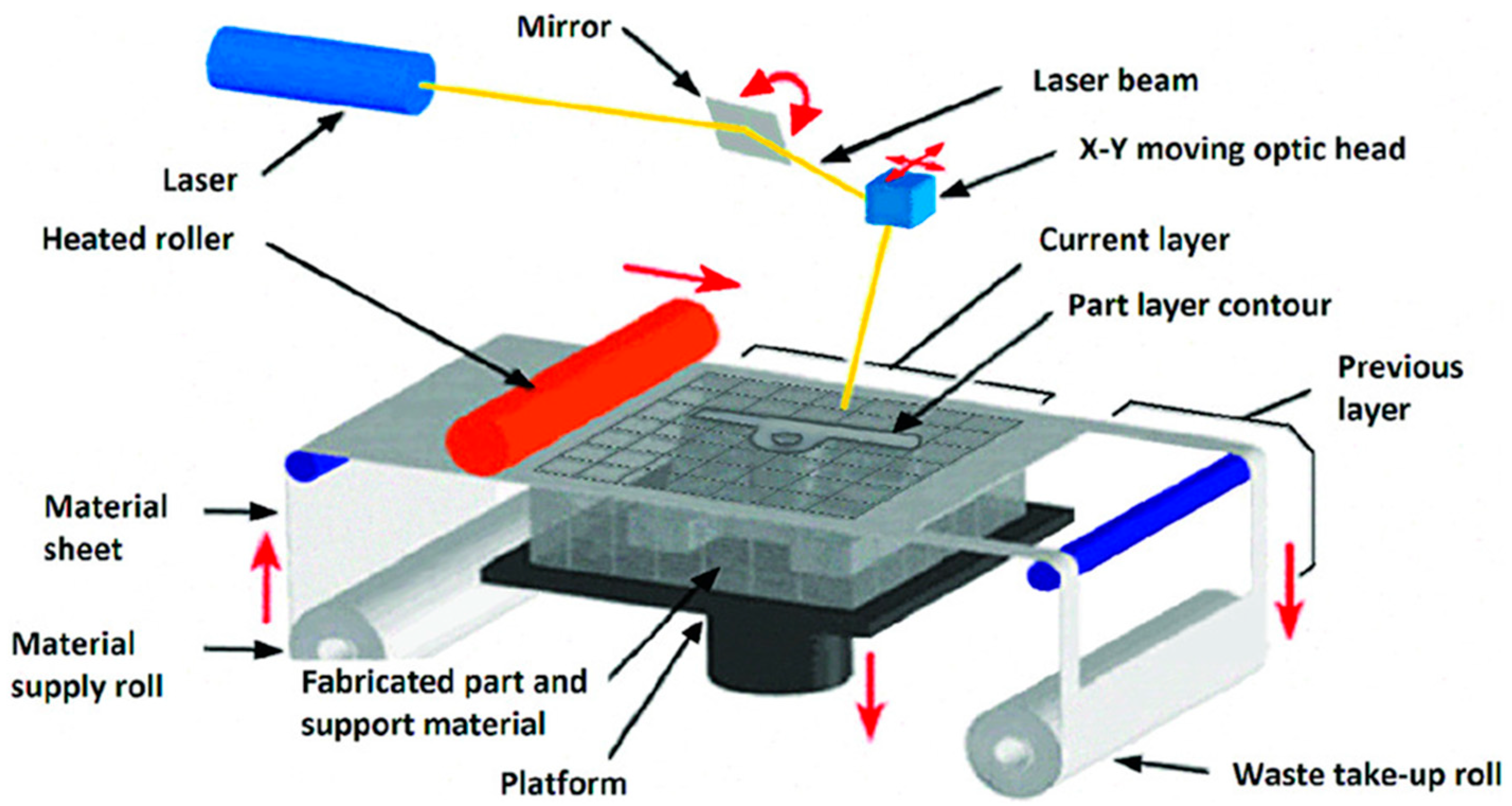

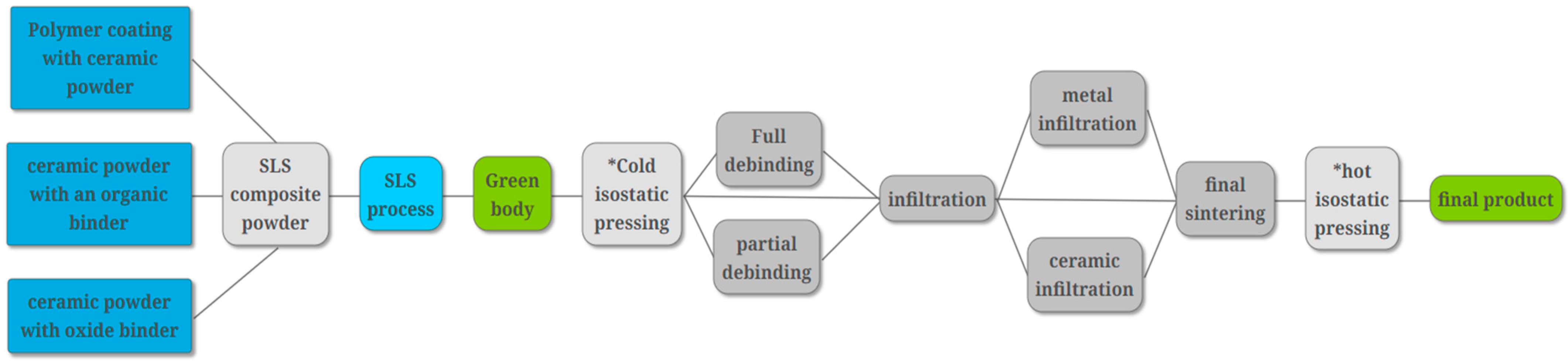

2.2.2. Selective Laser Sintering (SLS)

2.3. Bulk Solid-Based Technologies

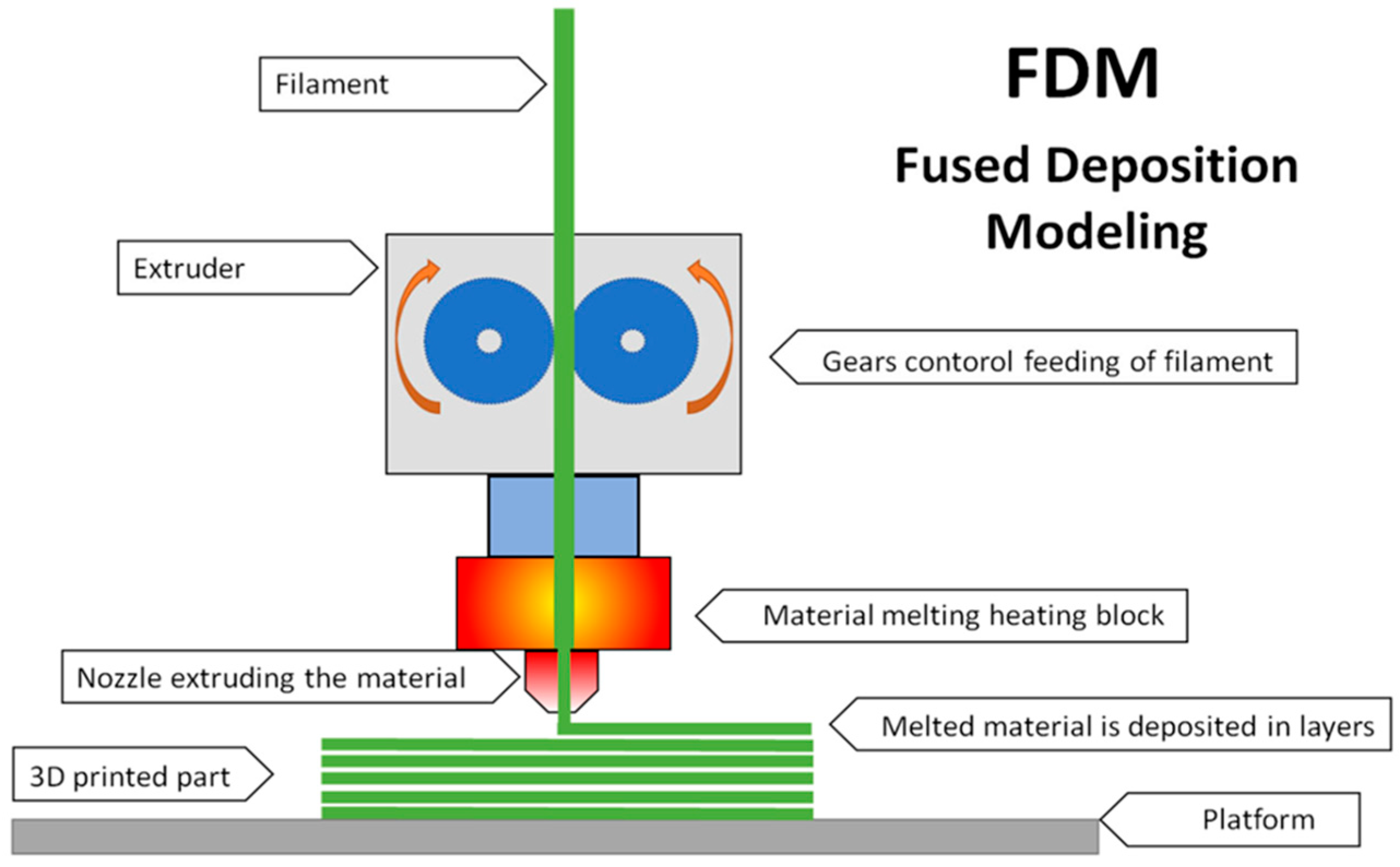

2.4. Other Additive Manufacturing Approaches

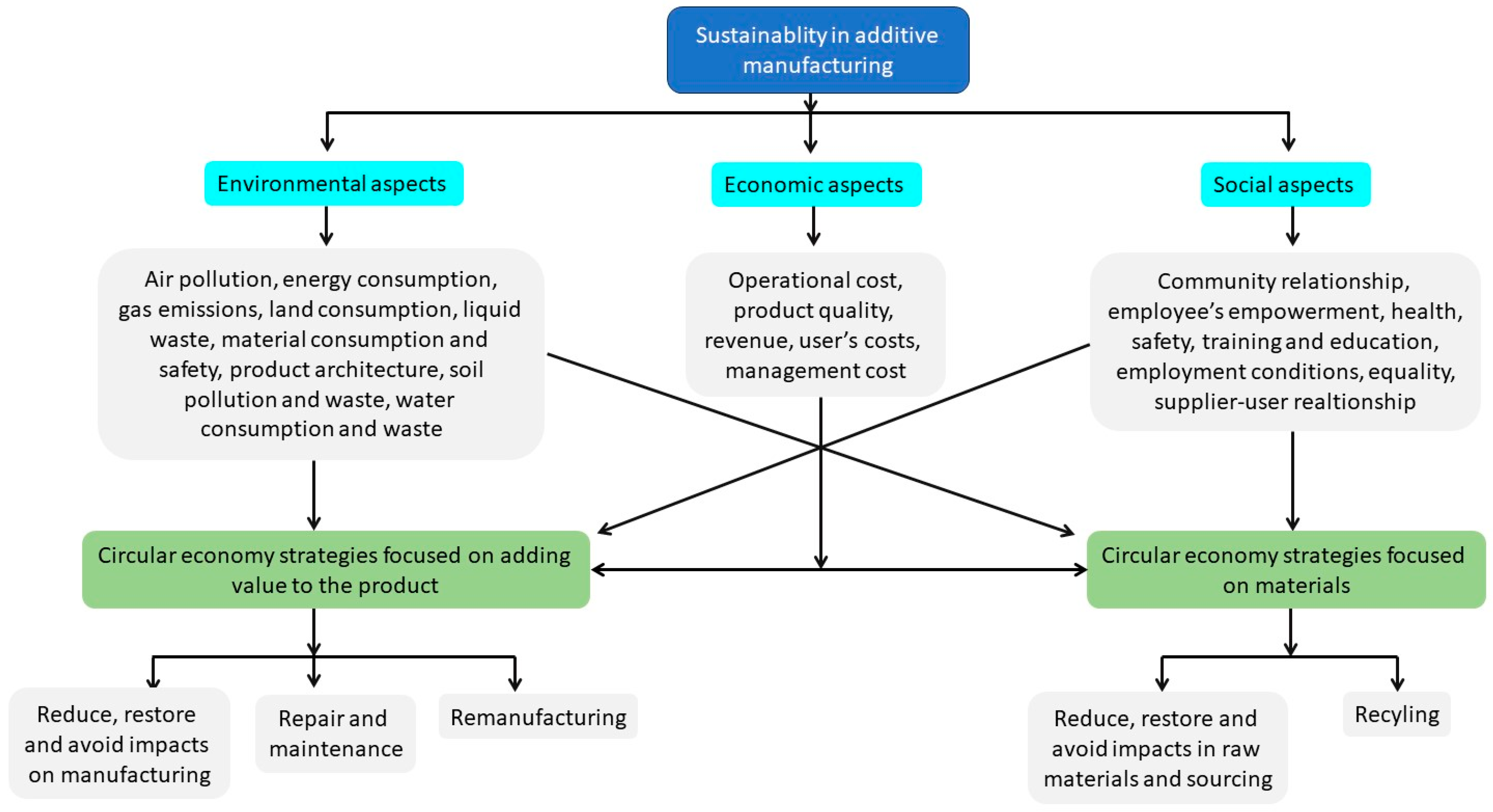

3. Sustainability of Additive Manufacturing

3.1. Sustainability Pillars for Additive Manufacturing

3.1.1. Environmental Pillar

3.1.2. Economical Pillar

3.1.3. Social and Personal Health Pillar

3.2. Sustainable and Circular Economy Approaches for Additive Manufacturing

4. Possible Recycling Options and Sustainable Materials in the Additive Manufacturing of Ceramics

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fiume, E.; Coppola, B.; Montanaro, L.; Palmero, P. Vat-photopolymerization of ceramic materials: Exploring current applications in advanced multidisciplinary fields. Front. Mater. 2023, 10, 1242480. [Google Scholar] [CrossRef]

- Gao, C.; Wolff, S.; Wang, S. Eco-friendly additive manufacturing of metals: Energy efficiency and life cycle analysis. J. Manuf. Syst. 2021, 60, 459–472. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- ISO/ASTM 17296; Standard on Additive Manufacturing (AM) Technologies. Comite Europeen de Normalisation: Brussels, Belgium, 2016.

- Potestio, I. Lithoz: How lithography-based ceramic AM is expanding the opportunities for technical ceramics. Powder Inject. Mould. Int. 2019, 13, 2–5. [Google Scholar]

- Griffith, M.L.; Halloran, J.W. Freeform fabrication of ceramics via stereolithography. J. Am. Ceram. Soc. 1996, 79, 2601–2608. [Google Scholar] [CrossRef]

- Lombardo, S.J. Minimum time heating cycles for diffusion-controlled binder removal from ceramic green bodies. J. Am. Ceram. Soc. 2015, 98, 57–65. [Google Scholar] [CrossRef]

- Gentry, S.P.; Halloran, J.W. Depth and width of cured lines in photopolymerizable ceramic suspensions. J. Eur. Ceram. Soc. 2013, 33, 1981–1988. [Google Scholar] [CrossRef]

- Felzmann, R.; Gruber, S.; Mitteramskogler, G.; Tesavibul, P.; Boccaccini, A.R.; Liska, R.; Stampfl, J. Lithography-based additive manufacturing of cellular ceramic structures. Adv. Eng. Mater. 2012, 14, 1052–1058. [Google Scholar] [CrossRef]

- Vaz, V.M.; Kumar, L. 3D Printing as a Promising Tool in Personalized Medicine. AAPS PharmSciTech 2021, 22, 49. [Google Scholar] [CrossRef]

- Chaudhary, R.; Fabbri, P.; Leoni, E.; Mazzanti, F.; Akbari, R.; Antonini, C. Additive manufacturing by digital light processing: A review. Prog. Addit. Manuf. 2023, 8, 331–351. [Google Scholar] [CrossRef]

- Varadan, V.K.; Jiang, X.; Varadan, V.V. Microstereolithography and Other Fabrication Techniques for 3D MEMS; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Zabidi, A.Z.; Li, S.; Felfel, R.M.; Thomas, K.G.; Grant, D.M.; McNally, D.; Scotchford, C. Computational mechanical characterization of geometrically transformed Schwarz P lattice tissue scaffolds fabricated via two photon polymerization (2PP). Addit. Manuf. 2019, 25, 399–411. [Google Scholar] [CrossRef]

- Dong, H.; Carr, W.W.; Morris, J.F. An experimental study of drop-on-demand drop formation. Phys. Fluids 2006, 18, 072102. [Google Scholar] [CrossRef]

- Kosmala, A.; Zhang, Q.; Wright, R.; Kirby, P. Development of high concentrated aqueous silver nanofluid and inkjet printing on ceramic substrates. Mater. Chem. Phys. 2012, 132, 788–795. [Google Scholar] [CrossRef]

- Peymannia, M.; Soleimani-Gorgani, A.; Ghahari, M.; Jalili, M. The effect of different dispersants on the physical properties of nano CoAl2O4 ceramic ink-jet ink. Ceram. Int. 2015, 41, 9115–9121. [Google Scholar] [CrossRef]

- Verwey, E.; Overbeek, J.T.G. Theory of the stability of lyophobic colloids. J. Colloid Sci. 1955, 10, 224–225. [Google Scholar] [CrossRef]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Capillary flow as the cause of ring stains from dried liquid drops. Nature 1997, 389, 827–829. [Google Scholar] [CrossRef]

- Sukeshini, A.; Cummins, R.; Reitz, T.; Miller, R. Inkjet printing of anode supported SOFC: Comparison of slurry pasted cathode and printed cathode. Electrochem. Solid-State Lett. 2009, 12, B176. [Google Scholar] [CrossRef][Green Version]

- Kumar, R.; Kumar, M.; Chohan, J.S. Material-specific properties and applications of additive manufacturing techniques: A comprehensive review. Bull. Mater. Sci. 2021, 44, 181. [Google Scholar] [CrossRef]

- Lamnini, S.; Elsayed, H.; Lakhdar, Y.; Baino, F.; Smeacetto, F.; Bernardo, E. Robocasting of advanced ceramics: Ink optimization and protocol to predict the printing parameters—A review. Heliyon 2022, 8, e10651. [Google Scholar] [CrossRef] [PubMed]

- Li, J.P.; Habibovic, P.; van den Doel, M.; Wilson, C.E.; de Wijn, J.R.; van Blitterswijk, C.A.; de Groot, K. Bone ingrowth in porous titanium implants produced by 3D fiber deposition. Biomaterials 2007, 28, 2810–2820. [Google Scholar] [CrossRef] [PubMed]

- Miranda, P.; Saiz, E.; Gryn, K.; Tomsia, A.P. Sintering and robocasting of β-tricalcium phosphate scaffolds for orthopaedic applications. Acta Biomater. 2006, 2, 457–466. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, T.; Ma, H.; Zhai, D.; Deng, C.; Wang, J.; Zhuo, S.; Chang, J.; Wu, C. 3D-printed scaffolds with bioactive elements-induced photothermal effect for bone tumor therapy. Acta Biomater. 2018, 73, 531–546. [Google Scholar] [CrossRef] [PubMed]

- Tulyaganov, D.U.; Fiume, E.; Akbarov, A.; Ziyadullaeva, N.; Murtazaev, S.; Rahdar, A.; Massera, J.; Verné, E.; Baino, F. In vivo evaluation of 3D-printed silica-based bioactive glass scaffolds for bone regeneration. J. Funct. Biomater. 2022, 13, 74. [Google Scholar] [CrossRef] [PubMed]

- Colombo, P.; Schmidt, J.; Franchin, G.; Zocca, A.; Günster, J. Additive manufacturing techniques for fabricating complex ceramic components from preceramic polymers. Am. Ceram. Soc. Bull. 2017, 96, 16–23. [Google Scholar]

- Khan, S.A.; Lazoglu, I. Development of additively manufacturable and electrically conductive graphite–polymer composites. Prog. Addit. Manuf. 2020, 5, 153–162. [Google Scholar] [CrossRef]

- Sachs, E.; Haggerty, J.; Cima, M.; Williams, P. Three-Dimensional Printing Techniques: Google Patents. U.S. Patent US5340656A, 23 August 1994. [Google Scholar]

- Moon, J.; Grau, J.E.; Knezevic, V.; Cima, M.J.; Sachs, E.M. Ink-jet printing of binders for ceramic components. J. Am. Ceram. Soc. 2002, 85, 755–762. [Google Scholar] [CrossRef]

- Lauder, A.; Cima, M.; Sachs, E.; Fan, T. Three dimensional printing: Surface finish and microstructure of rapid prototyped components. MRS Online Proc. Libr. 1991, 249, 331–336. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Espera, A.H.; Dizon, J.R.C.; Chen, Q.; Advincula, R.C. 3D-printing and advanced manufacturing for electronics. Prog. Addit. Manuf. 2019, 4, 245–267. [Google Scholar] [CrossRef]

- Vishnu, V.; Prabhu, T.R.; Imam, M.; Vineesh, K.P. High-temperature dry sliding wear behavior of additively manufactured austenitic stainless steel (316L). Wear 2024, 540–541, 205259. [Google Scholar] [CrossRef]

- Jiao, L.; Chua, Z.Y.; Moon, S.K.; Song, J.; Bi, G.; Zheng, H. Femtosecond Laser Produced Hydrophobic Hierarchical Structures on Additive Manufacturing Parts. Nanomaterials 2018, 8, 601. [Google Scholar] [CrossRef] [PubMed]

- Lakshminarayan, U.; Ogrydiziak, S.; Marcus, H. Selective laser sintering of ceramic materials. In Proceedings of the 1990 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 1990; pp. 16–26. [Google Scholar]

- Shahzad, K.; Deckers, J.; Boury, S.; Neirinck, B.; Kruth, J.-P.; Vleugels, J. Preparation and indirect selective laser sintering of alumina/PA microspheres. Ceram. Int. 2012, 38, 1241–1247. [Google Scholar] [CrossRef]

- Wohlert, M.; Bourell, D. Rapid prototyping of Mg/SiC composites by a combined SLS and pressureless infiltration process. In Proceedings of the 1996 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 1996. [Google Scholar]

- Yves-Christian, H.; Jan, W.; Wilhelm, M.; Konrad, W.; Reinhart, P. Net shaped high performance oxide ceramic parts by selective laser melting. Phys. Procedia 2010, 5, 587–594. [Google Scholar] [CrossRef]

- Friedel, T.; Travitzky, N.; Niebling, F.; Scheffler, M.; Greil, P. Fabrication of polymer derived ceramic parts by selective laser curing. J. Eur. Ceram. Soc. 2005, 25, 193–197. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Schindler, K.; Roosen, A. Manufacture of 3D structures by cold low pressure lamination of ceramic green tapes. J. Eur. Ceram. Soc. 2009, 29, 899–904. [Google Scholar] [CrossRef]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Przekop, R.E.; Gabriel, E.; Pakuła, D.; Sztorch, B. Liquid for Fused Deposition Modeling Technique (L-FDM)—A Revolution in Application Chemicals to 3D Printing Technology: Color and Elements. Appl. Sci. 2023, 13, 7393. [Google Scholar]

- Donate, R.; Monzón, M.; Alemán-Domínguez, M.E. Additive manufacturing of PLA-based scaffolds intended for bone regeneration and strategies to improve their biological properties. e-Polymers 2020, 20, 571–599. [Google Scholar] [CrossRef]

- Distler, T.; Fournier, N.; Grünewald, A.; Polley, C.; Seitz, H.; Detsch, R.; Boccaccini, A.R. Polymer-Bioactive Glass Composite Filaments for 3D Scaffold Manufacturing by Fused Deposition Modeling: Fabrication and Characterization. Front. Bioeng. Biotechnol. 2020, 8, 552. [Google Scholar] [CrossRef]

- Furong, N.; Xiaole, Y.; Yuanbing, L.; Jinyu, G.; Peng, L.; Zhipeng, X.; Xianfeng, Y. Fused deposition modeling of Si3N4 ceramics: A cost-effective 3D-printing route for dense and high performance non-oxide ceramic materials. J. Eur. Ceram. Soc. 2022, 42, 7369–7376. [Google Scholar] [CrossRef]

- Luo, Y.; Ji, Z.; Leu, M.C.; Caudill, R. Environmental performance analysis of solid freedom fabrication processes. In Proceedings of the 1999 IEEE International Symposium on Electronics and the Environment (Cat. No. 99CH36357), Danvers, MA, USA, 13 May 1999; pp. 1–6. [Google Scholar]

- Sreenivasan, R.; Goel, A.; Bourell, D.L. Sustainability issues in laser-based additive manufacturing. Phys. Procedia 2010, 5, 81–90. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Jawahir, I.; Rouch, K.E.; Dillon, O.; Holloway, L.; Hall, A. Design for sustainability (DFS): New challenges in developing and implementing a curriculum for next generation design and manufacturing engineers. Int. J. Eng. Educ. 2007, 23, 1053–1064. [Google Scholar]

- Výtisk, J.; Honus, S.; Kočí, V.; Pagáč, M.; Hajnyš, J.; Vujanovic, M.; Vrtek, M. Comparative study by life cycle assessment of an air ejector and orifice plate for experimental measuring stand manufactured by conventional manufacturing and additive manufacturing. Sustain. Mater. Technol. 2022, 32, e00431. [Google Scholar] [CrossRef]

- Achillas, C.; Aidonis, D.; Iakovou, E.; Thymianidis, M.; Tzetzis, D. A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory. J. Manuf. Syst. 2015, 37, 328–339. [Google Scholar] [CrossRef]

- Dotchev, K.; Yusoff, W. Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp. J. 2009, 15, 192–203. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Reeves, P. Additive Manufacturing–A Supply Chain Wide Response to Economic Uncertainty and Environmental Sustainability; Econolyst Limited: Wirksworth, UK, 2009. [Google Scholar]

- Khorram Niaki, M.; Nonino, F.; Palombi, G.; Torabi, S.A. Economic sustainability of additive manufacturing: Contextual factors driving its performance in rapid prototyping. J. Manuf. Technol. Manag. 2019, 30, 353–365. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Andries, P.; Debackere, K.; Van Looy, B. Simultaneous experimentation as a learning strategy: Business model development under uncertainty. Strateg. Entrep. J. 2013, 7, 288–310. [Google Scholar] [CrossRef]

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for sustainable additive manufacturing: A review. Sustain. Mater. Technol. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Stefaniak, A.; Johnson, A.; Du Preez, S.; Hammond, D.; Wells, J.; Ham, J.; LeBouf, R.; Martin Jr, S.; Duling, M.; Bowers, L. Insights into emissions and exposures from use of industrial-scale additive manufacturing machines. Saf. Health Work. 2019, 10, 229–236. [Google Scholar] [CrossRef] [PubMed]

- Ameta, K.L.; Solanki, V.S.; Singh, V.; Devi, A.P.; Chundawat, R.; Haque, S. Critical appraisal and systematic review of 3D & 4D printing in sustainable and environment-friendly smart manufacturing technologies. Sustain. Mater. Technol. 2022, 34, e00481. [Google Scholar]

- Kravchenko, M.; Pigosso, D.C.; McAloone, T.C. Circular economy enabled by additive manufacturing: Potential opportunities and key sustainability aspects. In DS 101: Proceedings of NordDesign 2020, Lyngby, Denmark, 12–14 August 2020; The Design Society: Copenhagen, Denmark, 2020; pp. 1–14. [Google Scholar]

- Marchelli, G.; Prabhakar, R.; Storti, D.; Ganter, M. The guide to glass 3D printing: Developments, methods, diagnostics and results. Rapid Prototyp. J. 2011, 17, 187–194. [Google Scholar] [CrossRef]

- Klein, S.; Simske, S.; Adams, G.; Parraman, C.; Walters, P.; Huson, D.; Hoskins, S. 3D printing of transparent glass. In Proceedings of the NIP & Digital Fabrication Conference, Quebec, QC, Canada, 9–13 September 2012; pp. 336–337. [Google Scholar]

- Klein, S.; Dickin, F.; Adams, G.; Simske, S. Glass: An old material for the future of manufacturing. MRS Online Proc. Libr. 2013, 1492, 73–77. [Google Scholar] [CrossRef]

- Annapareddy, A.; Li, M.; Tan, M.J.; Ting, A.G.H.; Tay, D.Y.W. Effect of recycled glass gradation in 3D cementitious material printing. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018. [Google Scholar]

- Ting, G.H.A.; Tay, Y.W.D.; Qian, Y.; Tan, M.J. Utilization of recycled glass for 3D concrete printing: Rheological and mechanical properties. J. Mater. Cycles Waste Manag. 2019, 21, 994–1003. [Google Scholar] [CrossRef]

- Cuevas, K.; Chougan, M.; Martin, F.; Ghaffar, S.H.; Stephan, D.; Sikora, P. 3D printable lightweight cementitious composites with incorporated waste glass aggregates and expanded microspheres–Rheological, thermal and mechanical properties. J. Build. Eng. 2021, 44, 102718. [Google Scholar] [CrossRef]

- Deng, Q.; Zou, S.; Xi, Y.; Singh, A. Development and Characteristic of 3D-Printable Mortar with Waste Glass Powder. Buildings 2023, 13, 1476. [Google Scholar] [CrossRef]

- Małek, M.; Kluczyński, J.; Łasica, W.; Jackowski, M.; Szachogłuchowicz, I.; Łuszczek, J.; Torzewski, J.; Grzelak, K. Performance Properties of Cement–Glass Composite Bricks (CGCB) with Additively Manufactured (AM) Polymeric Scaffolding. Materials 2023, 16, 1909. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Steinbach, J.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Experimental study on mechanical properties of material extrusion additive manufactured parts from recycled glass fibre-reinforced polypropylene composite. Compos. Sci. Technol. 2023, 110125. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled glass fiber composites from wind turbine waste for 3D printing feedstock: Effects of fiber content and interface on mechanical performance. Materials 2019, 12, 3929. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.L. Local and recyclable materials for additive manufacturing: 3D printing with mussel shells. Mater. Today Commun. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Demiral, N.C.; Ekinci, M.O.; Sahin, O.; Ilcan, H.; Kul, A.; Yildirim, G.; Sahmaran, M. Mechanical anisotropy evaluation and bonding properties of 3D-printable construction and demolition waste-based geopolymer mortars. Cem. Concr. Compos. 2022, 134, 104814. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villa, A.; Gianchandani, P.K.; Baino, F. Sustainable Approaches for the Additive Manufacturing of Ceramic Materials. Ceramics 2024, 7, 291-309. https://doi.org/10.3390/ceramics7010019

Villa A, Gianchandani PK, Baino F. Sustainable Approaches for the Additive Manufacturing of Ceramic Materials. Ceramics. 2024; 7(1):291-309. https://doi.org/10.3390/ceramics7010019

Chicago/Turabian StyleVilla, Alice, Pardeep Kumar Gianchandani, and Francesco Baino. 2024. "Sustainable Approaches for the Additive Manufacturing of Ceramic Materials" Ceramics 7, no. 1: 291-309. https://doi.org/10.3390/ceramics7010019

APA StyleVilla, A., Gianchandani, P. K., & Baino, F. (2024). Sustainable Approaches for the Additive Manufacturing of Ceramic Materials. Ceramics, 7(1), 291-309. https://doi.org/10.3390/ceramics7010019