Agricultural Tire Test: Straw Cover Effect on Reducing Soil Compaction by Cargo Vehicles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Site of Study

2.2. Test Proceedings

2.3. Details of Rigid Surface Test

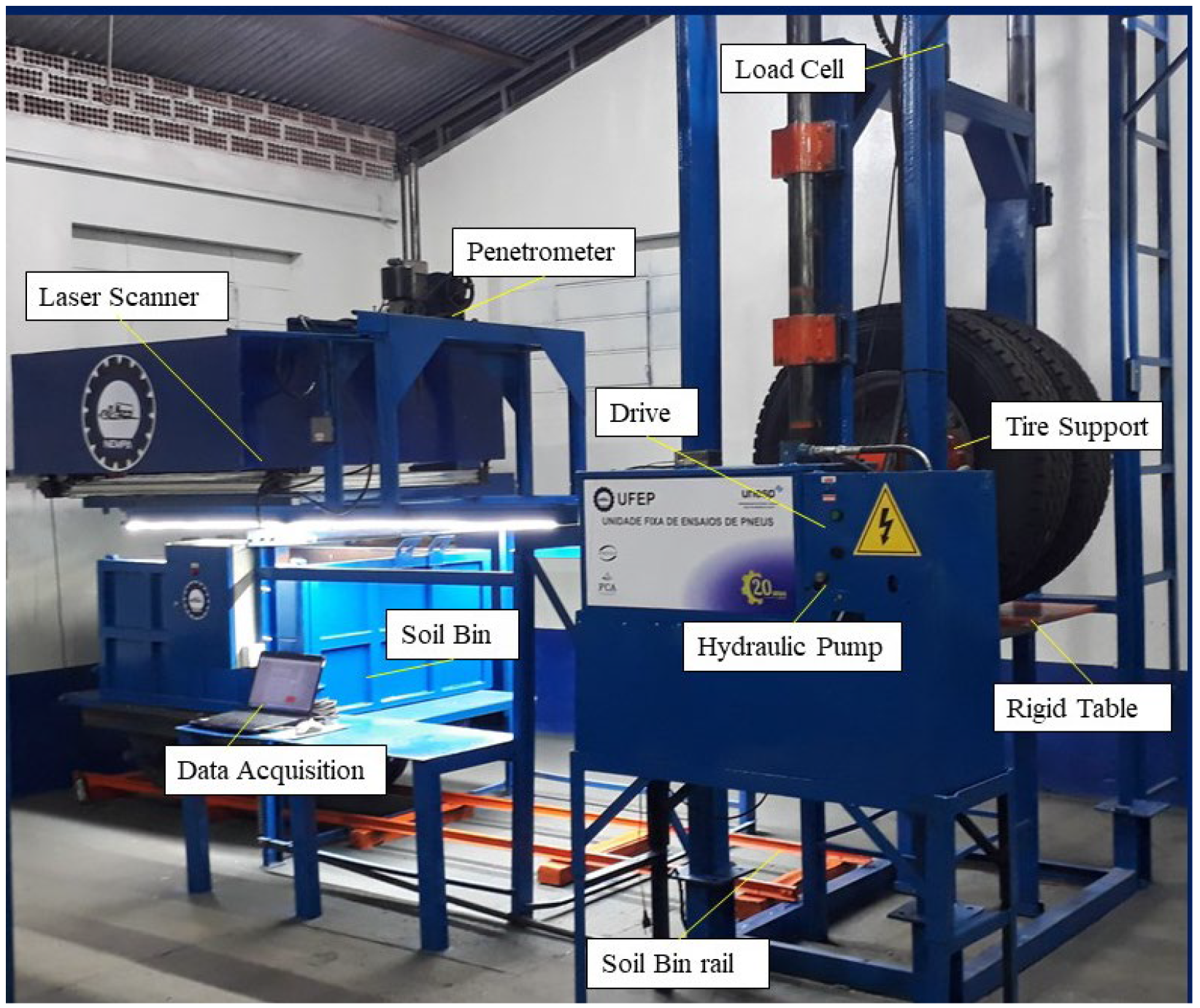

2.4. Details of Soil Bin Controlled Tests

2.5. Statistical Analysis

3. Results and Discussion

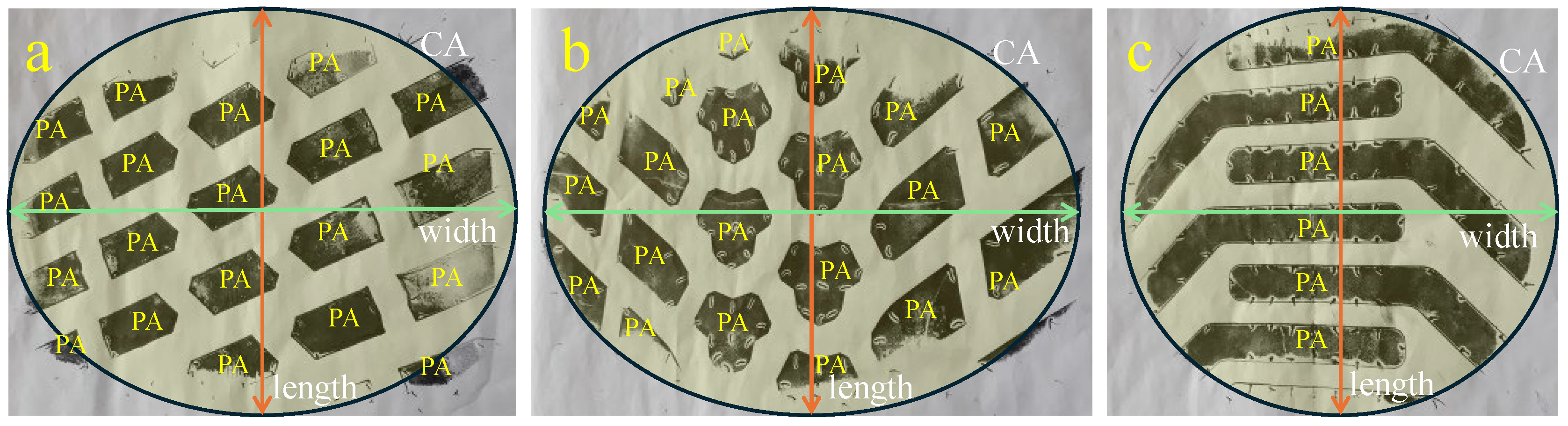

3.1. Rigid Surface Test

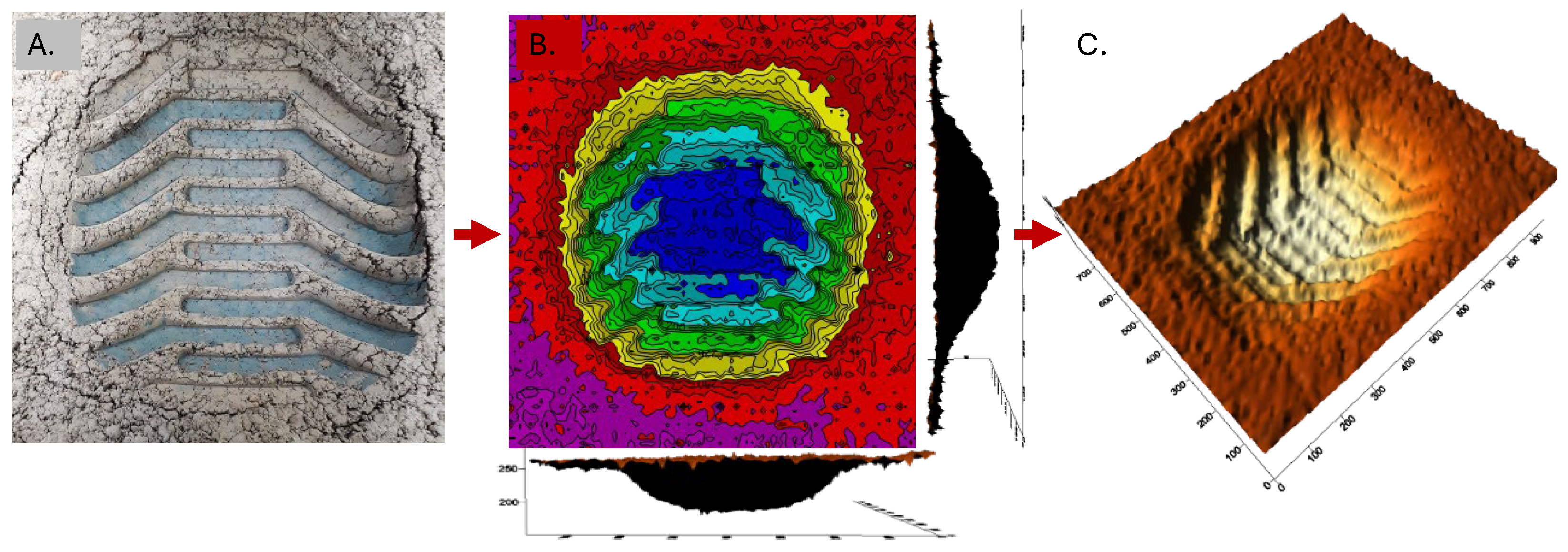

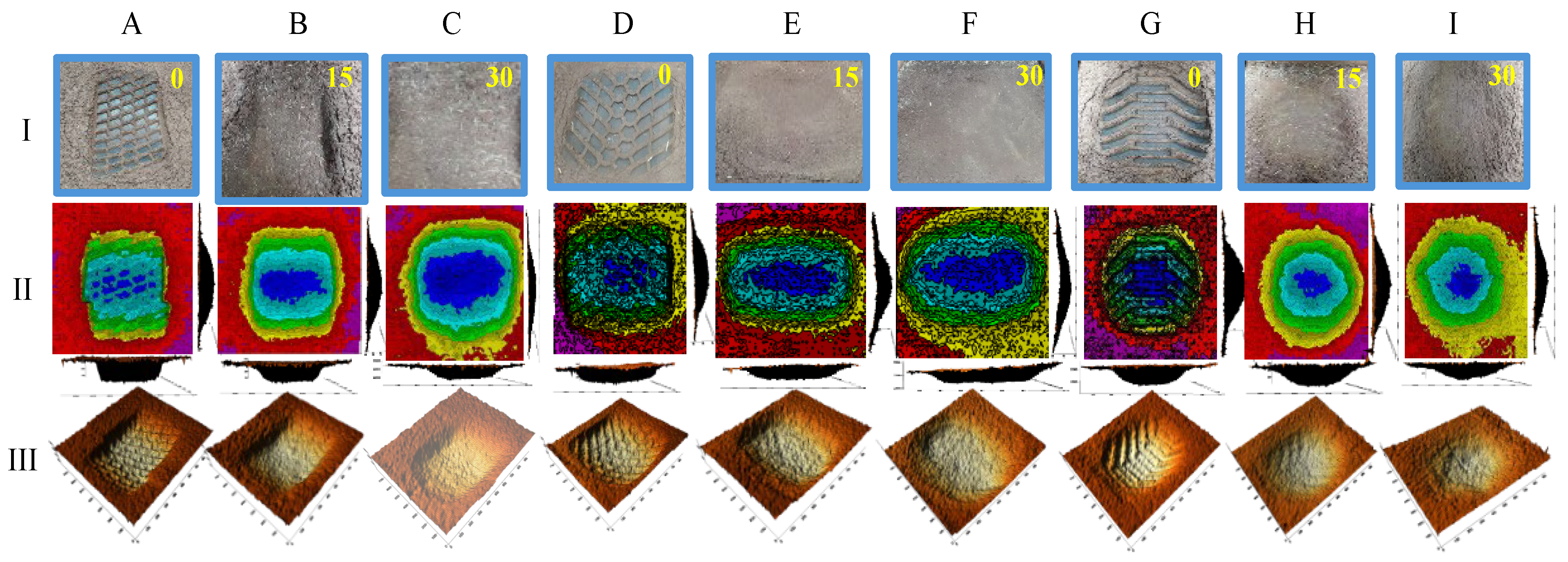

3.2. Deformable Surface Test

4. Conclusions

- The tire’s claw design determines its punctual contact area. However, the main tire design and construction model affect the total contact area.

- The radial tires’ IF (p2) and VF (p1) technology established the largest total contact areas. Smaller modern tires with high flexibility technologies can prevent plant trampling and enable controlled traffic, reducing soil compaction.

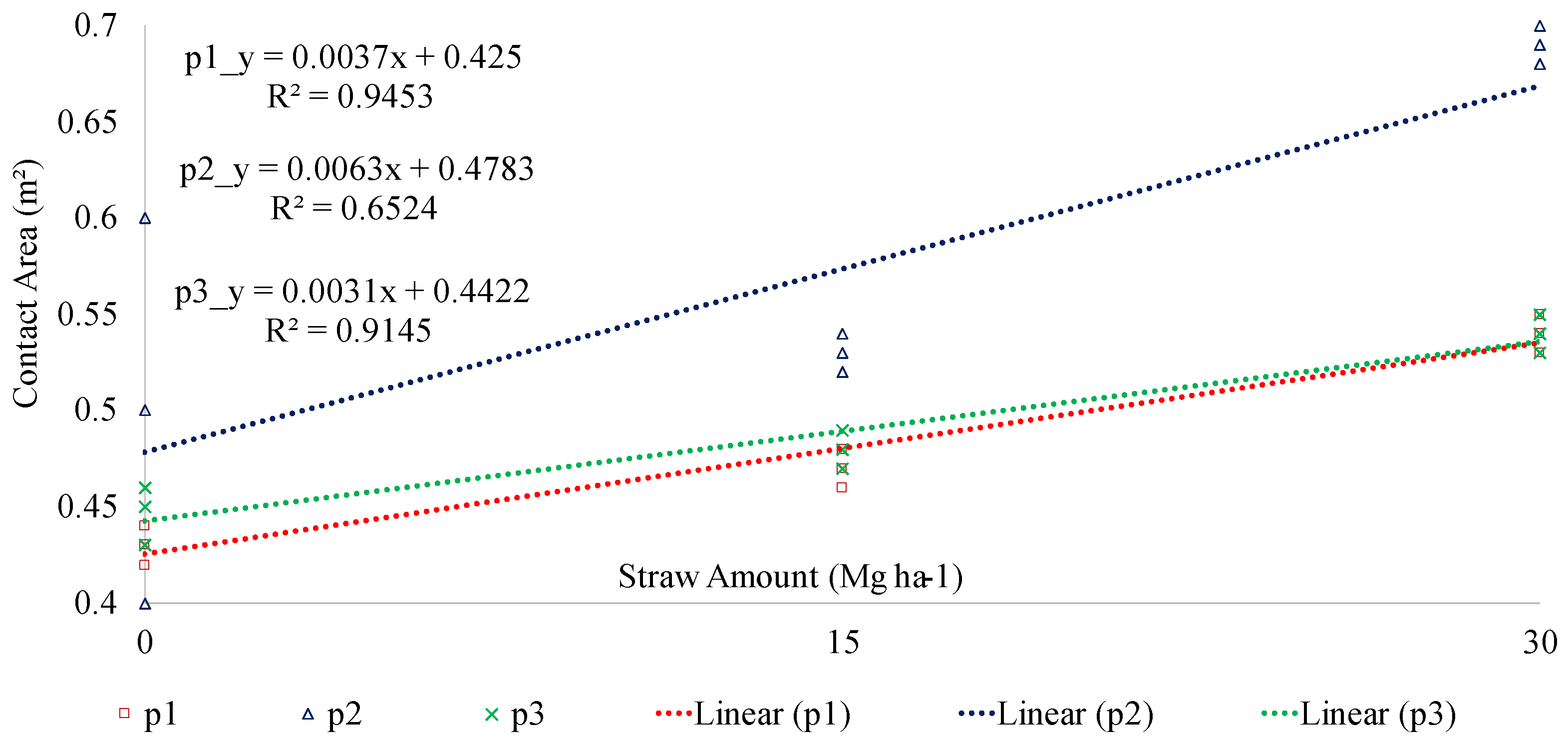

- The contact area on the deformable surface (soil bin) increased linearly due to the increased straw covering, which reduced sinkage (tread mark depth). The largest contact areas were found in p2 to 30 Mg ha−1 straw.

- The increase in straw soil surface from 0 to 30 Mg ha−1 promoted an increase in contact areas by 25.5, 38.0, and 20.0% for p1, p2, and p3, respectively. Compared to the rigid surface, the p1 and p3 contact areas in the soil bin increased 6.2, 6.8, and 7.8 times in bare soil, 15, and 30 Mg, respectively; for p2, this increase was 4.2, 4.5, and 5.9 times on the same surfaces.

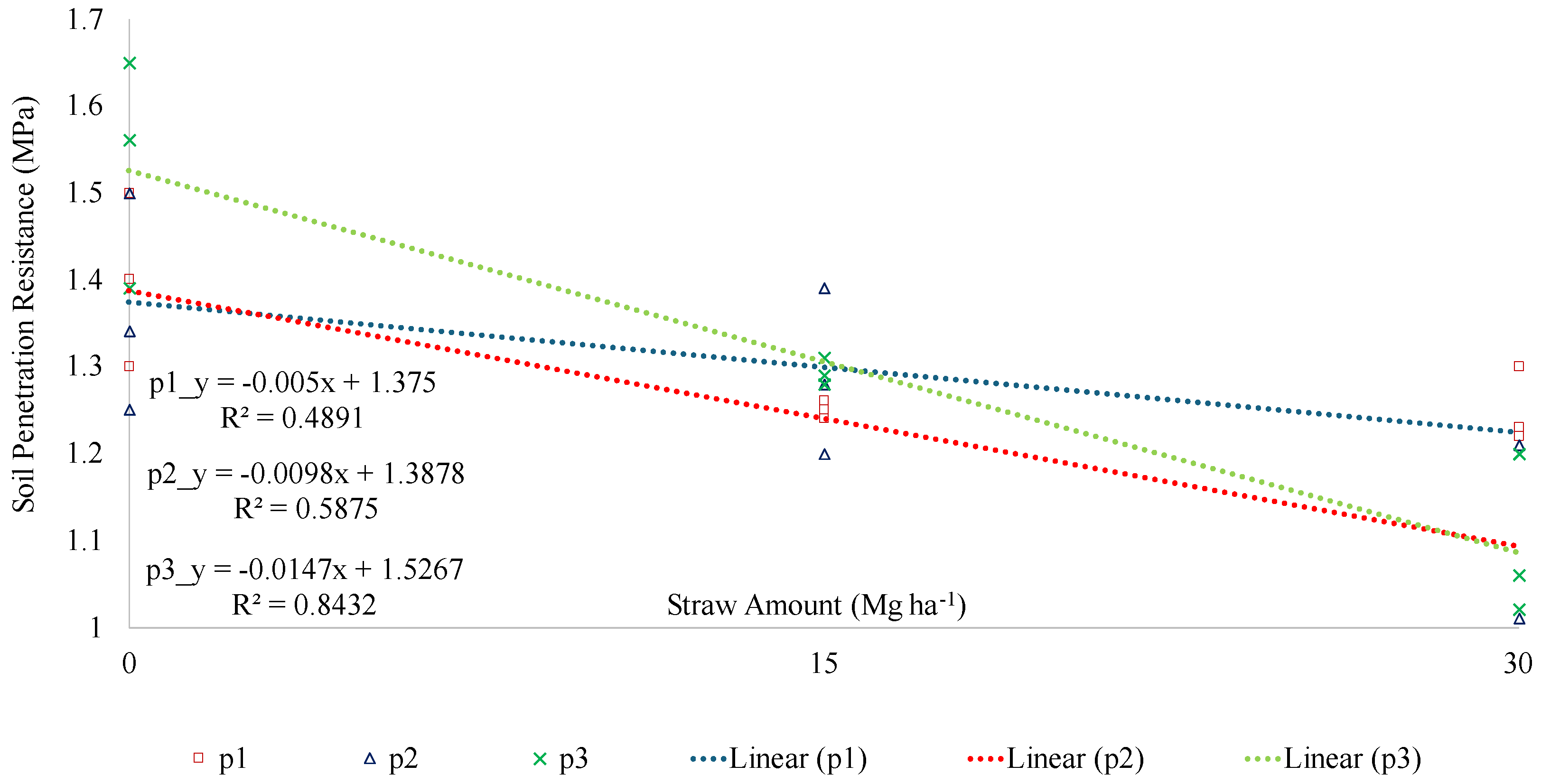

- The positive angular coefficients indicate that the amount of straw cover proportionally increases the tire contact area. Straw reduces soil penetration resistance linearly (negative angular coefficients), attenuating soil compaction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keller, T.; Sandin, M.; Colombi, T.; Horn, R.; Or, D. Historical increase in agricultural machinery weights enhanced soil stress levels and adversely affected soil functioning. Soil Tillage Res. 2019, 194, 104293. [Google Scholar] [CrossRef]

- Farhadi, P.; Golmohammadi, A.; Malvajerdi, A.S.; Gholamhossein, S. Finite element modeling of the interaction of a treaded tire with clay-loam soil. Comput. Electron. Agric. 2019, 162, 793–806. [Google Scholar] [CrossRef]

- Yue, L.; Yi, W.; Wang, L.; Yao, S.; Cong, C.; Ren, L.; Zhang, B. Impacts of soil compaction and historical soybean variety growth on soil macropore structure. Soil Tillage Res. 2021, 214, 105166. [Google Scholar] [CrossRef]

- Zeng, H.; Wei, X.; Zang, M. Experimental investigation of tire traction performance on granular terrain. J. Terramech. 2022, 104, 49–58. [Google Scholar] [CrossRef]

- Roşca, R.; Cârlescu, P.; Vlahidis, I.T.V.; Perşu, C. The improvement of a traction model for agricultural tire–soil interaction. Agriculture 2022, 12, 2035. [Google Scholar] [CrossRef]

- Marques Filho, A.C.; Medeiros, S.D.S.; Martins, M.B.; Moura, M.S.; Lanças, K.P. Can the Straw Remaining on the Ground Reduce the Wheelsets Impact on Sugarcane Crop? Sugar Tech 2022, 24, 1814–1820. [Google Scholar] [CrossRef]

- Alkhalifa, N.; Tekeste, M.Z.; Jjagwe, P.; Way, T.R. Effects of vertical load and inflation pressure on tire-soil interaction on artificial soil. J. Terramech. 2024, 112, 19–34. [Google Scholar] [CrossRef]

- Marques Filho, A.C.; Martins, M.B.; Medeiros, S.D.S.; Santana, L.S.; Lopes, A.G.C.; Lanças, K.P. Wheel–Ground Interaction Test for Sugarcane Cargo Transshipments. Sugar Tech 2024, 26, 894–901. [Google Scholar] [CrossRef]

- El-Sayegh, Z.; El-Gindy, M.; Johansson, I.; Öijer, F. Modelling tire-moist terrain interaction using advanced computational techniques. J. Terramech. 2020, 91, 23–30. [Google Scholar] [CrossRef]

- Cutini, M.; Costa, C.; Brambilla, M.; Bisaglia, C. Relationship between the 3D footprint of an agricultural tire and drawbar pull using an artificial neural network. Appl. Eng. Agric. 2022, 38, 293–301. [Google Scholar] [CrossRef]

- He, R.; Sandu, C.; Osorio, J.E. Systematic tests for study of tire tractive performance on soft soil: Part I—Experimental data collection. J. Terramech. 2019, 85, 59–76. [Google Scholar] [CrossRef]

- Yadav, R.; Raheman, H. Development of an artificial neural network model with graphical user interface for predicting contact area of bias-ply tractor tyres on firm Surface. J. Terramech. 2023, 107, 1–11. [Google Scholar] [CrossRef]

- Acquah, K.; Chen, Y. Discrete element modelling of soil pressure under varying number of tire passes. J. Terramech. 2023, 107, 23–33. [Google Scholar] [CrossRef]

- Teimourlou, R.F.; Taghavifar, H. Determination of the super-elliptic shape of tire-soil contact area using image processing method. Cercet. Agron. Mold. 2015, 48, 5–14. [Google Scholar] [CrossRef]

- Jasoliya, D.; Untaroiu, A.; Untaroiu, C. A review of soil modeling for numerical simulations of soil-tire/agricultural tools interaction. J. Terramech. 2024, 111, 41–64. [Google Scholar] [CrossRef]

- Golanbari, B.; Mardani, A. An analytical model for stress estimation at the soil-tire interface using the dynamic contact length. J. Terramech. 2024, 111, 1–7. [Google Scholar] [CrossRef]

- Karelina, M.; Balabina, T.; Mamaev, A. Wheel Rolling on a Deformable Support Surface. In Proceedings of the 2022 International Conference on Engineering Management of Communication and Technology, Vienna, Austria, 20–22 October 2022; Volume 1, pp. 1–4. [Google Scholar] [CrossRef]

- Vieira, D.; Orjuela, R.; Spisser, M.; Basset, M. An adapted Burckhardt tire model for off-road vehicle applications. J. Terramech. 2022, 104, 15–24. [Google Scholar] [CrossRef]

- Silva, R.B.; Iori, P.; Souza, Z.M.D.; Pereira, D.M.G.; Vischi Filho, O.J.; Silva, F.A.M. Contact pressures and the impact of farm equipment on Latosol with the presence and absence of sugarcane straw. Ciência Agrotecnol. 2016, 40, 265–278. [Google Scholar] [CrossRef]

- Gheshlaghi, F.; Aref, M. Prediction of soil vertical stress under off-road tire using smoothed-particle hydrodynamics. J. Terramech. 2021, 95, 7–14. [Google Scholar] [CrossRef]

- Jjagwe, P.; Tekeste, M.Z.; Alkhalifa, N.; Way, T.R. Modeling tire-soil compression resistance on artificial soil using the scaling law of pressure-soil sinkage relationship. J. Terramech. 2023, 108, 7–19. [Google Scholar] [CrossRef]

- Zhao, H.; Yuxiang, H.; Liu, Z.; Liu, W.; Zheng, Z. Applications of discrete element method in the research of agricultural machinery: A review. Agriculture 2021, 11, 425. [Google Scholar] [CrossRef]

- Phakdee, S.; Suvanjumrat, C. Development of a tire testing machine for evaluating the performance of tractor tires based on the soil compaction. J. Terramech. 2023, 110, 13–25. [Google Scholar] [CrossRef]

- Deng, Y.; Wang, Z.; Shen, H.; Gong, J.; Zhen, X. A comprehensive review on non-pneumatic tyre research. Mater. Des. 2023, 1, 111742. [Google Scholar] [CrossRef]

- Zhang, F.; Qiu, Y.; Teng, S.; Cui, X.; Wang, X.; Sun, H.; Ali, S.; Guo, Z.; Jiajia, W.; Fu, S. Design and Test of Tread-Pattern Structure of Biomimetic Goat-Sole Tires. Biomimetics 2022, 7, 236. [Google Scholar] [CrossRef] [PubMed]

- Luz, F.B.; Gonzaga, L.C.; Castioni, G.A.F.; Lima, R.P.; Carvalho, J.L.M.; Cherubin, M.R. Controlled traffic farming maintains soil physical functionality in sugarcane fields. Geoderma 2023, 432, 116427. [Google Scholar] [CrossRef]

- Farhadi, P.; Golmohammadi, A.; Malvajerdi, A.S.; Gholamhossein, S. Tire and soil effects on power loss: Measurement and comparison with finite element model results. J. Terramech. 2020, 92, 13–22. [Google Scholar] [CrossRef]

- Harris, B.J. Increased Deflection Agricultural Radial Tires Following the Tire and Rim Association IF, VF, and IF/CFO Load and Inflation Standards; ASABE, Distinguished Lecture Series. Tractor Design No. 39. ASABE Publication 913C0117; ASABE: St. Joseph, MI, USA, 2017. [Google Scholar]

- Guimarães Júnnyor, W.S.; Diserens, E.; De Maria, I.C.; Araujo-Junior, C.F.; Farhate, C.V.V.; Souza, Z.M.D. Prediction of soil stresses and compaction due to agricultural machines in sugarcane cultivation systems with and without crop rotation. Sci. Total Environ. 2019, 681, 424–434. [Google Scholar] [CrossRef] [PubMed]

- Castioni, G.A.; de Lima, R.P.; Cherubin, M.R.; Bordonal, R.O.; Rolim, M.M.; Carvalho, J.L. Machinery traffic in sugarcane straw removal operation: Stress transmitted and soil compaction. Soil Tillage Res. 2021, 213, 105122. [Google Scholar] [CrossRef]

- Alapa. Associação Latino-Americana dos Fabricantes de Pneus, Aros e Rodas. 2019. Available online: https://alapa.org.br/manuais-e-publicacoes/ (accessed on 20 December 2021).

- Santos, H.G.; Jacomine, P.K.T.; Dos Anjos, L.H.C.; De Oliveira, V.A.; Lumbreras, J.F.; Coelho, M.R.; Cunha, T.J.F. Sistema Brasileiro de Classificação de Solos, 5th ed.; Embrapa: Brasília, DF, Brasil, 2018; Available online: http://www.infoteca.cnptia.embrapa.br/infoteca/handle/doc/1094003 (accessed on 26 March 2024).

- USDA. Soil Survey Staff, Keys to Soil Taxonomy, 12th ed.; United States Department of Agriculture: Washington, DC, USA, 2014. [Google Scholar]

- Araújo, F.S.; Souza, Z.M.; Souza, G.S.; Silva, R.B.; Esteban, D.A.A.; Tavares, R.L.M. Load-Bearing Capacity of an Oxisol under Burned and Mechanized Harvest Sugarcane Crops. Sustainability 2023, 15, 15185. [Google Scholar] [CrossRef]

- Teixeira, P.C.; Donagemma, G.K.; Fontana, A.; Teixeira, W.G. Manual de Métodos de Análise de Solo, 3rd ed.; Empresa Brasileira de Pesquisa Agropecuária: Brasília, DF, Brasil, 2017; 564p. [Google Scholar]

- Cutini, M.; Brambilla, M.; Pochi, D.; Fanigliulo, R.; Bisaglia, C. A simplified approach to the evaluation of the influences of key factors on agricultural tractor fuel consumption during heavy drawbar tasks under field conditions. Agronomy 2022, 12, 1017. [Google Scholar] [CrossRef]

- Mamontov, A.; Pelypenko, Y.; Rebrova, O.; Shevtsov, V. Determination of Rational Operating Modes of Operation of Tractor Agricultural Tires. Technol. Transf. Fundam. Princ. Innov. Tech. Solut. 2020, 1, 36–38. [Google Scholar] [CrossRef]

- Mamkagh, A.M. Effect of soil moisture, tillage speed, depth, ballast weight and, used implement on wheel slippage of the tractor: A review. Asian J. Adv. Agric. Res. 2019, 1, 1–7. [Google Scholar] [CrossRef]

- Boussinesq, J. Application des Potentiels à L’étude de L’équilibre et du Mouvement des Solides Élastiques; Gauthier-Villars, Imprimeur-Libraire: Paris, France, 1885. [Google Scholar]

- Soane, B.; Blackwell, P.; Dickson, J.; Painter, D. Compaction by agricultural vehicles: A review ii. compaction under tyres and other running gear. Soil Tillage Res. 1980, 1, 373–400. [Google Scholar] [CrossRef]

- Otto, R.; Silva, A.P.; Franco, H.C.J.; Oliveira, E.; Trivelin, P.C.O. High soil penetration resistance reduces sugarcane root system development. Soil Tillage Res. 2011, 117, 201–210. [Google Scholar] [CrossRef]

- Sá, M.A.C.; Santos Junior, J.D.G.; Franz, C.A.B.; Rein, T.A. Soil physical quality and sugarcane yield with the use of inter-row chiseling. Pesqui. Agropecuária Bras. 2016, 51, 1610–1622. [Google Scholar] [CrossRef]

- Alaoui, A.; Diserens, E. Mapping soil compaction—A review. Curr. Opin. Environ. Sci. Health 2018, 5, 60–66. [Google Scholar] [CrossRef]

- Martins, M.B.; Marques Filho, A.C.; Seron, C.D.C.; Guimarães Júnnyor, W.D.S.; Vendruscolo, E.P.; Bortolheiro, F.P.D.A.P.; Santana, L.S. Controlled Traffic Farm: Fuel Demand and Carbon Emissions in Soybean Sowing. AgriEngineering 2024, 6, 1794–1806. [Google Scholar] [CrossRef]

- Marques Filho, A.C.; Medeiros, S.D.S.; Martins, M.B.; Lanças, K.P. Can Road Tires be Applied in Agriculture? Paper No. 2023-36-0086; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2024. [Google Scholar] [CrossRef]

| Rigid Surface Test Tires | CA Contact Area (m2) | Length (m) | Width (m) | PA Punctual Area (m2) | % PA Punctual Area | % of Factory Width |

|---|---|---|---|---|---|---|

| p1 | 0.069 b | 0.256 c | 0.347 b | 0.039 a | 56.5 | 78.5 |

| p2 | 0.117 a | 0.430 a | 0.543 a | 0.040 a | 34.2 | 90.0 |

| p3 | 0.070 b | 0.324 b | 0.395 b | 0.038 b | 54.2 | 65.8 |

| Contact Area (m2) | Length (m) | Width (m) | Depth (m) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Straw (Mg ha−1) | 0 | 15 | 30 | 0 | 15 | 30 | 0 | 15 | 30 | 0 | 15 | 30 |

| p1 | 0.43 Bb | 0.47 Ba | 0.54 Ab | 0.66 Ba | 0.67 ABa | 0.70 Aa | 0.48 Bc | 0.55 ABc | 0.59 Ac | 0.12 Aa | 0.11 Aa | 0.10 Aa |

| p2 | 0.50 Ba | 0.53 Ba | 0.69 Aa | 0.66 Ba | 0.68 ABa | 0.72 Aa | 0.67 Ba | 0.74 Aa | 0.76 Aa | 0.09 Aa | 0.08 Ab | 0.07 Aa |

| p3 | 0.45 Bb | 0.48 ABa | 0.54 Ab | 0.68 Aa | 0.72 Aa | 0.73 Aa | 0.59 Ab | 0.64 Ab | 0.66 Ab | 0.12 Aa | 0.10 ABa | 0.09 Ba |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagaoka, A.K.; Marques Filho, A.C.; Lanças, K.P. Agricultural Tire Test: Straw Cover Effect on Reducing Soil Compaction by Cargo Vehicles. AgriEngineering 2024, 6, 3016-3029. https://doi.org/10.3390/agriengineering6030173

Nagaoka AK, Marques Filho AC, Lanças KP. Agricultural Tire Test: Straw Cover Effect on Reducing Soil Compaction by Cargo Vehicles. AgriEngineering. 2024; 6(3):3016-3029. https://doi.org/10.3390/agriengineering6030173

Chicago/Turabian StyleNagaoka, Alberto Kazushi, Aldir Carpes Marques Filho, and Kléber Pereira Lanças. 2024. "Agricultural Tire Test: Straw Cover Effect on Reducing Soil Compaction by Cargo Vehicles" AgriEngineering 6, no. 3: 3016-3029. https://doi.org/10.3390/agriengineering6030173

APA StyleNagaoka, A. K., Marques Filho, A. C., & Lanças, K. P. (2024). Agricultural Tire Test: Straw Cover Effect on Reducing Soil Compaction by Cargo Vehicles. AgriEngineering, 6(3), 3016-3029. https://doi.org/10.3390/agriengineering6030173