Large-Scale Enclosure Fire Experiments Adopting CLT Slabs with Different Types of Polyurethane Adhesives: Genesis and Preliminary Findings

Abstract

:1. Introduction

2. Motivations and Objectives

- Experiments conducted to date have focussed on small enclosures, reflecting predominantly residential use. Limited consideration has been given to large enclosures, such as offices, where the fire may not develop to flashover and only a single combustible surface might be present (e.g., only a ceiling).

- Secondary flashover events have been observed in smaller enclosures. This has often been attributed to extensive/premature char fall-off and the interaction of exposed combustible surfaces.

- The type of adhesive between the CLT lamella influences the fire performance of CLT panels. The vast majority of CLT in Europe is produced with polyurethane (PUR) adhesives that were developed without a focus on fire performance (hereinafter called standard PUR adhesives), which are prone to bond-line failures and subsequent (premature) char fall-off. These, correspondingly, show a greater total char depth than solid timber. However, a modified PUR adhesive has demonstrated improved performance relative to the standard PUR products commonly used in the production of European CLT.

- What is the nature of the ceiling jet and flame extension anticipated in a large enclosure with a combustible ceiling?

- What mode of fire could be expected in a larger enclosure with exposed combustible ceiling given the ceiling jet/flame extension may develop differently, and what might this mean for internal fire spread?

- Given only an exposed ceiling, i.e., without heat flux from other combustible surfaces as might be expected in residential-type enclosures, is the averting of significant/premature char fall-off a prerequisite for auto-extinction?

- If averting significant/premature char fall-off is not a prerequisite for auto-extinction in such enclosures, are there other benefits for adopting modified PUR adhesives and/or what compromises must be accepted if they are not used?

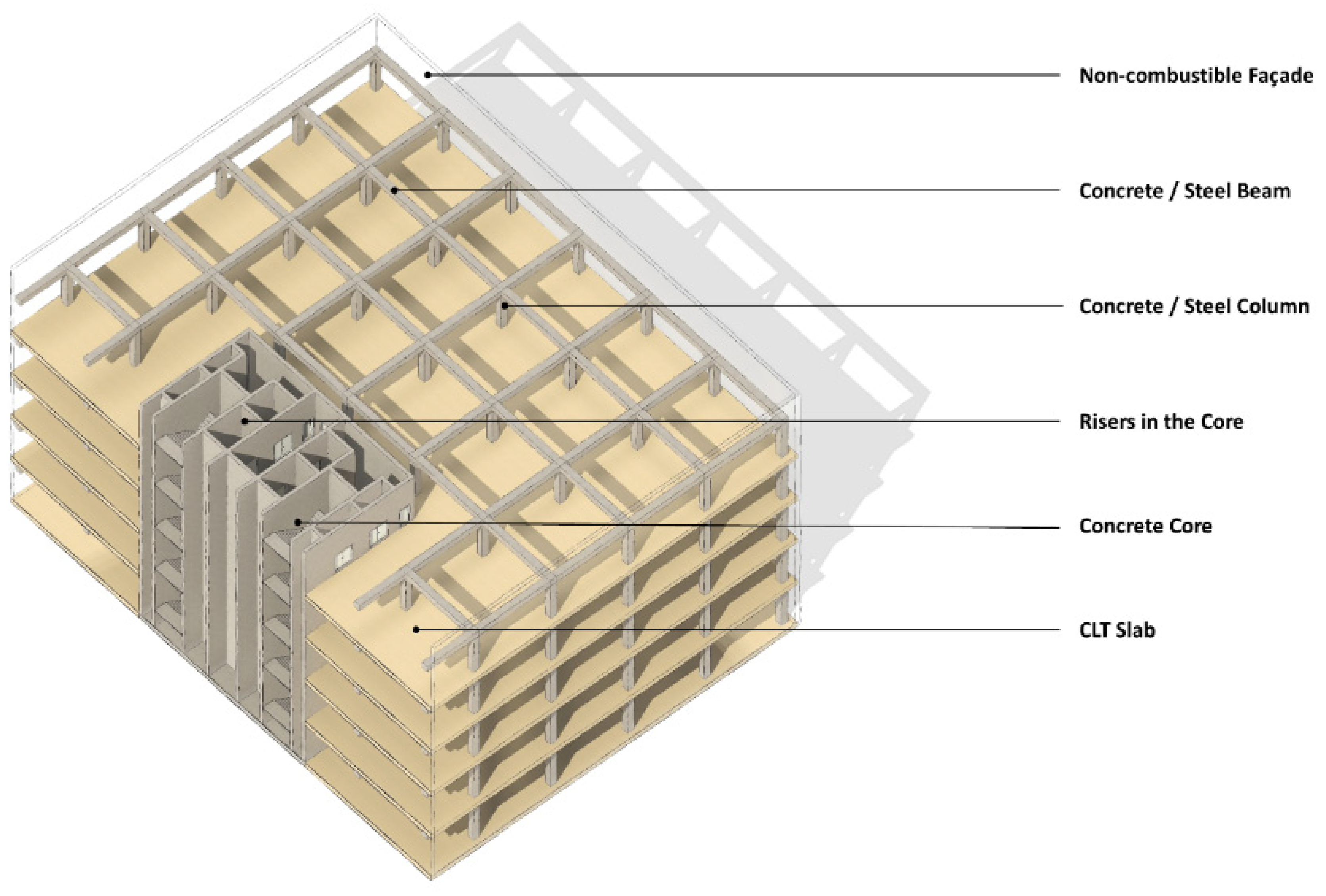

3. Experimental Configuration

3.1. Enclosure Geometry

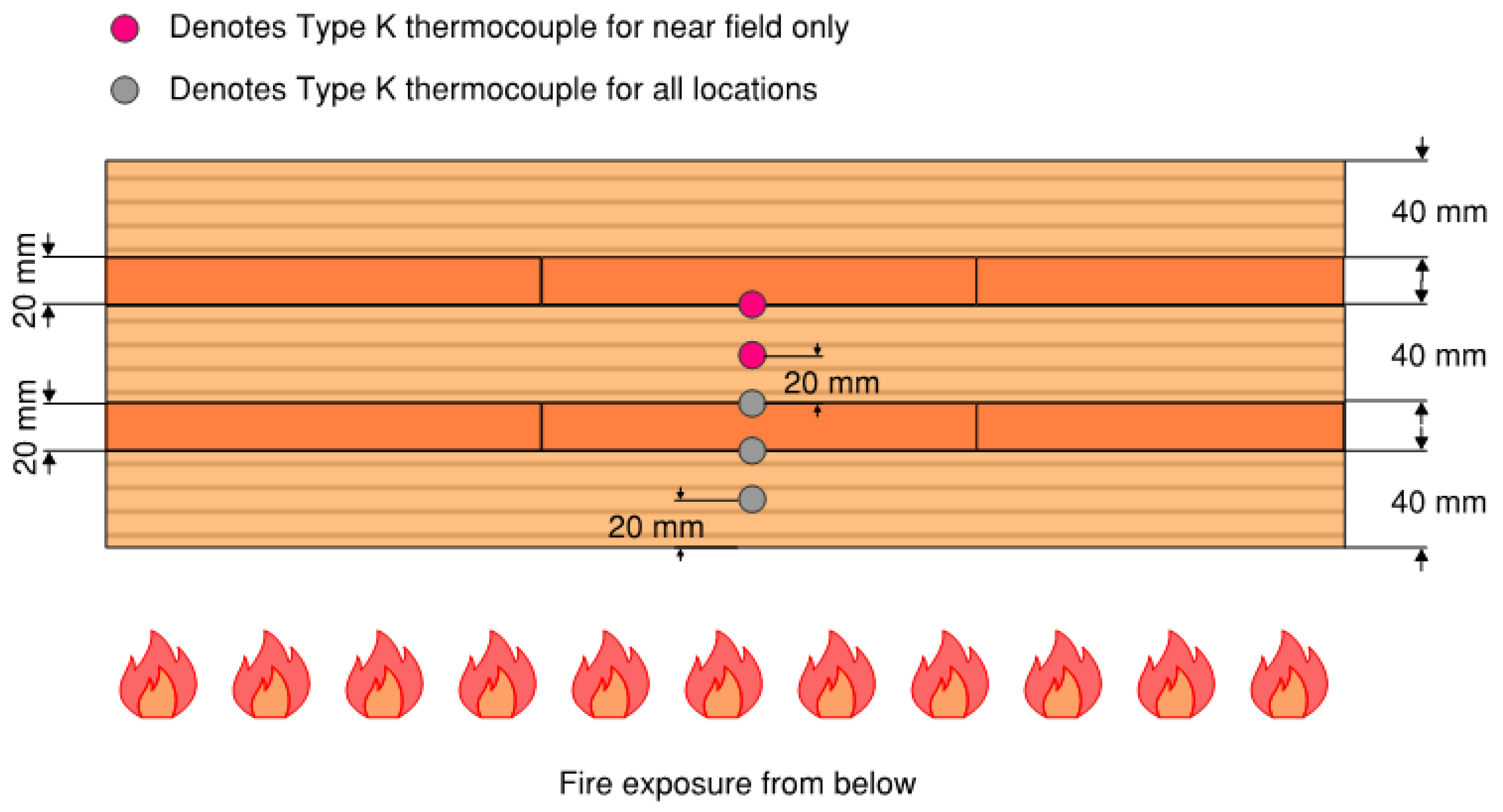

3.2. Protection Lining and CLT Specification

- Experiment 1: CLT using a standard polyurethane (PUR) adhesive (Henkel Loctite HB S) lined with 2 × 15 mm thick layers of Type F (fire-rated) plasterboard.

- Experiment 2: Exposed CLT using a standard polyurethane (PUR) adhesive (Henkel Loctite HB S), with non-edge-bonded facing lamella.

- Experiment 3: Exposed CLT using a modified PUR adhesive (Henkel Loctite HB X), with edge-bonded facing lamella.

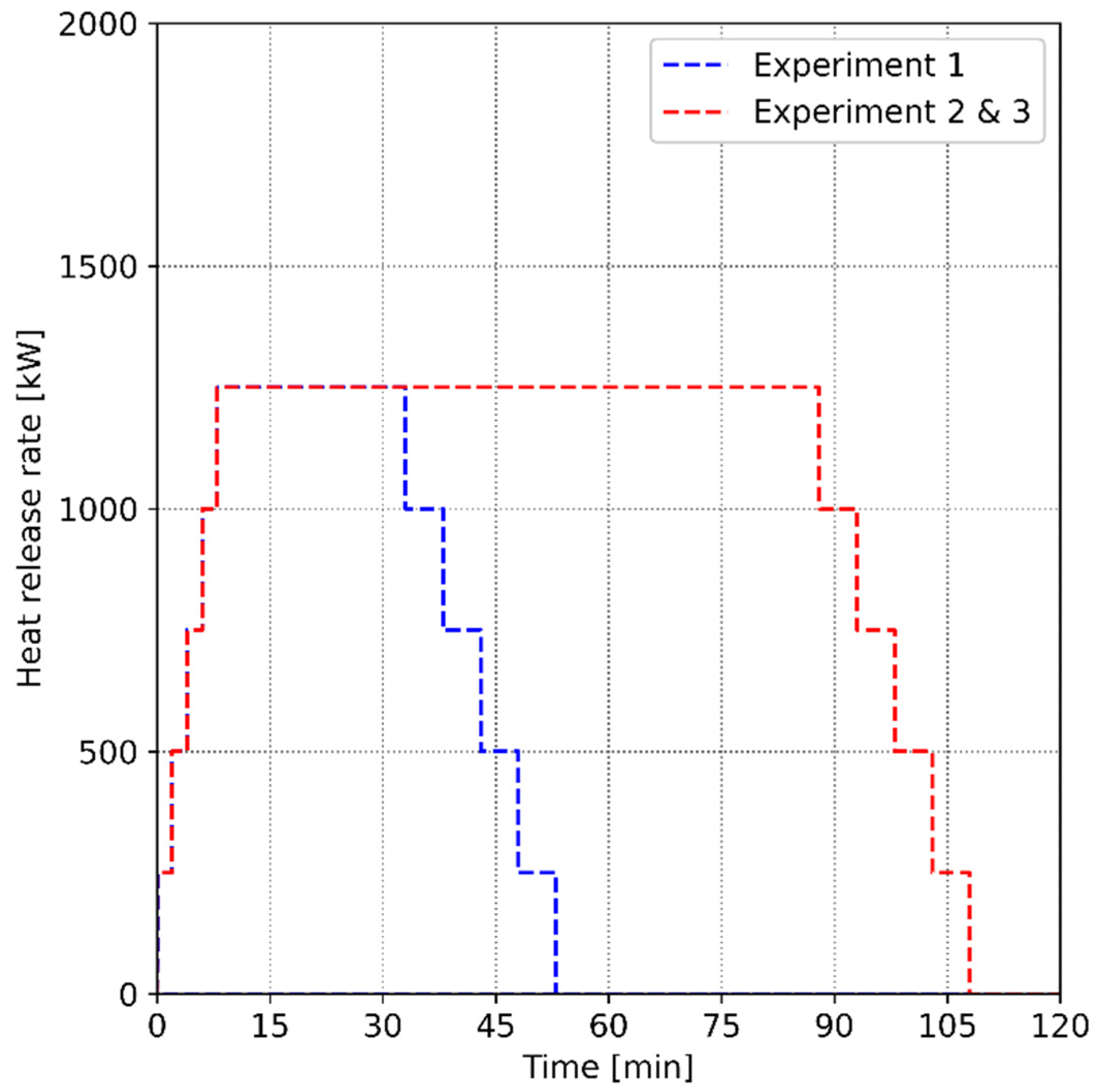

3.3. Fire Source

3.4. Mechanical Loading

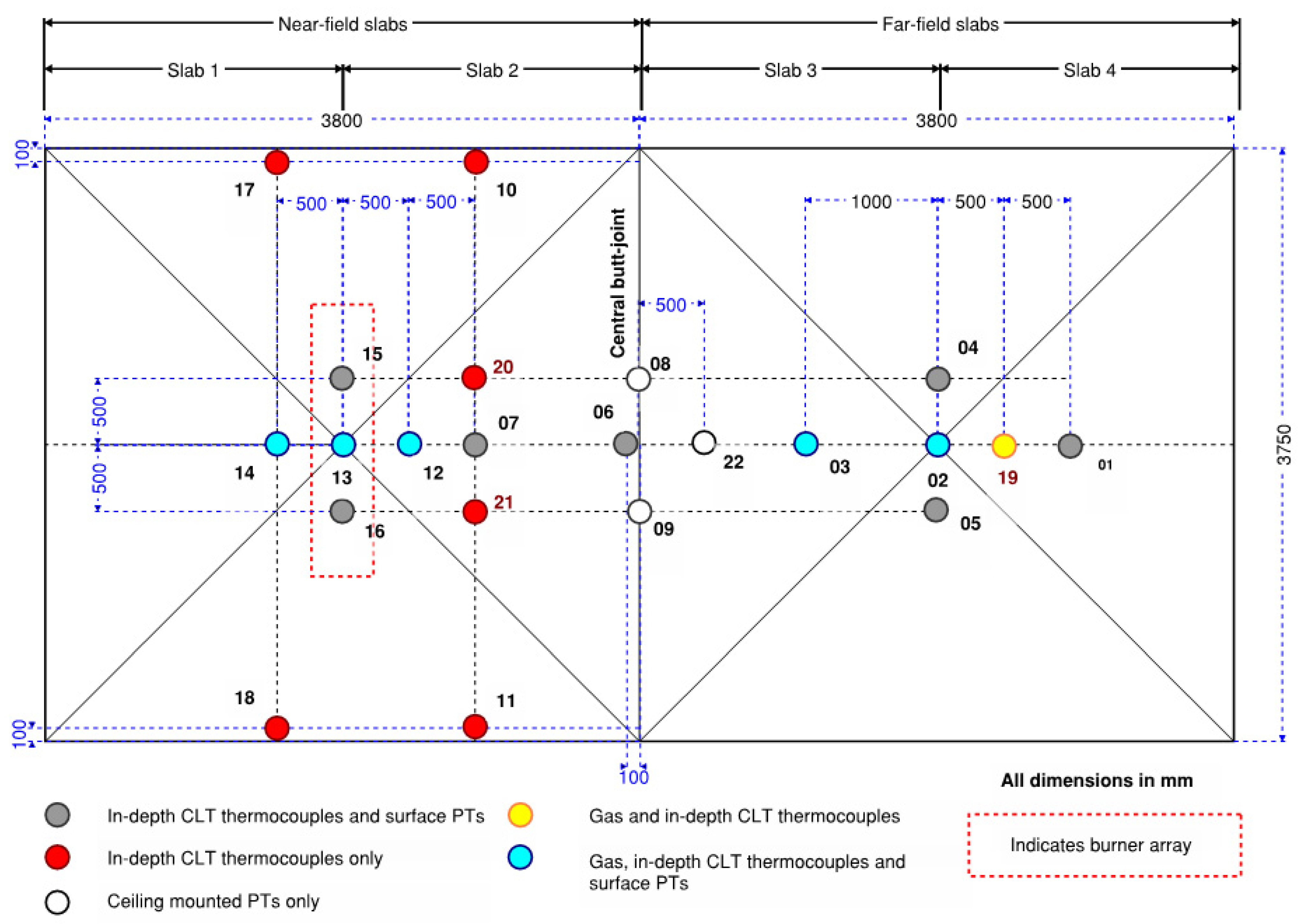

4. Instrumentation

4.1. Temperature Sensing Devices

- Surface mounted PTs were equipped with Type K thermocouples, each validated to have precision of ±15 K and comply with Clause 4.5.1.1 of EN 1363-1;

- Gas-phase and in-depth TCs were all Type K Ni-Cr, 1 mm in diameter, located 30 mm below the ceiling in all cases.

4.2. Load Cells and Displacement Transducers

5. Results

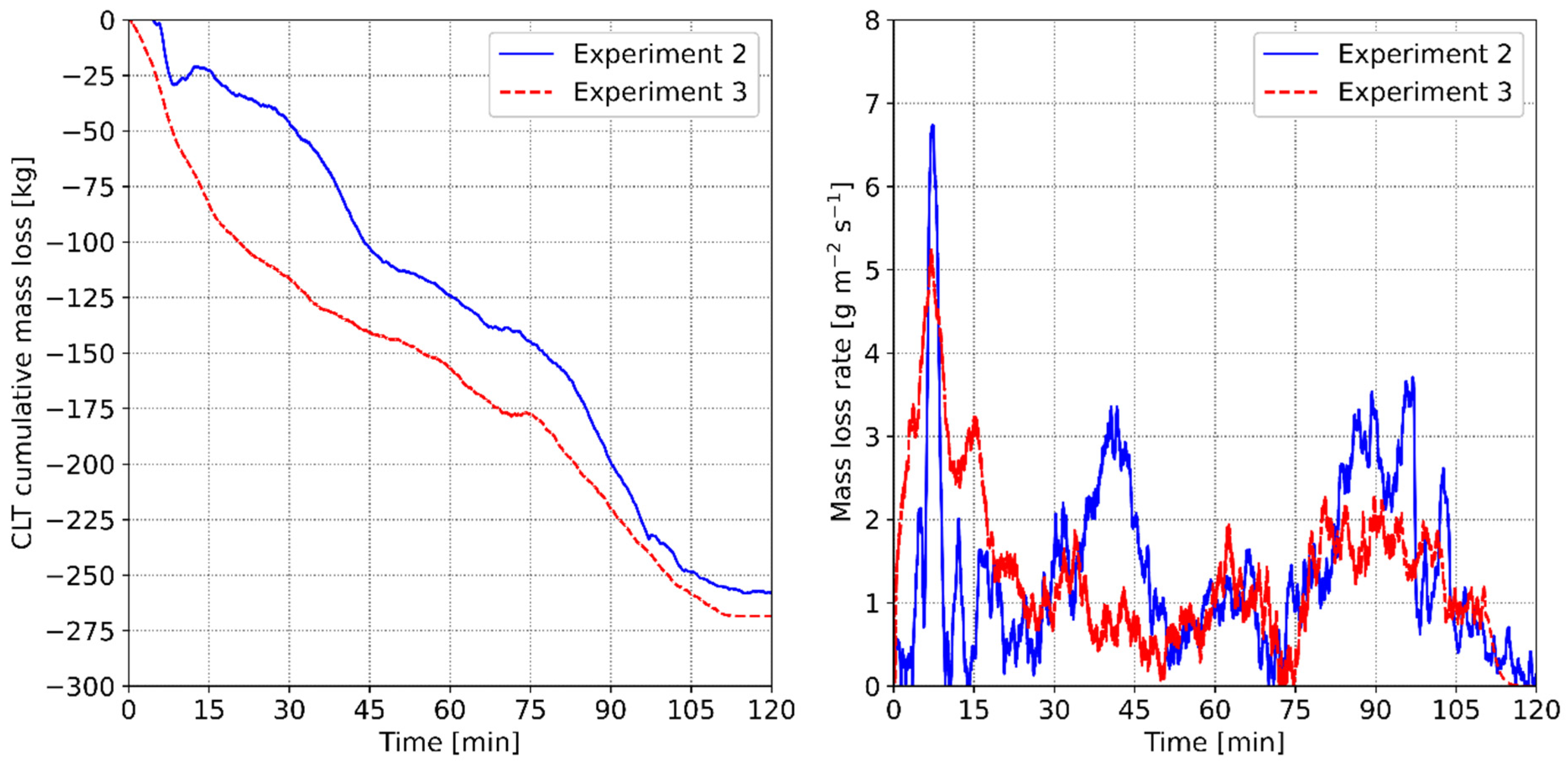

5.1. CLT Mass Loss and Mass Loss Rate

5.2. Heat Release Rate

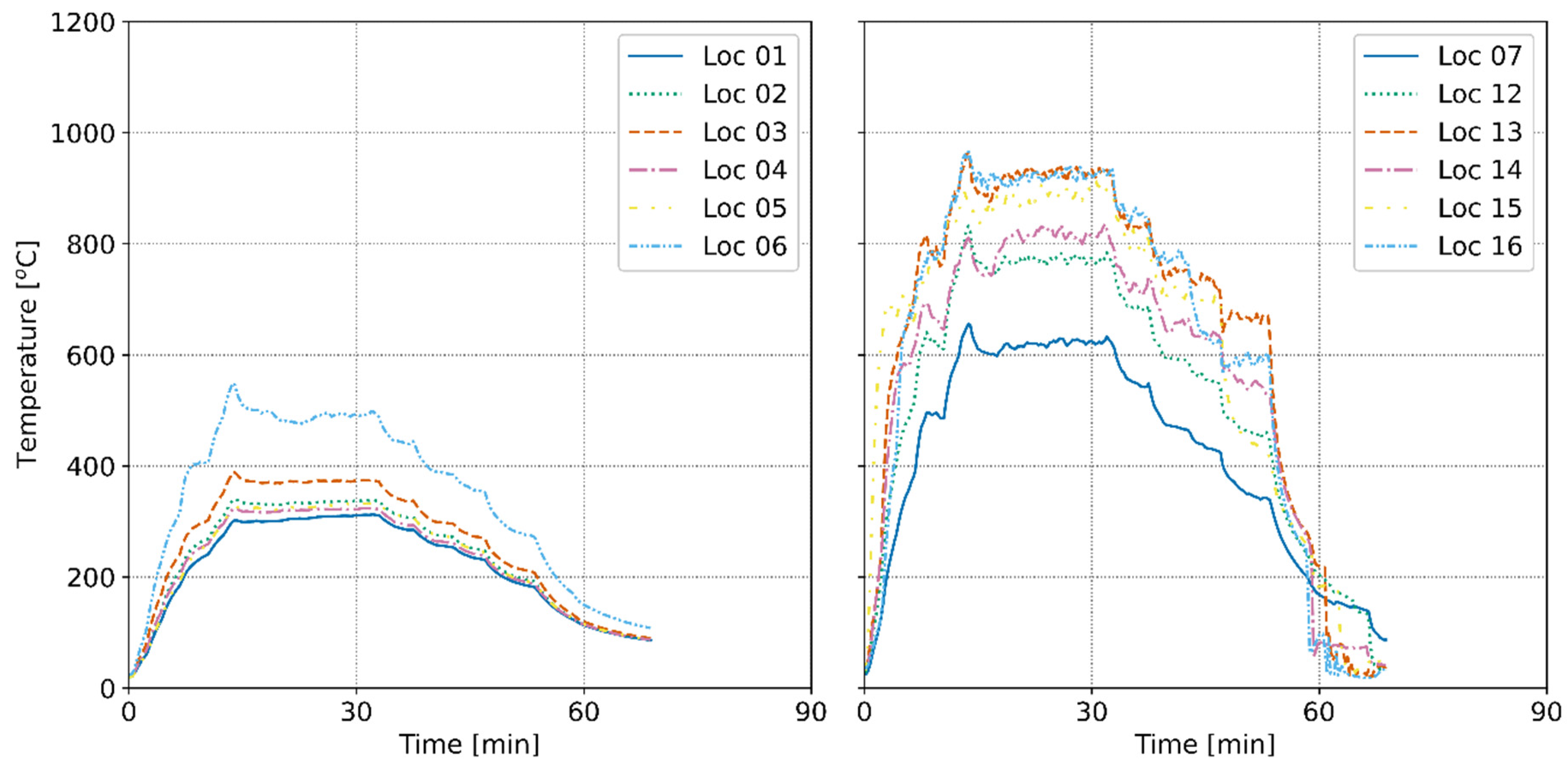

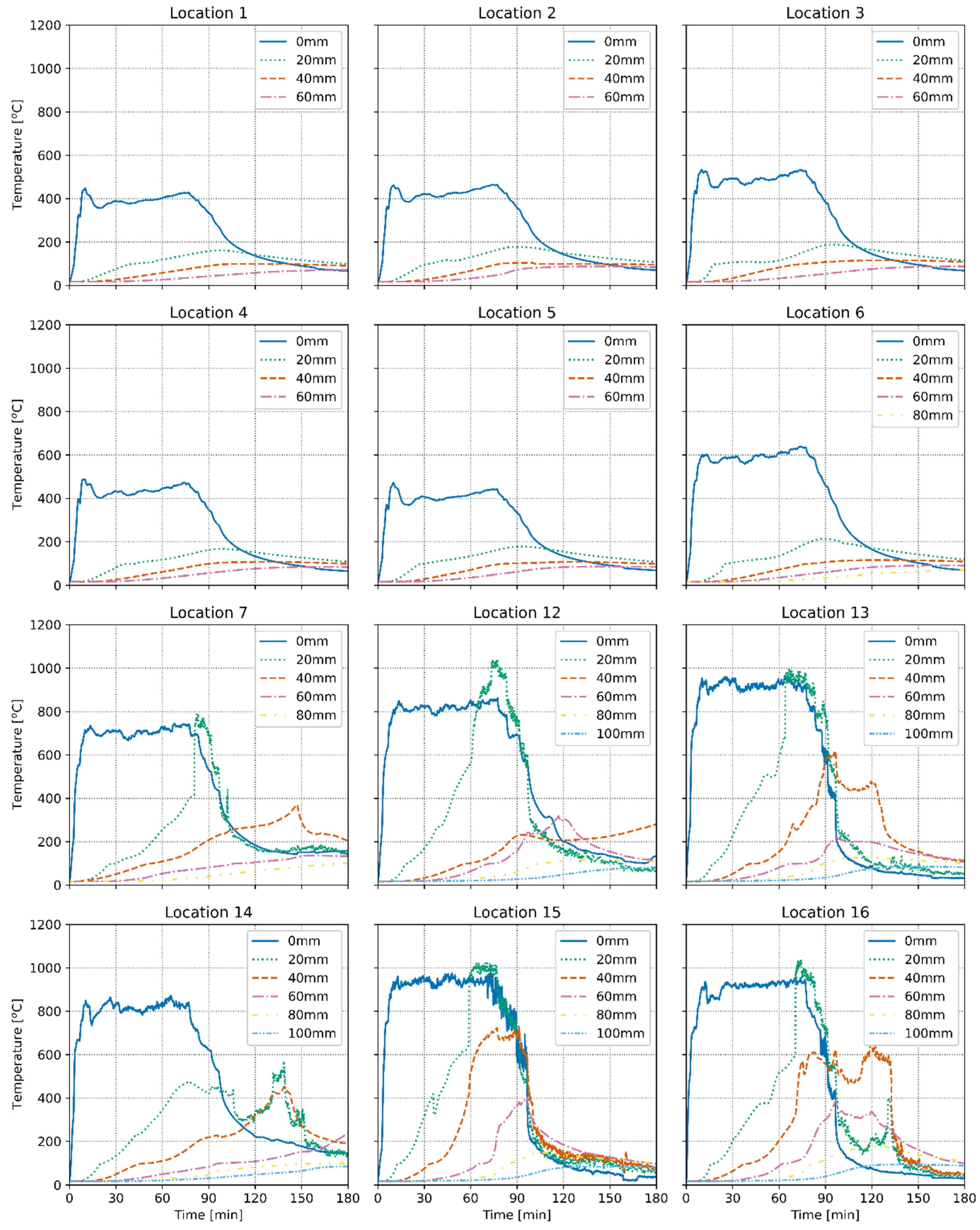

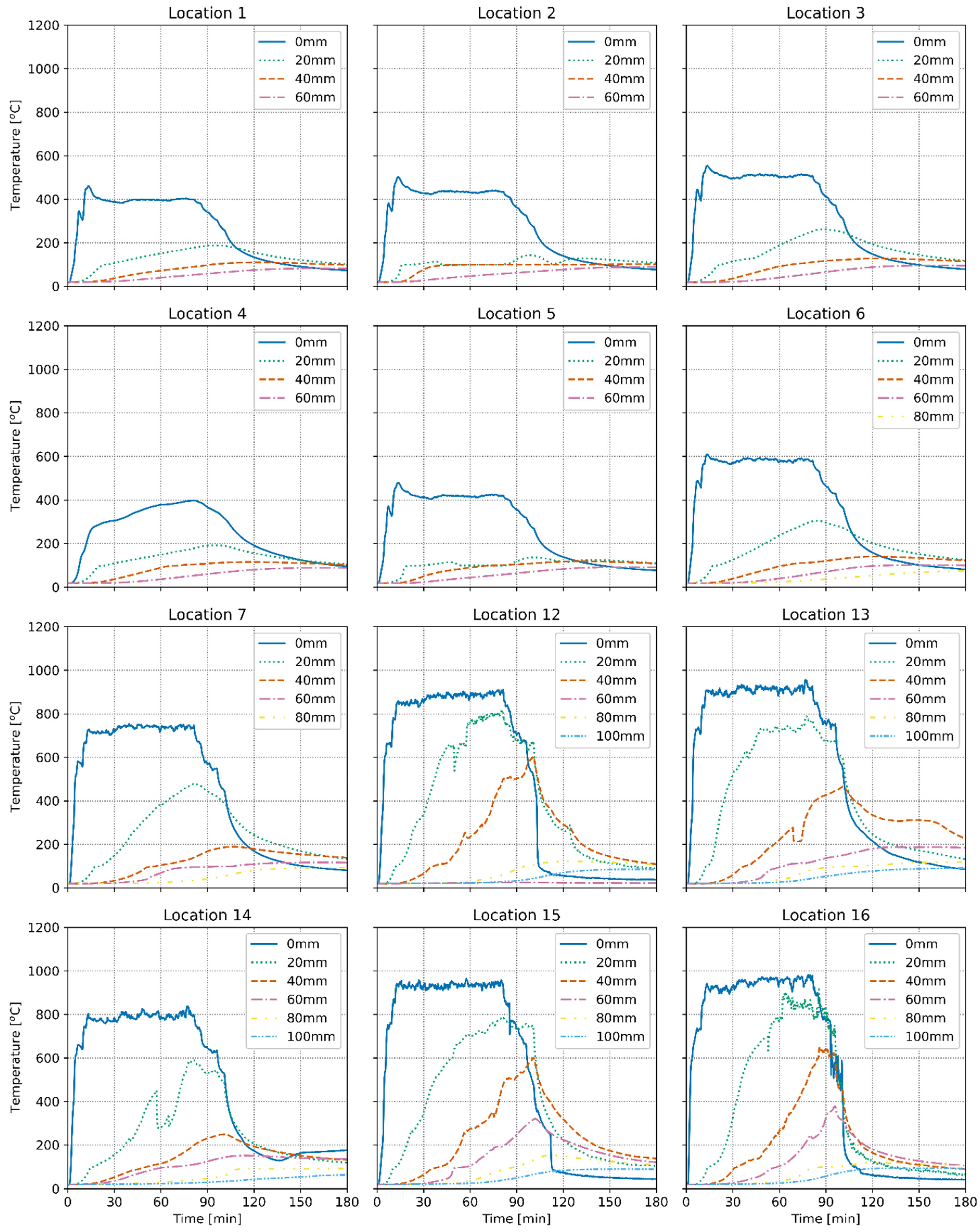

5.3. CLT Surface and In-Depth Temperatures

5.4. Ceiling Gas-Phase Temperatures

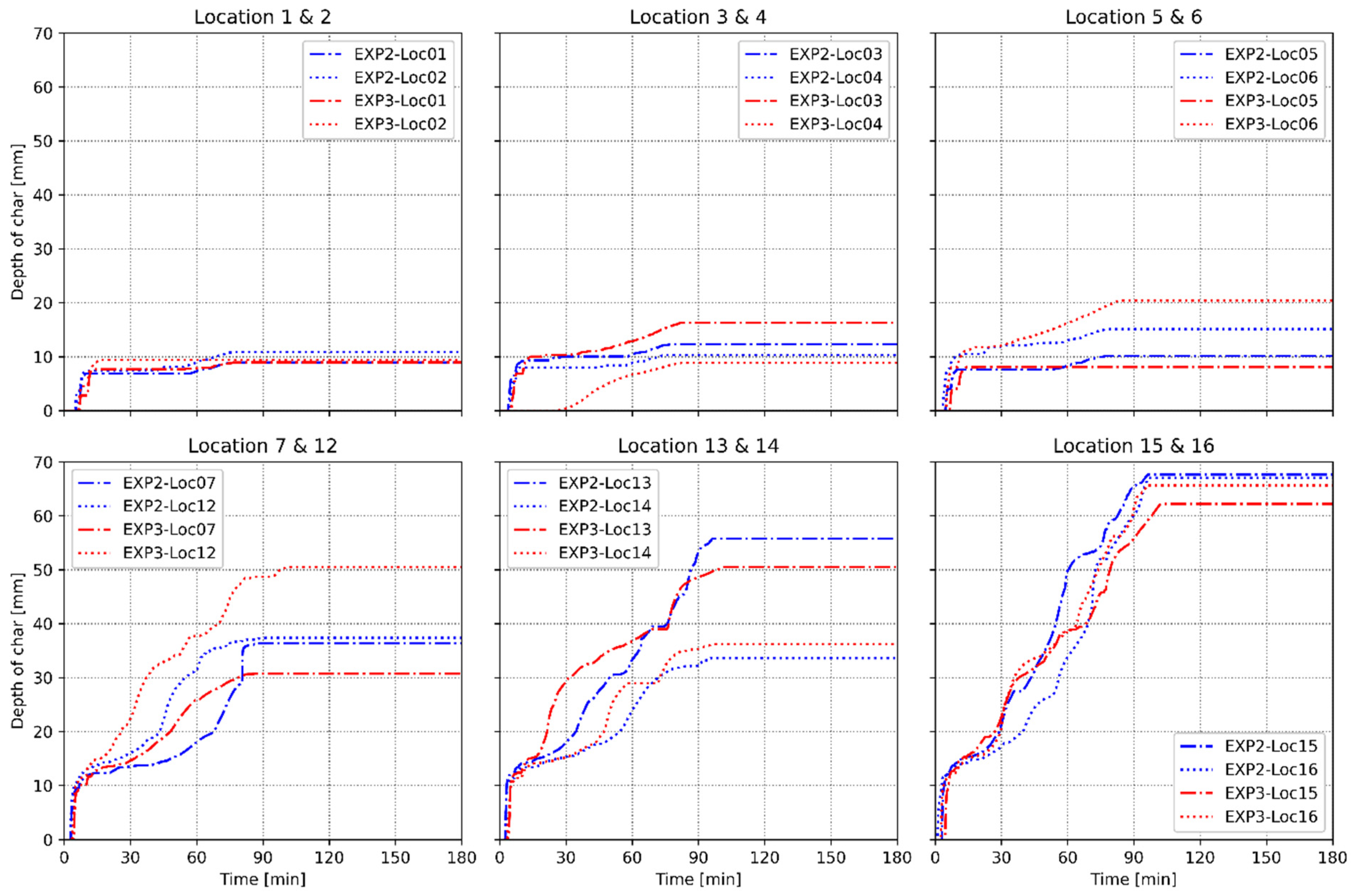

5.5. Charring Depths

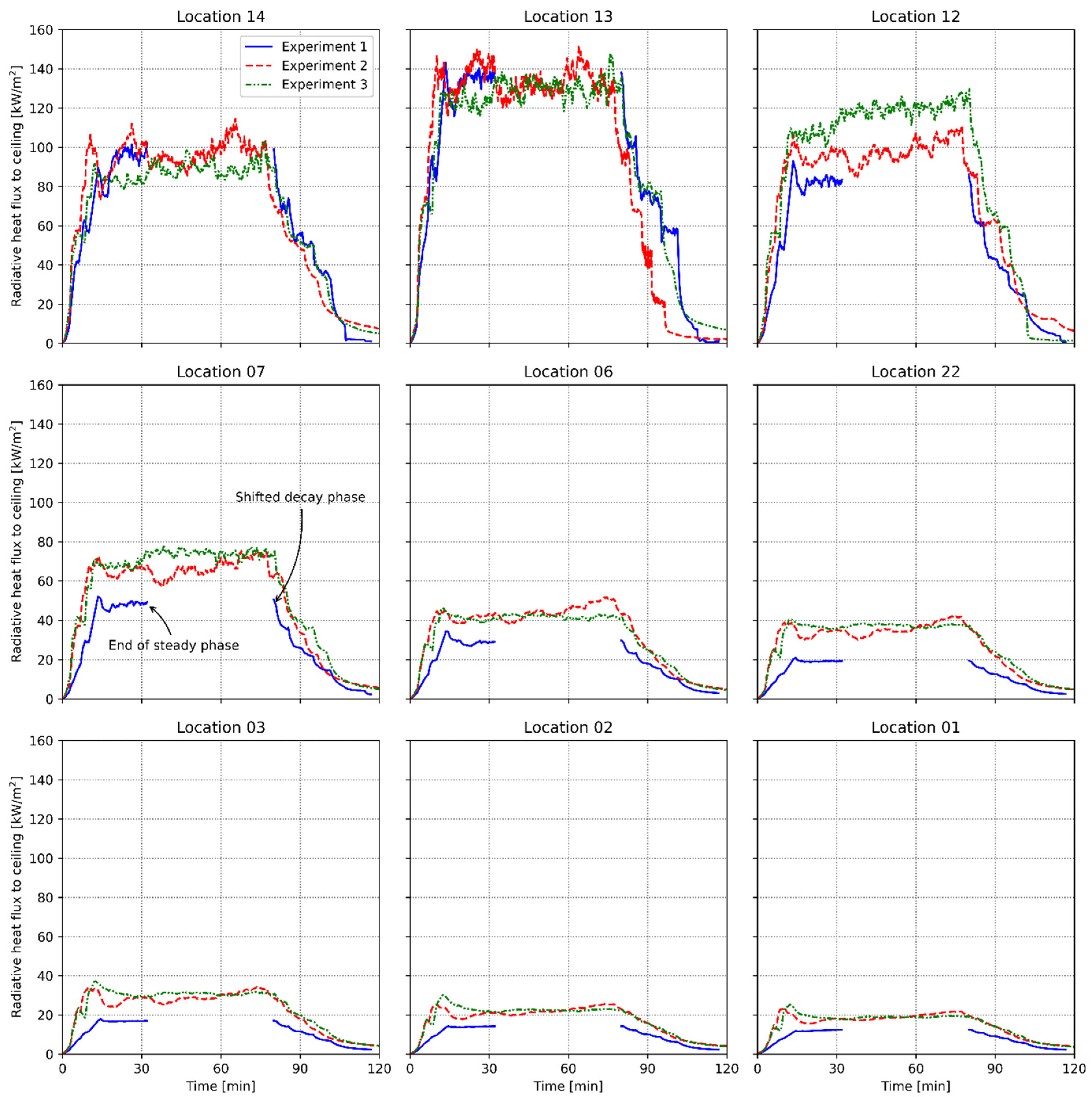

5.6. Ceiling Radiative Heat Flux Measurements

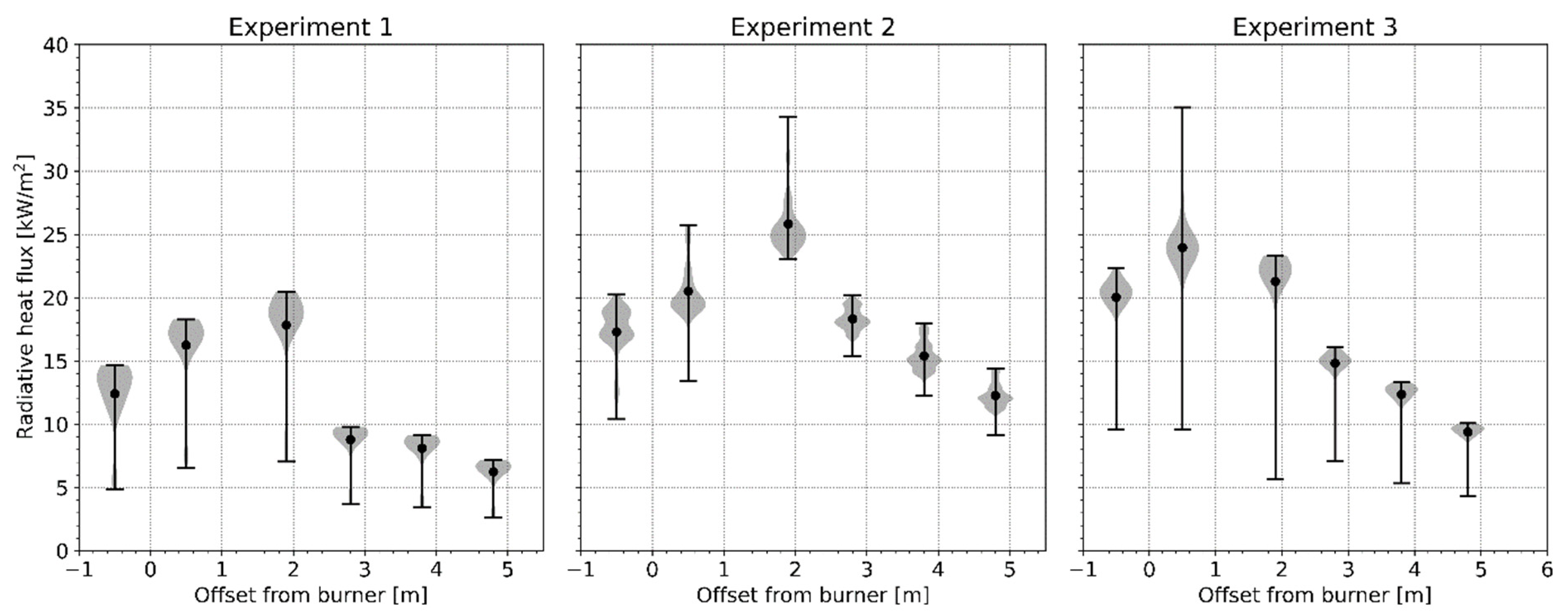

5.7. Floor Radiative Heat Flux Measurements

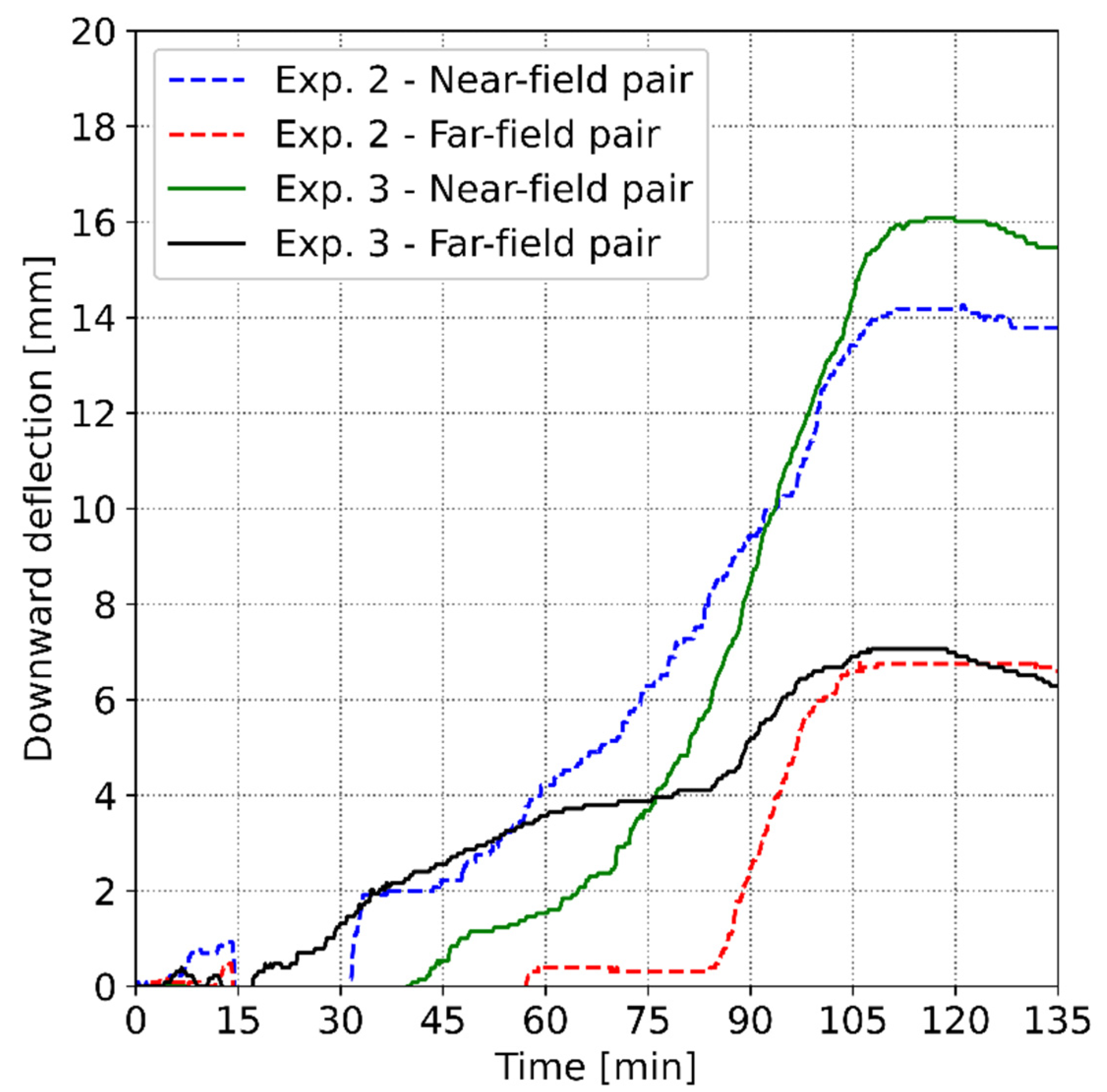

5.8. CLT Slab Deflection

6. Analysis and Observations

6.1. Char Fall-Off and Bond-Line Failure Terminology

- Bond-line failure (BLF) is defined herein as the failure, in this case due to heating, of the adhesion between lamella, leading to its detachment;

- Char fall-off is the detachment of charred pieces of lamella. BLF may be an underlying mechanism that leads to premature char fall-off (as commonly observed with standard PUR adhesives) or char fall-off may occur without BLF, i.e., there is a loss of connectivity between the char and its substrate that may occur away from bond-lines.

6.2. CLT Implications for Heat Release Rate

6.3. Adhesive Choice and Auto-Extinction of CLT Ceilings

6.4. Flame Extension and Implications for Ceiling Thermal Exposure

6.5. Implications of Ceiling Flame Extension for Internal Fire Spread

6.6. Charring Depths and Estimate of Equivalent Duration of Furnace Exposure

6.7. Structural Stability

7. Conclusions

- Upon initial ignition/involvement of the CLT, the experiments featuring exposed CLT (Experiments 2 and 3) delivered a peak HRR that was up to three times larger than that of the plasterboard lined reference (Experiment 1).

- During the steady phase of fire development, where the propane burners remained at 1250 kW, the contribution of the CLT stabilised at ca. 500 kW, with nominal difference between the two CLT specifications adopted.

- Premature char fall-off was observed in Experiment 2 and typically coincided with BLF, leading to detachment of larger pieces of lamella in proximity to the burner array. These events were observed to occur several times (estimated as ca. 5 in total), with the detached lamella measuring up to ca. 400 mm long and 100 mm in width. This led to spikes in the CLT slab mass loss rate and, correspondingly, HRR. Char fall-off was witnessed in Experiment 3, although this did not appear to be whole parts of lamella and were instead smaller pieces of char of the scale of ca. 50 mm square. Consequently, this had a less pronounced influence on the measured CLT mass loss rate and HRR.

- Despite quite significant premature char fall-off in Experiment 2, auto-extinction of the slabs was observed once the burner array was switched off. This aligned with observations for Experiment 3, where char fall-off was limited. It can, therefore, be concluded that for the configuration studied, i.e., an exposed ceiling with otherwise inert boundaries, averting significant char fall-off was not a prerequisite for the cessation of flaming combustion. Whilst fresh timber was increasingly exposed in Experiment 2, the incident heat flux to the CLT ultimately reached a level where flaming combustion could not continue (in this case, below ca. 40 kW/m2). The detached lamella was seen to fall to the floor and flame for a period, before transitioning to smouldering. The heat flux from the fallen flaming or smouldering lamella made no material impact to that received at ceiling level.

- Premature char fall-off resulted in local significantly reduced residual CLT sections in Experiment 2 that were not apparent in Experiment 3, with the third lamella from the exposed side visible for the CLT adopting standard PUR adhesive. Therefore, whilst averting significant char fall-off was not a prerequisite for auto-extinction, it would be expected to come with the compromise of increased section depth to ensure adequate mechanical performance in the event of fire.

- Despite pronounced char fall-off events in Experiment 2, mean charring depths to the slabs above the burner array were comparable for both adhesive types studied, reaching ca. 45 mm in both cases based upon estimates of the 300 °C isotherm positions measured via in-depth thermocouples. This could be due to the mechanical fixing of PTs to the ceiling nearby, which locally prevented the detachment of the lamella which was observed elsewhere in Experiment 2.

- In Experiment 1, flame extension was observed over ca. 50% of the plasterboard-lined ceiling, with a radiative heat flux of 20 kW/m2 noted at PTs located halfway along the rig. Upon involvement of the CLT in Experiments 2 and 3, this flaming was observed to extend over the entire enclosure ceiling area, with heat fluxes in the far field consistently ca. 20 kW/m2 higher than that observed in Experiment 1.

- The increased flame extension at the ceiling level translated to increased radiative heat flux to the floor in both Experiments 2 and 3, when measured relative to Experiment 1. Based upon the magnitude of these radiative heat flux measures (>10 kW/m2), it is postulated that if the experiment had the facility to accommodate flame spread over fuel load on the floor, it would have been rapid. Through benchmarking against the studies of Gupta et al., it is foreseen that in many large enclosures with exposed CLT ceilings, a “Mode 1” (post-flashover) fire would ensue owing to the large heat fluxes observed to the floor in advance of the fire front. This is consistent with observations from recent large enclosure fire experiments with exposed CLT ceilings [23].

- Despite significant section loss in the vicinity of the burner, with char depths estimated to be ca. 70 mm in locations, the CLT ceiling remained structurally stable under load, both during and beyond the thermal exposure from the propane burner array. Little deflection was observed, reaching a maximum of 14 mm in Experiment 2 and 16 mm in Experiment 3.

- The enclosure energy balance, with emphasis on large enclosures and auto-extinction. In particular, the fidelity of data collected herein provides a means for the development and validation of computational models that could be used to estimate fire development behaviours in large enclosures.

- The study has highlighted that modified PUR offers benefits over standard PUR in terms of mitigating premature char fall-off due to bond-line failure, although the mean charring depths across locations were not significantly different across adhesive types. Given this, there is merit in further understanding the mechanisms through which modified PUR offers enhanced performance over standard PUR. Further study is proposed to better understand mechanical performance using Dynamic Mechanical Analysis (DMA) and moisture transport using Nuclear Magnetic Resonance (NMR) methods.

- How the mechanical resistance of the CLT slabs may have evolved with time, noting limited deflection was observed, and how this might vary between the two adhesive types adopted.

- What impact ceiling protrusions, such as glulam beams, might have on the conclusions drawn herein, particularly regarding auto-extinction and the relationship with bond-line failure and subsequent premature char fall-off, flame extension across the ceiling and the corresponding impact on heat flux to the floor/flame spread.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Structural Timber Association. Mass timber structures. In Structural Timber Buildings Fire Safety in Use Guidance; Building Regulation Compliance B3(1), V1.1; Structural Timber Association: Alloa, UK, 2020; Volume 6. [Google Scholar]

- Hopkin, D.; Spearpoint, M.; Gorksa, C.; Krenn, H.; Sleik, T.; Milner, M. Compliance road-map for the structural fire safety design of mass timber buildings in England. SFPE Eur. Q 2020, 4, 27–34. [Google Scholar]

- Structural Timber Association. CLT Special Interest Group. 2021. Available online: http://www.structuraltimber.co.uk/sectors/clt-special-interest-group (accessed on 4 May 2021).

- Law, A.; Bisby, L. The rise and rise of fire resistance. Fire Saf. J. 2020, 116, 103188. [Google Scholar] [CrossRef]

- Law, A.; Hadden, R.M. Burnout Means Burnout. SFPE Eur. Q 2017, 1. Available online: https://www.sfpe.org/page/Issue5Feature1 (accessed on 2 October 2019).

- Law, A.; Hadden, R.M. We need to talk about timber: Fire safety design in tall buildings. Struct. Eng. J. Inst. Struct. Eng. 2020, 98, 10–15. [Google Scholar]

- Gorska, C.; Hidalgo, J.P.; Torero, J.L. Fire dynamics in mass timber compartments. Fire Saf. J. 2020, 120, 103098. [Google Scholar] [CrossRef]

- Emberley, R.; Putynska, C.G.; Bolanos, A.; Lucherini, A.; Solarte, A.; Soriguer, D.; Gonzalez, G.; Humphreys, K.; Hidalgo, J.P.; Maluk, C.; et al. Description of small and large-scale cross laminated timber fire tests. Fire Saf. J. 2017, 91, 327–335. [Google Scholar] [CrossRef] [Green Version]

- Bartlett, A. Auto-Extinction of Engineered Timber. Ph.D. Thesis, University of Edinburgh, Edinburgh, UK, 2018. [Google Scholar]

- Bartlett, A.I.; Hadden, R.M.; Bisby, L.A. A review of factors affecting the burning behaviour of wood for application to tall timber construction. Fire Technol. 2019, 55, 1–49. [Google Scholar] [CrossRef] [Green Version]

- Ronquillo, G.; Hopkin, D.; Spearpoint, M. Review of large-scale fire tests on cross-laminated timber. J. Fire Sci. 2021, 39, 327–369. [Google Scholar] [CrossRef]

- Stern-Gottfried, J.; Rein, G. Travelling fires for structural design—Part I: Literature review. Fire Saf. J. 2012, 54, 74–85. [Google Scholar] [CrossRef] [Green Version]

- Stern-Gottfried, J.; Rein, G. Travelling fires for structural design—Part II: Design methodology. Fire Saf. J. 2012, 54, 96–112. [Google Scholar] [CrossRef] [Green Version]

- Rackauskaite, E. iTFM: Improved Travelling Fires Methodology for Structural Design and the Effects on Steel Framed Buildings. Doctoral Dissertation, Imperial College London, London, UK, 2017. [Google Scholar] [CrossRef]

- Heidari, M.; Kotsovinos, P.; Rein, G. Flame extension and the near field under the ceiling for travelling fires inside large compartments. Fire Mater. 2020, 44, 423–436. [Google Scholar] [CrossRef]

- Pope, I.; Hidalgo, J.P.; Hadden, R.M.; Torero, J.L. A simplified correction method for thermocouple disturbance errors in solids. Int. J. Therm. Sci. 2022, 172, 107324. [Google Scholar] [CrossRef]

- Wickström, U.; Anderson, J.; Sjöström, J. Measuring incident heat flux and adiabatic surface temperature with plate thermometers in ambient and high temperatures. Fire Mater. 2019, 43, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Su, J.; Lafrance, P.-S.; Hoehler, M.; Bundy, M. Fire Safety Challenges of Tall Wood Buildings-Phase 2: Task 2 & 3-Cross Laminated Timber Compartment Fire Tests; FPRF-2018-01; Fire Protection Research Foundation: Quincy, MA, USA, 2018. [Google Scholar]

- Ingason, H.; Wickström, U. Measuring incident radiant heat flux using the plate thermometer. Fire Saf. J. 2007, 42, 161–166. [Google Scholar] [CrossRef]

- Häggkvist, A.; Sjöström, J.; Wickström, U. Using plate thermometer measurements to calculate incident heat radiation. J. Fire Sci. 2013, 31, 166–177. [Google Scholar] [CrossRef]

- Drysdale, D. An Introduction to Fire Dynamics, 3rd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Brandon, D.; Hopkin, D.; Emberley, R.; Wade, C. Timber Structures. In International Handbook of Structural Fire Engineering; LaMalva, K., Hopkin, D., Eds.; Springer International Publishing: Cham, Germany, 2021; pp. 235–322. [Google Scholar] [CrossRef]

- Kotsovinos, P.; Rackauskaite, E.; Christensen, E.; Glew, A.; O’Loughlin, E.; Mitchell, H.; Amin, R.; Robert, F.; Heidari, M.; Barber, D.; et al. Fire dynamics inside a large and open-plan compartment with exposed timber ceiling and columns: CODERED #01. Fire Mater. 2022. [Google Scholar] [CrossRef]

- Lattimer, B.Y. Heat transfer from fires to surfaces. In SFPE Handbook of Fire Protection Engineering, 5th ed.; Springer: New York, NY, USA, 2016; pp. 745–798. [Google Scholar]

- Guthrie, W.F. NIST/SEMATECH e-Handbook of Statistical Methods (NIST Handbook 151); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2020. [CrossRef]

- Spearpoint, M.J.; Quintiere, J.G. Predicting the burning of wood using an integral model. Combust. Flame 2000, 123, 308–325. [Google Scholar] [CrossRef]

- Morrisset, D.; Hadden, R.M.; Bartlett, A.I.; Law, A.; Emberley, R. Time dependent contribution of char oxidation and flame heat feedback on the mass loss rate of timber. Fire Saf. J. 2020, 120, 103058. [Google Scholar] [CrossRef]

- Hopkin, D.; Gorska, C.; Spearpoint, M.J.; Fu, I.; Krenn, H.; Sleik, T.; Stapf, G. Experimental characterisation of the fire behaviour of CLT ceiling elements from different leading suppliers. In Proceedings of the Applications of Structural Fire Engineering, Ljubljana, Slovenia, 10–11 June 2021. [Google Scholar]

- Gupta, V.; Osorio, A.F.; Torero, J.L.; Hidalgo, J.P. Mechanisms of flame spread and burnout in large enclosure fires. Proc. Combust. Inst. 2021, 38, 4525–4533. [Google Scholar] [CrossRef]

- EN 1995-1-2:2020 (E); Eurocode 5—Design of Timber Structures Part 1-2: General—Structural fire Design (DRAFT). European Committee for Standardization: Brussels, Belgium, 2019.

- Ministry of Housing, Communities and Local Government. Approved Document B: Fire Safety—Volume 2; RIBA Publishing: London, UK, 2020.

- BS 9999:2017; Fire Safety in the Design, Management and Use of Buildings. Code of Practice. BSI: London, UK, 2017.

- BS 476-20:1987; Fire Tests on Building Materials and Structures. Method for Determination of the Fire Resistance of Elements of Construction (General Principles). BSI: London, UK, 1987.

| Parameter | Description | Value | Unit |

|---|---|---|---|

| Emissivity of the PT | 0.9 | - | |

| Boltzmann constant | 5.67 × 10−8 | W·m−2·K−4 | |

| Convection coefficient for PT | 10 | W/m2·K | |

| Conduction correction factor | 8 | W/m2·K | |

| PT temperature | Varies | K | |

| Ambient temperature | 293 | K |

| Offset [mm] | Experiment 1 | Experiment 2 | Experiment 3 | ||

|---|---|---|---|---|---|

| Mean Radiative Heat Flux | Mean Radiative Heat Flux | Increase Relative to Experiment 1 | Mean Radiative Heat Flux | Increase Relative to Experiment 1 | |

| (kW/m2) | (kW/m2) | (%) | (kW/m2) | (%) | |

| −500 | 12.4 | 17.3 | 40 | 20.1 | 62 |

| +500 | 16.3 | 20.6 | 26 | 24.0 | 47 |

| +1900 | 17.8 | 25.9 | 46 | 21.3 | 20 |

| +2800 | 8.7 | 18.3 | 110 | 14.8 | 70 |

| +3800 | 8.1 | 15.4 | 90 | 12.3 | 52 |

| +4800 | 6.4 | 12.3 | 92 | 9.4 | 47 |

| Location | Experiment 2 | Experiment 3 | ||

|---|---|---|---|---|

| Max. Char Depth | Equivalent Duration of Furnace Heating | Max. Char Depth | Equivalent Duration of Furnace Heating | |

| (mm) | (min) | (mm) | (min) | |

| 1 | 8.9 | 13.7 | 9.0 | 13.8 |

| 2 | 10.9 | 16.8 | 9.4 | 14.5 |

| 3 | 12.3 | 18.9 | 16.3 | 25.1 |

| 4 | 20.3 | 31.2 | 8.9 | 13.7 |

| 5 | 10.1 | 15.5 | 8.1 | 12.5 |

| 6 | 15.1 | 23.2 | 20.4 | 31.4 |

| 7 | 36.3 | 55.8 | 30.7 | 47.2 |

| 12 | 37.4 | 57.5 | 50.5 | 77.7 |

| 13 | 55.8 | 85.8 | 50.5 | 77.7 |

| 14 | 33.6 | 51.7 | 36.2 | 55.7 |

| 15 | 67.7 | 104.2 | 62.2 | 95.7 |

| 16 | 67.0 | 103.1 | 65.6 | 100.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hopkin, D.; Węgrzyński, W.; Spearpoint, M.; Fu, I.; Krenn, H.; Sleik, T.; Gorska, C.; Stapf, G. Large-Scale Enclosure Fire Experiments Adopting CLT Slabs with Different Types of Polyurethane Adhesives: Genesis and Preliminary Findings. Fire 2022, 5, 39. https://doi.org/10.3390/fire5020039

Hopkin D, Węgrzyński W, Spearpoint M, Fu I, Krenn H, Sleik T, Gorska C, Stapf G. Large-Scale Enclosure Fire Experiments Adopting CLT Slabs with Different Types of Polyurethane Adhesives: Genesis and Preliminary Findings. Fire. 2022; 5(2):39. https://doi.org/10.3390/fire5020039

Chicago/Turabian StyleHopkin, Danny, Wojciech Węgrzyński, Michael Spearpoint, Ian Fu, Harald Krenn, Tim Sleik, Carmen Gorska, and Gordian Stapf. 2022. "Large-Scale Enclosure Fire Experiments Adopting CLT Slabs with Different Types of Polyurethane Adhesives: Genesis and Preliminary Findings" Fire 5, no. 2: 39. https://doi.org/10.3390/fire5020039

APA StyleHopkin, D., Węgrzyński, W., Spearpoint, M., Fu, I., Krenn, H., Sleik, T., Gorska, C., & Stapf, G. (2022). Large-Scale Enclosure Fire Experiments Adopting CLT Slabs with Different Types of Polyurethane Adhesives: Genesis and Preliminary Findings. Fire, 5(2), 39. https://doi.org/10.3390/fire5020039