An Integrated Engineering Method for Improving Air Quality of Cage-Free Hen Housing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ethical Approval

2.2. Research Facilities and Animal Management

2.3. Experimental Design

2.4. Environment Parameter Measurements

2.4.1. Temperature and Relative Humidity

2.4.2. Ventilation Measurement

2.4.3. Litter Depth and Litter Moisture Content Measurements

2.5. PM Measurement

2.6. Working Principle of EPI

2.7. Footpad Dermatitis Scoring

2.8. Statistical Analysis

3. Results and Discussion

3.1. Environment Parameters

3.1.1. Temperature and Relative Humidity

3.1.2. Ventilation Rates

3.1.3. Litter Moisture Content

3.2. Effects on PM

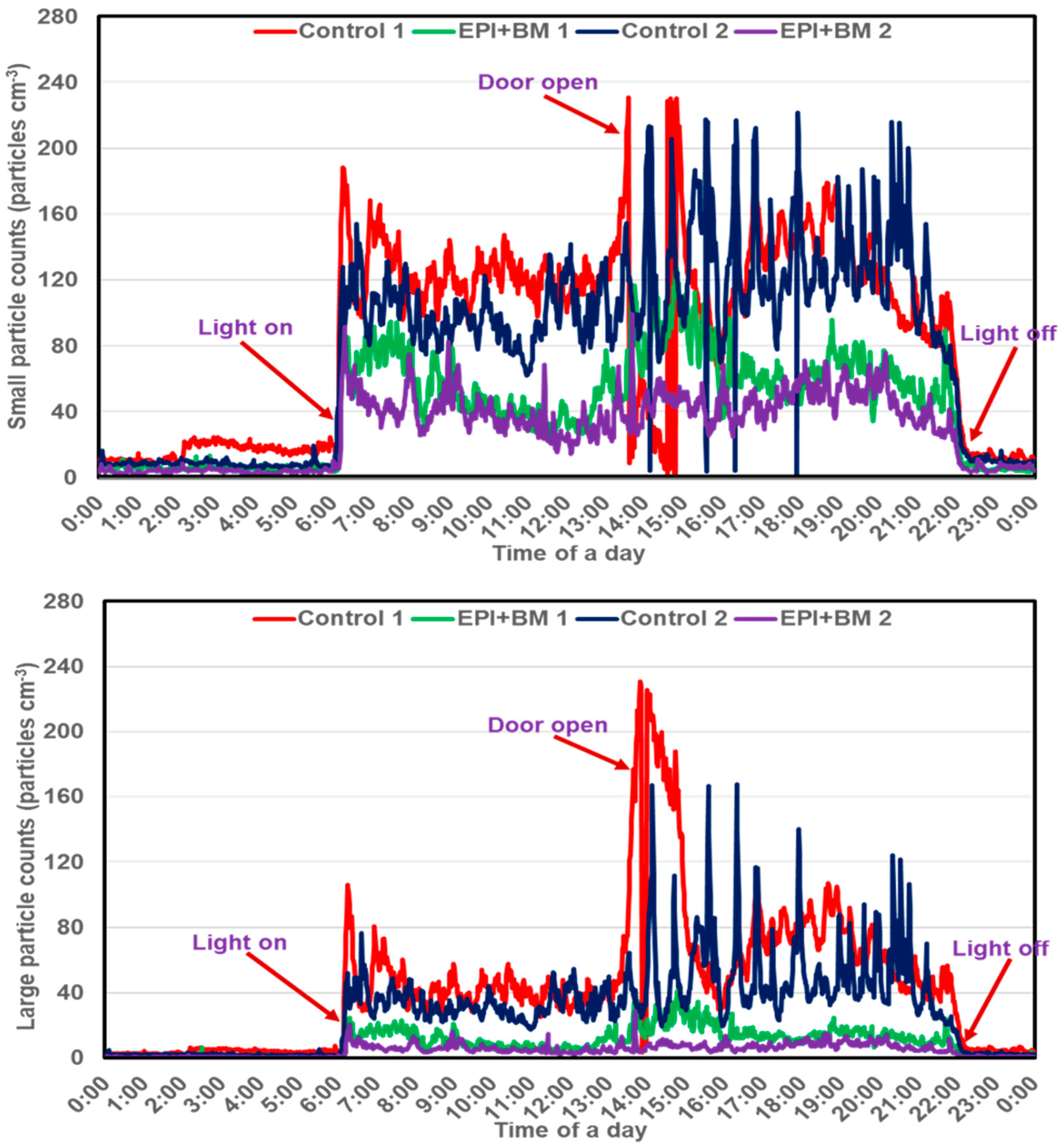

3.2.1. Temporal Variation in Particle Concentrations

3.2.2. Particle Concentration

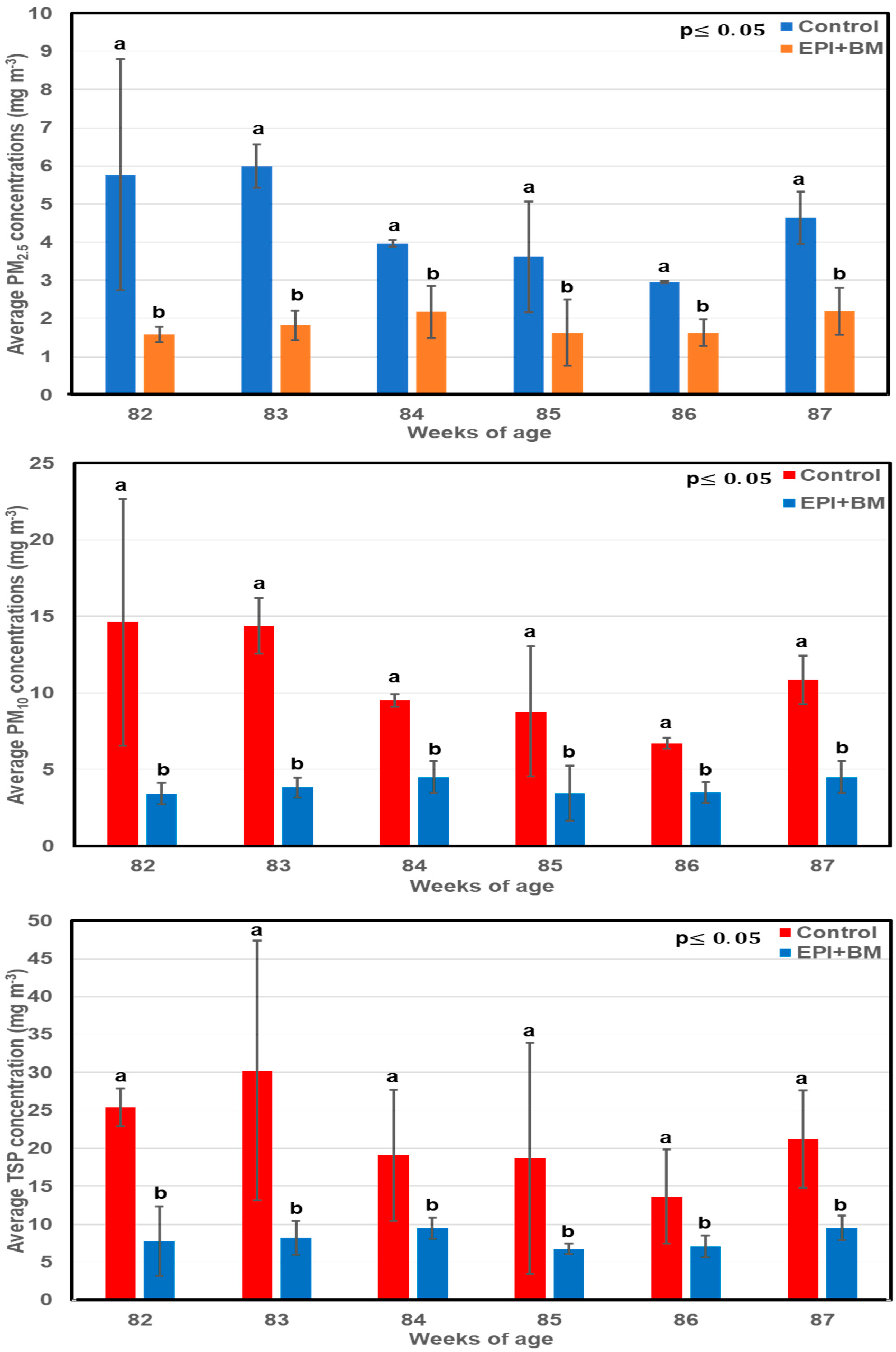

3.2.3. PM Mass Concentrations

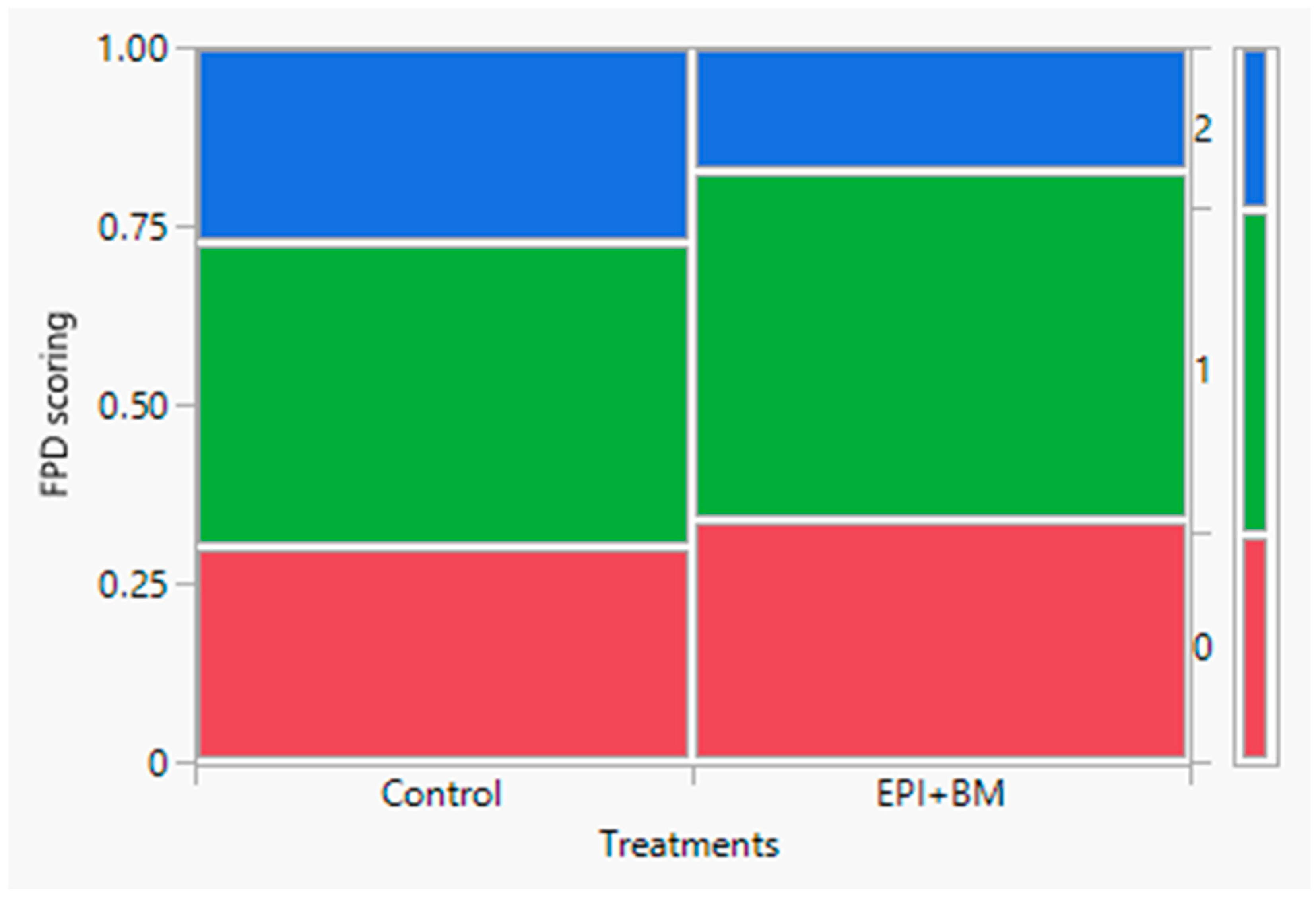

3.3. Footpad Dermatitis Scoring

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ni, J.-Q. Research and Demonstration to Improve Air Quality for the US Animal Feeding Operations in the 21st Century—A Critical Review. Environ. Pollut. 2015, 200, 105–119. [Google Scholar] [CrossRef] [PubMed]

- Chai, L.; Xin, H.; Zhao, Y.; Wang, T.; Soupir, M.; Liu, K. Mitigating Ammonia and PM Generation of Cage-Free Henhouse Litter with Solid Additive and Liquid Spray. Trans. ASABE 2018, 61, 287–294. [Google Scholar] [CrossRef]

- Bist, R.B.; Chai, L. Advanced Strategies for Mitigating Particulate Matter Generations in Poultry Houses. Appl. Sci. 2022, 12, 11323. [Google Scholar] [CrossRef]

- Ni, J.-Q.; Erasmus, M.; Jones, D.R.; Campbell, D.L. Effectiveness and Characteristics of a New Technology to Reduce Ammonia, Carbon Dioxide, and Particulate Matter Pollution in Poultry Production with Artificial Turf Floor. Environ. Technol. Innov. 2023, 29, 102976. [Google Scholar] [CrossRef]

- Zhao, Y.; Shepherd, T.A.; Li, H.; Xin, H. Environmental Assessment of Three Egg Production Systems—Part I: Monitoring System and Indoor Air Quality. Poult. Sci. 2015, 94, 518–533. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhao, D.; Ma, H.; Liu, K.; Atilgan, A.; Xin, H. Environmental Assessment of Three Egg Production Systems—Part III: Airborne Bacteria Concentrations and Emissions. Poult. Sci. 2016, 95, 1473–1481. [Google Scholar] [CrossRef] [PubMed]

- US EPA. Health and Environmental Effects of Particulate Matter (PM). Available online: https://www.epa.gov/pm-pollution/health-and-environmental-effects-particulate-matter-pm (accessed on 30 September 2022).

- US EPA. Particulate Matter (PM) Basics. Available online: https://www.epa.gov/pm-pollution/particulate-matter-pm-basics (accessed on 30 September 2022).

- Koren, H.; Bisesi, M. Handbook of Environmental Health, Fourth Edition, Volume II: Pollutant Interactions in Air, Water, and Soil; Herman, K., Michael, S.B., Eds.; Routledge: London, UK, 2003; Volume 2. [Google Scholar]

- Schwarze, P.; Øvrevik, J.; Låg, M.; Refsnes, M.; Nafstad, P.; Hetland, R.; Dybing, E. Particulate Matter Properties and Health Effects: Consistency of Epidemiological and Toxicological Studies. Hum. Exp. Toxicol. 2006, 25, 559–579. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Aarnink, A.; De Jong, M.; Ogink, N.; Koerkamp, P.G. Effectiveness of Multi-Stage Scrubbers in Reducing Emissions of Air Pollutants from Pig Houses. Trans. ASABE 2011, 54, 285–293. [Google Scholar] [CrossRef]

- Winkel, A.; Mosquera, J.; Aarnink, A.J.; Koerkamp, P.W.G.; Ogink, N.W. Evaluation of Oil Spraying Systems and Air Ionisation Systems for Abatement of Particulate Matter Emission in Commercial Poultry Houses. Biosyst. Eng. 2016, 150, 104–122. [Google Scholar] [CrossRef]

- Chai, L.; Xin, H.; Wang, Y.; Oliveira, J.; Wang, K.; Zhao, Y. Mitigating Particulate Matter Generation in a Commercial Cage-Free Hen House. Trans. ASABE 2019, 62, 877–886. [Google Scholar] [CrossRef]

- Shepherd, E.; Fairchild, B. Footpad Dermatitis in Poultry. Poult. Sci. 2010, 89, 2043–2051. [Google Scholar] [CrossRef] [PubMed]

- De Jong, I.C.; Gunnink, H.; Van Harn, J. Wet Litter Not Only Induces Footpad Dermatitis but Also Reduces Overall Welfare, Technical Performance, and Carcass Yield in Broiler Chickens. J. Appl. Poult. Res. 2014, 23, 51–58. [Google Scholar] [CrossRef]

- Forero, D.; Pena, C.; Acevedo, P.; Hernandez, M.; Cabeza, I. Biofiltration of Acetic Acid Vapours Using Filtering Bed Compost from Poultry Manure-Pruning Residues-Rice Husks. Chem. Eng. Trans. 2018, 64, 511–516. [Google Scholar]

- Strohmaier, C.; Schmithausen, A.J.; Krommweh, M.S.; Diekmann, B.; Büscher, W. Evaluation of a Dry Filter for Dust Removal under Laboratory Conditions in Comparison to Practical Use at a Laying Hen Barn. Environ. Sci. Pollut. Res. 2018, 25, 29511–29517. [Google Scholar] [CrossRef]

- Mitchell, B.; Buhr, R.; Berrang, M.; Bailey, J.; Cox, N. Reducing Airborne Pathogens, Dust and Salmonella Transmission in Experimental Hatching Cabinets Using an Electrostatic Space Charge System. Poult. Sci. 2002, 81, 49–55. [Google Scholar] [CrossRef]

- Mitchell, B.W.; Waltman, W.D. Reducing Airborne Pathogens and Dust in Commercial Hatching Cabinets with an Electrostatic Space Charge System. Avian Dis. 2003, 47, 247–253. [Google Scholar] [CrossRef]

- Ritz, C.; Fairchild, B.; Lacy, M. Implications of Ammonia Production and Emissions from Commercial Poultry Facilities: A Review. J. Appl. Poult. Res. 2004, 13, 684–692. [Google Scholar] [CrossRef]

- Mitchell, B.W.; Baumgartner, J.W. Electrostatic Space Charge System for Reducing Dust in Poultry Production Houses and the Hatchery. In International Conference How to Improve Air Quality; Citeseer, 2007; pp. 23–24. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=b5467e69bce33c3b5691d6a4a4a8d065ed1a35f2 (accessed on 23 April 2024).

- Cambra-López, M.; Winkel, A.; Van Harn, J.; Ogink, N.; Aarnink, A. Ionization for Reducing Particulate Matter Emissions from Poultry Houses. Trans. ASABE 2009, 52, 1757–1771. [Google Scholar] [CrossRef]

- Jerez, S.B.; Mukhtar, S.; Faulkner, W.; Casey, K.D.; Borhan, M.S.; Smith, R.A. Evaluation of Electrostatic Particle Ionization and BioCurtainTM Technologies to Reduce Air Pollutants from Broiler Houses. Appl. Eng. Agric. 2013, 29, 975–984. [Google Scholar]

- Ritz, C.; Mitchell, B.; Fairchild, B.; Czarick III, M.; Worley, J. Improving In-House Air Quality in Broiler Production Facilities Using an Electrostatic Space Charge System. J. Appl. Poult. Res. 2006, 15, 333–340. [Google Scholar] [CrossRef]

- Mitchell, B.; Richardson, L.; Wilson, J.; Hofacre, C. Application of an Electrostatic Space Charge System for Dust, Ammonia, and Pathogen Reduction in a Broiler Breeder House. Appl. Eng. Agric. 2004, 20, 87. [Google Scholar] [CrossRef]

- Munir, M.; Belloncle, C.; Irle, M.; Federighi, M. Wood-Based Litter in Poultry Production: A Review. World’s Poult. Sci. J. 2019, 75, 5–16. [Google Scholar] [CrossRef]

- Bist, R.B.; Regmi, P.; Karcher, D.; Guo, Y.; Singh, A.K.; Ritz, C.W.; Kim, W.K.; Jones, D.R.; Chai, L. Bedding Management for Suppressing Particulate Matter in Cage-Free Hen Houses. AgriEngineering 2023, 5, 1663–1676. [Google Scholar] [CrossRef]

- Hy-Line 36 COM ENG. Available online: https://www.hyline.com/filesimages/Hy-Line-Products/Hy-Line-Product-PDFs/W-36/36%20COM%20ENG.pdf (accessed on 10 September 2022).

- Bist, R.B.; Yang, X.; Subedi, S.; Ritz, C.W.; Kim, W.K.; Chai, L. Electrostatic Particle Ionization for Suppressing Air Pollutants in Cage-Free Layer Facilities. Poult. Sci. 2024, 103, 103494. [Google Scholar] [CrossRef]

- Bist, R.B.; Yang, X.; Subedi, S.; Sharma, M.K.; Singh, A.K.; Ritz, C.W.; Kim, W.K.; Chai, L. Temporal Variations of Air Quality in Cage-Free Experimental Pullet Houses. Poultry 2023, 2, 320–333. [Google Scholar] [CrossRef]

- Yasmeen, R.; Ali, Z.; Tyrrel, S.; Nasir, Z.A. Estimation of Particulate Matter and Gaseous Concentrations Using Low-Cost Sensors from Broiler Houses. Environ. Monit. Assess. 2019, 191, 470. [Google Scholar] [CrossRef]

- Bist, R.B.; Yang, X.; Subedi, S.; Paneru, B.; Chai, L. Enhancing Dust Control for Cage-Free Hens with Electrostatic Particle Charging Systems at Varying Installation Heights and Operation Durations. AgriEngineering 2024, 6, 1747–1759. [Google Scholar] [CrossRef]

- GAP Chicken Welfare Standards. Available online: http://glblanimalpartnership.blob.core.windows.net/standards/Chicken%20Welfare%20Standards.pdf (accessed on 25 June 2023).

- Verma, K.K.; Singh, V.; Gupta, S.L.; Yadav, J.; Verma, A.K. Environmentally Controlled House-In Poultry Production. Poult. Line 2014, 1, 29–32. [Google Scholar]

- Elliott, H.; Collins, N. Factors Affecting Ammonia Release in Broiler Houses. Trans. ASAE 1982, 25, 413–0418. [Google Scholar] [CrossRef]

- Chen, B.; Shao, Y.; Shi, M.; Ji, L.; He, Q.; Yan, S. Anaerobic Digestion of Chicken Manure Coupled with Ammonia Recovery by Vacuum-Assisted Gas-Permeable Membrane Process. Biochem. Eng. J. 2021, 175, 108135. [Google Scholar] [CrossRef]

- Carr, L.; Wheaton, F.; Douglass, L. Empirical Models to Determine Ammonia Concentrations from Broiler Chicken Litter. Trans. ASAE 1990, 33, 1337–1342. [Google Scholar] [CrossRef]

- Shepherd, E.M.; Fairchild, B.D.; Ritz, C.W. Alternative Bedding Materials and Litter Depth Impact Litter Moisture and Footpad Dermatitis. J. Appl. Poult. Res. 2017, 26, 518–528. [Google Scholar] [CrossRef]

- Bilgili, S.; Hess, J.; Blake, J.; Macklin, K.; Saenmahayak, B.; Sibley, J. Influence of Bedding Material on Footpad Dermatitis in Broiler Chickens. J. Appl. Poult. Res. 2009, 18, 583–589. [Google Scholar] [CrossRef]

| Score 0 | Score 1 | Score 2 |

|---|---|---|

| No or very small lesions | Mild and/or superficial lesions | Severe lesions with ulceration and significant damage |

| No discoloration or slight area | Substantial footpad discoloration | Dark papillae and ulceration |

| Old scars or no scarring | Dark papillae without ulceration | Abscesses and/or swollen feet (bumblefoot) |

| Treatments | PM1 (mg/m3) | PM2.5 (mg/m3) | PM4 (mg/m3) | PM10 (mg/m3) | TSP (mg/m3) |

|---|---|---|---|---|---|

| Control | 4.25 ± 1.45 a | 4.49 ± 1.56 a | 5.25 ± 1.91 a | 10.82 ± 4.14 a | 21.39 ± 9.62 a |

| EPI + BM | 1.77 ± 0.47 b | 1.84 ± 0.50 b | 2.06 ± 0.54 b | 3.88 ± 0.93 b | 8.15 ± 2.06 b |

| PM reduction (%) | 58.41 | 59.09 | 60.80 | 64.17 | 61.89 |

| p-value (treatments) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| p-value (WOA) | 0.331 | 0.339 | 0.358 | 0.363 | 0.607 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bist, R.B.; Yang, X.; Subedi, S.; Paneru, B.; Chai, L. An Integrated Engineering Method for Improving Air Quality of Cage-Free Hen Housing. AgriEngineering 2024, 6, 2795-2810. https://doi.org/10.3390/agriengineering6030162

Bist RB, Yang X, Subedi S, Paneru B, Chai L. An Integrated Engineering Method for Improving Air Quality of Cage-Free Hen Housing. AgriEngineering. 2024; 6(3):2795-2810. https://doi.org/10.3390/agriengineering6030162

Chicago/Turabian StyleBist, Ramesh Bahadur, Xiao Yang, Sachin Subedi, Bidur Paneru, and Lilong Chai. 2024. "An Integrated Engineering Method for Improving Air Quality of Cage-Free Hen Housing" AgriEngineering 6, no. 3: 2795-2810. https://doi.org/10.3390/agriengineering6030162