Thermal Effect of Firebrand Accumulation in Ceramic Roof Tiles

Abstract

:1. Introduction

1.1. Objectives

1.2. Extension in Wildfire Protection Research

1.3. Research Significance

2. Previous Studies in Roof Tiles

2.1. Post Wildfire Damage Observations

2.2. Review of Wildfire Testing

3. Experimental Campaign

3.1. Chosen Construction Materials

3.2. Chosen Construction Elements

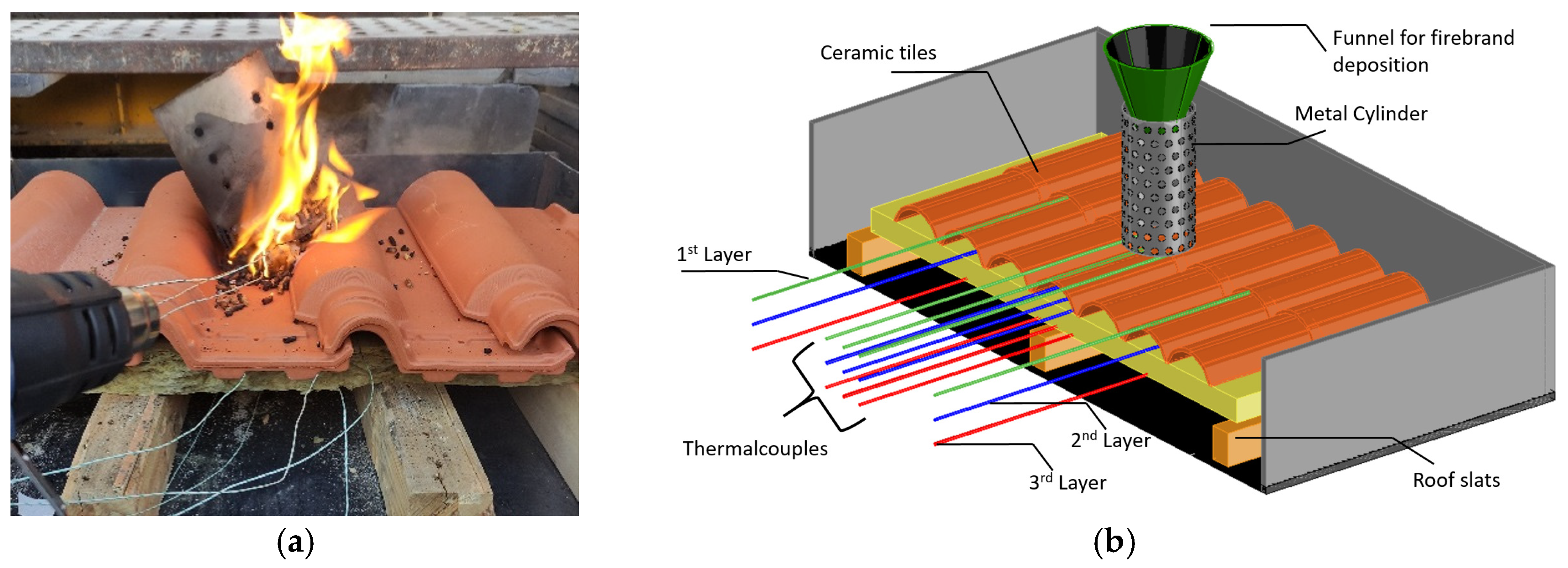

3.3. Test Setup

4. Experimental Outputs and Observations

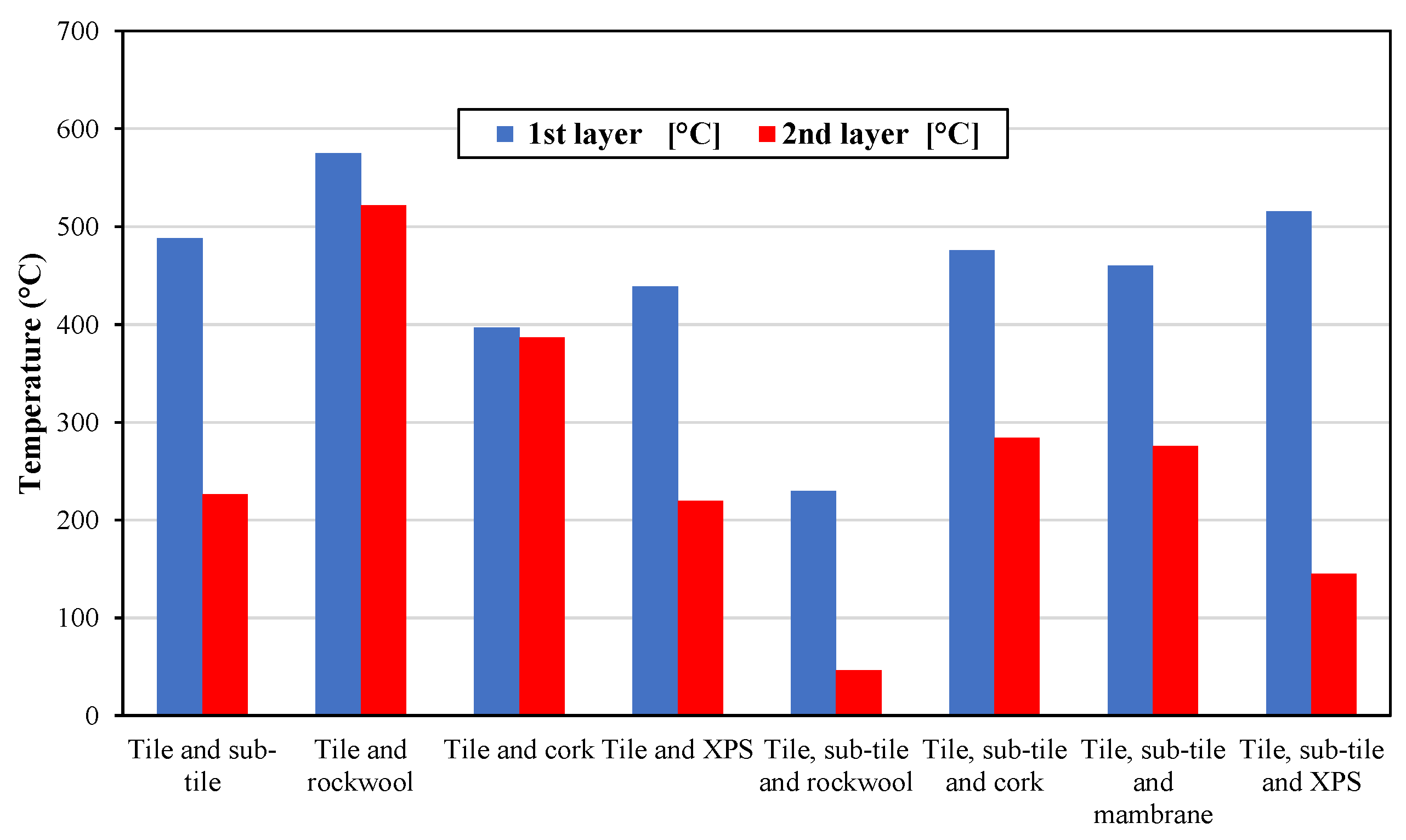

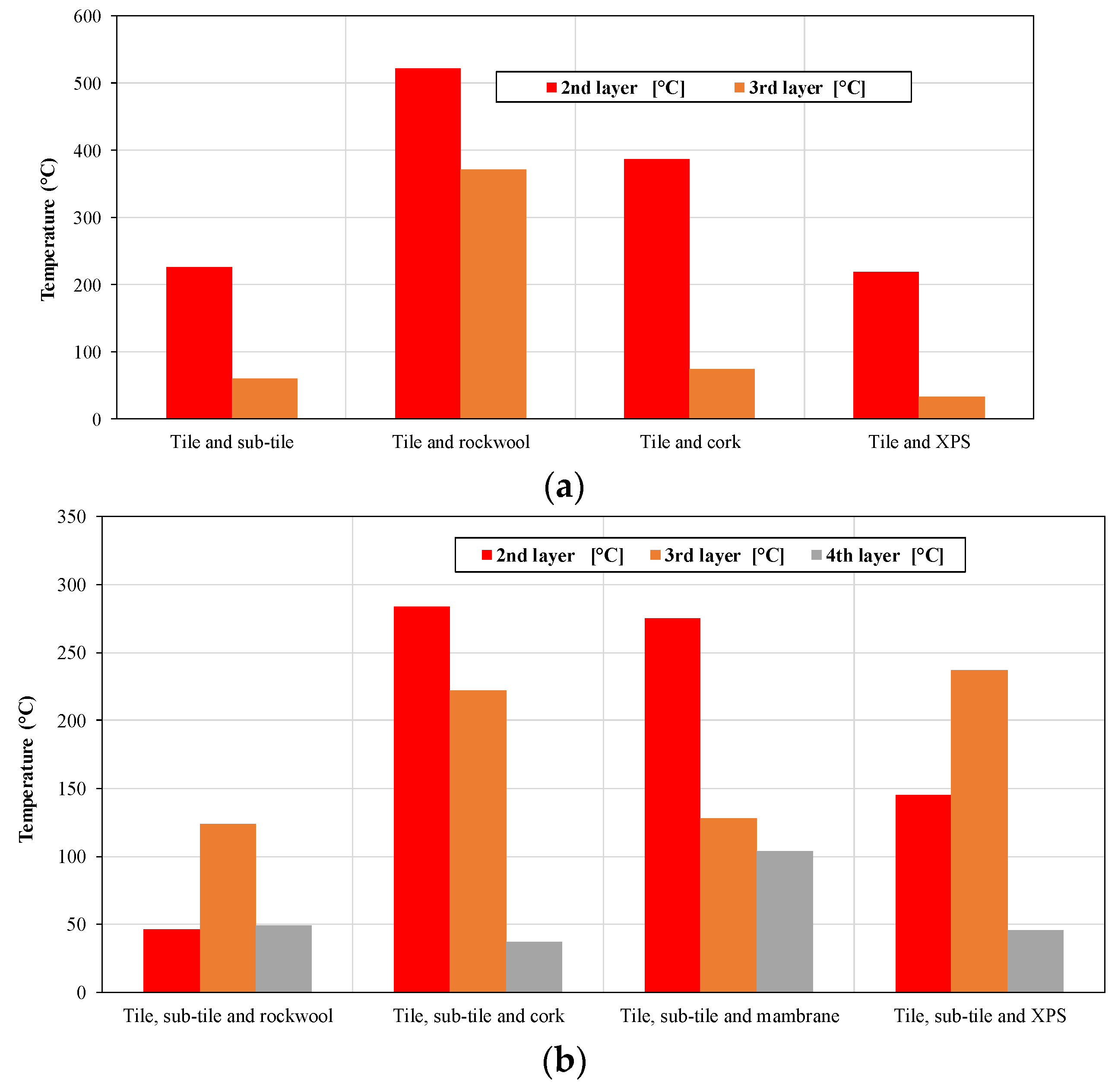

4.1. Measured Temperature

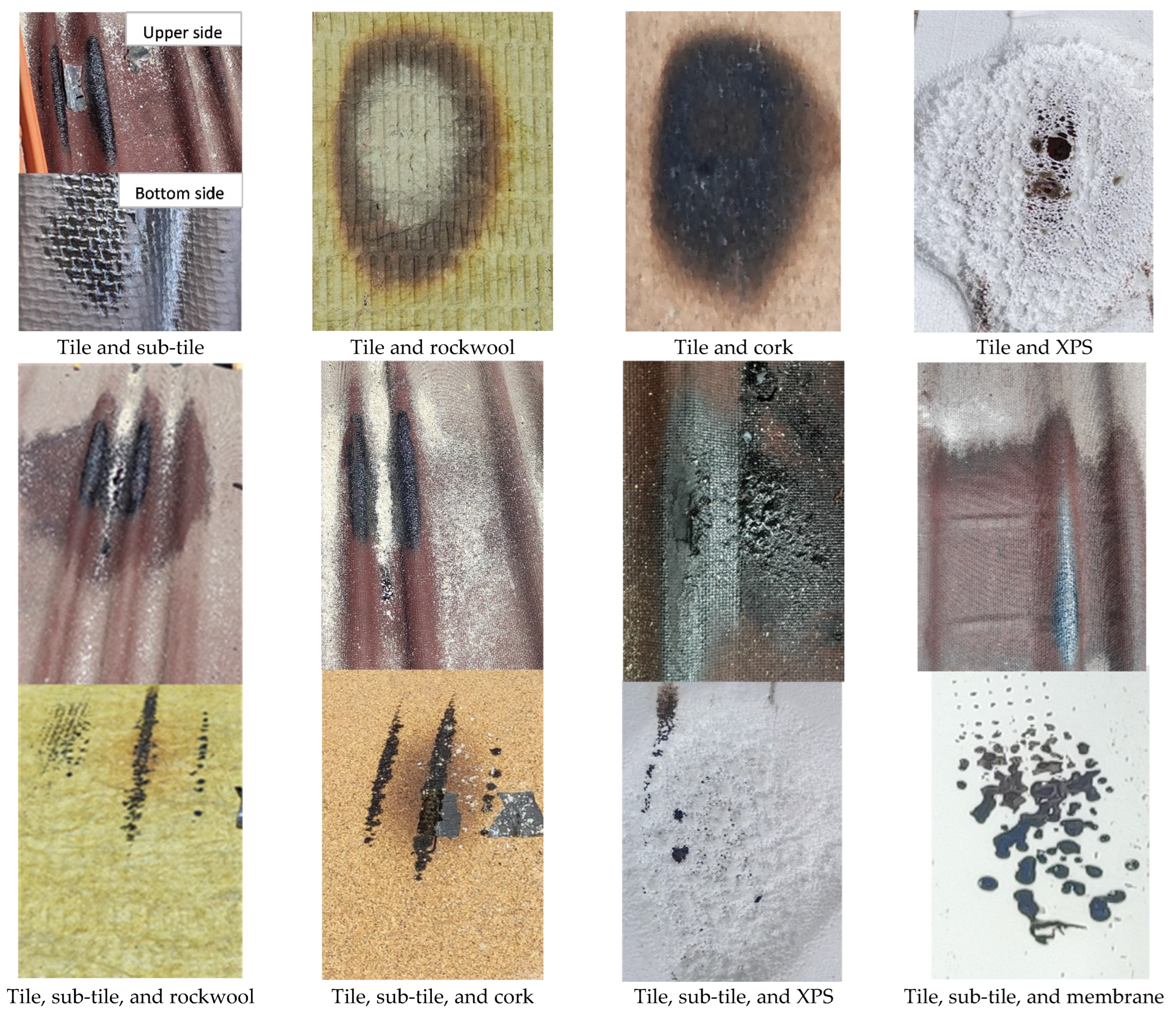

4.2. Observed Fire Reaction and Ignition

4.3. Firebrand Heat Penetration in the Layers

5. Discussion and Conclusions

5.1. Recommendations for Roofs Against Wildfires

5.2. Limitations of the Study

5.3. Future Developments

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manzello, S.L.; Suzuki, S. Experimental investigation of wood decking assemblies exposed to firebrand showers. Fire Saf. J. 2017, 92, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Koo, E.; Pagni, P.J.; Weise, D.R.; Woycheese, J.P. Firebrands and spotting ignition in large-scale fires. Int. J. Wildland Fire 2010, 19, 818–843. [Google Scholar] [CrossRef]

- Tenreiro, T.C. Construction Techniques to Protect Houses from Wildland Fires; University of Lisbon, Instituto Superior Técnico, Lisbon: Lisbon, Portugal, 2018. [Google Scholar]

- Viegas, D.X.; Almeida, M.F.; Ribeiro, L.M. O Complexo de Incêndios de Pedrógão Grande e Concelhos Limítrofes, Iniciado a 17 de Junho de 2017; Universidade de Coimbra: Coimbra, Portugal, 2017. [Google Scholar]

- Guerreiro, J.; Fonseca, C.; Salgueiro, A.; Fernandes, P.; Lopez, I.E.; Neufville, R.; Mateus, F.; Castellnou, R.M.; Sande, S.J.; Moura, J.M.; et al. Avaliação dos Incêndios Ocorridos Entre 14 e 16 de Outubro de 2017 em Portugal Continental; Assembleia da República: Lisboa, Portugal, 2018. [Google Scholar]

- Cantor, P.; Bicelli, A.R.; de Assis, E.B.; Arruda, M.R.; Branco, F. Report on Existing Fireproof Construction Guidelines for Dwellings against Wildfires. CivilEng 2023, 4, 657–678. [Google Scholar] [CrossRef]

- El Houssami, M.; Mueller, E.; Filkov, A.; Thomas, J.C.; Skowronski, N.; Gallagher, M.R.; Clark, K.; Kremens, R.; Simeoni, A. Experimental Procedures Characterising Firebrand Generation in Wildland Fires. Fire Technol. 2016, 52, 731–751. [Google Scholar] [CrossRef]

- Manzello, S.L.; Suzuki, S. The world is burning: What exactly are firebrands and why should anyone care? Front. Mech. Eng. 2023, 8, 1072214. [Google Scholar] [CrossRef]

- Arruda, M.; Tenreiro, T.C.; Branco, F. Rethinking Dwellings Protection for Wildland Fire. ASCE J. Perform. Constr. 2021, 35. [Google Scholar] [CrossRef]

- Fernandez-Pello, A.C. Wildland fire spot ignition by sparks and firebrands. Fire Saf. J. 2017, 91, 2–10. [Google Scholar] [CrossRef]

- Hadden, R.M.; Scott, S.; Lautenberger, C.; Fernandez-Pello, A.C. Ignition of Combustible Fuel Beds by Hot Particles: An Experimental and Theoretical Study. Fire Technol. 2011, 47, 341–355. [Google Scholar] [CrossRef]

- Almeida, M.; Porto, L.; Viegas, D. Characterization of Firebrands Released From Different Burning Tree Species. Front. Mech. Eng. 2021, 7, 651135. [Google Scholar] [CrossRef]

- Sardoy, N.; Consalvi, J.-L.; Porterie, B.; Fernandez-Pello, A.C. Modeling transport and combustion of firebrands from burning trees. Combust. Flame 2007, 150, 151–169. [Google Scholar] [CrossRef]

- Manzello, S.; Zhou, K.; Suzuki, S. Experimental Study of Firebrand Transport. In Proceedings of the Annual Symposium of the Japan Association for Fire Science and Engineering, Tokyo, Japan, 27–28 May 2014. [Google Scholar]

- Koo, E.; Linn, R.R.; Pagni, P.J.; Edminster, C.B. Modelling firebrand transport in wildfires using HIGRAD/FIRETEC. Int. J. Wildland Fire 2012, 21, 396–417. [Google Scholar] [CrossRef]

- Cantor, P.; Arruda, M.R.T.; Firmo, J.; Branco, F. Proposal of Standard Wildfire Curves for the Design Protection of Dwellings Against Wildland Fire. J. Hazard. Toxic Radioact. Waste 2022, 26, 04022021. [Google Scholar] [CrossRef]

- Bicelli, A.R.; Cantor, P.; Arruda, M.R.; Tiago, C.; Bernardes de Assis, E.; Branco, F. Numerical Assessment of Standard Firebrand Accumulation Curve When Transferring Temperature to Contact Surfaces. Appl. Sci. 2023, 13, 9657. [Google Scholar] [CrossRef]

- Cantor, P.; Arruda, M.R.T.; Firmo, J.; Branco, F. Development of a standard firebrand accumulation temperature curve for residential wildfire protection system. Results Eng. 2023, 17, 100935. [Google Scholar] [CrossRef]

- Arruda, M.R.T.; Bicelli, A.R.A.; Cantor, P.; Assis, E.B.; Branco, F. Proposal of a fireproof design code for dwellings against the action of wildland fires. Resilient Cities Struct. 2023, 2, 104–119. [Google Scholar] [CrossRef]

- Arruda, M.R.T.; Bicelli, A.R.A.; Branco, F. Ignition Locations and Simplified Design Guidelines for Enhancing the Resilience of Dwellings against Wildland Fires. Fire 2024, 7, 40. [Google Scholar] [CrossRef]

- Arruda, M.R.T.; Cantor, P.; Bicelli, A.; Branco, F. Thermal reaction of firebrand accumulation in construction materials. Case Stud. Constr. Mater. 2024, 20, e02985. [Google Scholar] [CrossRef]

- Manzello, S.L.; Hayashi, Y.; Yoneki, T.; Yamamoto, Y. Quantifying the vulnerabilities of ceramic tile roofing assemblies to ignition during a firebrand attack. Fire Saf. J. 2010, 45, 35–43. [Google Scholar] [CrossRef]

- Dossi, S.; Messerschmidt, B.; Ribeiro, L.M.; Almeida, M.; Rein, G. Relationships between building features and wildfire damage in California, USA and Pedrógão Grande, Portugal. Int. J. Wildland Fire 2023, 32, 296–312. [Google Scholar] [CrossRef]

- Àgueda, A.; Vacca, P.; Planas, E.; Pastor, E. Evaluating wildfire vulnerability of Mediterranean dwellings using fuzzy logic applied to expert judgement. Int. J. Wildland Fire 2023, 32, 1011–1029. [Google Scholar] [CrossRef]

- Vacca, P.; Caballero, D.; Pastor, E.; Planas, E. WUI fire risk mitigation in Europe: A performance-based design approach at home-owner level. J. Saf. Sci. Resil. 2020, 1, 97–105. [Google Scholar] [CrossRef]

- Xanthopoulos, G.; Bushey, C.; Arnol, C.; Caballero, D. Characteristics of wildland–urban interface areas in Mediterranean Europe, North America and Australia and differences between them. In Proceedings of the 1st International Conference in Safety and Crisis Management in the Construction, Tourism and SME Sectors (1st CoSaCM), Nicosia, Cyprus, 24–28 June 2011; pp. 24–28. [Google Scholar]

- Mitchell, J.; Patashnik, O. Firebrand protection as the key design element for structural survival during catastrophic wildfire fires. In Proceedings of the Tenth International Conference on Fire and Materials Conference, San Francisco, CA, USA, 29–31 January 2007. [Google Scholar]

- Blanchi, R.; Leonard, J. Investigation of Bushfire Attack Mechanisms Resulting in House Loss in the ACT Bushfire 2003; Report for Bushfire CRC; CSIRO Manufacturing and Infrastructure Technology: Highett, Australia, 2005. [Google Scholar]

- Quarles, S.L.; Valachovic, Y.; Nakamura, G.M.; Nader, G.A.; De Lasaux, M.J. Home Survival in Wildfire-Prone Areas: Building Materials and Design Considerations; University of California: Berkeley, CA, USA, 2010. [Google Scholar] [CrossRef]

- Quarles, S.L.; Tenwolde, A. Attic and Crawlspace Ventilation: Implications for Homes Located in the Urban-Wildland Interface. 2004. Available online: https://research.fs.usda.gov/treesearch/20227 (accessed on 22 December 2024).

- Xanthopoulos, G. Forest Fires in the Wildland-Urban Interface and Rural Areas in Europe: An Integral Planning and Management Challenge. In Volume of Proceedings of International Workshop Held 15–16 May 2003, Athens, Greece, Under the Framework of the EU-Funded Project “Wildland-Urban Area Fire Risk Management“ (WARM); Mediterranean Agronomic Institute of Chania (MAICh): Chania, Greece, 2004; 239p. [Google Scholar]

- Lopes, R.F.R.; Rodrigues, J.P.C.; Camargo, A.L.; Tadeu, A.J.B. Resilience of Industrial Buildings to Wildland-Urban Interface Fires. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 022034. [Google Scholar] [CrossRef]

- Manzello, S.L.; Shields, J.R.; Hayashi, Y.; Nii, D. Investigating the vulnerabilities of structures to ignition from a firebrand attack. Fire Saf. Sci. 2008, 9, 143–154. [Google Scholar] [CrossRef]

- Sindelar, M. Wildfire Ignition Resistant Home Design (WIRHD) Program: Full-Scale Testing and Demonstration Final Report; USDA Forest Service-Savannah River: New Ellenton, SC, USA, 2011. [CrossRef]

- Manzello, S.L.; Manzello, S.L. The Performance of Concrete Tile and Terracotta Tile Roofing Assemblies Exposed to Wind-Driven Firebrand Showers; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013. [CrossRef]

- Manzello, S.L.; Suzuki, S.; Naruse, T. Quantifying wind-driven firebrand production from roofing assembly combustion. Fire Mater. 2019, 43, 3–7. [Google Scholar] [CrossRef]

- Papakosta, P.; Xanthopoulos, G.; Štraub, D. Probabilistic prediction of wildfire economic losses to housing in Cyprus using Bayesian network analysis. Int. J. Wildland Fire 2017, 26, 10–23. [Google Scholar] [CrossRef]

- Nguyen, D.; Kaye, N.B. Experimental investigation of rooftop hotspots during wildfire ember storms. Fire Saf. J. 2021, 125, 103445. [Google Scholar] [CrossRef]

- ISO 6021:2024; Firebrand Generator. ISO: Geneva, Switzerland, 2024.

- Samora-Arvela, A.; Aranha, J.; Correia, F.; Pinto, D.M.; Magalhães, C.; Tedim, F. Understanding Building Resistance to Wildfires: A Multi-Factor Approach. Fire 2023, 6, 32. [Google Scholar] [CrossRef]

- Wessies, S.S.; Chang, M.K.; Marr, K.C.; Ezekoye, O.A. Experimental and Analytical Characterization of Firebrand Ignition of Home Insulation Materials. Fire Technol. 2019, 55, 1027–1056. [Google Scholar] [CrossRef]

- Owens Corning. Owens Corning. Extruded Polystyrene (XPS) Insulation Board. Owens Corning Foam Insulation LLC. Product Data Sheet. Toledo, Ohio, 2015. Available online: https://www2.owenscorning.com/literature/pdfs/10018927.pdf (accessed on 22 December 2024).

- EN13501-1; Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests. British Standards Institution: London, UK, 2009.

- EN13501-2; Fire Classification of Construction Products and Building Elements—Part 2: Classification Using Data from Fire Resistance Tests, Excluding Ventilation Services. Svenska Institutet for Standarder: Stockholm, Sweden, 2009.

- CBC. California Building Code Part 2 Vol 1 and 2. In Chapter 7A [SFM] Materials and Construction Methods for Exterior Wildfire Exposure; International Code Council, Ed.; California Building Standards Commission: Sacramento, CA, USA, 2016. [Google Scholar]

- SFM-12-7A-4; California Code of Regulations Title 24—Chapter 12-7A-4 Materials and Construction Methods for Exterior Wildfire Exposure, Decking. California Building Standards Commission: Sacramento, CA, USA, 2016.

- Thomas, J.C.; Mueller, E.V.; Hadden, R.M. Estimating net heat flux from surrogate firebrand accumulations using an inverse heat transfer approach. Adv. For. Fire Res. 2018, 769–779. [Google Scholar] [CrossRef]

- Bearinger, E.; Lattimer, B.Y.; Hodges, J.L.; Rippe, C.; Kapahi, A. Statistical Assessment of Parameters Affecting Firebrand Pile Heat Transfer to Surfaces. Front. Mech. Eng. 2021, 7, 702181. [Google Scholar] [CrossRef]

- Prohanov, S.; Filkov, A.; Kasymov, D.; Agafontsev, M.; Reyno, V. Determination of Firebrand Characteristics Using Thermal Videos. Fire 2020, 3, 68. [Google Scholar] [CrossRef]

- Vieira, F.N.; Almeida, M.; Rodrigues, J.P.C.; Lopes, R.F.R. Study of Building Vulnerabilities to Forest Fires in Portugal. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 022022. [Google Scholar] [CrossRef]

- Ribeiro, L.M.; Rodrigues, A.; Lucas, D.; Viegas, D.X. The Impact on Structures of the Pedrógão Grande Fire Complex in June 2017 (Portugal). Fire 2020, 3, 57. [Google Scholar] [CrossRef]

- Laranjeira, J.; Cruz, H. Building Vulnerabilities to Fires at the Wildland Urban Interface. 2014. Available online: https://repositorio.lnec.pt/handle/123456789/1006732 (accessed on 22 December 2024).

- EN13501-5; Fire Classification of Construction Products and Building Elements—Part 5: Classification Using Data from External Fire Exposure to Roofs Tests. Comite Europeen de Normalisation: Brussels, Belgium, 2016.

- D8591/2022; Despacho n.º 8591/2022 Requisitos Para Adoção de Medidas de Proteção Relativas à Resistência do Edifício à Passagem do Fogo Florestal. Assembleia da República Lisbon: Lisbon, Portugal, 2022; pp. 67–72.

- AS 3959:2018; Construction of Buildings in Bushfire-Prone Areas. Australian Standard Committee: Sydney, NSW, Australia, 2018.

| Material | Fire Reaction | Thermal Conductivity (W/m·K) | Thickness (mm) |

|---|---|---|---|

| Tile | A1 | 0.400 | 20 |

| Bituminous tile | E | 0.099 | 3 |

| Composite Cork | E | 0.050 | 30 |

| Impermeable Membrane | Broof and E | 0.040 | 2 |

| Rockwool | A1 | 0.037 | 60 |

| Polystyrene Foam (XPS) | C or even B. | 0.027 | 30 |

| Roofs Specimens | Sub-Tile | Thermal Insulation |

|---|---|---|

| Tile and sub-tile (TS) | Bituminous tile | Without |

| Tile and rockwool (TR) | Without | Rockwool |

| Tile and cork (TC) | Without | Cork |

| Tile and XPS (TX) | Without | XPS |

| Tile, sub-tile, and rockwool (TSR) | Bituminous tile | Rockwool |

| Tile, sub-tile, and cork (TSC) | Bituminous tile | Cork |

| Tile, sub-tile, and XPS (TSX) | Bituminous tile | XPS |

| Tile, sub-tile, and membrane (TSM) | Bituminous tile | Membrane |

| Material | Rockwool | Cork | XPS | Membrane | Bituminous Tile | |||

|---|---|---|---|---|---|---|---|---|

| Specimen | TR | TSR | TC | TSC | TX | TSX | TSM | In all specimens |

| Type of Ignition | SI | SI | SI | SI | NI | NI | NI | FI |

| Smoke Production | YES | YES | YES | YES | YES | NO | NO | YES |

| Droplets Production | NO | NO | NO | NO | YES | YES | NO | YES |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zitouni, M.; Tiago Arruda, M.R.; Cantor, P.; Branco, F. Thermal Effect of Firebrand Accumulation in Ceramic Roof Tiles. Fire 2025, 8, 55. https://doi.org/10.3390/fire8020055

Zitouni M, Tiago Arruda MR, Cantor P, Branco F. Thermal Effect of Firebrand Accumulation in Ceramic Roof Tiles. Fire. 2025; 8(2):55. https://doi.org/10.3390/fire8020055

Chicago/Turabian StyleZitouni, Mohamed, Mário Rui Tiago Arruda, Pedro Cantor, and Fernando Branco. 2025. "Thermal Effect of Firebrand Accumulation in Ceramic Roof Tiles" Fire 8, no. 2: 55. https://doi.org/10.3390/fire8020055

APA StyleZitouni, M., Tiago Arruda, M. R., Cantor, P., & Branco, F. (2025). Thermal Effect of Firebrand Accumulation in Ceramic Roof Tiles. Fire, 8(2), 55. https://doi.org/10.3390/fire8020055