Scratch-Induced Wear Behavior of Multi-Component Ultra-High-Temperature Ceramics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Solid-Solution Synthesis of MC-UHTCs

2.2. Scratch Testing and Characterization of Worn Surface

3. Results and Discussion

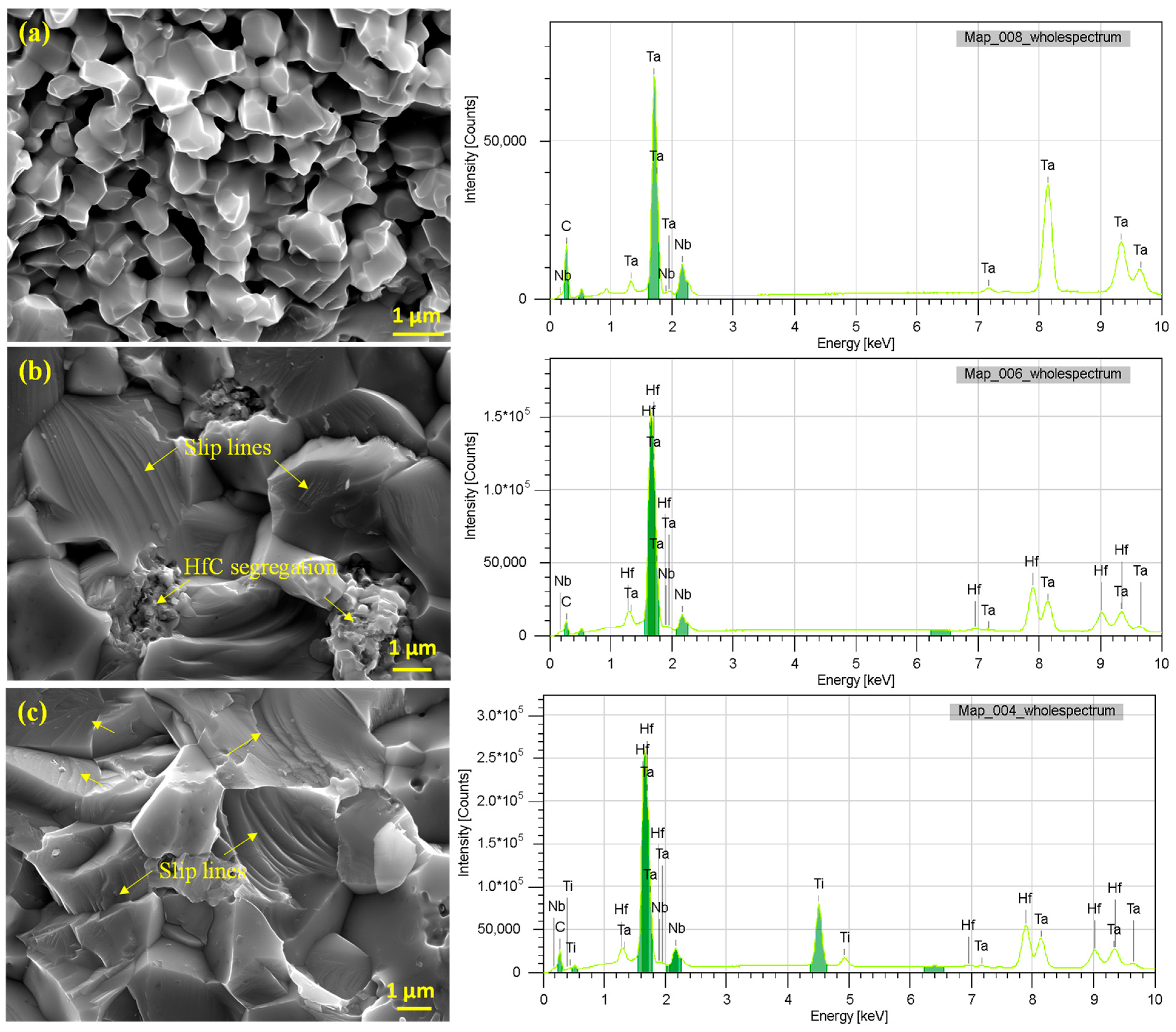

3.1. Microstructural Analysis of MC-UHTCs

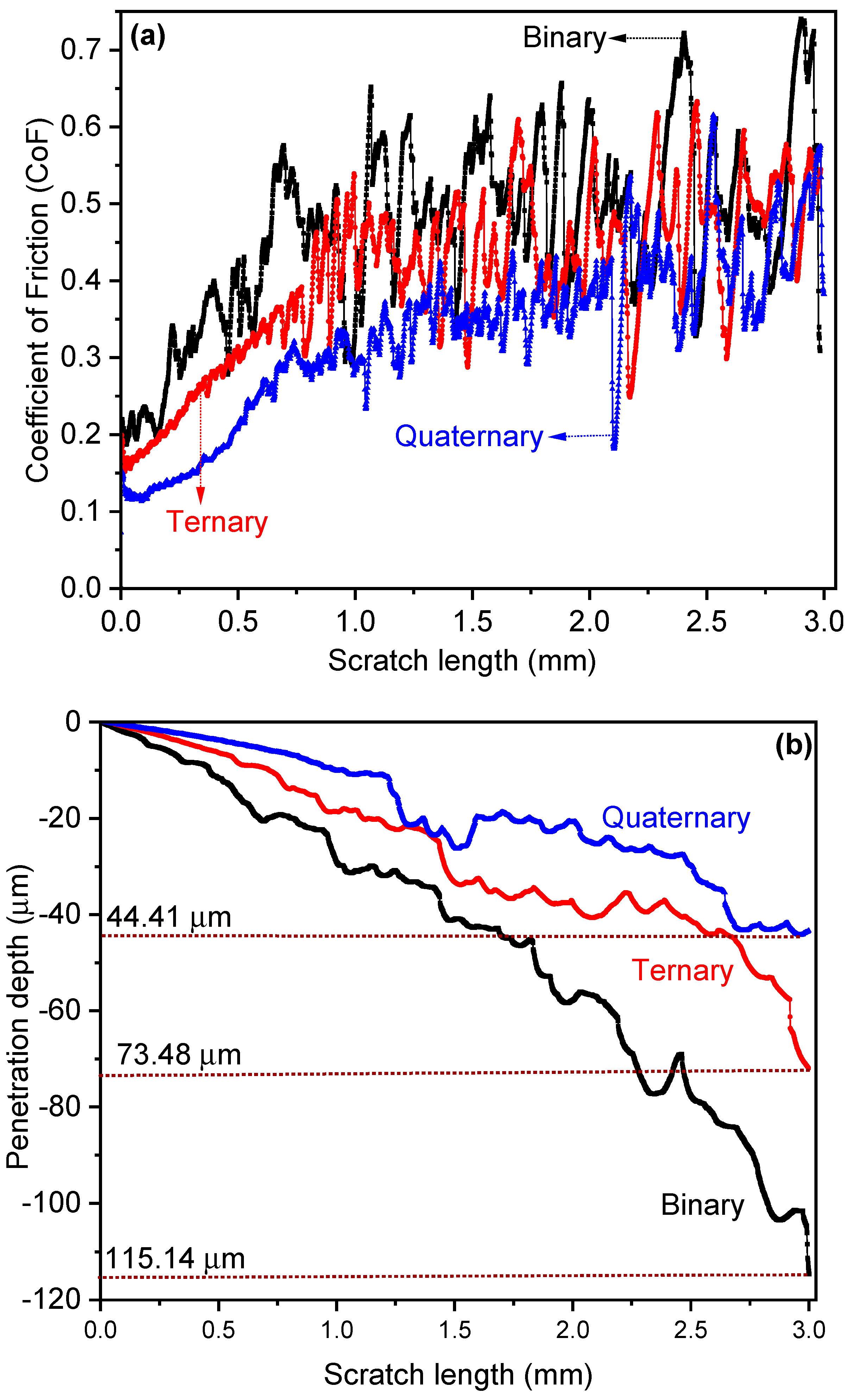

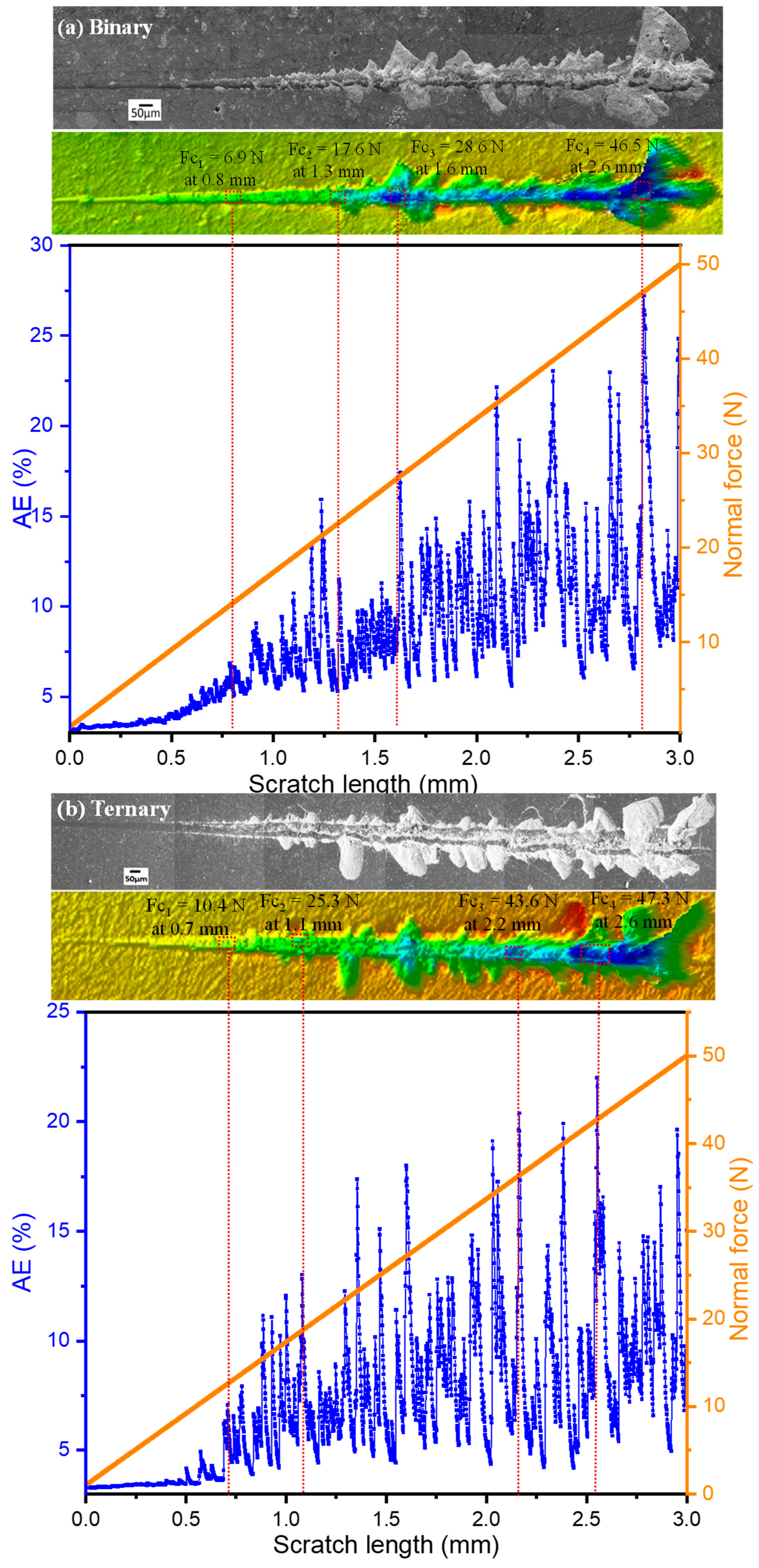

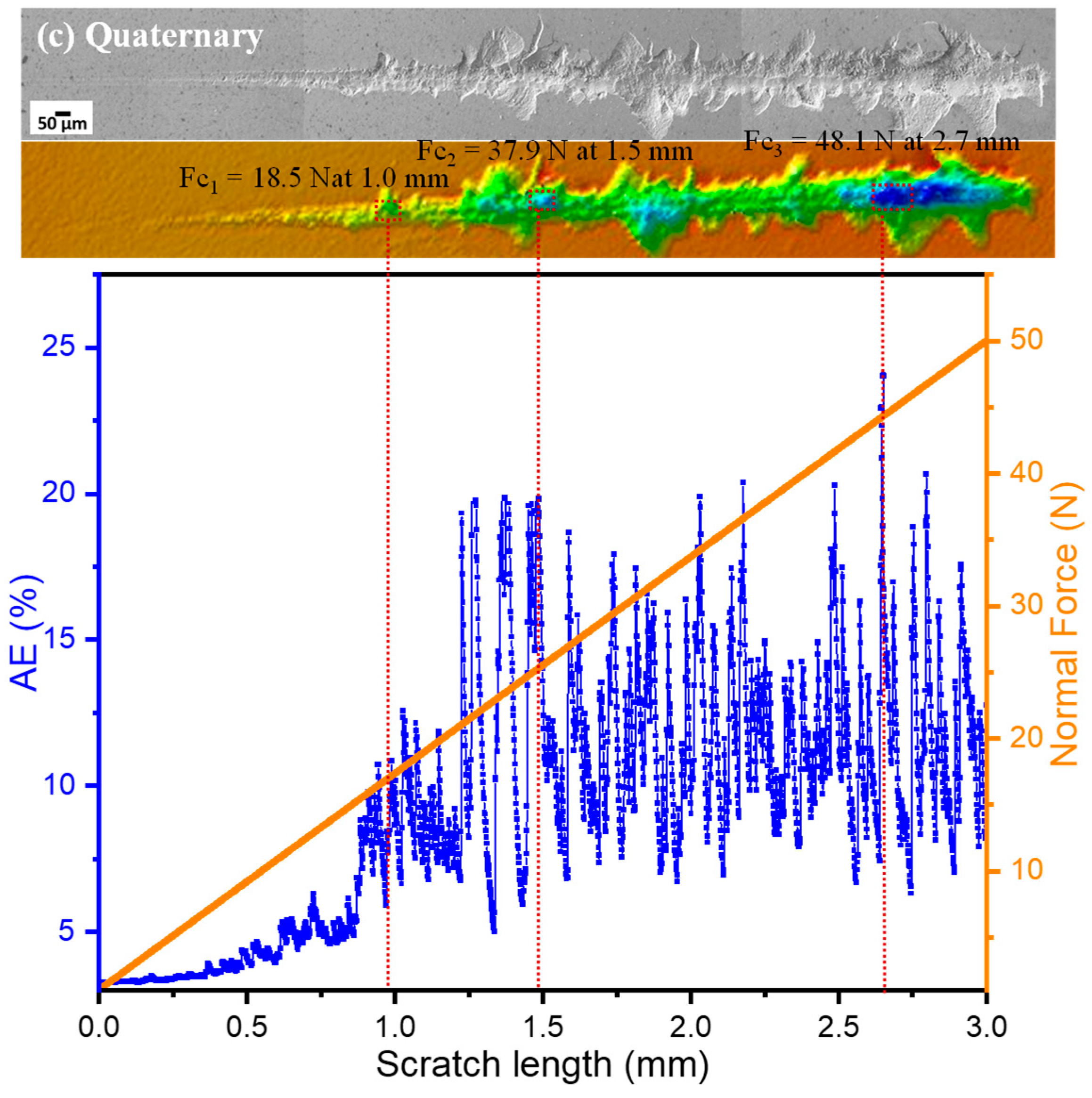

3.2. Wear Behavior of MC-UHTCs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fahrenholtz, W.G.; Hilmas, G.E. Ultra-high temperature ceramics: Materials for extreme environments. Scr. Mater. 2017, 129, 94–99. [Google Scholar] [CrossRef]

- Upadhya, K.; Yang, J.M.; Hoffman, W. Advanced materials for ultrahigh temperature structural applications above 2000 deg C. Am. Ceram. Soc. Bull 1997, 76, 23. [Google Scholar]

- Wuchina, E.; Opila, E.; Opeka, M.; Fahrenholtz, B.; Talmy, I. UHTCs: Ultra-high temperature ceramic materials for extreme environment applications. Electrochem. Soc. Interface 2007, 16, 30. [Google Scholar] [CrossRef]

- Zhou, Y. Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications; American Ceramic Society/Wiley: Westerville, NJ, USA, 2014. [Google Scholar]

- Eakins, E.; Jayaseelan, D.D.; Lee, W.E. Toward oxidation-resistant ZrB 2-SiC ultra high temperature ceramics. Metall. Mater. Trans. A 2011, 42, 878–887. [Google Scholar] [CrossRef]

- Hwang, S.S.; Vasiliev, A.L.; Padture, N.P. Improved processing and oxidation-resistance of ZrB2 ultra-high temperature ceramics containing SiC nanodispersoids. Mater. Sci. Eng. A 2007, 464, 216–224. [Google Scholar] [CrossRef]

- Zhang, X.-H.; Hu, P.; Han, J.-C. Structure evolution of ZrB2–SiC during the oxidation in air. J. Mater. Res. 2008, 23, 1961–1972. [Google Scholar] [CrossRef]

- Peng, F.; Berta, Y.; Speyer, R.F. Effect of SiC, TaB2 and TaSi2 additives on the isothermal oxidation resistance of fully dense zirconium diboride. J. Mater. Res. 2009, 24, 1855–1867. [Google Scholar] [CrossRef]

- Oses, C.; Toher, C.; Curtarolo, S. High-entropy ceramics. Nat. Rev. Mater. 2020, 5, 295–309. [Google Scholar] [CrossRef]

- Shu, R.; Paschalidou, E.-M.; Rao, S.G.; Lu, J.; Greczynski, G.; Lewin, E.; Nyholm, L.; Le Febvrier, A.; Eklund, P. Microstructure and mechanical, electrical, and electrochemical properties of sputter-deposited multicomponent (TiNbZrTa) Nx coatings. Surf. Coat. Technol. 2020, 389, 125651. [Google Scholar] [CrossRef]

- Nisar, A.; Zhang, C.; Boesl, B.; Agarwal, A. A perspective on challenges and opportunities in developing high entropy-ultra high temperature ceramics. Ceram. Int. 2020, 46, 25845–25853. [Google Scholar] [CrossRef]

- Albedwawi, S.H.; AlJaberi, A.; Haidemenopoulos, G.N.; Polychronopoulou, K. High entropy oxides-exploring a paradigm of promising catalysts: A review. Mater. Des. 2021, 202, 109534. [Google Scholar] [CrossRef]

- Feng, L.; Fahrenholtz, W.G.; Brenner, D.W. High-entropy ultra-high-temperature borides and carbides: A new class of materials for extreme environments. Annu. Rev. Mater. Res. 2021, 51, 165–185. [Google Scholar] [CrossRef]

- Wang, F.; Monteverde, F.; Cui, B. Will high-entropy carbides and borides be enabling materials for extreme environments? Int. J. Extrem. Manuf. 2023, 5, 022002. [Google Scholar] [CrossRef]

- Gild, J.; Zhang, Y.; Harrington, T.; Jiang, S.; Hu, T.; Quinn, M.C.; Mellor, W.M.; Zhou, N.; Vecchio, K.; Luo, J. High-entropy metal diborides: A new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Sci. Rep. 2016, 6, 37946. [Google Scholar] [CrossRef]

- Sarker, P.; Harrington, T.; Toher, C.; Oses, C.; Samiee, M.; Maria, J.-P.; Brenner, D.W.; Vecchio, K.S.; Curtarolo, S. High-entropy high-hardness metal carbides discovered by entropy descriptors. Nat. Commun. 2018, 9, 4980. [Google Scholar] [CrossRef] [PubMed]

- Dippo, O.F.; Mesgarzadeh, N.; Harrington, T.J.; Schrader, G.D.; Vecchio, K.S. Bulk high-entropy nitrides and carbonitrides. Sci. Rep. 2020, 10, 21288. [Google Scholar] [CrossRef]

- Moskovskikh, D.; Vorotilo, S.; Buinevich, V.; Sedegov, A.; Kuskov, K.; Khort, A.; Shuck, C.; Zhukovskyi, M.; Mukasyan, A. Extremely hard and tough high entropy nitride ceramics. Sci. Rep. 2020, 10, 19874. [Google Scholar] [CrossRef]

- Post, B.; Glaser, F.W.; Moskowitz, D. Transition metal diborides. Acta Metall. 1954, 2, 20–25. [Google Scholar] [CrossRef]

- Xiang, H.; Wang, J.; Zhou, Y. Theoretical predictions on intrinsic lattice thermal conductivity of ZrB3. J. Eur. Ceram. Soc. 2019, 39, 2982–2988. [Google Scholar] [CrossRef]

- Yan, X.; Constantin, L.; Lu, Y.; Silvain, J.F.; Nastasi, M.; Cui, B. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2) C high-entropy ceramics with low thermal conductivity. J. Am. Ceram. Soc. 2018, 101, 4486–4491. [Google Scholar]

- Lu, K.; Liu, J.-X.; Wei, X.-F.; Bao, W.; Wu, Y.; Li, F.; Xu, F.; Zhang, G.-J. Microstructures and mechanical properties of high-entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) C ceramics with the addition of SiC secondary phase. J. Eur. Ceram. Soc. 2020, 40, 1839–1847. [Google Scholar] [CrossRef]

- Han, X.; Girman, V.; Sedlak, R.; Dusza, J.; Castle, E.G.; Wang, Y.; Reece, M.; Zhang, C. Improved creep resistance of high entropy transition metal carbides. J. Eur. Ceram. Soc. 2020, 40, 2709–2715. [Google Scholar] [CrossRef]

- Chen, H.; Xiang, H.; Dai, F.-Z.; Liu, J.; Zhou, Y. Porous high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2) B2: A novel strategy towards making ultrahigh temperature ceramics thermal insulating. J. Mater. Sci. Technol. 2019, 35, 2404–2408. [Google Scholar]

- Chen, H.; Xiang, H.; Dai, F.-Z.; Liu, J.; Zhou, Y. Low thermal conductivity and high porosity ZrC and HfC ceramics prepared by in-situ reduction reaction/partial sintering method for ultrahigh temperature applications. J. Mater. Sci. Technol. 2019, 35, 2778–2784. [Google Scholar] [CrossRef]

- Sun, Q.; Tan, H.; Zhu, S.; Zhu, Z.; Wang, L.; Cheng, J.; Yang, J. Single-phase (Hf-Mo-Nb-Ta-Ti) C high-entropy ceramic: A potential high temperature anti-wear material. Tribol. Int. 2021, 157, 106883. [Google Scholar] [CrossRef]

- Kavak, S.; Bayrak, K.G.; Bellek, M.; Mertdinç, S.; Muhaffel, F.; Gökçe, H.; Ayas, E.; Derin, B.; Öveçoğlu, M.L.; Ağaoğulları, D. Synthesis and characterization of (HfMoTiWZr) C high entropy carbide ceramics. Ceram. Int. 2022, 48, 7695–7705. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Z.; Liu, M.; Hai, W.; Sun, W. Synthesis, microstructure and mechanical properties of high-entropy (VNbTaMoW) C5 ceramics. J. Eur. Ceram. Soc. 2021, 41, 7498–7506. [Google Scholar] [CrossRef]

- Dusza, J.; Csanádi, T.; Medveď, D.; Sedlák, R.; Vojtko, M.; Ivor, M.; Ünsal, H.; Tatarko, P.; Tatarková, M.; Šajgalík, P. Nanoindentation and tribology of a (Hf-Ta-Zr-Nb-Ti) C high-entropy carbide. J. Eur. Ceram. Soc. 2021, 41, 5417–5426. [Google Scholar] [CrossRef]

- Jin, X.; Hou, C.; Zhao, Y.; Wang, Z.; Wang, J.; Fan, X. Mechanical properties and deformation mechanisms of (Ti0.2Zr0.2Nb0.2Hf0.2Ta0.2)C high-entropy ceramics characterized by nanoindentation and scratch tests. Ceram. Int. 2022, 48, 35445–35451. [Google Scholar] [CrossRef]

- Nisar, A.; Balani, K. Role of Interfaces on Multi-length Scale Wear Mechanics of TaC-based Composites. Adv. Eng. Mater. 2017, 19, 1600713. [Google Scholar] [CrossRef]

- Jaworski, R.; Pawlowski, L.; Roudet, F.; Kozerski, S.; Petit, F. Characterization of mechanical properties of suspension plasma sprayed TiO2 coatings using scratch test. Surf. Coat. Technol. 2008, 202, 2644–2653. [Google Scholar] [CrossRef]

- Kumar, N.; Barve, S.A.; Chopade, S.S.; Kar, R.; Chand, N.; Dash, S.; Tyagi, A.K.; Patil, D.S. Scratch resistance and tribological properties of SiOx incorporated diamond-like carbon films deposited by rf plasma assisted chemical vapor deposition. Tribol. Int. 2015, 84, 124–131. [Google Scholar] [CrossRef]

- Nisar, A.; Dolmetsch, T.; Paul, T.; Sakthivel, T.S.; Zhang, C.; Boesl, B.; Seal, S.; Agarwal, A. Unveiling enhanced oxidation resistance and mechanical integrity of multicomponent ultra-high temperature carbides. J. Am. Ceram. Soc. 2022, 105, 2500–2516. [Google Scholar] [CrossRef]

- Nisar, A.; Sakthivel, T.; Zhang, C.; Boesl, B.; Seal, S.; Agarwal, A. Quantification of complex protective surface oxide layer formed during plasma jet exposure of multicomponent ultra-high temperature carbides. Appl. Surf. Sci. 2022, 592, 153247. [Google Scholar] [CrossRef]

- Nisar, A.; Mohammed, M.A.K.S.; Garino, G.; Kumar, U.; John, D.; Aguiar, A.B.; Seal, S.; Agarwal, A. In-situ Crack Propagation Dynamics in Multicomponent Ultra-High Temperature Carbides. Int. J. Refract. Met. Hard Mater. 2024, 125, 106897. [Google Scholar] [CrossRef]

- Ghosh, D.; Subhash, G.; Bourne, G.R. Room-temperature dislocation activity during mechanical deformation of polycrystalline ultra-high-temperature ceramics. Scr. Mater. 2009, 61, 1075–1078. [Google Scholar] [CrossRef]

| Samples | Densification (%) [34] | Elastic modulus, E (GPa) [34] | Hardness, H (GPa) [34] | CoF | Max. Penetration Depth (µm) |

|---|---|---|---|---|---|

| Binary | 84 | 307.52 ± 36.07 | 15.23 ± 4.51 | 0.741–0.198 | 115.14 ± 5.23 |

| Ternary | 100 | 403.66 ± 9.93 | 33.67 ± 1.69 | 0.635–0.155 | 73.48 ± 6.02 |

| Quaternary | 100 | 381.16 ± 9.82 | 34.82 ± 2.27 | 0.615–0.113 | 44.41 ± 4.82 |

| Samples | Critical Loads (N) | Scratch Width at Max. Load (mm) | Wear Volume (×10−3 mm3) | |||

|---|---|---|---|---|---|---|

| Fc1 | Fc2 | Fc3 | Fc4 | |||

| Binary | 6.9 | 17.6 | 28.6 | 46.5 | 354.07 ± 53.11 | 6.18 ± 0.91 |

| Ternary | 10.4 | 25.3 | 43.6 | 47.3 | 245.78 ± 62.54 | 4.38 ± 0.87 |

| Quaternary | 18.5 | 37.9 | 48.1 | N.A. | 207.12 ± 28.68 | 3.16 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garino, G.; Nisar, A.; Sukumaran, A.K.; Agarwal, A. Scratch-Induced Wear Behavior of Multi-Component Ultra-High-Temperature Ceramics. Ceramics 2024, 7, 1658-1669. https://doi.org/10.3390/ceramics7040106

Garino G, Nisar A, Sukumaran AK, Agarwal A. Scratch-Induced Wear Behavior of Multi-Component Ultra-High-Temperature Ceramics. Ceramics. 2024; 7(4):1658-1669. https://doi.org/10.3390/ceramics7040106

Chicago/Turabian StyleGarino, Gia, Ambreen Nisar, Abhijith K. Sukumaran, and Arvind Agarwal. 2024. "Scratch-Induced Wear Behavior of Multi-Component Ultra-High-Temperature Ceramics" Ceramics 7, no. 4: 1658-1669. https://doi.org/10.3390/ceramics7040106

APA StyleGarino, G., Nisar, A., Sukumaran, A. K., & Agarwal, A. (2024). Scratch-Induced Wear Behavior of Multi-Component Ultra-High-Temperature Ceramics. Ceramics, 7(4), 1658-1669. https://doi.org/10.3390/ceramics7040106