Determining the Conditions That Lead to the Self-Extinguished and Self-Sustained Smoldering Combustion of Wood

Abstract

1. Introduction

2. Experiment

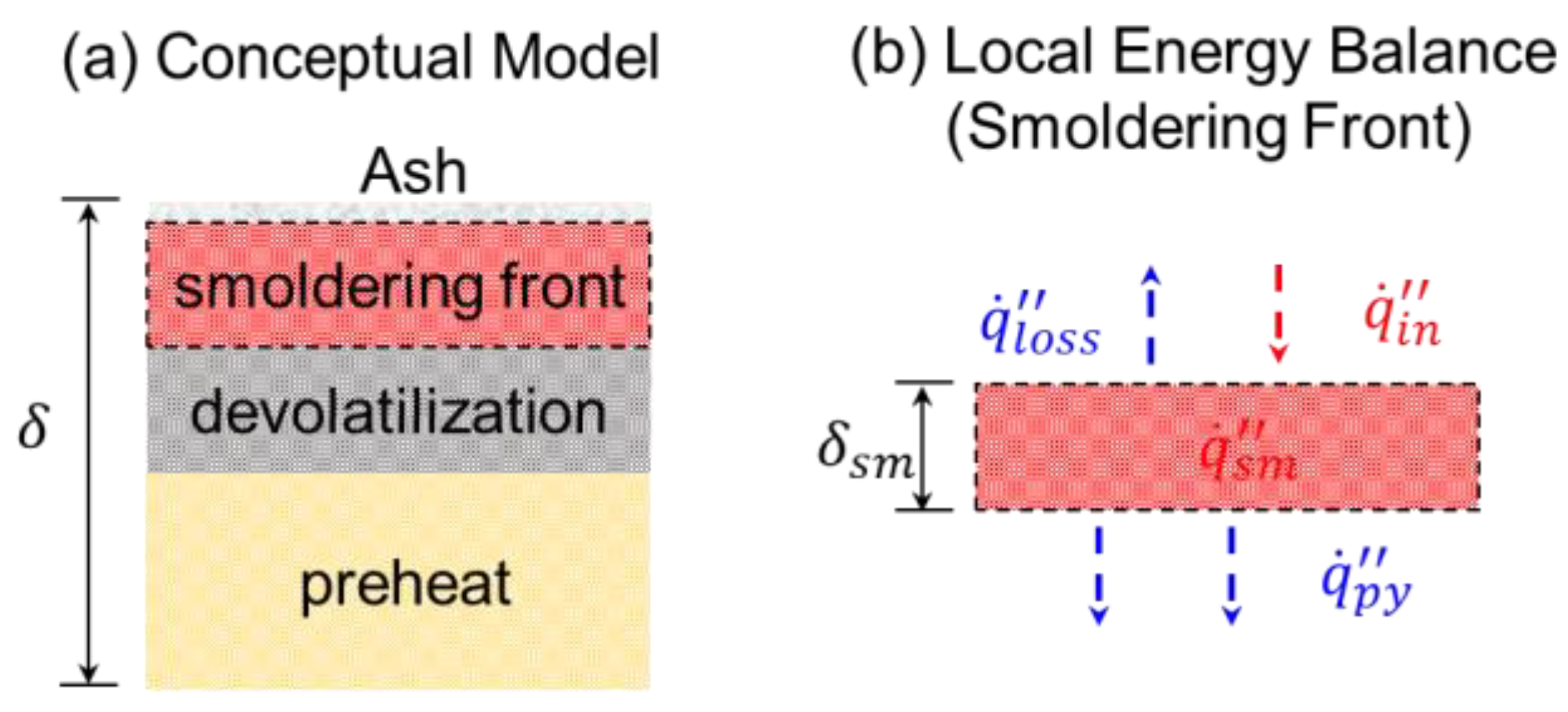

2.1. Materials

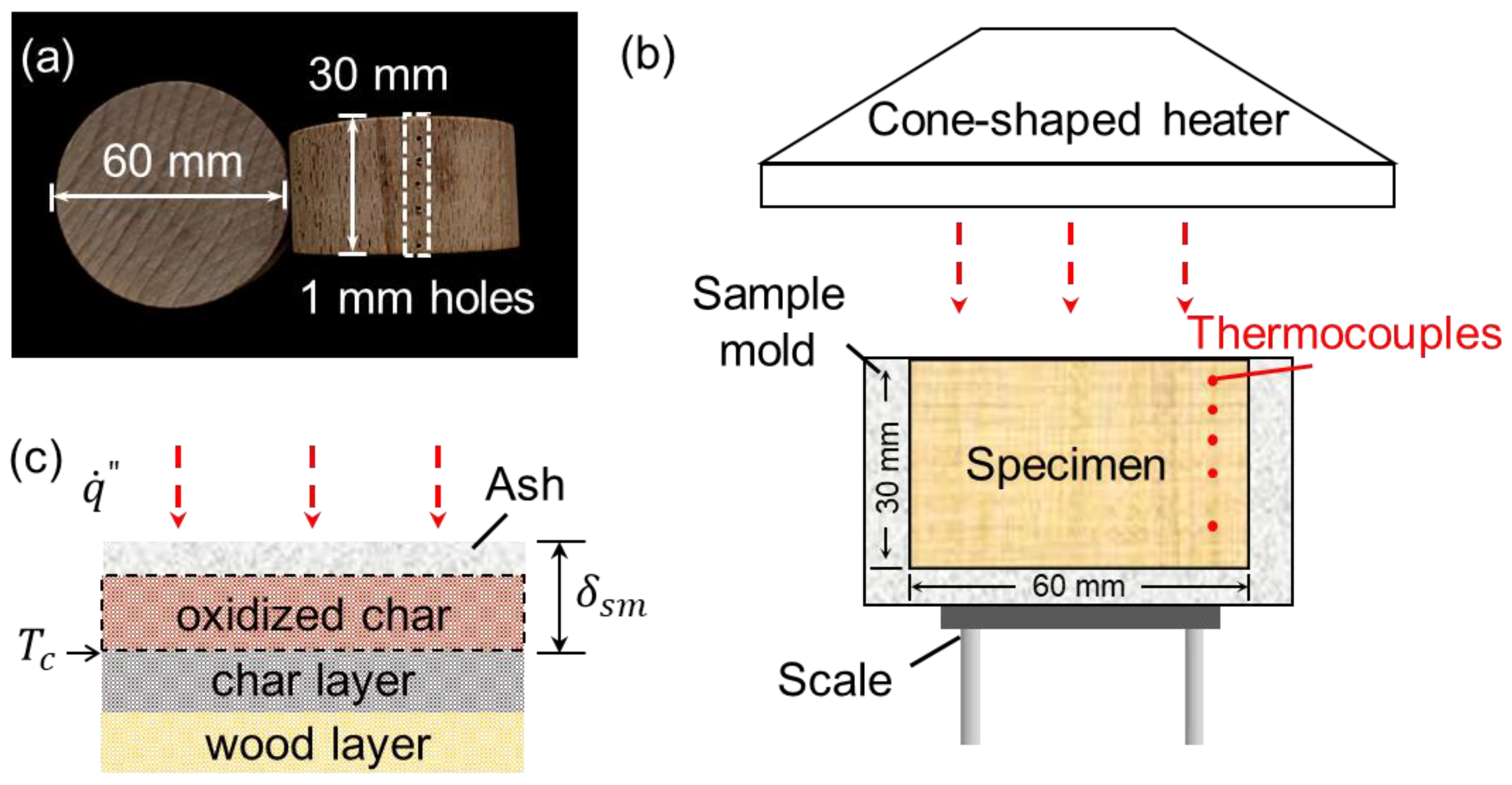

2.2. Setup and Test Procedures

2.3. Smoldering Front Depth

3. Experimental Results

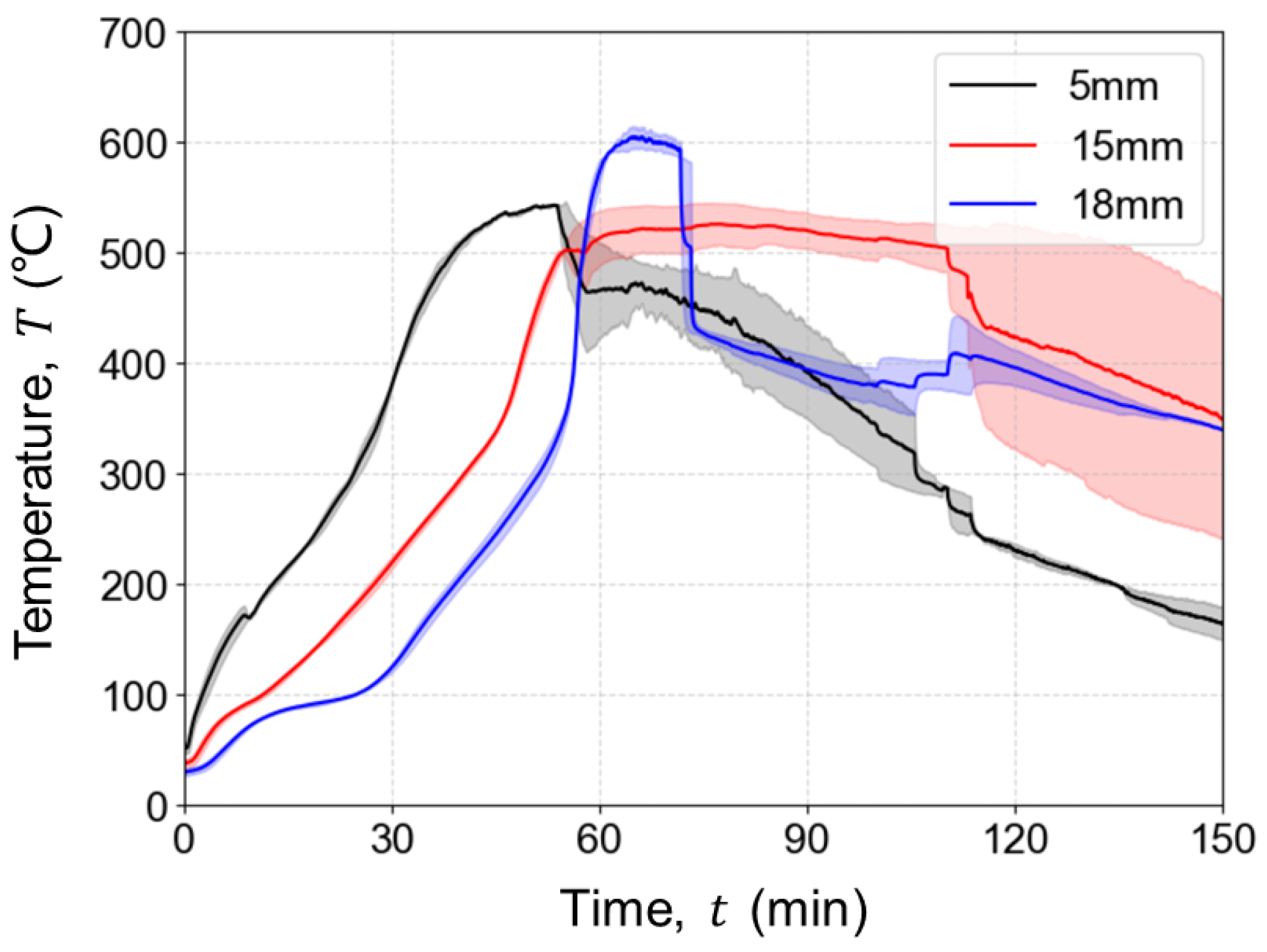

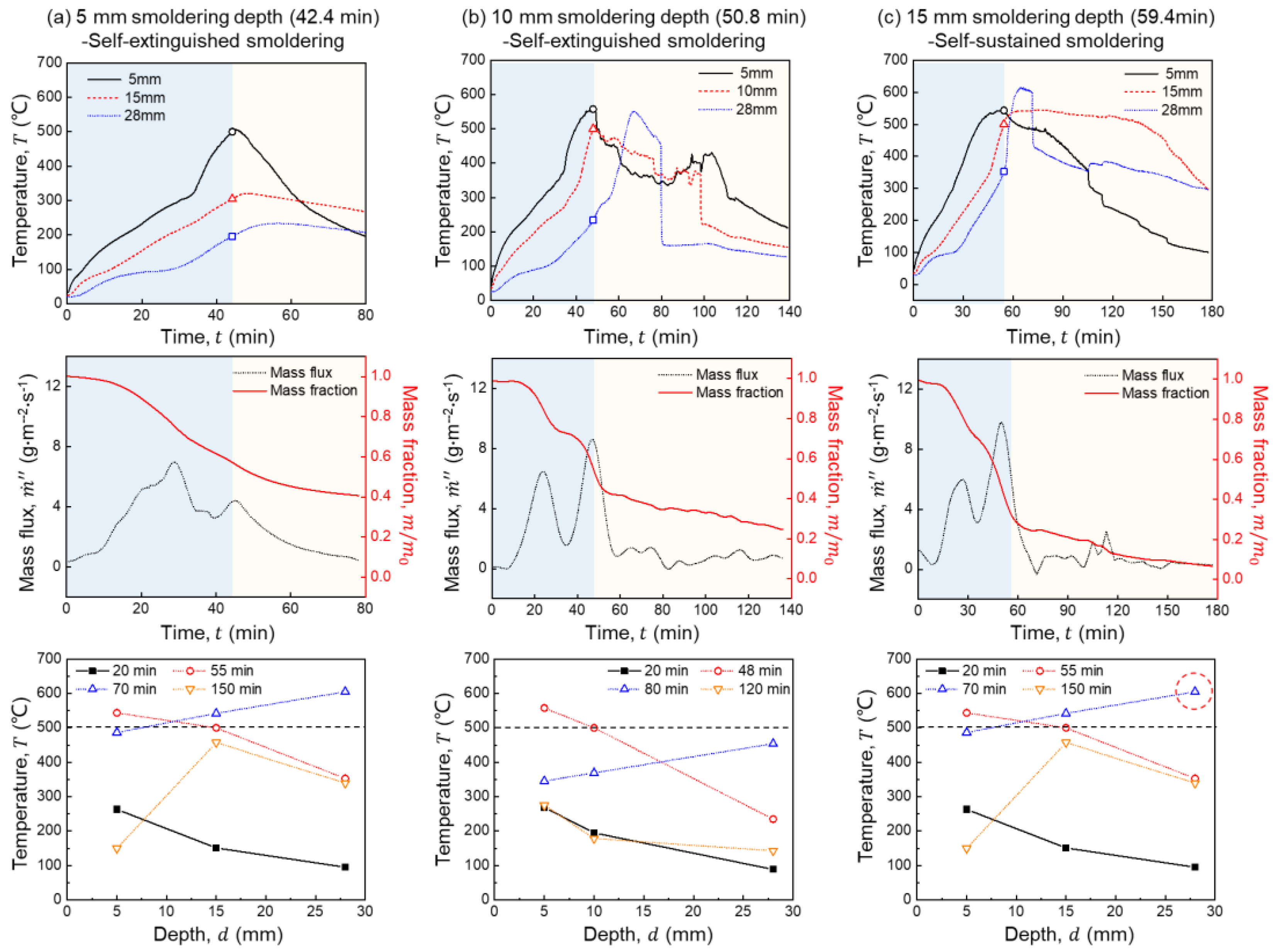

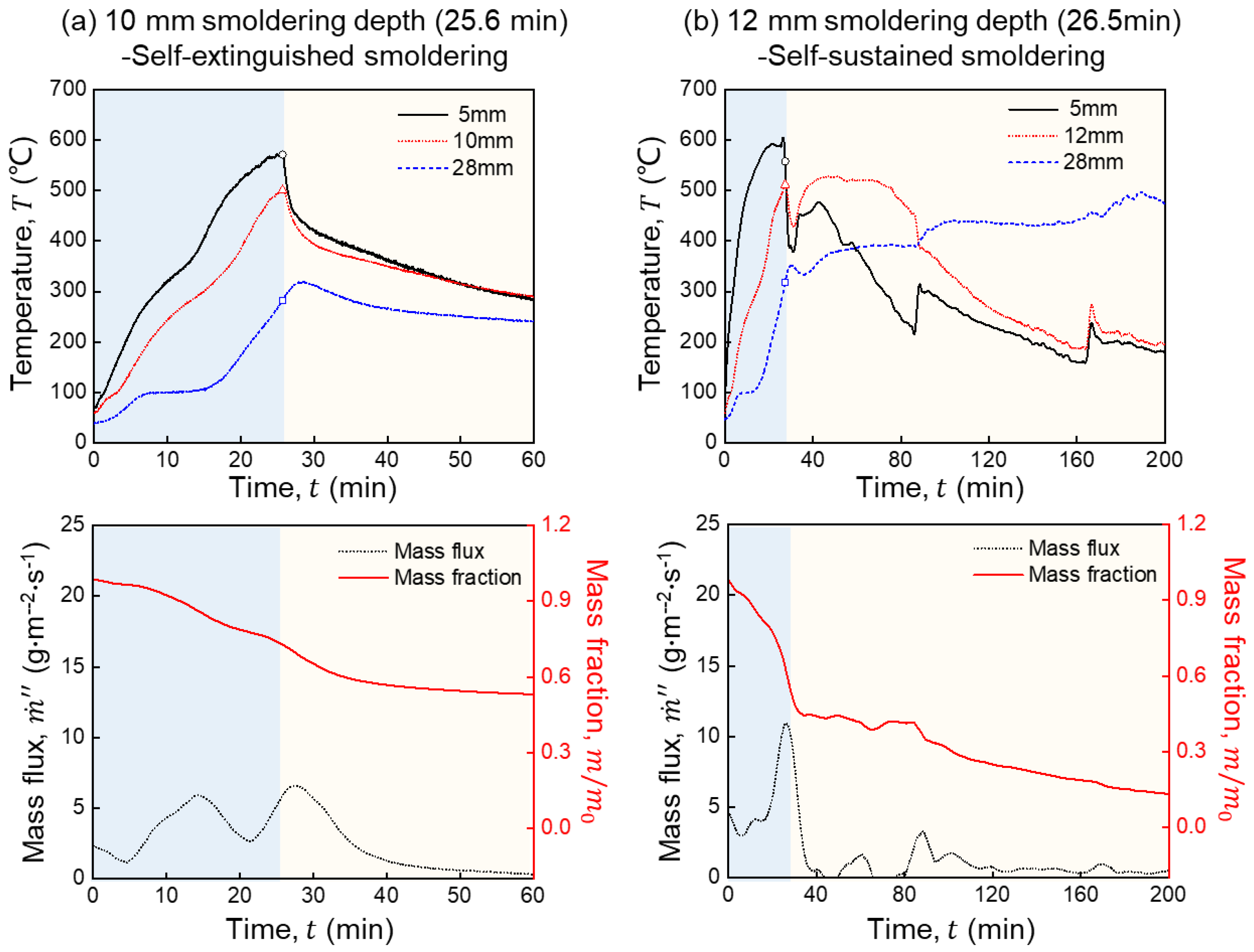

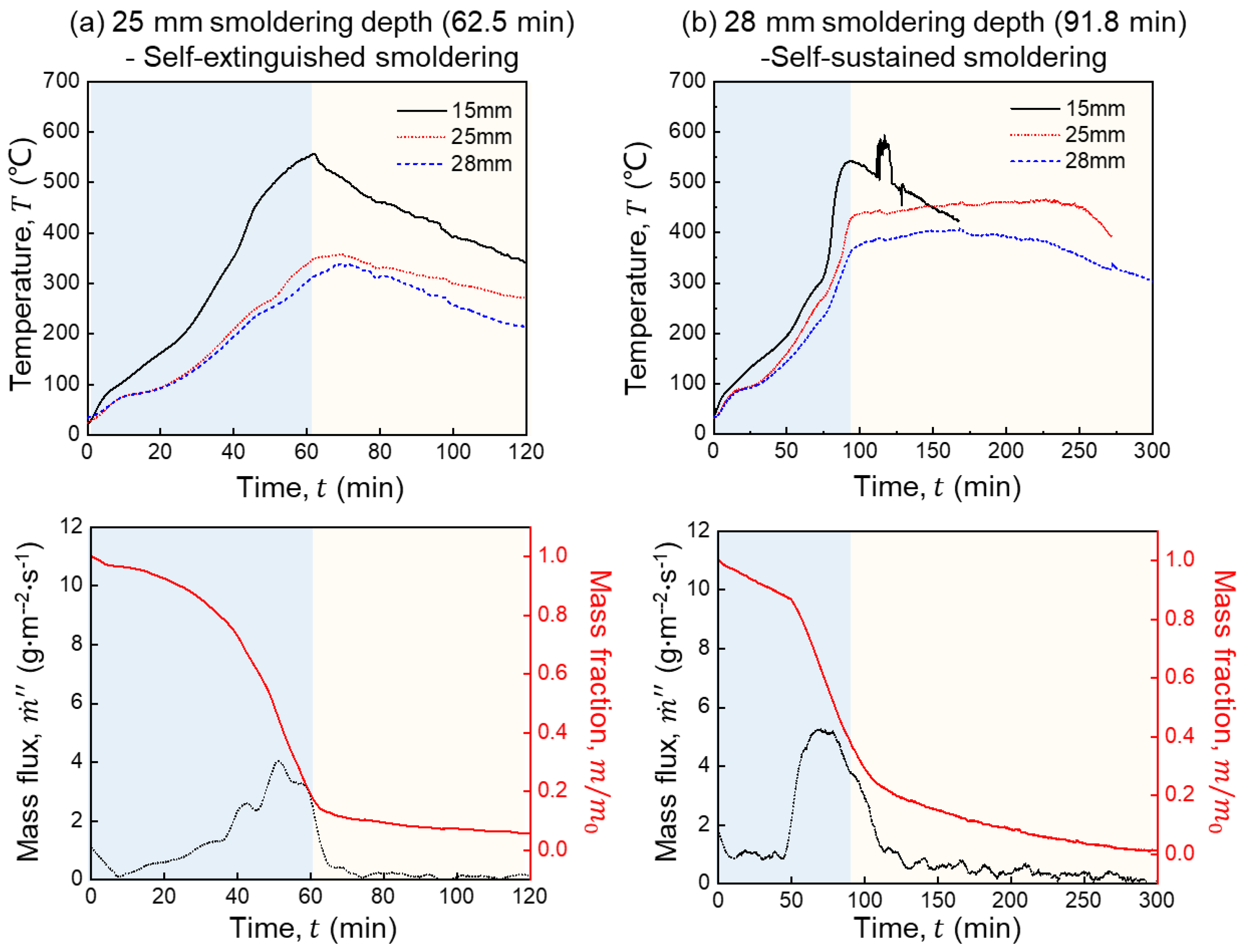

3.1. Self-Extinguished and Self-Sustained Smoldering Phenomena

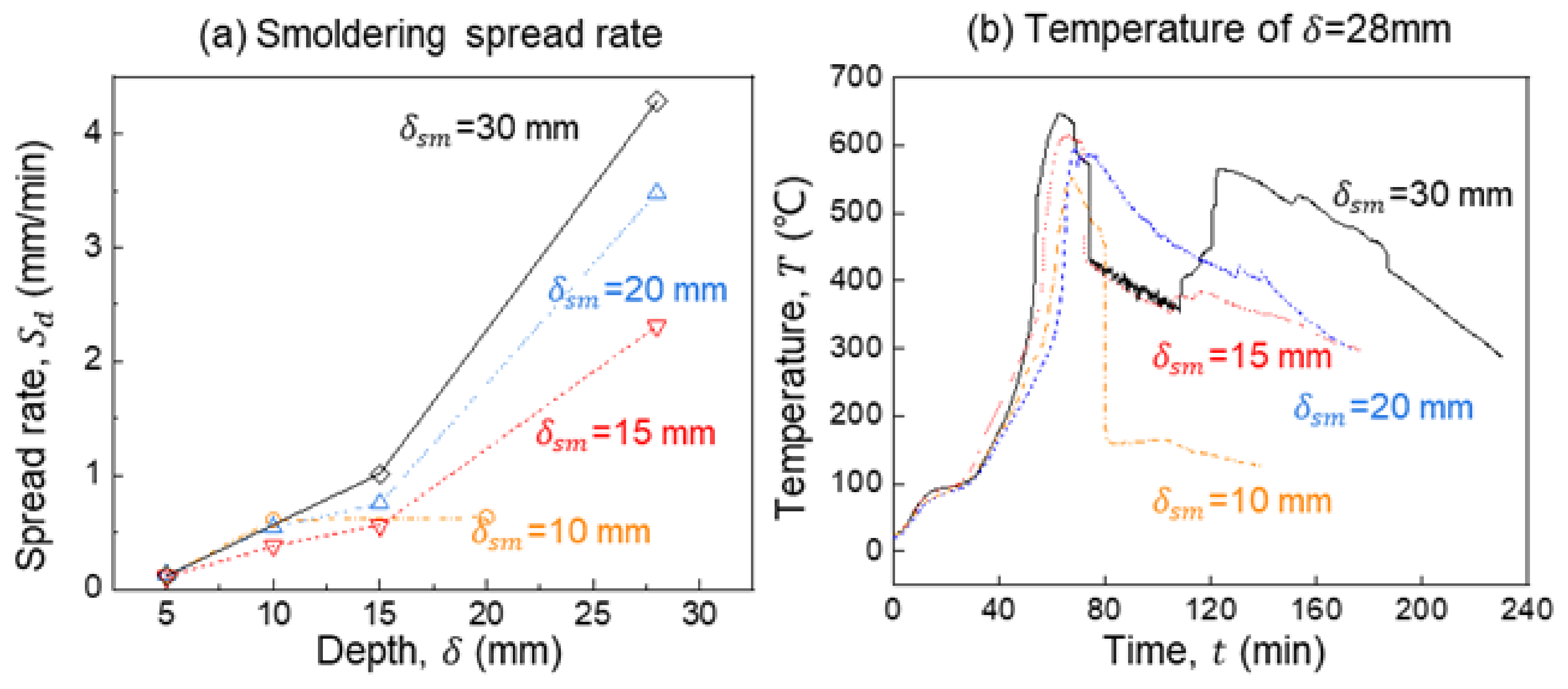

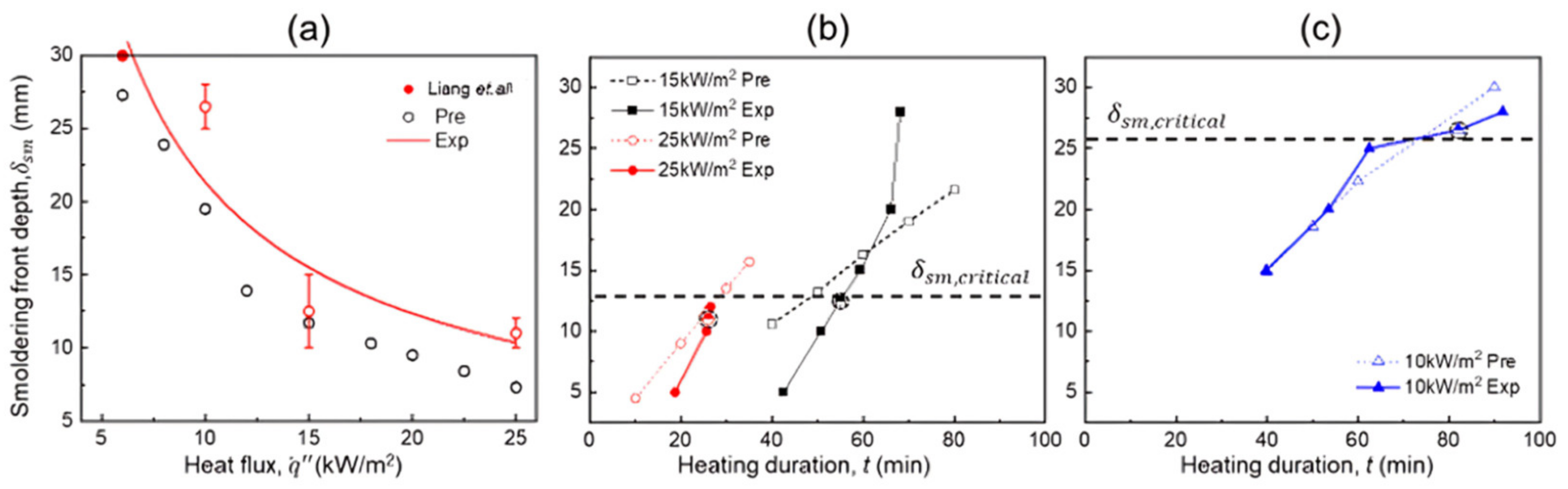

3.2. Effect of Smoldering Front Depth on Smoldering Characteristics

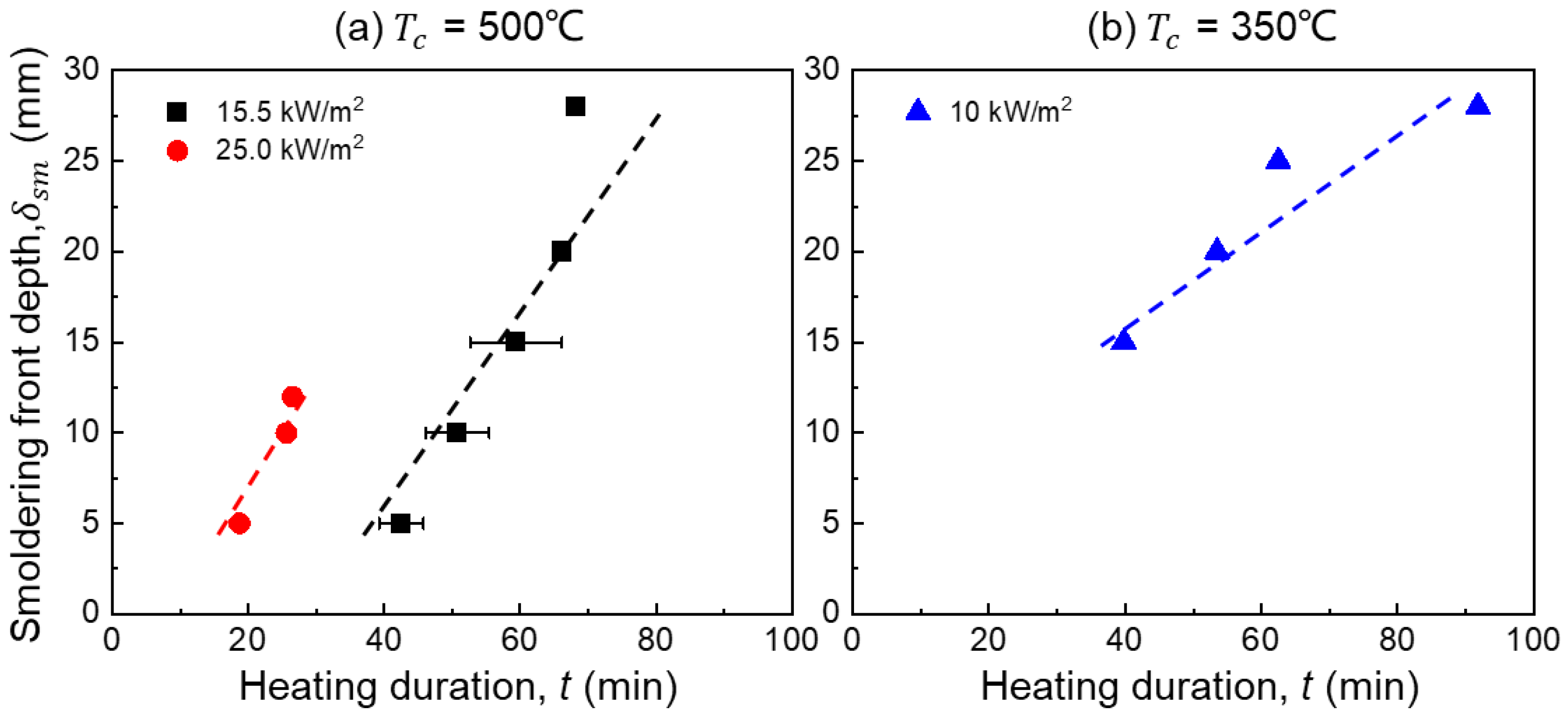

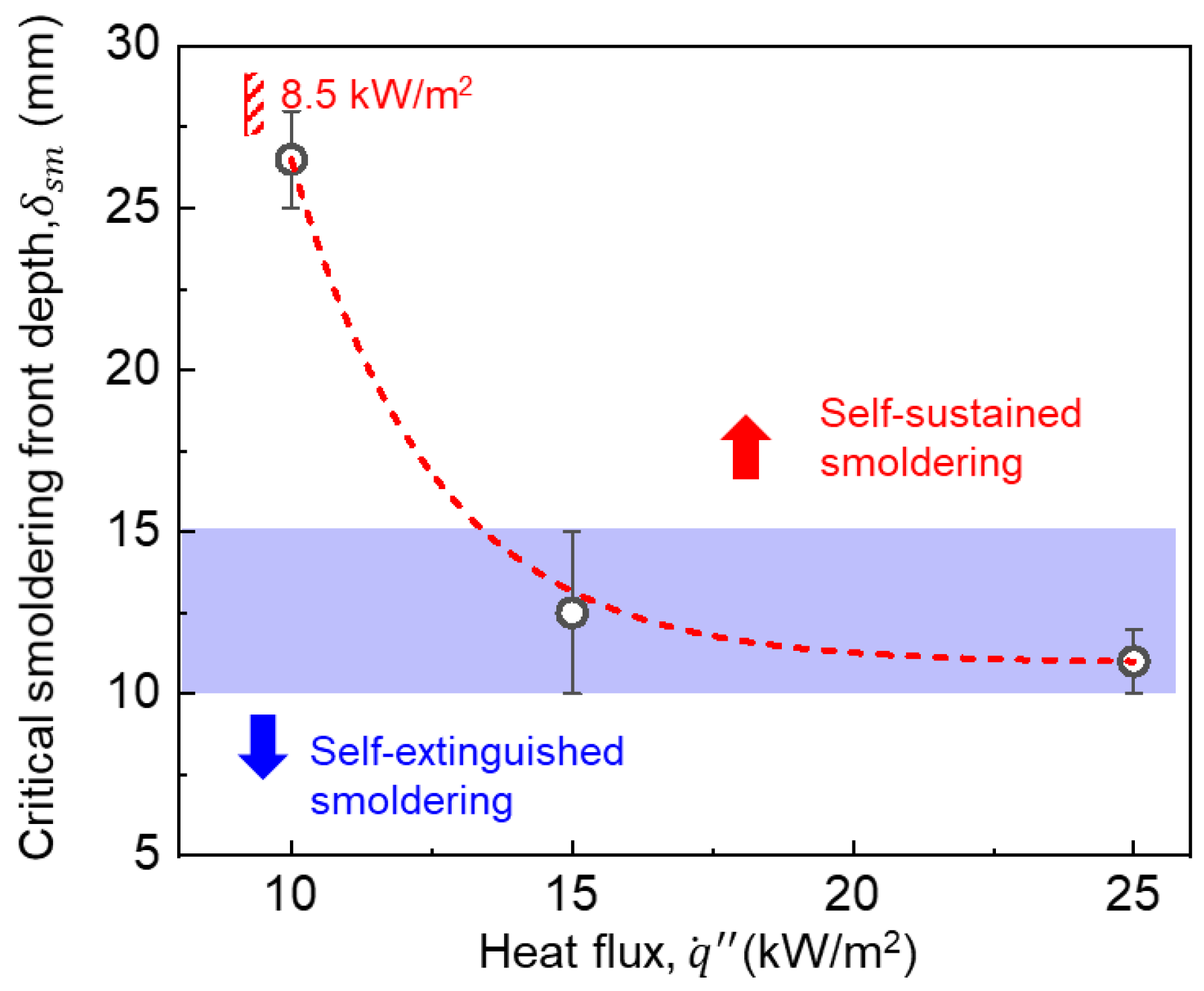

3.3. Effect of Heat Flux on the Critical Smoldering Front Depth

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- MacDicken, K.G. Global Forest Resources Assessment 2015: What, Why and How? For. Ecol. Manag. 2015, 352, 3–8. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The Wood from the Trees: The Use of Timber in Construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Leslie, A.D.; Mencuccini, M.; Perks, M. The Potential for Eucalyptus as a Wood Fuel in the UK. Appl. Energy 2012, 89, 176–182. [Google Scholar] [CrossRef]

- Quintiere, J.G. Fundamentals of Fire Phenomena; Wiley: Hoboken, NJ, USA, 2006; ISBN 0470091134. [Google Scholar]

- Lin, S.; Huang, X.; Gao, J.; Ji, J. Extinction of Wood Fire: A Near-Limit Blue Flame above Hot Smoldering Surface. Fire Technol. 2022, 58, 415–434. [Google Scholar] [CrossRef]

- Wang, S.; Ding, P.; Lin, S.; Gong, J.; Huang, X. Smoldering and Flaming of Disc Wood Particles under External Radiation: Autoignition and Size Effect. Front. Mech. Eng. 2021, 7, 65. [Google Scholar] [CrossRef]

- Lin, S.; Huang, X.; Urban, J.; McAllister, S.; Fernandez-Pello, C. Piloted Ignition of Cylindrical Wildland Fuels under Irradiation. Front. Mech. Eng. 2019, 5, 54. [Google Scholar] [CrossRef]

- Wang, S.; Ding, P.; Lin, S.; Huang, X.; Usmani, A. Deformation of Wood Slice in Fire: Interactions between Heterogeneous Chemistry and Thermomechanical Stress. Proc. Combust. Inst. 2021, 38, 5081–5090. [Google Scholar] [CrossRef]

- Safdari, M.S.; Amini, E.; Weise, D.R.; Fletcher, T.H. Heating Rate and Temperature Effects on Pyrolysis Products from Live Wildland Fuels. Fuel 2019, 242, 295–304. [Google Scholar] [CrossRef]

- Chen, G.; Shiyuan, L.; Linwei, W. Current Investigation Status of Oxy-Fuel Circulating Fluidized Bed Combustion. Fuel 2023, 342, 127699. [Google Scholar] [CrossRef]

- Fawaz, M.; Lautenberger, C.; Bond, T.C. Prediction of Organic Aerosol Precursor Emission from the Pyrolysis of Thermally Thick Wood. Fuel 2020, 269, 117333. [Google Scholar] [CrossRef]

- Rein, G. Smoldering Combustion. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2014; pp. 581–603. [Google Scholar] [CrossRef]

- Rein, G. Smouldering Fires and Natural Fuels. In Fire Phenomena and the Earth System; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 15–33. ISBN 9781118529539. [Google Scholar]

- Zanoni, M.A.B.; Torero, J.L.; Gerhard, J.I. Experimental and Numerical Investigation of Weak, Self-Sustained Conditions in Engineered Smouldering Combustion. Combust. Flame 2020, 222, 27–35. [Google Scholar] [CrossRef]

- Emberley, R.; Inghelbrecht, A.; Yu, Z.; Torero, J.L. Self-Extinction of Timber. Proc. Combust. Inst. 2017, 36, 3055–3062. [Google Scholar] [CrossRef]

- Emberley, R.; Putynska, C.G.; Bolanos, A.; Lucherini, A.; Solarte, A.; Soriguer, D.; Gonzalez, M.G.; Humphreys, K.; Hidalgo, J.P.; Maluk, C.; et al. Description of Small and Large-Scale Cross Laminated Timber Fire Tests. Fire Saf. J. 2017, 91, 327–335. [Google Scholar] [CrossRef]

- Emberley, R.; Do, T.; Yim, J.; Torero, J.L. Critical Heat Flux and Mass Loss Rate for Extinction of Flaming Combustion of Timber. Fire Saf. J. 2017, 91, 252–258. [Google Scholar] [CrossRef]

- Rein, G. Smouldering Combustion Phenomena in Science and Technology. Int. Rev. Chem. Eng. 2009, 1, 3–18. [Google Scholar]

- Ohlemiller, T.J. Modeling of Smoldering Combustion Propagation. Prog. Energy Combust. Sci. 1985, 11, 277–310. [Google Scholar] [CrossRef]

- Lin, S.; Huang, X. Quenching of Smoldering: Effect of Wall Cooling on Extinction. Proc. Combust. Inst. 2021, 38, 5015–5022. [Google Scholar] [CrossRef]

- Rashwan, T.L.; Torero, J.L.; Gerhard, J.I. Heat Losses in a Smouldering System: The Key Role of Non-Uniform Air Flux. Combust. Flame 2021, 227, 309–321. [Google Scholar] [CrossRef]

- Kadowaki, O.; Suzuki, M.; Kuwana, K.; Nakamura, Y.; Kushida, G. Limit Conditions of Smoldering Spread in Counterflow Configuration: Extinction and Smoldering-to-Flaming Transition. Proc. Combust. Inst. 2021, 38, 5005–5013. [Google Scholar] [CrossRef]

- Torero, J.L.; Gerhard, J.I.; Martins, M.F.; Zanoni, M.A.B.; Rashwan, T.L.; Brown, J.K. Processes Defining Smouldering Combustion: Integrated Review and Synthesis. Prog. Energy Combust. Sci. 2020, 81, 100869. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; Chen, H.; Liu, N. Interaction between Flaming and Smouldering in Hot-Particle Ignition of Forest Fuels and Effects of Moisture and Wind. Int. J. Wildland Fire 2017, 26, 71–81. [Google Scholar] [CrossRef]

- Xie, Q.; Zhang, Z.; Lin, S.; Qu, Y.; Huang, X. Smoldering Fire of High-Density Cotton Bale Under Concurrent Wind. Fire Technol. 2020, 56, 2241–2256. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, K.; Wang, S. Effect of Porosity on Ignition and Burning Behavior of Cellulose Materials. Fuel 2022, 322. [Google Scholar] [CrossRef]

- Ohlemiller, T.J. Smoldering Combustion Propagation on Solid Wood. In Fire Safety Science: Proceedings of the Third International Symposium, Edinburgh, Scotland, 8–12 July 1991; Routledge: London, UK, 1991; pp. 565–574. [Google Scholar] [CrossRef]

- Torero, J.L.; Fernandez-Pello, A.C.; Kitano, M. Opposed Forced Flow Smoldering of Polyurethane Foam. Combust. Sci. Technol. 1993, 91, 95–117. [Google Scholar] [CrossRef]

- Yamazaki, T.; Matsuoka, T.; Nakamura, Y. Near-Extinction Behavior of Smoldering Combustion under Highly Vacuumed Environment. Proc. Combust. Inst. 2019, 37, 4083–4090. [Google Scholar] [CrossRef]

- Gratkowski, M.T.; Dembsey, N.A.; Beyler, C.L. Radiant Smoldering Ignition of Plywood. Fire Saf. J. 2006, 41, 427–443. [Google Scholar] [CrossRef][Green Version]

- Miry, S.Z.; Zanoni, M.A.B.; Rashwan, T.L.; Torero, J.L.; Gerhard, J.I. Investigation of Multi-Dimensional Transfer Effects in Applied Smouldering Systems: A 2D Numerical Modelling Approach. Combust. Flame 2022, 246, 112385. [Google Scholar] [CrossRef]

- Rashwan, T.L.; Fournie, T.; Green, M.; Duchesne, A.L.; Brown, J.K.; Grant, G.P.; Torero, J.L.; Gerhard, J.I. Applied Smouldering for Co-Waste Management: Benefits and Trade-Offs. Fuel Process. Technol. 2023, 240, 107542. [Google Scholar] [CrossRef]

- Linan, A. The Asymptotic Structure of Counterflow Diffusion Flames for Large Activation Energies. Acta Astronaut. 1974, 1, 1007–1039. [Google Scholar] [CrossRef]

- Dosanjh, S.S.; Pagni, P.J.; Fernandez-Pello, A.C. Forced Cocurrent Smoldering Combustion. Combust. Flame 1987, 68, 131–142. [Google Scholar] [CrossRef]

- Zanoni, M.A.B.; Torero, J.L.; Gerhard, J.I. Delineating and Explaining the Limits of Self-Sustained Smouldering Combustion. Combust. Flame 2019, 201, 78–92. [Google Scholar] [CrossRef]

- Zanoni, M.A.B.; Torero, J.L.; Gerhard, J.I. Determining the Conditions That Lead to Self-Sustained Smouldering Combustion by Means of Numerical Modelling. Proc. Combust. Inst. 2019, 37, 4043–4051. [Google Scholar] [CrossRef]

- Huang, X.; Rein, G. Downward Spread of Smouldering Peat Fire: The Role of Moisture, Density and Oxygen Supply. Int. J. Wildland Fire 2017, 26, 907–918. [Google Scholar] [CrossRef]

- Huang, X.; Rein, G. Upward-and-Downward Spread of Smoldering Peat Fire. Proc. Combust. Inst. 2019, 37, 4025–4033. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, N.; Yuan, H.; Chen, H.; Xie, X.; Zhang, L.; Rein, G. Smouldering and Its Transition to Flaming Combustion of Polyurethane Foam: An Experimental Study. Fuel 2022, 309, 122249. [Google Scholar] [CrossRef]

- Liang, Z.; Lin, S.; Huang, X. Smoldering Ignition and Emission Dynamics of Wood under Low Irradiation. Fire Mater. 2022, 47, 514–524. [Google Scholar] [CrossRef]

| = 25 kW/m2 | = 15.5 kW/m2 | = 10 kW/m2 | |||

|---|---|---|---|---|---|

| (mm) | (min) | (mm) | (min) | (mm) | (min) |

| 5 | 18.7 | 5 | 42.4 ± 3.2 | _ | _ |

| 10 | 25.6 | 10 | 50.8 ± 4.7 | _ | _ |

| 12 | 26.5 | _ | _ | _ | _ |

| _ | _ | 15 | 59.4 ± 6.4 | 15 | 39.8 |

| _ | _ | 20 | 66.1 | 20 | 53.2 |

| _ | _ | _ | _ | 25 | 62.5 |

| _ | _ | 28 | 68.2 | 28 | 91.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, P.; Zhang, C.; He, Q.; Wang, L.; Yang, Y. Determining the Conditions That Lead to the Self-Extinguished and Self-Sustained Smoldering Combustion of Wood. Fire 2024, 7, 60. https://doi.org/10.3390/fire7020060

Ding P, Zhang C, He Q, Wang L, Yang Y. Determining the Conditions That Lead to the Self-Extinguished and Self-Sustained Smoldering Combustion of Wood. Fire. 2024; 7(2):60. https://doi.org/10.3390/fire7020060

Chicago/Turabian StyleDing, Pengfei, Chunyin Zhang, Qize He, Lijing Wang, and Yun Yang. 2024. "Determining the Conditions That Lead to the Self-Extinguished and Self-Sustained Smoldering Combustion of Wood" Fire 7, no. 2: 60. https://doi.org/10.3390/fire7020060

APA StyleDing, P., Zhang, C., He, Q., Wang, L., & Yang, Y. (2024). Determining the Conditions That Lead to the Self-Extinguished and Self-Sustained Smoldering Combustion of Wood. Fire, 7(2), 60. https://doi.org/10.3390/fire7020060