Effect of Lignin or Lignosulfonate Addition on the Fire Resistance of Areca (Areca catechu) Particleboards Bonded with Ultra-Low-Emitting Urea-Formaldehyde Resin

Abstract

:1. Introduction

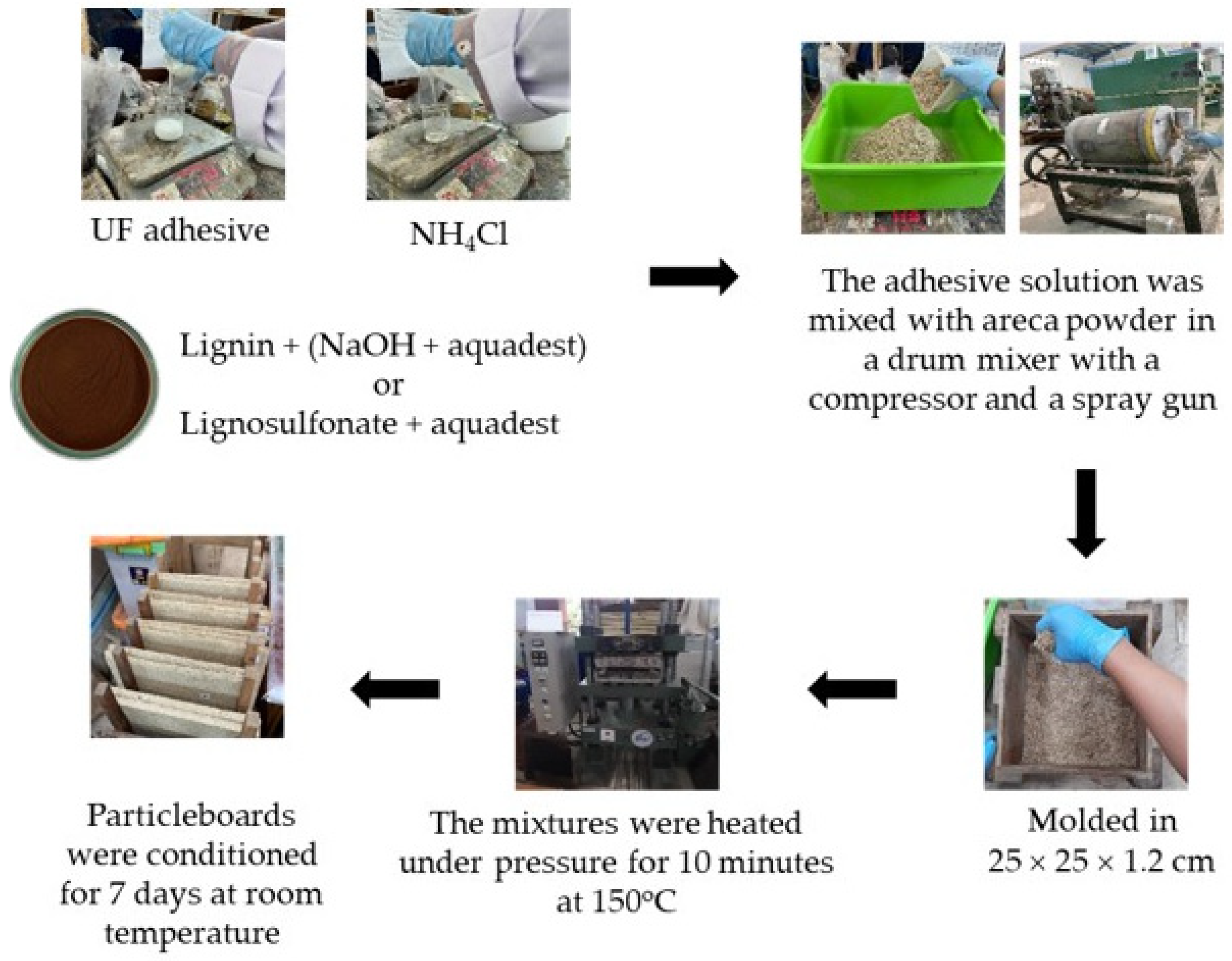

2. Materials and Methods

2.1. Physical Properties (JIS-A-5908-2003)

2.1.1. Density

2.1.2. Moisture Content

2.1.3. Water Absorption

2.1.4. Thickness Swelling

2.2. Mechanical Characteristics (JIS-A-5908-2003)

2.2.1. Modulus of Rupture (MOR)

2.2.2. Modulus of Elasticity (MOE)

2.2.3. Internal Bond Strength (IB)

2.3. Statistical Analysis

2.4. Fire Resistance Characteristics

3. Results and Discussion

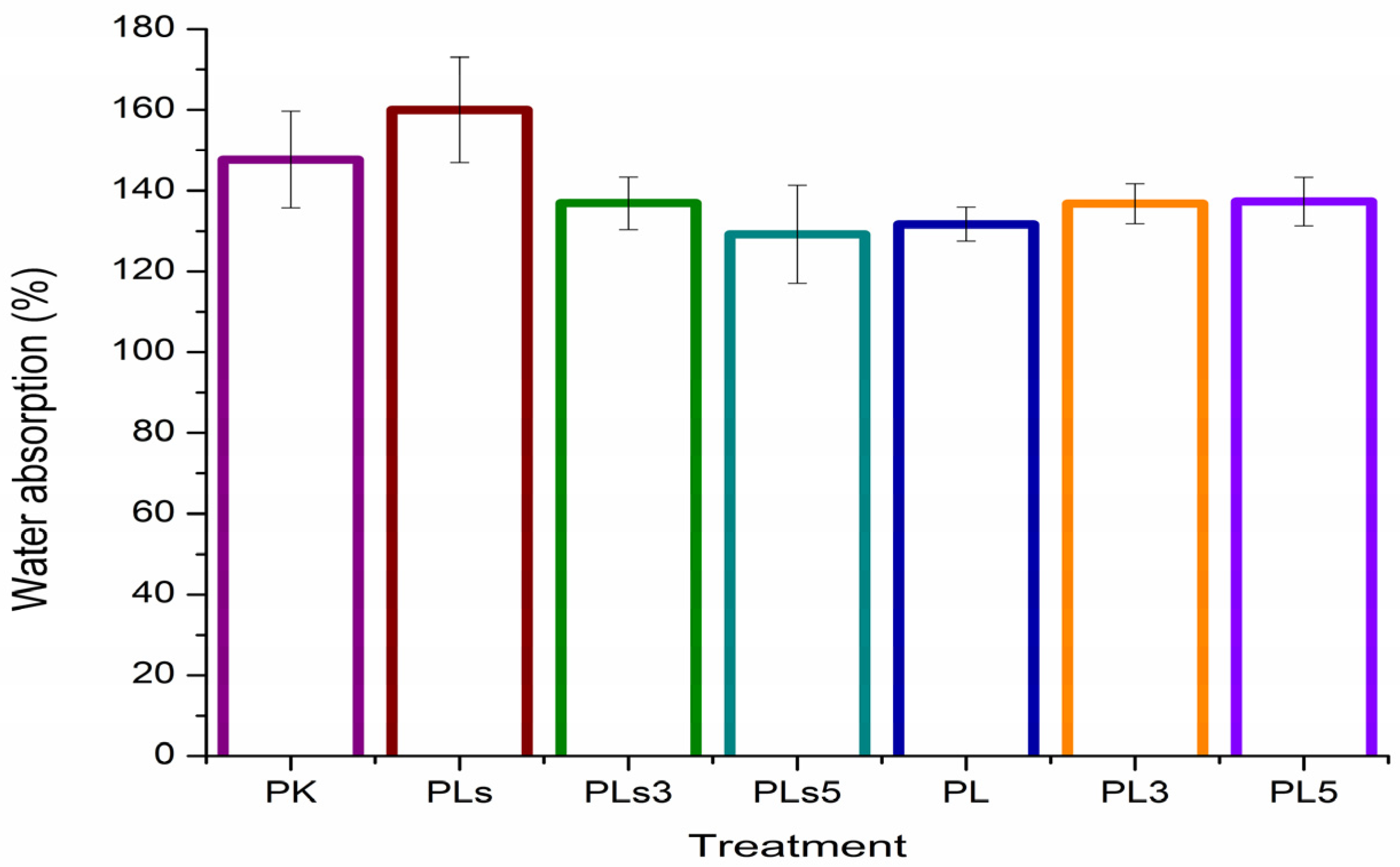

3.1. Physical Characteristics

3.2. Mechanical Characteristics

3.3. Fire Resistance Characteristics

4. Conclusions

- The particleboards with lignin solution had the highest density of 0.84 g/cm3 (PL3), the lowest moisture content, thickness swelling, and water absorption of 9.35% (PL3), 72.16% (PL), and 131.65% (PL), and the highest MOE, MOR, and IB at 987.99 kg/cm2 (PL3), 10.16 kg/cm2 (PL5), and 0.67 kg/cm2 (PL).

- The particleboards with lignosulfonate solution had the highest density at 0.83 g/cm3 (PLs3), the lowest moisture content, thickness swelling, and water absorption at 9.06% (PLs3), 83.61% (PLs5), and 129.17% (PLs5), and the highest MOE, MOR, and IB at 1045.72 kg/cm2 (PLs5), 11.13 kg/cm2 (PLs5), and 0.68 kg/cm2 (PLs).

- All the particleboards had a rating of V-0 for the UL-94 test, and the lowest mass loss for the torch gas test was 16.70% (PLs5). The weight loss of particleboard can be minimized by adding additives with lignosulfonate as fire retardants.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Romadhon, M.R.; Tulalo, M.A. Akaike Information Criterion (AIC) and stepwise regression method to select the areca nut population as across parent material. IOP Conf. Ser. Earth Environ. Sci. 2022, 974, 012100. [Google Scholar] [CrossRef]

- Pant, B.D.; Neupane, D.; Paudel, D.R.; Lohani, P.C.; Gautam, S.K.; Pokhrel, M.R.; Poudel, B.R. Efficient biosorption of hexavalent chromium from water by modified arecanut leaf sheath. Heliyon 2022, 8, e09283. [Google Scholar] [CrossRef]

- Kurniawan, S.; Isnen, M.; Setiawan, A.; Legi, I.W. Pengaruh Tempe ratur dan Lama Waktu Pengepresan Alat Hot Press Pelepah Daun Pinang. J. Inov. 2018, 1, 14–17. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, A.; Ferrandez-Garcia, M.T.; Garcia-Ortuño, T.; Ferrandez-Villena, M. Influence of the Density in Binderless Particleboards Made from Sorghum. Agronomy 2022, 12, 1387. [Google Scholar] [CrossRef]

- de Almeida Mesquita, R.G.; Mendes, L.M.; Sanadi, A.R.; Neto, A.S.; Claro, P.I.C.; Correa, A.C.; Marconcini, J.M. Urea Formaldehyde and Cellulose Nanocrystals Adhesive: Studies Applied to Sugarcane Bagasse Particleboards. J. Polym. Environ. 2018, 26, 3040–3050. [Google Scholar] [CrossRef]

- Atoyebi, O.D.; Aladegboye, O.J.; Fatoki, F.O. Physico-Mechanical Properties of Particle Board made from Coconut Shell, Coconut Husk and Palm Kernel Shell. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1107, 012131. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Athanassiadou, E.T.; Barbu, M.C.; Wijnendaele, K. Adhesive systems used in the European particleboard, MDF and OSB industries. Wood Mater. Sci. Eng. 2017, 13, 104–116. [Google Scholar] [CrossRef]

- Kumar, R.N.; Pizzi, A. Environmental Aspects of Adhesives—Emission of Formaldehyde. In Adhesives for Wood and Lignocellulosic Materials; Wiley-Scrivener Publishing: Hoboken, NJ, USA, 2019; pp. 293–315. [Google Scholar] [CrossRef]

- Savov, V.; Antov, P.; Zhou, Y.; Bekhta, P. Eco-Friendly Wood Composites: Design, Characterization and Applications. Polymers 2023, 15, 892. [Google Scholar] [CrossRef]

- Antov, P.; Lee, S.H.; Lubis, M.A.R.; Kristak, L.; Réh, R. Advanced Eco-Friendly Wood-Based Composites II. Forests 2023, 14, 826. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Iswanto, A.H.; Hua, L.S.; Kristak, L.; Antov, P.; Putri, R.; Juliana, I.; Mardawati, E. Post-modification of ultra-low molar ratio urea-formaldehyde adhesive with different types and levels of organic acid hardener. IOP Conf. Ser. Earth Environ. Sci. 2022, 1115, 012037. [Google Scholar] [CrossRef]

- Yu, O.; Kim, K.H. Lignin to Materials: A Focused Review on Recent Novel Lignin Applications. Appl. Sci. 2020, 10, 4626. [Google Scholar] [CrossRef]

- Agustiany, E.A.; Rasyidur Ridho, M.; Rahmi , D.N.M.; Madyaratri, E.W.; Falah, F.; Lubis, M.A.R.; Solihat, N.N.; Syamani, F.A.; Karungamye, P.; Sohail, A.; et al. Recent developments in lignin modification and its application in lignin-based green composites: A review. Polym. Compos. 2022, 43, 4848–4865. [Google Scholar] [CrossRef]

- Madyaratri, E.W.; Iswanto, A.H.; Nawawi, D.S.; Lee, S.H.; Fatriasari, W. Improvement of Thermal Behavior of Rattan by Lignosulphonate Impregnation Treatment. Forests 2022, 13, 1773. [Google Scholar] [CrossRef]

- Solihat, N.N.; Hidayat, A.F.; Taib, M.N.A.M.; Hussin, M.H.; Lee, S.H.; Ghani, M.A.A.; Al Edrus, S.S.O.; Vahabi, H.; Fatriasari, W. Recent Developments in Flame-Retardant Lignin-Based Biocomposite: Manufacturing, and characterization. J. Polym. Environ. 2022, 30, 4517–4537. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Havrilyuk, M.R.; Balitska, V.O.; Kolesnikov, V.O.; Ivaskevych, L.M. Increasing Turbine Hall Safety by Using Fire-Resistant, Hydrogen-Containing Lubricant Cooling Liquid for Rotor Steel Mechanical Treatment. Energies 2023, 16, 535. [Google Scholar] [CrossRef]

- Ridho, M.R.; Agustiany, E.A.; Dn, M.R.; Madyaratri, E.W.; Ghozali, M.; Restu, W.K.; Falah, F.; Lubis, M.A.R.; Syamani, F.A.; Nurhamiyah, Y.; et al. Lignin as Green Filler in Polymer Composites: Development Methods, Characteristics, and Potential Applications. Adv. Mater. Sci. Eng. 2022, 2022, 1363481. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Production and Application of Lignosulfonates and Sulfonated Lignin. Chemsuschem 2017, 10, 1861–1877. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karthäuser, J.; Biziks, V.; Mai, C.; Militz, H. Lignin and Lignin-Derived Compounds for Wood Applications—A Review. Molecules 2021, 26, 2533. [Google Scholar] [CrossRef] [PubMed]

- Nasional, S.; Ics, I.; Nasional, B.S. Cara Uji Bakar Bahan Bangunan Untuk Pencegahan Bahaya Kebakaran Pada Bangunan Rumah dan Gedung; Scribd, Inc.: San Francisco, CA, USA, 2008. [Google Scholar]

- Fatisa, H.; Tanjungpura, U.; Nugroho, B.S.; Nurhanisa, M.; Wahyuni, D.; Asri, A. Analysis of acoustic and physical properties of oil palm empty fruit bunch particle composite boards fabricated with varying adhesive content. J. Ris. Fis. Edukasi Sains 2023, 10, 60–69. [Google Scholar] [CrossRef]

- Humaira, T.; Kurniawan, B.; At-Tsaqib, J.H.; Hasanah, S. Produksi papan partikel berbahan dasar sekam padi dan polystyrene. Einstein 2022, 10, 1–8. [Google Scholar] [CrossRef]

- Youngquist, J.A. Wood-Based Composites and Panel Products. In Wood Handbook: Wood as an Engineering Material; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Sandberg, D.; Gorbacheva, G.; Lichtenegger, H.; Niemz, P.; Teischinger, A. Advanced Engineered Wood-Material Concepts. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1835–1888. [Google Scholar]

- Fitra, F.; Nurdin, H.; Hasanuddin, H.; Waskito, W. Karakteristik Papan Partikel Berbahan Baku Serat Pinang. Ranah Res. J. Multidiscip. Res. Dev. 2019, 1, 1029–1036. [Google Scholar]

- Laksono, A.D.; Rozikin, M.N.; Pattara, N.A.S.; Cahyadi, I. Potensi Serbuk Kayu Ulin dan Serbuk Bambu Sebagai Aplikasi Papan Partikel Ramah Lingkungan—Review. J. Rekayasa Mesin 2021, 12, 267–274. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, C.E.; Ferrandez-Villena, M. Influence of Particle Size on the Properties of Boards Made from Washingtonia Palm Rachis with Citric Acid. Sustainability 2020, 12, 4841. [Google Scholar] [CrossRef]

- Maitz, S.; Schlemmer, W.; Hobisch, M.A.; Hobisch, J.; Kienberger, M. Preparation and Characterization of a Water-Soluble Kraft Lignin. Adv. Sustain. Syst. 2020, 4, 2000052. [Google Scholar] [CrossRef]

- Komisarz, K.; Majka, T.M.; Pielichowski, K. Chemical Transformation of Lignosulfonates to Lignosulfonamides with Improved Thermal Characteristics. Fibers 2022, 10, 20. [Google Scholar] [CrossRef]

- Boon, J.G.; Hashim, R.; Danish, M.; Nadhari, W.N.A.W. Physical and Mechanical Properties of Binderless Particleboard Made from Steam-Pretreated Oil Palm Trunk Particles. J. Compos. Sci. 2019, 3, 46. [Google Scholar] [CrossRef] [Green Version]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, Ľ.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef]

- Yetti, F.E.; Mora, M. Pengaruh Presentase Massa Partikel Kayu dan Serat Lidah Mertua pada Core terhadap Sifat Fisis dan Mekanis Papan Partikel. J. Fis. Unand 2019, 8, 380–386. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Krišťák, Ľ.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers 2021, 13, 220. [Google Scholar] [CrossRef]

- Nasution, W.M.; Mora, M. Analisis Pengaruh Komposisi Partikel Ampas Tebu dan Partikel Tempurung Kelapa terhadap Sifat Fisis dan Mekanis Komposit Papan Partikel Perekat Resin Epoksi. J. Fis. Unand 2018, 7, 117–123. [Google Scholar] [CrossRef]

- Ramadina, D.; Hafiza, M.; Zuhra, Z.; Razi, F. Pemanfaatan limbah kertas dan sekam padi sebagai filler papan partikel dengan menggunakan limbah botol plastik dan uUrea formaldehida sebagai perekat. Serambi Eng. 2022, 7, 3094–3101. [Google Scholar]

- Newman, W.H.; Glasser, W.G. Engineering Plastics from Lignin—XII. Synthesis and Performance of Lignin Adhesives with Isocyanate and Melamine. Holzforschung 1985, 39, 345–353. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and pMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef] [PubMed]

- Çetin, N.S.; Özmen, N. Use of organosolv lignin in phenol-formaldehyde resins for particleboard production: II. Particleboard production and properties. Int. J. Adhes. Adhes. 2002, 22, 481–486. [Google Scholar] [CrossRef]

- Legesse, A.A.; Gebremeskel, S.A.; Paramasivam, V.; Selvaraj, S.K. Development and characterization of bamboo—sesame stalk hybrid urea-formaldehyde matrix composite for particleboard application. Mater. Today Proc. 2021, 46, 7351–7358. [Google Scholar] [CrossRef]

- Eslah, F.; Enayati, A.A.; Tajvidi, M.; Faezipour, M.M. Regression models for the prediction of poplar particleboard properties based on urea formaldehyde resin content and board density. J. Agric. Sci. Technol. 2012, 14, 1321–1329. [Google Scholar]

- Rodriguez, A.; Herrero, M.; Asensio, M.; Santiago-Calvo, M.; Guerrero, J.; Cañibano, E.; Fernández, M.T.; Nuñez, K. Cooperative Effect of Chemical and Physical Processes for Flame Retardant Additives in Recycled ABS. Polymers 2023, 15, 2431. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, K.; Liu, W.; Liu, Y.; Wang, K.; Ge, W.; Guo, K. Fire performance of pultruded wood-cored GFRP sandwich components for building construction. Case Stud. Constr. Mater. 2022, 17, e01555. [Google Scholar] [CrossRef]

- Yew, M.C.; Yew, M.K.; Yuen, R.K.K. Experimental Analysis of Lightweight Fire-Rated Board on Fire Resistance, Mechanical, and Acoustic Properties. Fire 2023, 6, 221. [Google Scholar] [CrossRef]

| Treatment | Code |

|---|---|

| Particleboards-control | PK |

| Particleboards bonded with UF resin and commercial lignin | PL |

| Particleboards bonded with UF resin and isolated lignin after three washings | PL3 |

| Particleboards bonded with UF resin and isolated lignin after five washings | PL5 |

| Particleboards bonded with UF resin and commercial lignosulfonate | PLs |

| Particleboards bonded with UF resin and lignosulfonate from isolated lignin with three washings | PLs3 |

| Particleboards bonded with UF resin and lignosulfonate from isolated lignin with five washings | PLs5 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value * | |

|---|---|---|---|---|---|---|

| Modulus of rupture (MOR) | Between Groups | 6 | 2933.87 | 488.98 | 3.675 | 0.021 * |

| Within Groups | 14 | 1862.93 | 133.07 | |||

| Total | 20 | 4796.80 | ||||

| Modulus of elasticity (MOE) | Between Groups | 6 | 9,227,591.78 | 1,537,931.96 | 0.277 | 0.939 |

| Within Groups | 14 | 77,744,729.88 | 5,553,194.99 | |||

| Total | 20 | 86,972,321.66 | ||||

| Internal bond strength (IB) | Between Groups | 6 | 5.43 | 0.90 | 0.780 | 0.599 |

| Within Groups | 14 | 16.24 | 1.16 | |||

| Total | 20 | 21.67 | ||||

| Treatment | MOR | MOE | IB |

|---|---|---|---|

| PK | 79.71 ± 7.51 c | 10412.06 ± 3379 a | 6.52 ± 1.41 a |

| PLs | 77.13 ± 21.26 c | 8932.42 ± 1978 a | 5.38 ± 1.46 a |

| PLs3 | 95.26 ± 3.02 abc | 8736.15 ± 2176 a | 6.96 ± 1.19 a |

| PLs5 | 113.49 ± 7.80 a | 10663.42 ± 1458 a | 6.25 ± 1.23 a |

| PL | 94.53 ± 8.73 abc | 9816.21 ± 968 a | 6.87 ± 0.87 a |

| PL3 | 89.72 ± 14.56 bc | 10074.73 ± 3813 a | 6.80 ± 0.26 a |

| PL5 | 103.6 ± 8.04 ab | 9783.29 ± 1096 a | 6.18 ± 0.51 a |

| Treatment | t after Flame (s) | t after Extinguished (s) | Dripping | Rating |

|---|---|---|---|---|

| PK | 0 | 0 | No | V–0 |

| PL | 0 | 0 | No | V–0 |

| PL3 | 0 | 0 | No | V–0 |

| PL5 | 0 | 0 | No | V–0 |

| PLs | 0 | 0 | No | V–0 |

| PLs3 | 0 | 0 | No | V–0 |

| PLs5 | 0 | 0 | No | V–0 |

| Treatment | Weight before Flame (g) | Weight after Flame (g) | Mass Loss (%) |

|---|---|---|---|

| PK | 15.99 | 11.29 | 29.39 |

| PL | 15.57 | 5.88 | 62.24 |

| PL3 | 15.78 | 4.52 | 71.36 |

| PL5 | 16.1 | 4.5 | 72.05 |

| PLs | 16.5 | 8.23 | 50.12 |

| PLs3 | 17.62 | 12.38 | 29.74 |

| PLs5 | 17.55 | 14.62 | 16.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madyaratri, E.W.; Ridho, M.R.; Iswanto, A.H.; Osvaldová, L.M.; Lee, S.H.; Antov, P.; Fatriasari, W. Effect of Lignin or Lignosulfonate Addition on the Fire Resistance of Areca (Areca catechu) Particleboards Bonded with Ultra-Low-Emitting Urea-Formaldehyde Resin. Fire 2023, 6, 299. https://doi.org/10.3390/fire6080299

Madyaratri EW, Ridho MR, Iswanto AH, Osvaldová LM, Lee SH, Antov P, Fatriasari W. Effect of Lignin or Lignosulfonate Addition on the Fire Resistance of Areca (Areca catechu) Particleboards Bonded with Ultra-Low-Emitting Urea-Formaldehyde Resin. Fire. 2023; 6(8):299. https://doi.org/10.3390/fire6080299

Chicago/Turabian StyleMadyaratri, Elvara Windra, Muhammad Rasyidur Ridho, Apri Heri Iswanto, Linda Makovická Osvaldová, Seng Hua Lee, Petar Antov, and Widya Fatriasari. 2023. "Effect of Lignin or Lignosulfonate Addition on the Fire Resistance of Areca (Areca catechu) Particleboards Bonded with Ultra-Low-Emitting Urea-Formaldehyde Resin" Fire 6, no. 8: 299. https://doi.org/10.3390/fire6080299

APA StyleMadyaratri, E. W., Ridho, M. R., Iswanto, A. H., Osvaldová, L. M., Lee, S. H., Antov, P., & Fatriasari, W. (2023). Effect of Lignin or Lignosulfonate Addition on the Fire Resistance of Areca (Areca catechu) Particleboards Bonded with Ultra-Low-Emitting Urea-Formaldehyde Resin. Fire, 6(8), 299. https://doi.org/10.3390/fire6080299