Indoor Fire Simulation in Low-Rise Teaching Buildings Based on BIM–FDS

Abstract

1. Introduction

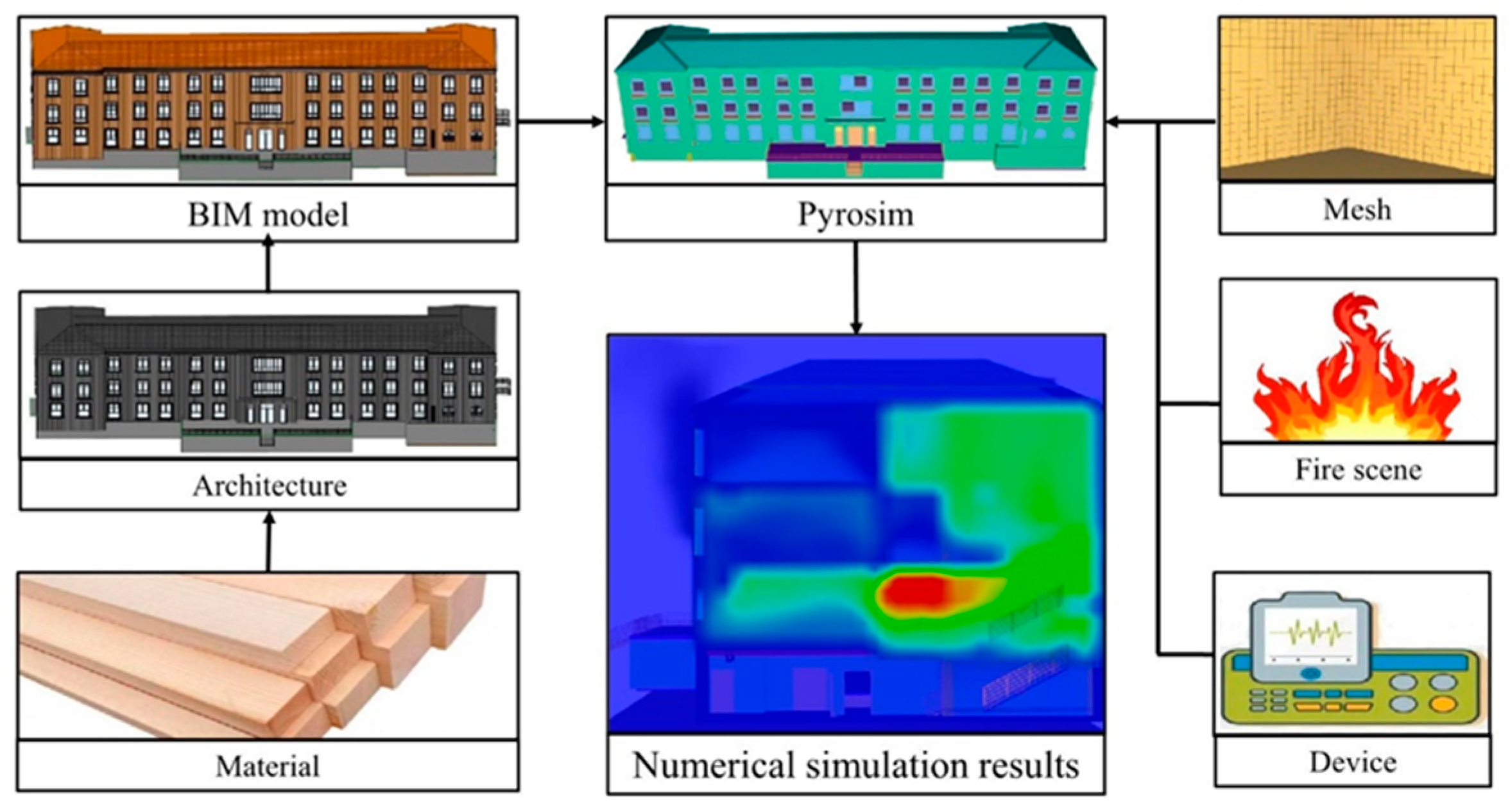

2. Research Methodology

2.1. Methods of FDS

2.2. BIM-Based Simulation Framework

3. Case Study

3.1. Fire Model Setting

3.1.1. Design of the Fire Scene

3.1.2. Grid Resolution Analysis

3.1.3. Configuring the Detecting Point

3.2. Scenarios of Simulation

4. Results and Analysis

4.1. Smoke Diffusion Law

4.2. Effect of HPWMS on Smoke Diffusion

4.2.1. Temperature

4.2.2. CO Concentration

4.3. Influence of Natural Smoke Exhaust Systems on Smoke Diffusion

4.3.1. CO Concentration

4.3.2. Temperature

4.4. Linkage Effect of the Fire Control System

5. Conclusions

- This study verified the practical value of the BIM technology in emergency evacuation management for public buildings. A public building emergency evacuation management model based on the BIM–FDS is established by combining accurate BIM building information data with a professional fire simulation program. The accurate smoke information and smoke diffusion law at each key node in the building evacuation path are obtained, which provides a basis for emergency management and better guides the emergency management that is difficult to predict and control.

- This study obtained the unique smoke diffusion law in “]” buildings. In the “]” building, the fire smoke diffuses through the penetrating corridor to the stairwells on both sides and through the stairwells to the whole building. In the diffusion process, the fire source and the top layer are the most vulnerable to smoke, followed by the middle floor. In the case studied in this paper, the asymmetric building structure at both ends of the corridor causes different smoke exhaust areas on both sides, resulting in a large difference in the amount of smoke diffused upward, reflecting the important influence of building structure on the smoke diffusion law and the accurate guarantee of fine BIM models for fire simulation.

- This study demonstrates the excellent performance of HPWMS in extinguishing fire and inhibiting smoke diffusion and stairwells’ natural smoke exhaust ability. Comparing Tests 1 and 3 shows that HPWMS shortens the fire extinguishing time by 76.6%, reduces the smoke temperature and diffusion velocity, and reduces the average concentration of CO in the R stairwell by more than 60%. In low-rise buildings, using the natural smoke exhaust in the stairwell can timely discharge the smoke, reduce the threat of smoke to other floors, and will not increase the hazard of smoke to other floors.

- This study demonstrates the negative effect of HPWMS on natural smoke exhaust and obtains the influence of this effect on smoke diffusion in buildings. HPWMS reduces the diffusion velocity and destabilizes the smoke layer, weakening the performance of natural smoke exhaust. However, in this case, the building floor is lower, and the difference between the natural smoke exhaust efficiency of Tests 2 and 4 is not obvious. Moreover, the ASET value at each staircase of Test 4 is the largest, which indicates that the combined effect of HPWMS and natural smoke exhaust can be more beneficial for fire evacuation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- USFA, Fire Risk in 2019. Available online: https://www.usfa.fema.gov/statistics/deaths-injuries/ (accessed on 14 December 2022).

- SAWS. Jiangxi Radio and Television Development Center Art Kindergarten Fire Accident; China’s Work Safety Yearbook: Beijing, China, 2002; pp. 456–457. [Google Scholar]

- Lulea, M.D.; Iordache, V.; Nastase, I. Numerical Model Development of the Air Temperature Variation in a Room Set on Fire for Different Ventilation Scenarios. Appl. Sci. 2021, 11, 11698. [Google Scholar] [CrossRef]

- Ji, J. Fire Dynamic in High-Rise Building; Science Press: Beijing, China, 2020; pp. 50–51. [Google Scholar]

- Rüppel, U.; Schatz, K. Designing a BIM-based serious game for fire safety evacuation simulations. Adv. Eng. Inf. 2011, 25, 600–611. [Google Scholar] [CrossRef]

- Wang, J.; Wei, G.; Dong, X. A dynamic fire escape path planning method with BIM. J. Ambient Intell. Hum. Comput. 2021, 12, 10253–10265. [Google Scholar] [CrossRef]

- Chen, X.-S.; Liu, C.-C.; Wu, I.C. A BIM-based visualization and warning system for fire rescue. Adv. Eng. Inf. 2018, 37, 42–53. [Google Scholar] [CrossRef]

- Shi, L.; Chew, M.Y.L.; Liu, X.Y.; Cheng, X.D.; Wang, B.; Zhang, G.M. An experimental and numerical study on fire behaviors of charring materials frequently used in buildings. Energy Build. 2017, 138, 140–153. [Google Scholar] [CrossRef]

- Doheim, R.M.; Yohanis, Y.G.; Nadjai, A.; Elkadi, H. The impact of atrium shape on natural smoke ventilation. Fire Saf. J. 2014, 63, 9–16. [Google Scholar] [CrossRef]

- Kaye, N.B.; Hunt, G.R. Smoke filling time for a room due to a small fire: The effect of ceiling height to floor width aspect ratio. Fire Saf. J. 2007, 42, 329–339. [Google Scholar] [CrossRef]

- Tang, J.; Shi, B.m.; Chen, K. Numerical simulation of fire smoke flow in typical structure of building corridor. J. Saf. Sci. Technol. 2015, 11, 33–37. [Google Scholar]

- Zhang, J.; Weng, J.W.; Zhou, T.N.; Ouyang, D.X.; Chen, Q.P.; Wei, R.C.; Wang, J. Investigation on Smoke Flow in Stairwells induced by an Adjacent Compartment Fire in High Rise Buildings. Appl. Sci. 2019, 9, 1431. [Google Scholar] [CrossRef]

- Lu, X.X.; Shi, G.Y.; Song, S.Y. Investigation on the fire behaviour and propagation rule of fire overflow in the high-rise concave building structure. Indoor Built Environ. 2022, 32, 214–229. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.F.; Bi, Q.; Li, Y.; Chow, W.K.; Cheng, C.H.; To, C.W.; Chow, C.L. Performance evaluation on fixed water-based firefighting system in suppressing large fire in urban tunnels. Tunn. Undergr. Space Technol. 2019, 84, 56–69. [Google Scholar] [CrossRef]

- Cheong, M.K.; Cheong, W.O.; Leong, K.W.; Lemaire, A.D.; Noordijk, L.M. Heat Release Rate of Heavy Goods Vehicle Fire in Tunnels with Fixed Water Based Fire-Fighting System. Fire Technol. 2014, 50, 249–266. [Google Scholar] [CrossRef]

- Dasgotra, A.; Rangarajan, G.; Tauseef, S.M. CFD-based study and analysis on the effectiveness of water mist in interacting pool fire suppression. Process Saf. Environ. Prot. 2021, 152, 614–629. [Google Scholar] [CrossRef]

- Li-wei, P.A.N.; Lo, S.M.; Guang-xuan, L.; Bei-hua, C. Experimental Study of Smoke Control in Subway Station for Tunnel Area Fire by Water Mist System. Procedia Eng. 2011, 11, 335–342. [Google Scholar] [CrossRef]

- Jiang, Q.; Gao, S.; Kong, X.X. Application analysis of high pressure water mist fire extinguishing system in subway train. Water Wastewater Eng. 2020, 56, 76–80, 85. [Google Scholar] [CrossRef]

- Lee, J. Numerical analysis on the rapid fire suppression using a water mist nozzle in a fire compartment with a door opening. Nucl. Eng. Technol. 2019, 51, 410–423. [Google Scholar] [CrossRef]

- Yang, P.Z.; Liu, T.; Qin, X.A. Experimental and numerical study on water mist suppression system on room fire. Build. Environ. 2010, 45, 2309–2316. [Google Scholar] [CrossRef]

- Santangelo, P.E.; Tarozzi, L.; Tartarini, P. Full-Scale Experiments of Fire Control and Suppression in Enclosed Car Parks: A Comparison Between Sprinkler and Water-Mist Systems. Fire Technol. 2016, 52, 1369–1407. [Google Scholar] [CrossRef]

- Li, B.Q.; Liu, B.; Tang, L.G.; Zhao, S.; Chen, Y. Application Analysis of High Pressure Fine Water Mist Extinguishing Technology in Metro Vehicles. Electr. Driv. Loco. 2020, 273, 124–128. [Google Scholar] [CrossRef]

- Yao, B.; Chow, W.K. Extinguishment of a PMMA fire by water spray with high droplet speeds. Int. J. Therm. Sci. 2005, 44, 410–419. [Google Scholar] [CrossRef]

- Yu, H.Z. The Ceiling Height Limits for Water Mist Protection of Two Solid Combustible Fire Hazards in Open Environment. Fire Technol. 2021, 57, 163–187. [Google Scholar] [CrossRef]

- Zhang, P.H.; Tang, X.; Tian, X.L.; Liu, C.; Zhong, M.H. Experimental study on the interaction between fire and water mist in long and narrow spaces. Appl. Therm. Eng. 2016, 94, 706–714. [Google Scholar] [CrossRef]

- Liu, H.; Wang, C.; De Cachinho Cordeiro, I.M.; Yuen, A.C.Y.; Chen, Q.; Chan, Q.N.; Kook, S.; Yeoh, G.H. Critical assessment on operating water droplet sizes for fire sprinkler and water mist systems. J. Build. Eng. 2020, 28, 100999. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Liu, T.; Ma, J.; Li, G.; Zhao, Z. Preliminary study on extinguishing shielded fire with water mist. Process Saf. Environ. Prot. 2020, 141, 344–354. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Huang, Y.; Tao, C.; Zhang, H. Experimental study on fire smoke control using water mist curtain in channel. J. Hazard. Mater. 2018, 342, 231–241. [Google Scholar] [CrossRef]

- Ku, Y.; Zhang, J.; Wang, Z.; Li, Y.; Yao, H. A Numerical Study on the Extinguishing Performances of High-Pressure Water Mist on Power-Transformer Fires for Different Flow Rates and Particle Velocities. Fld. Dyn. Mater. Process. 2021, 17, 1077–1090. [Google Scholar] [CrossRef]

- Lee, J.; Moon, J. Numerical analysis of the effect of horizontal distance between a water mist nozzle and ignition source on reduction in heat release rate. Ann. Nucl. Energy 2020, 144, 107560. [Google Scholar] [CrossRef]

- Gui, X.; Xue, H.; Hu, Z.; Cui, Z. Influence of Water Mist Nozzle Characteristic Parameters on Oil Pool Fire Extinguishing in Confined Space. Arab. J. Sci. Eng. 2023, 48, 3441–3454. [Google Scholar] [CrossRef]

- Papa, R.; Andrade, C.R.; Zaparoli, E.L.; Santos, L.C.D. CFD analysis of smoke transport inside an aircraft cargo compartment. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 327–334. [Google Scholar] [CrossRef]

- Li, G.C.; Pan, C.Y.; Liu, Y.P.; Zhu, X.L.; Ni, X.M.; Zhao, X.D.; Chen, G.X.; Wang, X.S. Evaluation of the effect of water mist on propane/air mixture deflagration: Large-scale test. Process Saf. Environ. Prot. 2021, 147, 1101–1109. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Y.; Wang, X.; Kong, X.; Li, G. Cooling control of thermally-induced thermal runaway in 18,650 lithium ion battery with water mist. Energy Convers. Manag. 2019, 199, 111969. [Google Scholar] [CrossRef]

- Liu, Y.P.; Wang, X.S.; Zhu, P.; Li, G.C.; Ni, X.M.; Zhang, J. Experimental study on gas jet suppressed by water mist: A clean control technique in natural gas leakage incidents. J. Cleaner Prod. 2019, 223, 163–175. [Google Scholar] [CrossRef]

- Liu, Y.P.; Shen, J.X.; Ma, J.; Li, G.C.; Zhao, Z.H.; Ni, X.M.; Wang, X.S. Laser-based measurement and numerical simulation of methane-air jet flame suppression with water mist. Process Saf. Environ. Prot. 2021, 148, 1033–1047. [Google Scholar] [CrossRef]

- Chen, Y.B. Influence of layout of windows in the staircase on natural smoke exhausting. Fire Sci. Technol. 2015, 34, 1436–1439. [Google Scholar]

- Ahn, C.-S.; Kim, D.-Y.; Park, C.; Kim, M.-W.; Kim, T.; Bang, B.-H.; An, S.; Yarin, A.L.; Yoon, S.S. Experimental and numerical study of smoke behavior in high-rise stairwells with open and closed windows. Int. J. Therm. Sci. 2020, 157, 106500. [Google Scholar] [CrossRef]

- Su, C.H.; Lin, Y.C.; Shu, C.M.; Hsu, M.C. Stack effect of smoke for an old-style apartment in Taiwan. Build. Environ. 2011, 46, 2425–2433. [Google Scholar] [CrossRef]

- McKeen, P.; Liao, Z. Numerical analysis on the hazards of open stairwell doors in high-rise residential buildings. J. Build. Eng. 2022, 54, 104561. [Google Scholar] [CrossRef]

- Sun, J.Y.; Fang, Z.; Tang, Z.; Beji, T.; Merci, B. Experimental study of the effectiveness of a water system in blocking fire-induced smoke and heat in reduced-scale tunnel tests. Tunn. Undergr. Space Technol. 2016, 56, 34–44. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.W.; Zhang, X.N.; Fan, C.G.; Gong, J.H. Performance evaluation of water mist fire suppression: A clean and sustainable fire-fighting technique in mechanically-ventilated place. J. Clean. Prod. 2019, 209, 1319–1331. [Google Scholar] [CrossRef]

- Lee, J. Numerical analysis of how ventilation conditions impact compartment fire suppression by water mist. Ann. Nucl. Energy 2020, 136, 107021. [Google Scholar] [CrossRef]

- Zhang, T.; Cao, D.; Lv, Z. Simulation Study on the Influence of Fire Partition on Curtain Wall Temperature in Super High-Rise Buildings in China. Complexity 2021, 2021, 4124049. [Google Scholar] [CrossRef]

- Zhang, T. Simulation Study on Fire Visibility of Typical Floor Planes of Modern Super High-Rise Office Buildings in China. Complexity 2020, 2020, 8868522. [Google Scholar] [CrossRef]

- Meng, N.; Hu, L.; Wu, L.; Yang, L.; Zhu, S.; Chen, L.; Tang, W. Numerical study on the optimization of smoke ventilation mode at the conjunction area between tunnel track and platform in emergency of a train fire at subway station. Tunn. Undergr. Space Technol. 2014, 40, 151–159. [Google Scholar] [CrossRef]

- Xiao, M.F.; Zhou, X.H.; Pan, X.X.; Wang, Y.A.; Wang, J.; Li, X.L.; Sun, Y.S.N.; Wang, Y.M. Simulation of emergency evacuation from construction site of prefabricated buildings. Sci. Rep. 2022, 12, 2732. [Google Scholar] [CrossRef]

- Wang, J.G.; Zhao, S.R.; Su, J.K. Influence of different smoke exhaust modes on personnel evacuation in subway station fire. Fire Sci. Technol. 2021, 40, 1141–1145. [Google Scholar]

- Blanchard, E.; Morlon, R.; Parent, G.; Fromy, P.; Boulet, P.; Borgiallo, D. Experimental Study of the Interaction Between Water Sprays and Smoke Layer. Fire Technol. 2018, 54, 479–501. [Google Scholar] [CrossRef]

- Morlon, R.; Boulet, P.; Parent, G.; Morlon, R.; Lechene, S.; Blanchard, E.; Rebuffat, C.; Fromy, P.; Vantelon, J.P.; Borgiallo, D. Study of De-stratification and Optical Effects Observed During Smoke/Mist Interactions. Fire Technol. 2015, 51, 1231–1248. [Google Scholar] [CrossRef]

- Xu, Z.S.; Jiang, X.P. Smoke Control Engineering; China Machine Press: Beijing, China, 2011; pp. 2–3. [Google Scholar]

| Settings | Parameters |

|---|---|

| HRRPUA (kW/m2) | 4000 |

| Burner size | 1 m × 1 m |

| Soot yield (kg/kg) | 0.07 [45] |

| CO yield (kg/kg) | 0.04 [45] |

| EPUMO2 (kJ/kg) | 13,100 |

| Initial temperature (°C) | 20 |

| Initial pressure (Pa) | 101,300 |

| Humidity (%) | 40 |

| Simulation time (s) | 500 |

| Initial visibility (m) | 30 |

| Parameter | HPWMS | WSS |

|---|---|---|

| Operating pressure (MPa) | 10 | 0.13 |

| K-Factor | 1.2 | 80 |

| Jet velocity (m/s) | 15 | 5 |

| Median volumetric diameter (µm) | 100 | 1000 |

| Distribution | Constant | Constant |

| Spray cone angle | 60° | 60° |

| Working Conditions | Sprinkler System | Window Type |

|---|---|---|

| Test 1 | WSS | Fixed window |

| Test 2 | WSS | Sliding window |

| Test 3 | HPWMS | Fixed window |

| Test 4 | HPWMS | Sliding window |

| Site | Detecting Point | Available Safety Egress Time (s) | ||

|---|---|---|---|---|

| CO Concentration | Temperature | Smoke Visibility | ||

| First floor | R1(1) | 101 | 101 | 72 |

| L1(1) | 93 | 97 | 76 | |

| R1(2) | 104 | 110 | 88 | |

| L1(2) | NO * | NO | 124 | |

| Stairwell | R1(3) | 134 | 168 | 100 |

| L1(3) | NO | NO | 124 | |

| R2(2) | 180 | 334 | 122 | |

| L2(2) | NO | NO | 126 | |

| R3(2) | 169 | 330 | 124 | |

| L3(2) | NO | NO | 132 | |

| Second floor | R2(1) | NO | NO | 299 |

| L2(1) | NO | NO | 392 | |

| Third floor | R3(1) | NO | NO | 188 |

| L3(1) | 398 | NO | 250 | |

| Point | Test | Average CO Concentration (ppm) | Degree of Reduction | ASET (s) | Difference Value (s) |

|---|---|---|---|---|---|

| R2(2) | 1 | 613.03 | 41.60% | 180 | 121 |

| 2 | 358.02 | 301 | |||

| R3(2) | 1 | 984.52 | 35.30% | 169 | 34 |

| 2 | 636.98 | 203 | |||

| R3(1) | 1 | 148.92 | 45.82% | NO * | NO |

| 2 | 80.68 | NO |

| Detecting Point | Test 1 | Test 2 | Difference |

|---|---|---|---|

| R2(1) | 30.56 °C | 29.99 °C | 0.57 °C |

| L2(1) | 30.19 °C | 30.05 °C | 0.14 °C |

| R3(1) | 35.22 °C | 32.27 °C | 2.96 °C |

| L3(1) | 33.14 °C | 31.22 °C | 1.92 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Wang, G. Indoor Fire Simulation in Low-Rise Teaching Buildings Based on BIM–FDS. Fire 2023, 6, 203. https://doi.org/10.3390/fire6050203

Liu M, Wang G. Indoor Fire Simulation in Low-Rise Teaching Buildings Based on BIM–FDS. Fire. 2023; 6(5):203. https://doi.org/10.3390/fire6050203

Chicago/Turabian StyleLiu, Mengkai, and Guoquan Wang. 2023. "Indoor Fire Simulation in Low-Rise Teaching Buildings Based on BIM–FDS" Fire 6, no. 5: 203. https://doi.org/10.3390/fire6050203

APA StyleLiu, M., & Wang, G. (2023). Indoor Fire Simulation in Low-Rise Teaching Buildings Based on BIM–FDS. Fire, 6(5), 203. https://doi.org/10.3390/fire6050203