Influence of Nanoceramic-Plated Waste Carbon Fibers on Alkali-Activated Mortar Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. WCFs

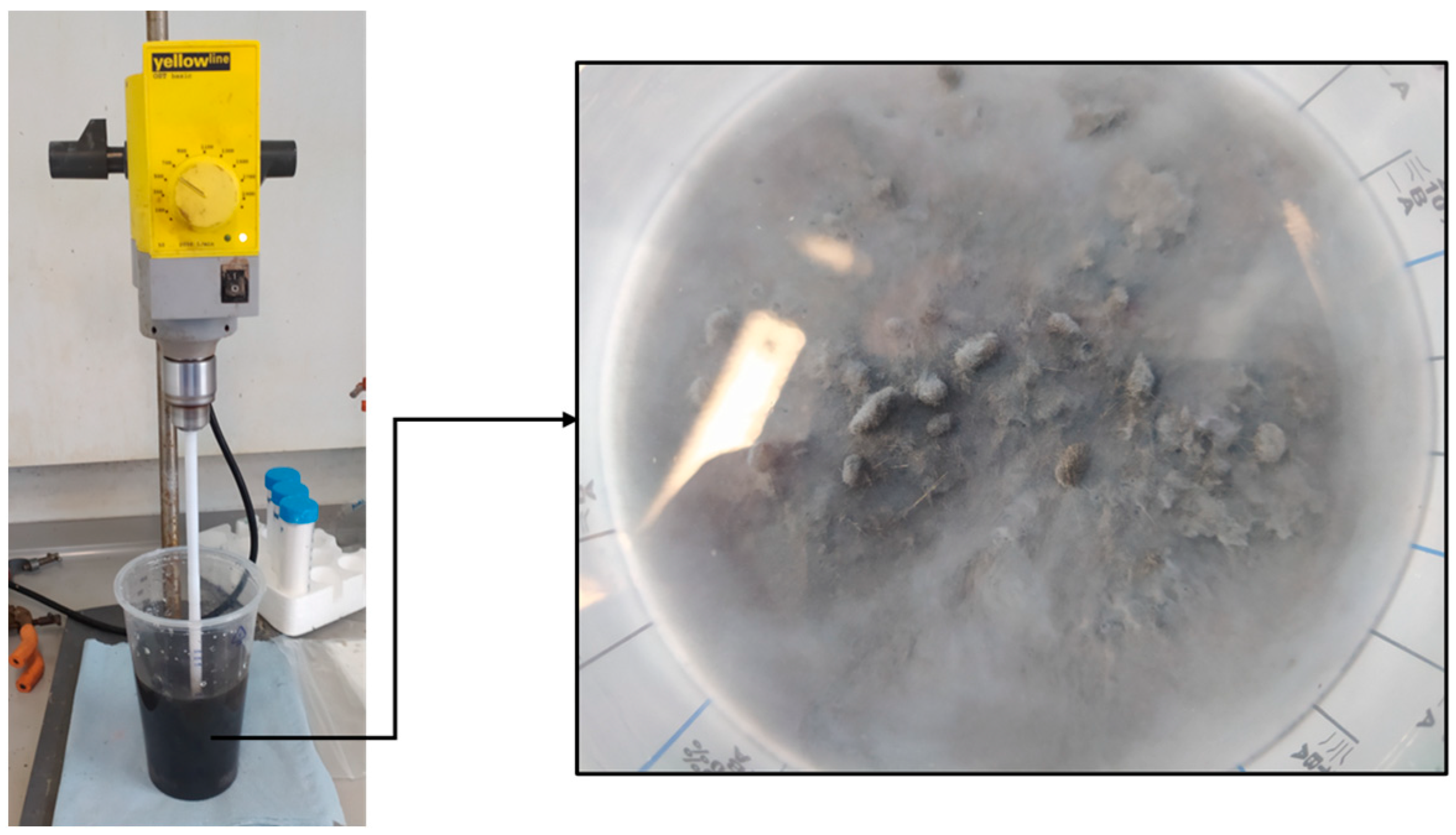

2.1.2. Surface Activation on WCFs

2.1.3. Fiber-Reinforced AAM Composites: Materials, Mix Designs, and Samples Fabrication

2.2. Methods

2.2.1. Characterization of WCFs after ANC-Based Conditioning

2.2.2. Test Methods for Fiber-Reinforced AAM Composites

3. Results

3.1. Characterization of WCFs after ANC-Based Conditioning

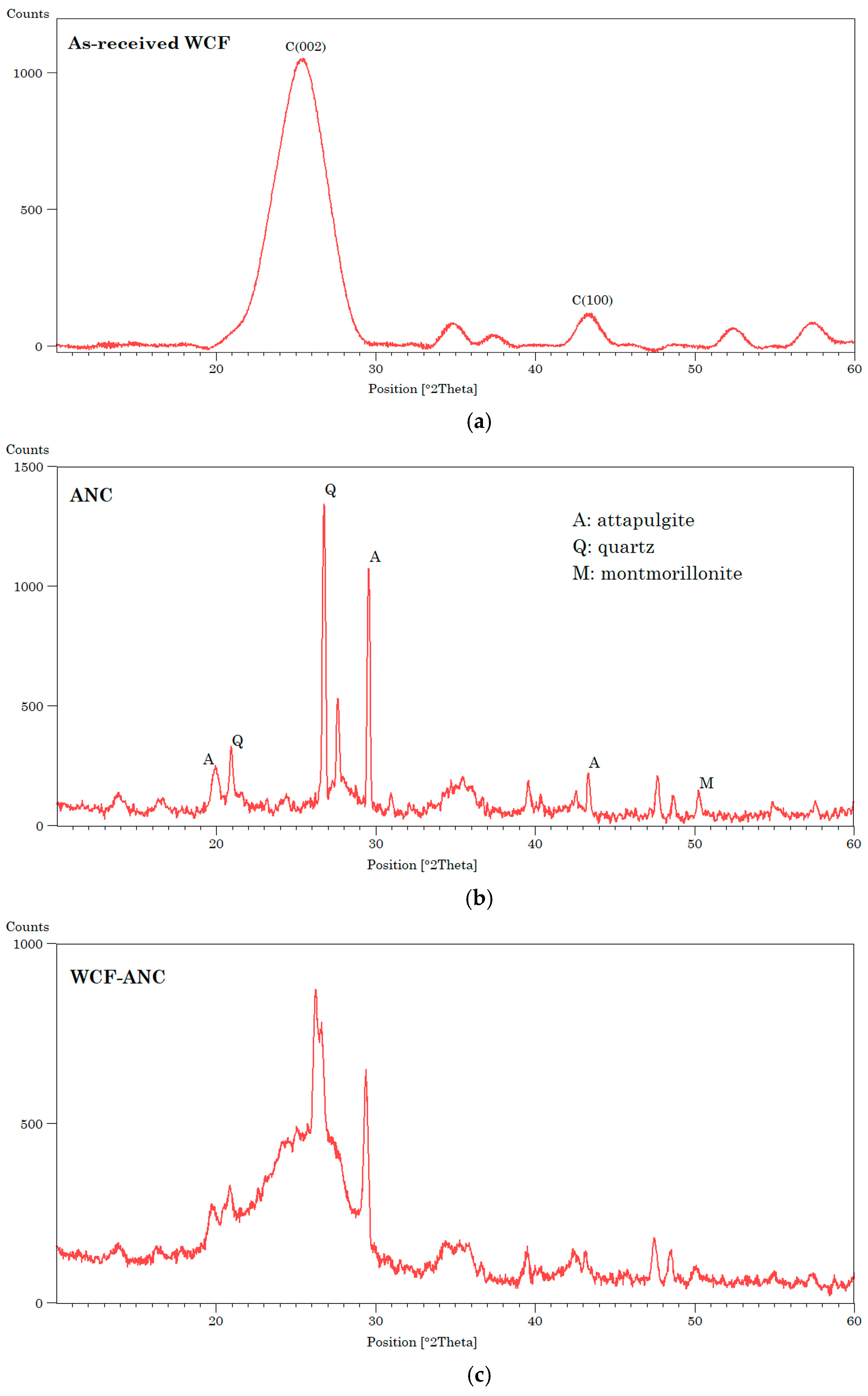

3.1.1. Influence of Nanoceramic-Plating on Crystallite Structure of WCFs

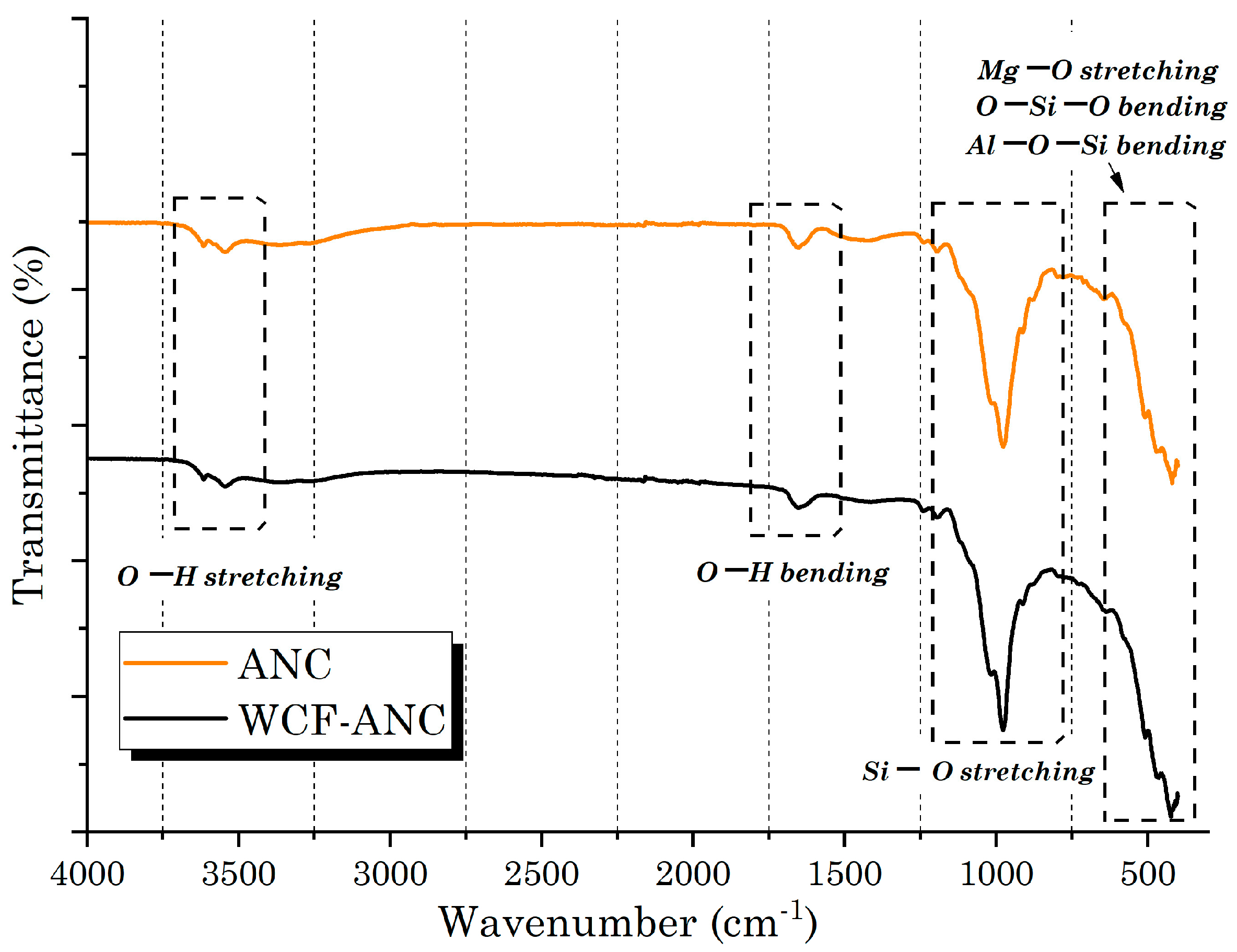

3.1.2. Influence of Nanoceramic-Plating on Surface Chemistry of WCFs

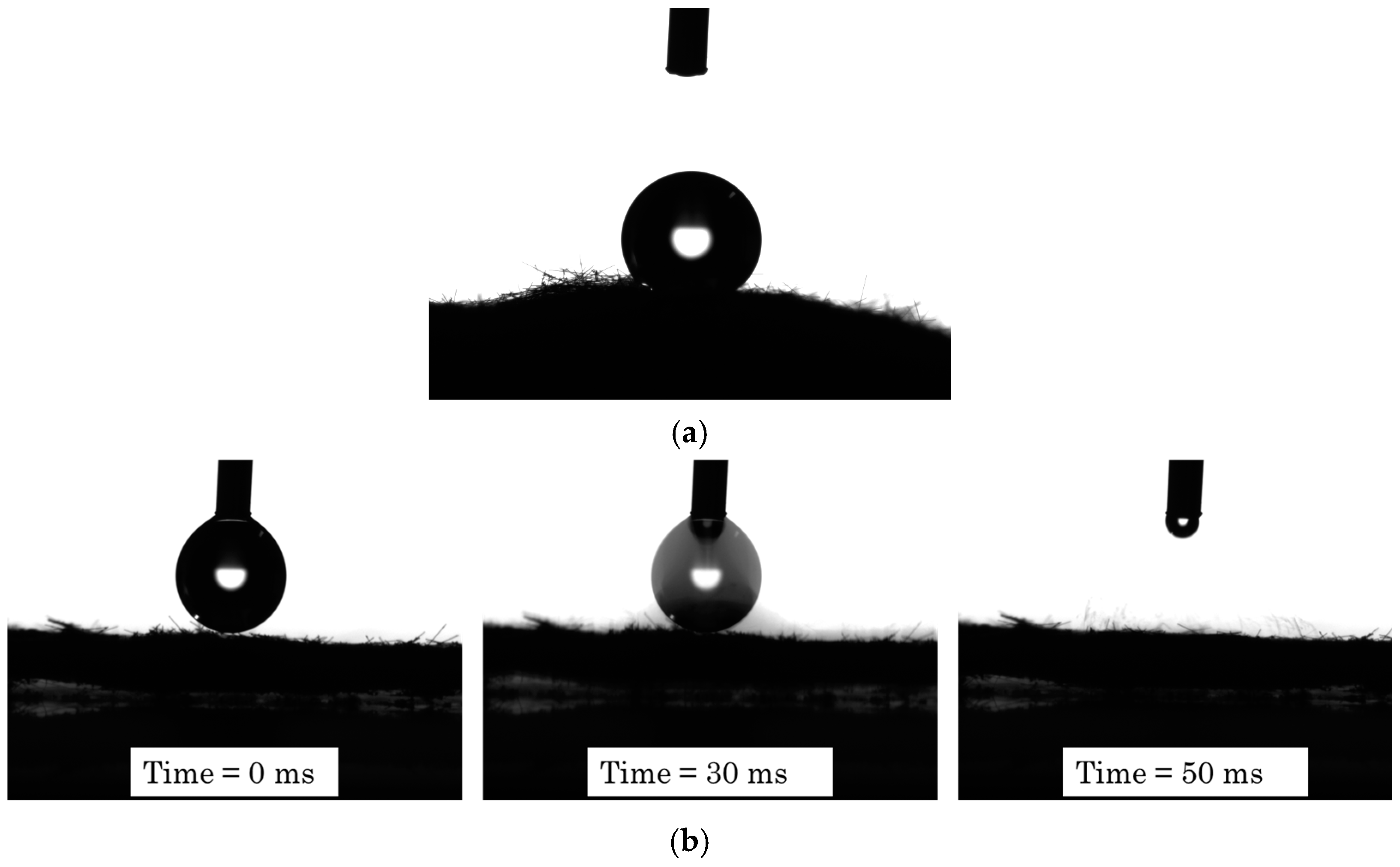

3.1.3. Influence of Nanoceramic-Plating on Surface Hydrophilicity of WCFs

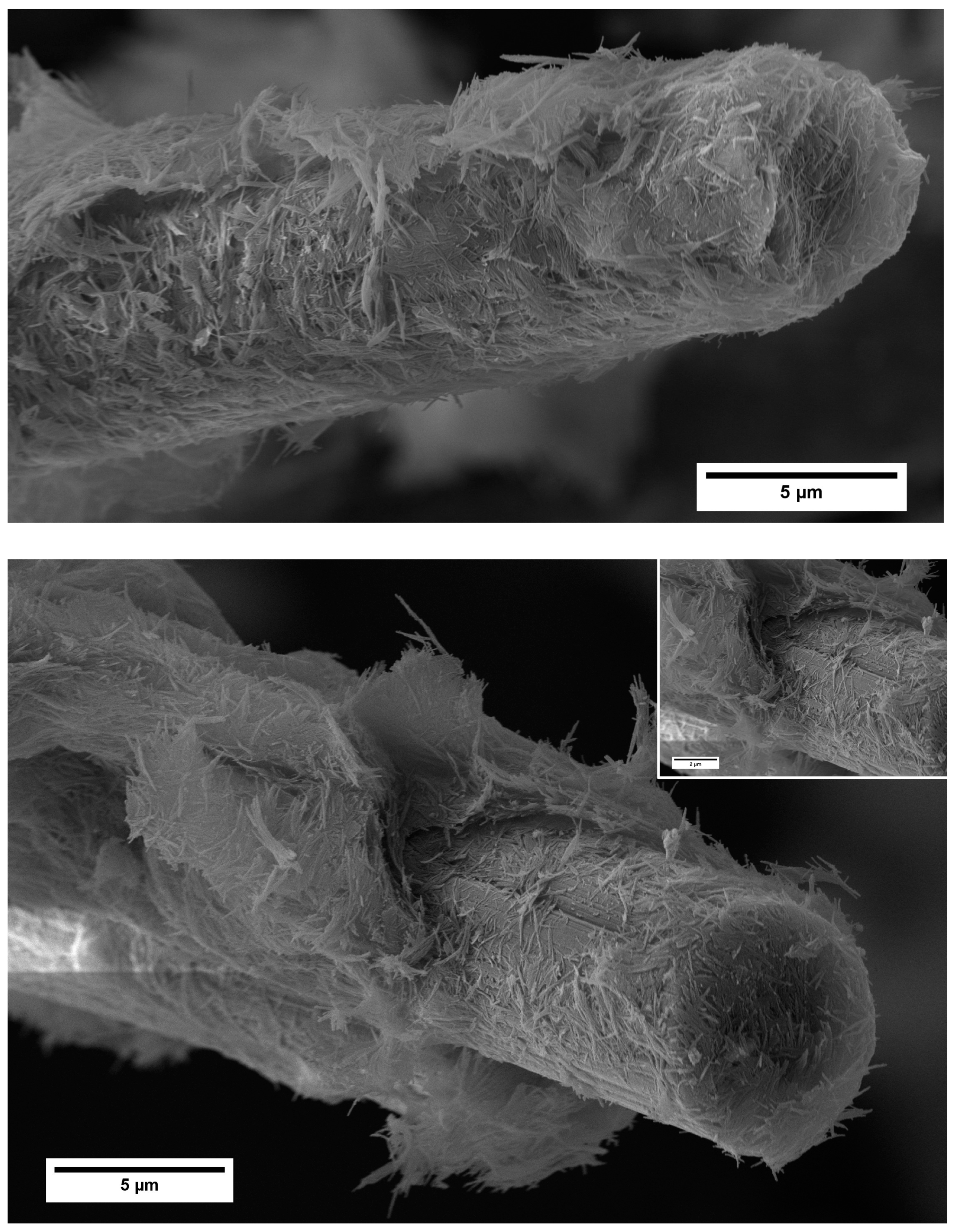

3.1.4. Influence of Nanoceramic-Plating on Microstructure of WCF

3.2. Characterization of Fiber-Reinforced AAM Composites

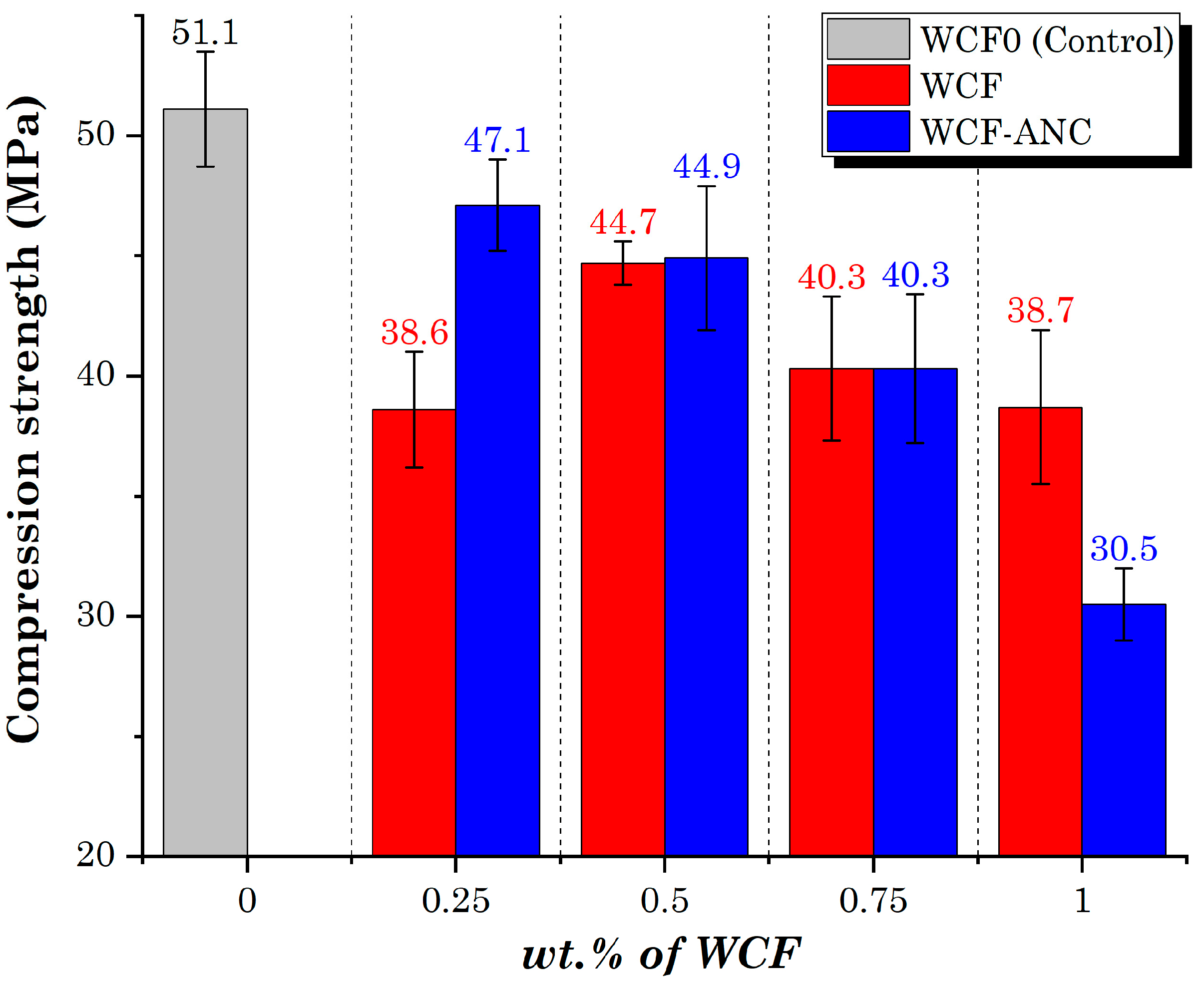

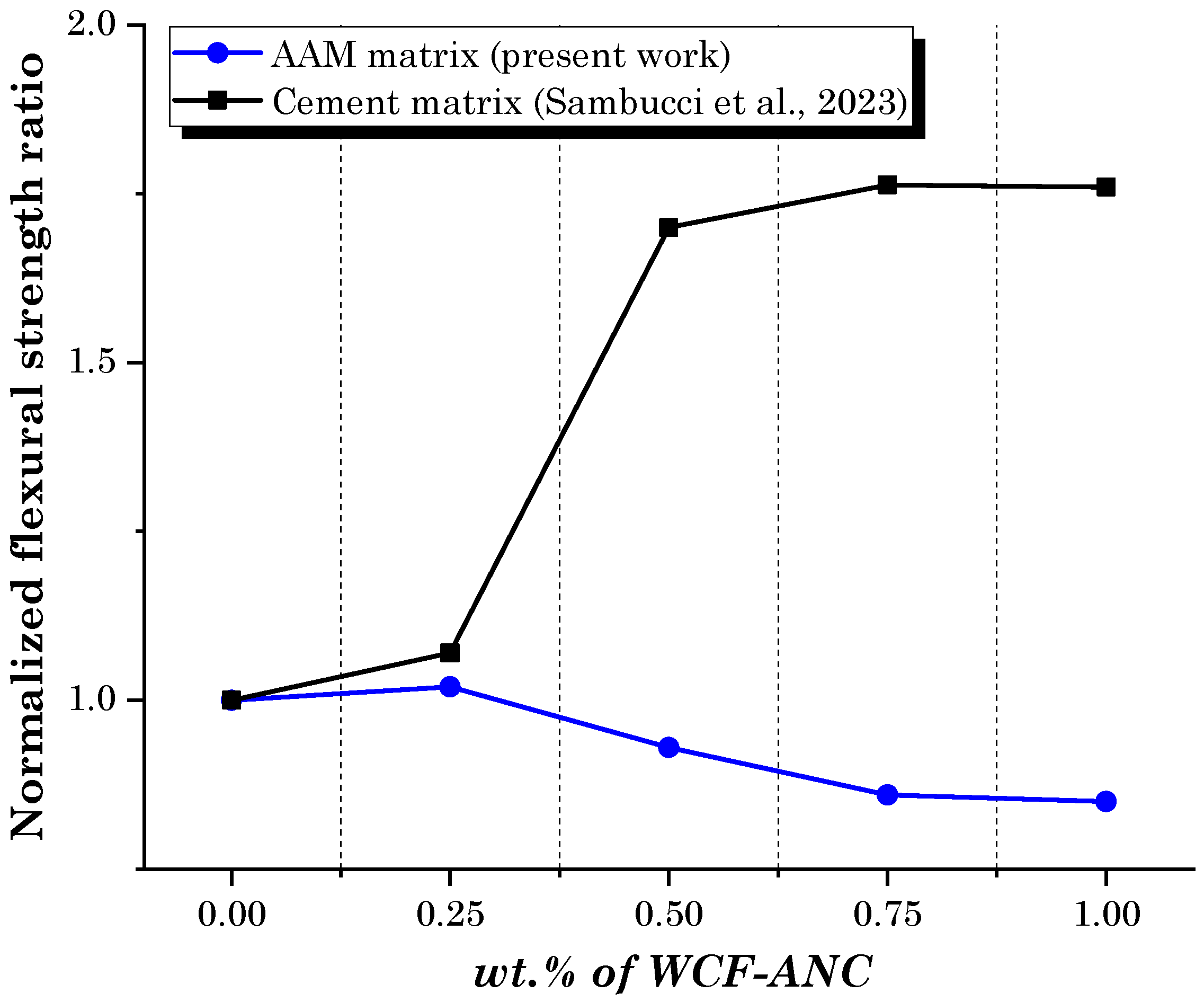

3.2.1. Flexural and Compression Mechanical Testing

3.2.2. SEM Fractography Analysis

4. Conclusions

- Further targeted analysis conducted on post-conditioned fibers verified an adequate interaction of the nanoceramic coating with WCFs and a significant increase in hydrophilicity, thus promoting the deagglomeration of the fibrous clusters.

- The mortars produced with ANC-treated WCF showed improvements in mechanical strength compared to those incorporating unconditioned fibers. The maximum increment in flexural strength (+19%) was found in WCF0.25-ANC. As the fiber dosage increased, the improving effect was gradually reduced due to the ineffectiveness of the nanoceramic treatment in compensating for fiber declustering.

- Only the formulation with the lowest fiber content (WCF0.25-ANC) proved a slight improvement in flexural performance compared to the plain mortar. This result corroborates the above conclusion regarding the difficulty of ensuring a stable integration of the reinforcement for high WCF concentrations.

- From the microstructural analysis, it was clear that the presence of WCF agglomerates, in addition to acting as structural defects, limited the alkaline activation and dissolution of the aluminosilicate precursors, mitigating the proper strength development of the matrix. In this sense, fiber declustering is crucial. Fiber breakage appeared to be the main failure mechanism of the mortars incorporating nanoceramic-functionalized fibers, indicating good fiber–matrix cohesion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valente, M.; Sambucci, M.; Chougan, M.; Ghaffar, S.H. Composite alkali-activated materials with waste tire rubber designed for additive manufacturing: An eco-sustainable and energy saving approach. J. Mater. Res. Technol. 2023, 24, 3098–3117. [Google Scholar] [CrossRef]

- Eskandarinia, M.; Esmailzade, M.; Aslani, F. Splitting tensile strength of recycled tire steel fiber-reinforced alkali-activated slag concrete designed by Taguchi method. Struct. Concr. 2023, 24, 3365–3384. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef] [PubMed]

- de Souza Abreu, F.; Ribeiro, C.C.; da Silva Pinto, J.D.; Nsumbu, T.M.; Buono, V.T.L. Influence of adding discontinuous and dispersed carbon fiber waste on concrete performance. J. Clean. Prod. 2020, 273, 122920. [Google Scholar] [CrossRef]

- Xu, J.; Yin, T.; Wang, Y.; Liu, L. Anisotropic electrical and piezoresistive sensing properties of cement-based sensors with aligned carbon fibers. Cem. Concr. Compos. 2021, 116, 103873. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives. Autom. Constr. 2020, 110, 103002. [Google Scholar] [CrossRef]

- Jiang, L.; Ulven, C.A.; Gutschmidt, D.; Anderson, M.; Balo, S.; Lee, M.; Vigness, J. Recycling carbon fiber composites using microwave irradiation: Reinforcement study of the recycled fiber in new composites. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Lamba, N.; Raj, R.; Singh, P. The effects of recycled carbon fibers on the mechanical properties of high-strength concrete and its resilience to impact. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 1–23. [Google Scholar] [CrossRef]

- Patchen, A.; Young, S.; Penumadu, D. An Investigation of Mechanical Properties of Recycled Carbon Fiber Reinforced Ultra-High-Performance Concrete. Materials 2023, 16, 314. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L.; Li, A.; Li, W.; Guo, B. Effect of modified recycled carbon fibers on the conductivity of cement-based materials. Constr. Build. Mater. 2024, 415, 135033. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Yang, J.; Davoodabadi, M.; Li, L.; Du, Y.; Yang, B.; Hempel, S.; Mechtcherine, V. Electrochemical oxidation of recycled carbon fibers for an improved interaction toward alkali-activated composites. J. Clean. Prod. 2022, 368, 133093. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Monte, M.C.; Blanco, A.; Negro, C. Recycled Fibers for Sustainable Hybrid Fiber Cement Based Material: A Review. Materials 2021, 14, 2408. [Google Scholar] [CrossRef] [PubMed]

- Sambucci, M.; Valente, M.; Nouri, S.M.; Chougan, M.; Ghaffar, S.H. Enhanced Compatibility of Secondary Waste Carbon Fibers through Surface Activation via Nanoceramic Coating in Fiber-Reinforced Cement Mortars. Coatings 2023, 13, 1466. [Google Scholar] [CrossRef]

- Sambucci, M.; Nouri, S.M.; Tayebi, S.T.; Valente, M. Synergic Effect of Recycled Carbon Fibers and Microfibrillated Cellulose Gel for Enhancing the Mechanical Properties of Cement-Based Materials. Gels 2023, 9, 981. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Chougan, M.; Al-kheetan, M.J.; Yio, M.H.; Wong, H.S.; Ghaffar, S.H. Upcycling end-of-life bricks in high-performance one-part alkali-activated materials. Dev. Built Environ. 2024, 16, 100231. [Google Scholar] [CrossRef]

- Toto, E.; Laurenzi, S.; Pellegrini, R.C.; Cavallini, E.; Santonicola, M.G. Eco-friendly synthesis of high-performance polyimide materials using bio-based greener solvents: Towards sustainable technologies in space environment. Mater. Today Sustain. 2024, 25, 100657. [Google Scholar] [CrossRef]

- Methods of Testing Cement. Part 1: Determination of Strength; BS EN 196-1:2016; BSI: London, UK, 2016. [Google Scholar]

- Jiang, G.; Pickering, S.J. Structure–property relationship of recycled carbon fibres revealed by pyrolysis recycling process. J. Mater. Sci. 2016, 51, 1949–1958. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, Y.; Li, X.; Wang, L.; He, X.; Ma, Y.; Zou, D. The Immobilization Effect of Natural Mineral Materials on Cr(VI) Remediation in Water and Soil. Int. J. Environ. Res. Public Health 2020, 17, 2832. [Google Scholar] [CrossRef]

- Elbassyoni, S.; Kamoun, E.A.; Taha, T.H.; Rashed, M.A.; ElNozahi, F.A. Effect of Egyptian attapulgite clay on the properties of PVA-HES–clay nanocomposite hydrogel membranes for wound dressing applications. Arab. J. Sci. Eng. 2020, 45, 4737–4749. [Google Scholar] [CrossRef]

- Chung, D.D. Dispersion of short fibers in cement. J. Mater. Civ. Eng. 2005, 17, 379–383. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Metselaar, H.S.C.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Diblíková, L.; Mašek, Z.; Král, M. The effect of carbon fiber plasma treatment on the wettability and interlaminar shear strength of geopolymer composite. J. Aust. Ceram. Soc. 2019, 55, 1139–1145. [Google Scholar] [CrossRef]

- Zhang, R.; Li, F.; Zhou, S.; Hou, Y. Carbon nanofiber dispersion in alkali solution and its reinforcement of alkali-activated volcanic ash-based geopolymers. J. Clean. Prod. 2023, 405, 137021. [Google Scholar] [CrossRef]

- Lindström, T.; Banke, K.; Larsson, T.; Glad-Nordmark, G.; Boldizar, A. Nanoclay plating of cellulosic fiber surfaces. J. Appl. Polym. Sci. 2008, 108, 887–891. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Y.; Pan, T.; Yin, K. The Synergistic Effect of Ester-Ether Copolymerization Thixo-Tropic Superplasticizer and Nano-Clay on the Buildability of 3D Printable Cementitious Materials. Materials 2021, 14, 4622. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Li, J.; Bian, D.; Ni, Z.; Qian, S.; Zhao, Y. Improving the Tribological Performance of Phosphate-Bonded Coatings Reinforced by Carbon Fiber/Graphene Oxide. ACS Appl. Nano Mater. 2023, 6, 13374–13384. [Google Scholar] [CrossRef]

- Zhang, P.; Zhao, Y.N.; Liu, C.H.; Wang, P.; Zhang, T.H. Combined effect of nano-SiO2 particles and steel fibers on flexural properties of concrete composite containing fly ash. Sci. Eng. Compos. Mater. 2014, 21, 597–605. [Google Scholar] [CrossRef]

- Wang, C.; Li, K.Z.; Li, H.J.; Jiao, G.S.; Lu, J.; Hou, D.S. Effect of carbon fiber dispersion on the mechanical properties of carbon fiber-reinforced cement-based composites. Mater. Sci. Eng. A 2008, 487, 52–57. [Google Scholar] [CrossRef]

- Akbar, A.; Kodur, V.K.R.; Liew, K.M. Microstructural changes and mechanical performance of cement composites reinforced with recycled carbon fibers. Cem. Concr. Compos. 2021, 121, 104069. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Cui, Y.; Hao, H.; Li, J.; Chen, W. Effect of adding methylcellulose on mechanical and vibration properties of geopolymer paste and hybrid fiber-reinforced geopolymer composite. J. Mater. Civ. Eng. 2020, 32, 04020166. [Google Scholar] [CrossRef]

- Criado, M.; Palomo, A.; Fernández-Jiménez, A.; Banfill, P.F.G. Alkali activated fly ash: Effect of admixtures on paste rheology. Rheol. Acta 2009, 48, 447–455. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Zhang, P.; Wang, Z.; Wang, M. Parametric Study on Mechanical Properties of Basalt Fiber-Reinforced Pea Gravel Concrete. Buildings 2024, 14, 380. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Z.; Shi, C.; Wu, Z.; Zhang, C. Steel fiber–matrix interfacial bond in ultra-high performance concrete: A review. Engineering 2023, 22, 215–232. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Sikora, P.; Mijowska, E.; Kukułka, W.; Stephan, D. Boosting Portland cement-free composite performance via alkali-activation and reinforcement with pre-treated functionalised wheat straw. Ind. Crops Prod. 2022, 178, 114648. [Google Scholar] [CrossRef]

- Gu, G.; Pei, Y.; Ma, T.; Chen, F.; Zhang, J.; Xu, F. Role of carbon fiber in the electrothermal behavior and geopolymerization process of carbon fiber-reinforced FA-GBFS geopolymer composite. Constr. Build. Mater. 2023, 369, 130597. [Google Scholar] [CrossRef]

| Average Fiber Length (μm) | Fiber Diameter (μm) | Agglomerate Density (kg/m3) |

|---|---|---|

| 550 | 6.6 | 1697 |

| Sample ID | Precursor (kg/m3) | Aggregate (kg/m3) | Activator (kg/m3) | Water (kg/m3) | Filler (kg/m3) | ||||

|---|---|---|---|---|---|---|---|---|---|

| FA | GGBS | Fine Sand | Coarse Sand | Quartz Sand | Na2SiO3 | WCF | ANC | ||

| WCF0 | 690 | 450 | 700 | 465 | 200 | 135 | 375 | - | - |

| WCF0.25 | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 2.85 | - |

| WCF0.5 | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 5.70 | - |

| WCF0.75 | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 8.55 | - |

| WCF1 | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 11.40 | - |

| WCF0.25-ANC | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 2.85 | 2.85 |

| WCF0.5-ANC | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 5.70 | 5.70 |

| WCF0.75-ANC | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 8.55 | 8.55 |

| WCF1-ANC | 690 | 450 | 700 | 465 | 200 | 135 | 375 | 11.40 | 11.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sambucci, M.; Al-Noaimat, Y.A.; Nouri, S.M.; Chougan, M.; Ghaffar, S.H.; Valente, M. Influence of Nanoceramic-Plated Waste Carbon Fibers on Alkali-Activated Mortar Performance. Ceramics 2024, 7, 821-839. https://doi.org/10.3390/ceramics7020054

Sambucci M, Al-Noaimat YA, Nouri SM, Chougan M, Ghaffar SH, Valente M. Influence of Nanoceramic-Plated Waste Carbon Fibers on Alkali-Activated Mortar Performance. Ceramics. 2024; 7(2):821-839. https://doi.org/10.3390/ceramics7020054

Chicago/Turabian StyleSambucci, Matteo, Yazeed A. Al-Noaimat, Seyed Mostafa Nouri, Mehdi Chougan, Seyed Hamidreza Ghaffar, and Marco Valente. 2024. "Influence of Nanoceramic-Plated Waste Carbon Fibers on Alkali-Activated Mortar Performance" Ceramics 7, no. 2: 821-839. https://doi.org/10.3390/ceramics7020054

APA StyleSambucci, M., Al-Noaimat, Y. A., Nouri, S. M., Chougan, M., Ghaffar, S. H., & Valente, M. (2024). Influence of Nanoceramic-Plated Waste Carbon Fibers on Alkali-Activated Mortar Performance. Ceramics, 7(2), 821-839. https://doi.org/10.3390/ceramics7020054