Study on the Effect of Pore Evolution on the Coal Spontaneous Combustion Characteristics in Goaf

Abstract

:1. Introduction

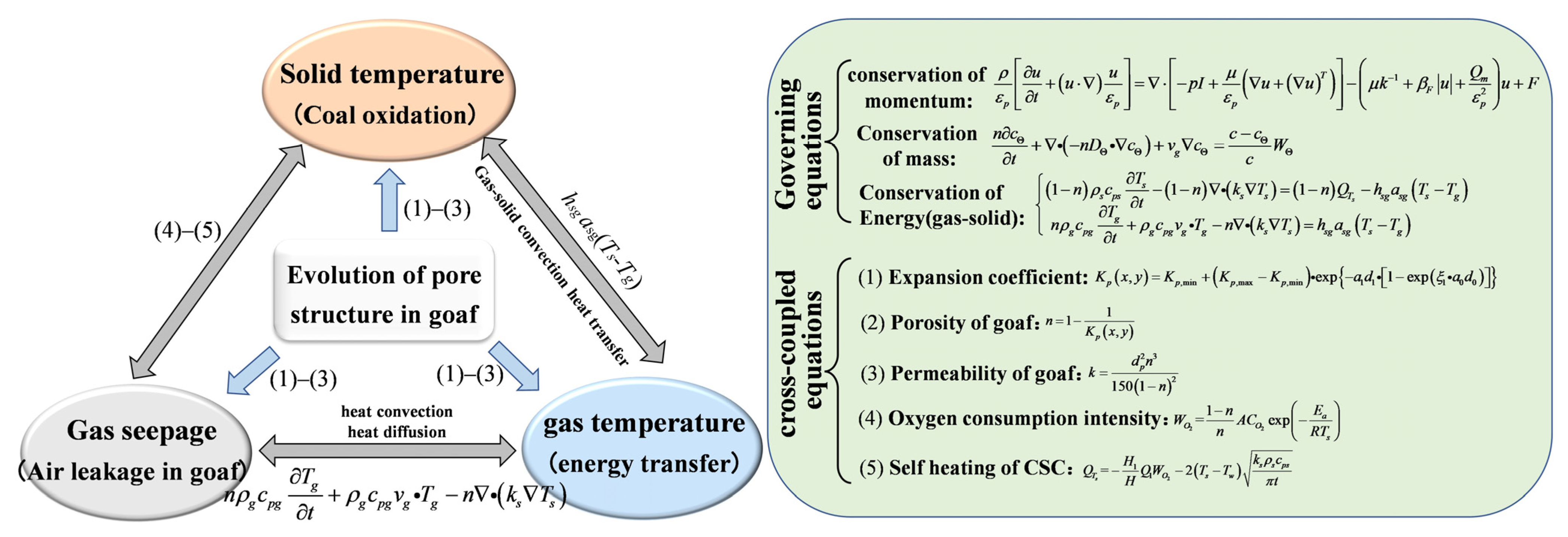

2. Governing Equations for Goaf CSC

2.1. Momentum Conservation Equation

2.2. Mass Conservation Equation

2.3. Energy Conservation Equation

2.4. Cross-Coupling Relationship

3. Model Construction and Validation

3.1. Engineering Overview

3.2. Assumptions and Physical Modelling

- (1)

- The gas movement in goaf conforms to the non-Darcy Forchheimer’s law, and the oxygen consumption for coal oxidation is determined using the Arrhenius equation.

- (2)

- The gas in the goaf is considered an ideal gas, and the impact of temperature on its kinetic viscosity is disregarded.

- (3)

- Disregarding the gas outflow from the goaf and other gases (CO, CO2, CH4, SO2 and NOX, etc.) produced during CSC, the gases in the goaf are mainly air.

- (4)

- The goaf is simplified to a two-dimensional non-homogeneous porous medium flow field.

- (5)

- Using the 1302 working face as an example, a physical model was established, as shown in Figure 2. The inlet and return airway measure 4 m in width and 8 m in length, the working face measures 7 m in width and 132 m in length, and the goaf measures 140 m in width and 150 m in length. The simulation boundaries and parameters for goaf CSC are shown in Table 1 and Table 2.

3.3. Permeability Evolution of Goaf

3.4. Parameter Setting

3.5. Model Validation

4. Results and Discussion

4.1. Spatial Distribution of Porosity and Permeability

4.2. Spatial Distribution of Oxygen Concentration and Airflow Velocity

4.3. Spatial Distribution of Temperature

4.4. Spatial Distribution of CSC Three Zones

5. Conclusions

- (1)

- Both porosity and permeability decrease with increasing goaf depth. The goaf porosity is positively correlated with the permeability. When the goaf maximum porosity was increased from 25 to 40%, the average flow velocity increased by about 6 times. This demonstrates that porosity has a significant impact on air leakage in the goaf.

- (2)

- The oxygen concentration in the extraction zone increases as the porosity increases and exhibits a trend of initially increasing and then decreasing over time. Similarly, the temperature trend varies with different goaf porosities, increasing over time. As porosity increases, the high temperature zone gradually expands along the goaf depth.

- (3)

- Over time, the CSC three zones in the goaf exhibit a tendency to decrease in the radiator and oxidation zones, while increasing in the asphyxiation zone. The range of the CSC three zones is positively correlated with the goaf porosity. Specifically, the higher the goaf porosity, the greater the area of the oxidation zone and, consequently, the higher the CSC risk.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, F. Study on the coexistence of gas and coal spontaneous combustion(Ⅰ):disaster mechanism. J. China Coal Soc. 2012, 37, 843–849. [Google Scholar]

- Pi, Z.; Li, R.; Guo, W.; Liu, X.; Zhang, Z.; Wang, Y.; Zhang, Y.; Yin, G.; Li, X. Experimental Study on the Influence of Pore Structure and Group Evolution on Spontaneous Combustion Characteristics of Coal Samples of Different Sizes During Immersion. ACS Omega 2023, 8, 22453–22465. [Google Scholar] [CrossRef] [PubMed]

- Said, K.O.; Onifade, M.; Genc, B.; Lawal, A.I.; Abdulsalam, J.; Githiria, J.M.; Bada, S. On the dependence of predictive models on experimental dataset: A spontaneous combustion studies scenario. Int. J. Min. Reclam. Environ. 2021, 35, 506–522. [Google Scholar] [CrossRef]

- Wu, G.; Yu, W.; Guo, H.; Pan, B.; Liu, X. Investigation on water inrush fracture mechanics model based on fracture mechanics and microseismic monitoring. Ain. Shams Eng. J. 2024, 15, 102587. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, K.; Li, Z.; Li, Z.; Si, L.; Hou, S.; Duan, Y. Experimental study on pore-fracture evolution law in the thermal damage process of coal. Int J Rock Mech Min 2019, 116, 13–24. [Google Scholar] [CrossRef]

- Gao, A.; Qin, B.; Zhang, L.; Ma, D.; Li, L. Experimental Study on Gas Migration Laws at Return Air Side of Goaf under High-Temperature Conditions. Combust. Sci. Technol. 2021, 195, 1930–1944. [Google Scholar] [CrossRef]

- Shi, G.-Q.; Liu, M.-x.; Wang, Y.-M.; Wang, W.-Z.; Wang, D.-M. Computational Fluid Dynamics Simulation of Oxygen Seepage in Coal Mine Goaf with Gas Drainage. Math. Probl. Eng. 2015, 2015, 723764. [Google Scholar] [CrossRef]

- Niu, H.; Liu, Y.; Wu, K.; Wu, J.; Li, S.; Wang, H. Study on Pore Structure Change Characteristics of Water-Immersed and Air-Dried Coal Based on SEM-BET. Combust. Sci. Technol. 2022, 195, 3994–4016. [Google Scholar] [CrossRef]

- Niu, H.; Yang, Y.; Li, S. Effects of pre-oxidized temperature and pre-oxidized oxygen concentration on burning characteristics of pre-oxidized coal. Fuel 2023, 332, 125723. [Google Scholar] [CrossRef]

- Balusu, R.; Belle, B.; Tanguturi, K. Development of Goaf Gas Drainage and Inertisation Strategies in 1.0-km- and 3.0-km-Long Panels. Min. Metall. Explor. 2019, 36, 1127–1136. [Google Scholar] [CrossRef]

- Xia, T.; Wang, X.; Zhou, F.; Kang, J.; Liu, J.; Gao, F. Evolution of coal self-heating processes in longwall gob areas. Int. J. Heat Mass Transfer 2015, 86, 861–868. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. The Impact of the Strength of Roof Rocks on the Extent of the Zone with a High Risk of Spontaneous Coal Combustion for Fully Powered Longwalls Ventilated with the Y-Type System—A Case Study. Appl. Sci. 2019, 9, 5315. [Google Scholar] [CrossRef]

- Taraba, B.; Michalec, Z.K. Effect of longwall face advance rate on spontaneous heating process in the gob area—CFD modelling. Fuel 2011, 8, 90. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, K.; Du, W.; Zhang, J.; Wang, H.; Zhang, J. A method to identify coal spontaneous combustion-prone regions based on goaf flow field under dynamic porosity. Fuel 2021, 288, 119690. [Google Scholar] [CrossRef]

- Lei, C.; Jiang, L.; Bao, R.; Deng, C.; Wang, C. Study on Multifield Migration and Evolution Law of the Oxidation Heating Process of Coal Spontaneous Combustion in Dynamic Goaf. ACS Omega 2023, 8, 14197–14207. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Chen, L.; Bai, Z.; Deng, J.; Liu, L.; Xiao, Y. Study on the dynamic evolution law of spontaneous coal combustion in high-temperature regions. Fuel 2022, 314, 123036. [Google Scholar] [CrossRef]

- Ao, X.; Wang, X.; Zhu, X.; Zhou, Z.; Zhang, X. Grouting Simulation and Stability Analysis of Coal Mine Goaf Considering Hydromechanical Coupling. J. Comput. Civil. Eng. 2017, 31, 04016069. [Google Scholar] [CrossRef]

- Niu, X.; Feng, G.; Liu, Q.; Han, Y.; Qian, R. Numerical investigation on mechanism and fluid flow behavior of goaf water inrush: A case study of Dongyu coal mine. Nat. Hazards 2022, 113, 1783–1802. [Google Scholar] [CrossRef]

- Gui, X.; Xue, H.; Zhan, X.; Hu, Z.; Song, X. Measurement and Numerical Simulation of Coal Spontaneous Combustion in Goaf under Y-type Ventilation Mode. ACS Omega 2022, 7, 9406–9421. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Q.; Zhu, P.; Li, X.; Zhang, G.; Ma, X.; Zhao, Y. Study on Multi-field Evolution and Influencing Factors of Coal Spontaneous Combustion in Goaf. Combust. Sci. Technol. 2021, 195, 247–264. [Google Scholar] [CrossRef]

- Sidiropoulou, M.G.; Moutsopoulos, K.N.; Tsihrintzis, V.A. Determination of Forchheimer equation coefficients a and b. Hydrol. Process. 2007, 21, 534–554. [Google Scholar] [CrossRef]

- Li, Z.; Yi, G.; Wu, J.; Guo, D.; Zhao, C. Study on spontaneous combustion distribution of goaf based on the “O” type risked falling and non-uniform oxygen. J. China Coal Soc. 2012, 37, 484–489. [Google Scholar]

- Yuan, L.; Smith, A.C. CFD modeling of spontaneous heating in a large-scale coal chamber. J. Loss Prev. Process Ind. 2009, 22, 426–433. [Google Scholar] [CrossRef]

- Ejlali, A.; Mee, D.J.; Hooman, K.; Beamish, B.B. Numerical modelling of the self-heating process of a wet porous medium. Int. J. Heat Mass Transfer 2011, 54, 5200–5206. [Google Scholar] [CrossRef]

- Alazmi, B.; Vafai, K. Analysis of Variants Within the Porous Media Transport Models. J Heat Trans-T Asme 2000, 122, 303–326. [Google Scholar] [CrossRef]

- Qin, Q. The determination of the “three zones” in the goaf of the 1302 isolated island fully mechanized caving face of Yunhe Coal Mine. Saf. Coal Mines 2010, 41, 53–55. [Google Scholar]

- Li, T.; Wu, B.; Lei, B.; Huang, Q. Study on air leakage and gas distribution in goaf of Y-type ventilation system. Energy Sources Part A 2020, 45, 2788–2810. [Google Scholar] [CrossRef]

- Chen, X.; Li, L.; Guo, Z.; Chang, T. Evolution characteristics of spontaneous combustion in three zones of the goaf when using the cutting roof and release pressure technique. Energy Sci. Eng. 2019, 7, 710–720. [Google Scholar] [CrossRef]

- Chai, J. Investigation of Spontaneous Combustion Zones and Index Gas Prediction System in Goaf of “Isolated Island” Working Face. Fire 2022, 5, 67. [Google Scholar] [CrossRef]

- Yang, S.; Xu, N.; Liu, H.; Zhang, X.; Mei, S. Research and application of ‘three zones’ range within overlying strata in goaf of steep coal seam. Front. Energy Res. 2024, 12, 1333016. [Google Scholar] [CrossRef]

- Li, z.; Wu, Q.; Wang, Z. Distribution characteristic of remaining coal oxygen consumption and spontaneous combustion heating-up in goaf. J. China Coal Soc. 2009, 34, 667–672. [Google Scholar]

- Li, J.; Niu, H.; Lu, Y.; Li, S.; Zhao, L.; Nie, Q. Study on effect of wind speed to air leakage and spontaneous combustion in goaf of contiguous seams. Coal Sci. Technol. 2019, 47, 156–162. [Google Scholar]

- Wang, H.; Li, J.; Dong, Z.; Fan, C.; Zhang, Y.; Chen, X. Effect of thermal damage on the pore–fracture system during coal spontaneous combustion. Fuel 2023, 339, 127439. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Zhang, Y.; Wu, Y.; Wang, Z. Study on the evolution of the pore structure of low rank coal during spontaneous combustion. Environ. Sci. Pollut. Res. 2023, 30, 39932–39945. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, J.; Fan, C.; Wang, L.; Chen, X. Thermal Kinetics of Coal Spontaneous Combustion Based on Multiphase Fully Coupled Fluid–Mechanical Porous Media Model. Nat. Resour. Res. 2022, 31, 2819–2837. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Chen, X.; Fan, C.; Wang, P.; Hu, L. Thermodynamic Characteristics of Oxidation and Combustion of Coal under Lean-Oxygen Conditions. ACS Omega 2021, 6, 17255–17266. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; An, J.; Wen, Z.; Zhang, K.; Pan, R.; Akter Al Mamun, N. Numerical investigation of coal self-heating in longwall goaf considering airflow leakage from mining induced crack. Process Saf. Environ. Prot. 2020, 134, 353–370. [Google Scholar] [CrossRef]

- Pamucar, D.; Qi, Y.; Wang, W.; Qi, Q.; Ning, Z.; Yao, Y. Distribution of spontaneous combustion three zones and optimization of nitrogen injection location in the goaf of a fully mechanized top coal caving face. PLoS ONE 2021, 16, e0256911. [Google Scholar]

| Coal Sample | Number | Mad (%) | Vad (%) | FCd (%) | Ad (%) |

|---|---|---|---|---|---|

| Lignite coal | S1 | 16 | 33.5 | 31.7 | 34.8 |

| Boundary | Pressure | Concentration | Temperature |

|---|---|---|---|

| AD | p = p0 + R·Q2·(L − y) | T = T0 | |

| AB/BC/CD |

| Parameters | Value | Unit | Parameters | Value | Unit |

|---|---|---|---|---|---|

| Initial expansion coefficient, | 1.5 | - | particle diameter, dp | 0.04 | m |

| Compaction expansion coefficient, | 1.12 | - | Initial pressure, p0 | 1 | atm |

| Attenuation rate, a0 | 0.0368 | - | Adjustable parameters, | 0.233 | - |

| Attenuation rate, a1 | 0.0268 | - | Initial O2 concentration, | 9.375 | mol/m3 |

| Initial temperature, T0 | 27 | °C | solid density, | 1250 | Kg/m3 |

| Activation energy, Ea | 45.5 | KJ/mol | Gas density, | 1.1 | Kg/m3 |

| Indexing factor, A | 180 | 1/s | Solid specific heat capacity, Cps | 1200 | J/(kg·K) |

| Ideal gas constant, R | 8.314 | J/(mol·K) | Gases specific heat capacity, Cpg | 1012 | J/(kg·K) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Xu, H.; Wu, G. Study on the Effect of Pore Evolution on the Coal Spontaneous Combustion Characteristics in Goaf. Fire 2024, 7, 164. https://doi.org/10.3390/fire7050164

Li J, Xu H, Wu G. Study on the Effect of Pore Evolution on the Coal Spontaneous Combustion Characteristics in Goaf. Fire. 2024; 7(5):164. https://doi.org/10.3390/fire7050164

Chicago/Turabian StyleLi, Jinglei, Hao Xu, and Genshui Wu. 2024. "Study on the Effect of Pore Evolution on the Coal Spontaneous Combustion Characteristics in Goaf" Fire 7, no. 5: 164. https://doi.org/10.3390/fire7050164

APA StyleLi, J., Xu, H., & Wu, G. (2024). Study on the Effect of Pore Evolution on the Coal Spontaneous Combustion Characteristics in Goaf. Fire, 7(5), 164. https://doi.org/10.3390/fire7050164