Novel Specifications Regarding Biogas Production from Agriengineering Activities in Romania

Abstract

:1. Introduction

2. Materials and Methods

- At large farms, the samples were taken from the most populated animal sheds;

- The mixture with the samples thus taken, specific to the farms, was performed mechanically;

- At the end, the quantity corresponding to the purpose of the analysis was retained, the quantity being subsequently subjected to various analyses (drying at 105 °C, calcination at 550 °C, etc.).

2.1. Laboratory Equipment

2.2. Results

| Sample | Input Material [g] | Inoculum [mL] |

|---|---|---|

| Sample A | 190 | 210 |

| Sample B | 24 | 376 |

| Sample C | 35 | 365 |

| Sample D | 13 | 387 |

| Sample E | 39 | 361 |

| Sample F | 42 | 358 |

| Sample G | 12 | 388 |

| Sample H | 49 | 351 |

| Sample I | 30 | 370 |

3. Discussion

4. Conclusions

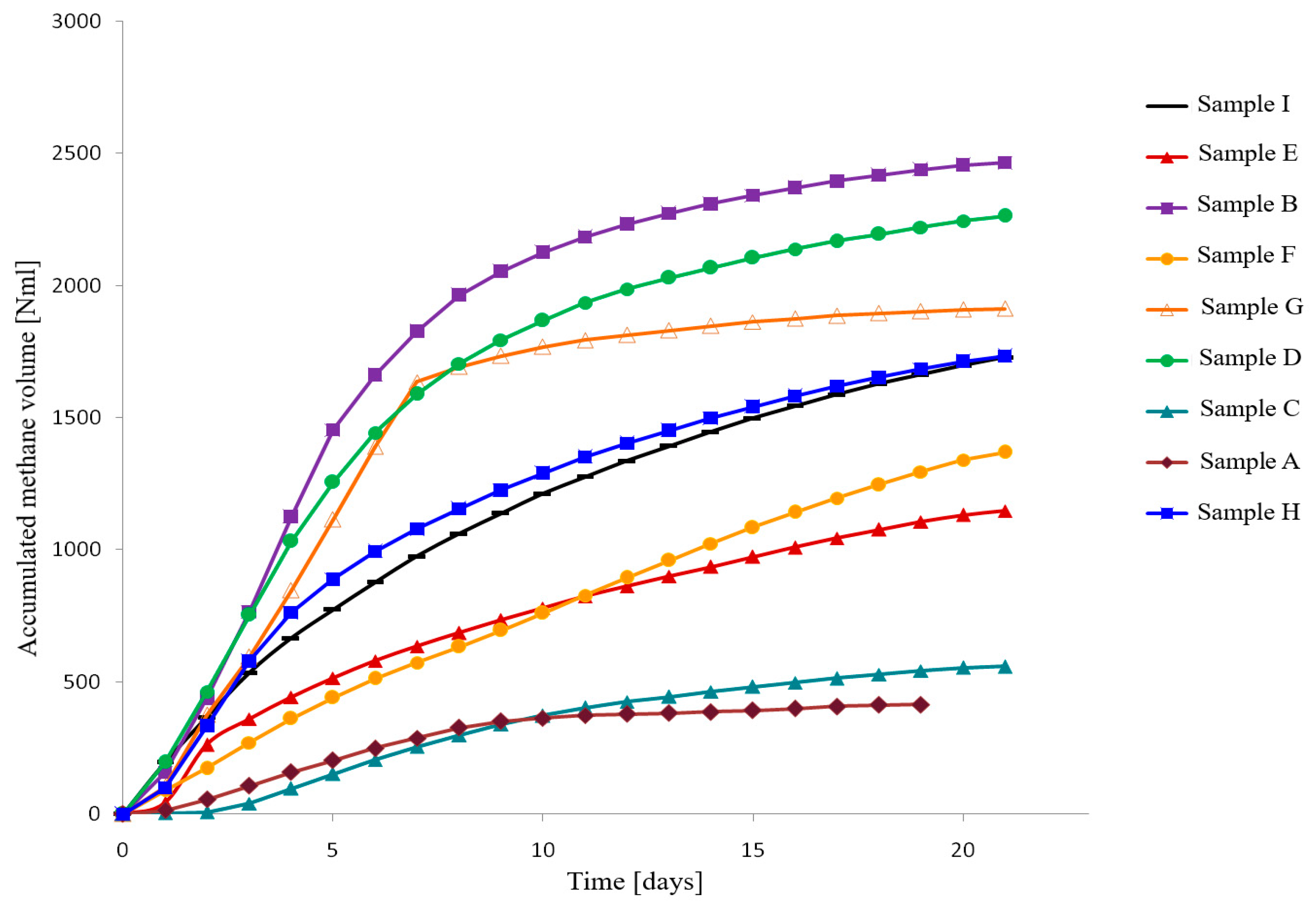

- Related to the analyzed lots, the recorded C/N ratio values ranged from 6.7 (Sample G, medium-sized chicken farm) and 6.8 (Sample A, medium-sized pig farm) up to 30.2 (Sample F, medium-sized cow farm). Some literature indicates 20–30 as the best ratio. Other authors found that this interval is not strict, with good results also being attested for ratios that exceed the values in the mentioned interval. The present results attest to this latter idea. The diverse values obtained can be related to the feed recipes, stating that in the case of Sample B (small pig farm), the feed is also administered based on biodegradable household waste. The greatest methane production was the one achieved by Sample B (small family pig farm), despite the C/N ratio equaling 13.8. For pig manure coming from a small farm (Sample D), the average ratio determined was 11.2. It can thus be stated that detecting the C/N ratio is important, but not necessarily decisive in the amount of biogas generated;

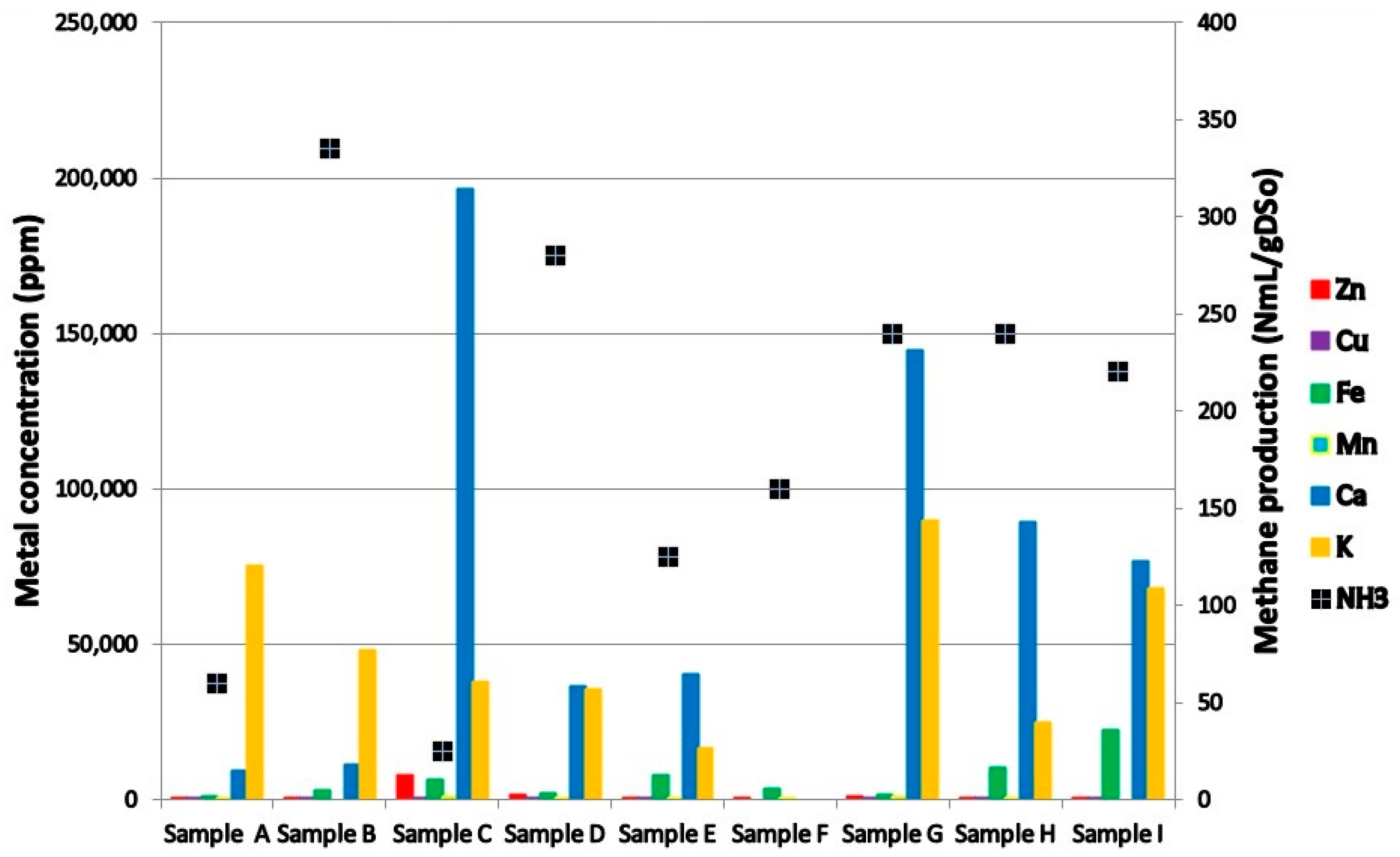

- Related to the content of heavy metals in the manure batches, the values were comparable to other bibliographic sources. In the case of potassium (K), the range covered by the determined values was narrower, varying between 1.64% (Sample E) and 8.96% (Sample G). For Sample D, it was found that the values of heavy metals were included in the variation range recorded for the other samples without approaching the extreme values recorded. Ca and K are the main metals depicted, a fact which does not raise great concern as these elements are not the most dangerous ones. An explanation for the dispersion of the values is related to the feed recipes used. Finally, we explained that the presence of heavy metals is important to know, not only for the potential to generate biogas but also for further use as fertilizer on agricultural fields, as the heavy metal content is limited in the soil.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Offie, I.; Piadeh, F.; Behzadian, K.; Campos, L.C.; Yaman, R. Development of an artificial intelligence-based framework for biogas generation from a micro anaerobic digestion plant. Waste Manag. 2023, 158, 66–75. [Google Scholar] [CrossRef]

- Deng, L.; Zheng, D.; Zhang, J.; Yang, H.; Wang, L.; Wang, W.; He, T.; Zhang, Y. Treatment and utilization of swine wastewater—A review on technologies in full-scale application. Sci. Total Environ. 2023, 880, 163223. [Google Scholar] [CrossRef] [PubMed]

- Mignogna, D.; Ceci, P.; Cafaro, C.; Corazzi, G.; Avino, P. Production of biogas and biomethane as renewable energy sources: A review. Appl. Sci. 2023, 13, 10219. [Google Scholar] [CrossRef]

- Sobczak, A.; Chomac-Pierzecka, E.; Kokiel, A.; Rozycka, M.; Stasiak, J.; Sobon, D. Economic conditions of using biodegradable waste for biogas production, Using the example of Poland and Germany. Energies 2022, 15, 5239. [Google Scholar] [CrossRef]

- Mohite, J.A.; Manvi, S.S.; Pardhi, K.; Khatri, K.; Bahulikar, R.A.; Rahalkar, M.C. Thermotolerant methanotrophs belonging to the Methylocaldum genus dominate the methanotroph communities in biogas slurry and cattle dung: A culture-based study from India. Environ. Res. 2023, 228, 115870. [Google Scholar] [CrossRef] [PubMed]

- Sumardiono, S.; Matin, H.H.A.; Sulistianingtias, I.; Nugroho, T.Y.; Budiyono, B. Effect of physical and biological pretreatment on sugarcane bagasse waste-based biogas production. Mater. Today Proc. 2023, 87, 41–44. [Google Scholar] [CrossRef]

- Liu, T.; Ferrari, G.; Pezzuolo, A.; Alengebawy, A.; Jin, K.; Yang, G.; Li, Q.; Ai, P. Evaluation and analysis of biogas potential from agricultural waste in Hubei Providence, China. Agric. Syst. 2023, 205, 103577. [Google Scholar] [CrossRef]

- Sakuma, S.; Endo, R.; Shibuya, T. Acidophilic nitrification of biogas digestates accelerates sustainable hydroponics by enhancing phosphorus dissolution. Bioresour. Technol. Rep. 2023, 22, 101391. [Google Scholar] [CrossRef]

- Feng, L.; Aryal, N.; Li, Y.; Horn, S.J.; Ward, A.J. Developing a biogas centralized circular bioeconomy using agricultural residues- Challenges and opportunities. Sci. Total Environ. 2023, 868, 161656. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Su, L.; Sun, X.; Liu, C.; Ji, R.; Zhen, G.; Chen, M.; Zhang, L. Thermophilic solid-state anaerobic digestion of corn straw, cattle manure, and vegetables waste: Effect of temperature, total solid content, and C/N ratio. Archaea 2020, 2020, 8841490. [Google Scholar] [CrossRef]

- Duong, C.M.; Lim, T.-T. Use of regression models for development of a simple and effective biogas decision-support tool. Sci. Rep. 2023, 13, 4933. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Yang, B.; Wang, Y.; Zheng, Z.; Wang, J.; Yue, Y.; Mu, W.; Xu, G.; Ying, J. Energy evolution of biogas production system in China from perspective of collection radius. Energy 2023, 265, 126377. [Google Scholar] [CrossRef]

- Arip, A.G. Widhorini Sustainable ways of biogas production using low-cost materials in environment. J. Phys. Conf. Ser. 2021, 1933, 012113. [Google Scholar] [CrossRef]

- Fagbeni, L.; Adamon, D.; Ekouedjen, E.K. Modeling Carbon-to-Nitrogen Ratio Influence on Biogas Production by the 4th-order Runge-Kutta Method. Energy Fuels 2019, 33, 8721–8726. [Google Scholar] [CrossRef]

- Tshemese, Z.; Deenadayalu, N.; Linganiso, L.Z.; Chetty, M. An Overview of Biogas Production from Anaerobic Digestion and the Possibility of Using Sugarcane Wastewater and Municipal Solid Waste in a South African Context. Appl. Syst Innov. 2023, 6, 13. [Google Scholar] [CrossRef]

- Shahbaz, M.; Ammar, M.; Korai, R.M.; Ahmad, N.; Ali, A.; Khalid, M.S.; Zou, D.; Li, X. Impact of C/N ratios and organic loading rates of paper, cardboard and tissue wastes in batch and CSTR anaerobic digestion with food waste on their biogas production and digester stability. SN Appl. Sci. 2020, 2, 1436. [Google Scholar] [CrossRef]

- Álvarez-Montero, X.; Mercado-Reyes, I.; Valdez-Solórzano, D.; Santos-Ordoñez, E.; Delgado-Plaza, E. Effect of temperature and the Carbon-Nitrogen (C/N) ratio on methane production through anaerobic co-digestion of cattle manure and Jatropha seed cake. In Proceedings of the 20th International Conference on Renewable Energies and Power Quality (ICREPQ’ 22), Vigo, Spain, 27–29 July 2022. [Google Scholar] [CrossRef]

- Yildirim, O.; Ozkaya, B. Prediction of biogas production of industrial scale anaerobic digestion plant by machine learning algorithms. Chemosphere 2023, 335, 138976. [Google Scholar] [CrossRef] [PubMed]

- Mortezaei, Y.; Williams, M.R.; Demirer, G.N. Effect of temperature and solids time on the removal of antibiotic resistance genes during anaerobic digestion of sludge. Bioresour. Technol. Rep. 2023, 21, 101377. [Google Scholar] [CrossRef]

- Rodriguez-Jimenez, L.M.; Perez-Vidal, A.; Torres-Lozada, P. Research trends and strategies for the improvement of anaerobic digestion of food waste in psychrophilic temperatures conditions. Heliyon 2022, 8, e11174. [Google Scholar] [CrossRef]

- Hidaka, T.; Nakamura, M.; Oritate, F.; Nishimura, F. Comparative anaerobic digestion of sewage sludge at different temperatures with and without heat pre-treatment. Chemosphere 2022, 307, 135808. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, S.; Xia, A.; Feng, D.; Huang, Y.; Zhu, X.; Zhu, X.; Liao, Q. Effects of oxytetracycline on mesophilic and thermophilic anaerobic digestion for biogas production from swine manure. Fuel 2023, 344, 128054. [Google Scholar] [CrossRef]

- Bhajani, S.S.; Pal, S.L. Review: Factors affecting biogas production. IJRASET 2022, 10, 79–88. [Google Scholar] [CrossRef]

- Ahlberg-Eliasson, K.; Westerholm, M.; Isaksoon, S.; Schnurer, A. Anerobic digestion of animal manure and influence of organic loading rate and temperature on process performance, microbiology, and methane emission from digestates. Front. Energy Res. 2021, 9, 740314. [Google Scholar] [CrossRef]

- Slim, Y.E.; Bahnasawy, A.H.; Khater, E.G.; Hamouda, R.M. Review: Biogas Productivity and Quality as Influenced by Fermentation Temperature and Agitation Process. ICBAA, Benha University. 8 April 2021. Available online: https://assjm.journals.ekb.eg/article_195611_6ec4ea3a0caee058f55cd05f2af4130c.pdf (accessed on 10 February 2024).

- Uddin, M.M.; Wright, M.M. Anaerobic digestion fundamentals, challenges, and technological advances. Phys. Sci. Rev. 2023, 8, 2819–2837. [Google Scholar] [CrossRef]

- Ceron-Vivas, A.; Caceres-Caceres, K.T. Influence of pH and the C/N ratio on the biogas production of wastewater. Rev. Fac. Ing. Univ. Antioq. 2019, 92, 88–95. [Google Scholar] [CrossRef]

- Sari, L.N.; Prayitno, H.; Farhan, M.; Syaichurrozi, I. Review: Biogas production from rice straw. WCEJ 2022, 6, 44–49. Available online: https://www.academia.edu/96394440/Review_Biogas_Production_from_Rice_Straw (accessed on 19 July 2024). [CrossRef]

- Laiq Ur Rehman, M.; Iqbal, A.; Chang, C.; Li, W.; Ju, M. Anaerobic digestion. Water Environ. Res. 2019, 91, 1253–1271. [Google Scholar] [CrossRef]

- Pan, S.Y.; Tsai, C.Y.; Liu, C.W.; Wang, S.W.; Kim, H.; Fan, C. Anaerobic co-digestion of agricultural wastes toward circular bioeconomy. iSciene 2021, 24, 102704. [Google Scholar] [CrossRef] [PubMed]

- Messineo, A.; Kabeyi, M.J.B.; Olanrewaju, O.A. Biogas production and applications in the sustainable energy transition. J. Energy 2022, 2022, 8750221. [Google Scholar] [CrossRef]

- Banerjee, S.; Prasad, N.; Selvaraju, S. Reactor design for biogas production—A short review. JEPT 2022, 4, 1–22. [Google Scholar] [CrossRef]

- Tanvir, R.U.; Ahmed, M.; Lim, T.T.; Li, Y.; Hu, Z.; Li, Y.; Zhou, Y. Chapter One-Arrested methanogenesis: Principles, practices, and perspectives. Adv. Bioenergy 2022, 7, 1–66. [Google Scholar] [CrossRef]

- Bumharter, C.; Bolonio, D.; Amez, I.; Garcia Marinez, M.J.; Ortega, M.F. New opportunities for the European biogas industry: A review on current installation development, production potentials and yield improvements for manure and agricultural waste mixtures. J. Clean. Prod. 2023, 388, 135867. [Google Scholar] [CrossRef]

- Wan, J.; Wang, X.; Yang, T.; Wei, Z.; Banerjee, S.; Friman, V.-P.; Mei, X.; Xu, Y.; Shen, Q. Livestock manure type affects microbial community composition and assembly during composting. Front. Microbial. 2021, 12, 621126. [Google Scholar] [CrossRef] [PubMed]

- Melis, E.; Asquers, C.; Carboni, G.; Scano, E.A.; Garcia-Tejero, I.V.; Duran-Zuazo, V.H. Chapter 4- Role of Cannabis sativa L. in energy production: Residues as a potential lignocellulosic biomass in anaerobic digestion plants. In Current Applications, Approaches, and Potential Perspectives for Hemp; Garcia-Tejero, I.F., Duran-Zuazo, V.H., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 111–199. [Google Scholar] [CrossRef]

- Ngan, N.V.C.; Chan, F.M.S.; Nam, T.S.; Van Thao, H.; Maguyon-Detras, M.C.; Hung, D.V.; Cuong, D.M.; Van Hung, N.; Gummert, M.; Hung, N.V.; et al. Anaerobic digestion of rice straw for biogas production. In Sustainable Rice Straw Management; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 65–92. [Google Scholar] [CrossRef]

- El-Mrini, S.; Aboutayeb, R.; Zouhri, A. Effect of initial C/N ratio and turning frequency on quality of final compost of turkey manure and olive pomace. J. Eng. Appl. Sci. 2022, 69, 37. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Chapter Four-Biological treatment of organic materials for energy and nutrients production- Anaerobic digestion and composting. Adv. Bioenergy 2019, 4, 121–181. [Google Scholar] [CrossRef]

- Muthudineshkumar, R.; Anand, R. 6-Anaerobic digestion of various feedstocks for second-generation biofuel production. In Woodhead Publishing Series in Energy; Woodhead Publishing: Sutton, UK, 2019; pp. 157–185. [Google Scholar] [CrossRef]

- Park, Y.; Khim, J.D. Application of a full-scale horizontalanaerobic digester for the co-digestion of pig manure, food waste, excretion, and thickened sewage sludge. Processes 2023, 11, 1294. [Google Scholar] [CrossRef]

- Dennis, M.S.; David, E.B. Carbon/Nitrogen ratio and anaerobic digestion of swine waste. Trans. ASAE 1978, 21, 537–541. [Google Scholar] [CrossRef]

- Cao, Q.; Zhang, W.; Zheng, Y.; Lian, T.; Dong, H. Production of short-chain carboxylic acids by co-digestion of swine manure and corn silage: Effect of carbon-nitrogen ratio. Trans. ASABE 2020, 63, 445–454. [Google Scholar] [CrossRef]

- Magdalena, J.A.; Greses, S.; Gonzalez-Fernandez, C. Impact of organic loading rate in volatile fatty acids production and population dynamics using microalgae biomass as substrate. Sci. Rep. 2019, 9, 18374. [Google Scholar] [CrossRef] [PubMed]

- Tassakka, M.I.S.; Islami, B.B.; Saragih, F.N.A.; Priadi, C.R. Optimum organic loading rates (ORL) for food waste anaerobic digestion: Study case Universitas Indonesia. Int. J. Technol. 2019, 10, 1105–1111. [Google Scholar] [CrossRef]

- Babaei, A.; Shayegan, J. Effect of organic loading rates (ORL) on production of methane from anaerobic digestion of vegetables waste. In Proceedings of the World Renewable Energy Congress, Linkoping, Sweden, 8–13 May 2011. [Google Scholar] [CrossRef]

- Ahmad, A.; Grufran, R.; Nasir, Q.; Shahitha, F.; Al-Sibani, M.; Al-Rahbi, A.S. Enhanced anaerobic co-digestion of food waste and solid poultry slaughterhouse waste using fixed bed digester: Performance and energy recovery. Environ. Technol. Innov. 2023, 30, 103099. [Google Scholar] [CrossRef]

- Shafizadeh, A.; Danesh, P. Chapter 15-Biomass and Energy Production: Thermochemical methods. In Biomass, Biorefineries and Bioeconomy; Samer, M., Ed.; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar] [CrossRef]

- Dong, R.; Qiao, W.; Guo, J.; Sun, H.; Stefanakis, A.; Nikolaou, I. Chapter 10- Manure treatment and recycling technologies. In Circular Economy and Sustainability; Elsevier: Amsterdam, The Netherlands, 2022; Volume 2, pp. 161–180. [Google Scholar] [CrossRef]

- Nelabhotla, A.B.T.; Khoshbakhtian, M.; Chopra, N.; Dinamarca, C. Effect of hydraulic retention time on MES operation for biomethane production. Front. Energy Res. 2020, 8, 87. [Google Scholar] [CrossRef]

- El Mashad, H.; Zhang, R. Biogas Energy from Organic Wastes. Introduction to Biosystems Engineering. 2020. Available online: https://vtechworks.lib.vt.edu/server/api/core/bitstreams/b676aa8e-2542-46e9-a4e4-bfab0cb6289b/content (accessed on 9 May 2024).

- Abomohra, A.E.F.; El-Hefnawy, M.E.; Wang, Q.; Huang, J.; Li, L.; Tang, J.; Mohammed, S. Sequential bioethanol and biogas production coupled with heavy metal removal using dry seaweeds: Towards enhanced economic feasibility. J. Clean. Prod. 2021, 316, 128341. [Google Scholar] [CrossRef]

- Montusiewicz, A.; Szaja, A.; Musielewicz, I.; Cydzik-Kwiatkowska, A.; Lebiocka, M. Effect of bioaugmentation on digestate metal concentrations in anaerobic digestion of sewage sludge. PLoS ONE 2020, 15, e0235508. [Google Scholar] [CrossRef] [PubMed]

- Czatzkowska, M.; Harnisz, M.; Korzeniewska, I. Inhibitors of the methane fermentation process with particular emphasis on the microbiological aspect: A review. Energy Sci. Eng. 2020, 8, 1880–1897. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Y.; Yang, M.; Li, W. Content of heavy metals in animal feeds and manures from farms of different scales in Northeast China. Int. J. Environ. Res. Public Health 2021, 9, 2658–2668. [Google Scholar] [CrossRef]

- Hejna, M.; Onelli, E.; Moscatelli, A.; Bellotto, M.; Cristiani, C.; Stroppa, N.; Rosii, L. Heavy-Metal phytoremediation from livestock wastewater and exploitation of exhausted biomass. Int. J. Environ. Res. Public Health 2021, 18, 2239. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Tong, Q.; Li, Y.; Wang, N.; Liu, B.; Zhang, X. Biogas production and metal passivation analysis during anaerobic digestion of pig manure: Effects of a magnetic Fe3O4/FA composite supplement. RSC Adv. 2019, 9, 4488–4498. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Zou, D.; Wu, Q.; Wang, H.; Li, S.; Liu, F.; Xiao, Z. Review on fate and bioavailability of heavy metals during anaerobic digestion and composting of animal manure. Waste Manag. 2022, 150, 75–89. [Google Scholar] [CrossRef]

- Golub, N.; Shynkarchuk, A.; Kozlovets, O.; Kozlovets, M. Effects of heavy metal ions (Fe3+, Cu2+, Zn2+ and Cr3+) on the Productivity of Biogas and Biomethane Production. Adv. Biosci. Biotechnol. 2022, 13, 1–14. [Google Scholar] [CrossRef]

- Guo, Q.; Majeed, S.; Xu, R.; Zhang, K.; Kakade, A.; Khan, A.; Hafeez, F.Y.; Mao, C.; Liu, P.; Li, X. Heavy metals interact with the microbial community and affect biogas production in anaerobic digestion: A review. J. Environ. Manag. 2019, 240, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Al bkoor Alrawashdeh, K. Anaerobic co-digestion efficiency under the stress exerted by different heavy metals concentration: An energy nexus analysis. Water-Energy Nexus 2022, 7, 100099. [Google Scholar] [CrossRef]

- Mudhoo, A.; Kumar, S. Effects of heavy metals as stress factors on anaerobic digestion processes and biogas production from biomass. Int. J. Environ. Sci. Technol. 2013, 10, 1383–1398. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, L.; Carswell, A.; Misselbrook, T.; Shen, J.; Han, J. Fate and transfer of heavy metals following repeated biogas slurry application in a rice-wheat crop rotation. J. Environ. Manag. 2020, 270, 110938. [Google Scholar] [CrossRef]

- Abdel-Shaft, H.I.; Mansour, M.S. Biogas production as affected by heavy metals in the anaerobic digestion of sludge. Egypt. J. Pet. 2014, 23, 409–417. [Google Scholar] [CrossRef]

- Kadam, R.; Khanthong, K.; Jang, H.; Lee, J.; Park, J. Occurrence, fate, and implications of heavy metals during anaerobic digestion: A review. Energies 2022, 15, 8618. [Google Scholar] [CrossRef]

- Nguyen, Q.-M.; Bui, D.-C.; Phuong, T.; Doan, V.-H.; Nguyen, T.-N.; Nguyen, M.-V.; Tran, T.-H.; Trung, D. Investigation of heavy metal effects on the anaerobic co-digestion process of waste activated sludge and septic tank sludge. Int. J. Chem. Eng. 2019, 2019, 5138060. [Google Scholar] [CrossRef]

- Rajaganapathy, V.; Xavier, F.; Sreekumar, D.; Mandal, P.K. Heavy metal contamination in soil, water and fodder and their presence in livestock and products: A review. J. Environ. Sci. Technol. 2011, 4, 234–249. [Google Scholar] [CrossRef]

- Bartkowaiak, A. Influence of heavy metals on quality of eaw materials, animal products, and human and animal health status. In Environmental Impact and Remediation of Heavy Metals; InterchOpen: Rijeka, Croatia, 2022; Volume 3. [Google Scholar] [CrossRef]

- Available online: https://www.leco.com/product/828-series (accessed on 28 May 2023).

- Available online: https://www.labcompare.com/Laboratory-Analytical-Instruments/176-Total-Nitrogen-Analyzer-TN-Analyzer/?search=nitrogen+analyzer+total+ (accessed on 28 May 2023).

- Carbon/Nitrogen Analyzer with Cornerstone. Instruction Manual CN 828/FP 828 P/FP 828, Version 2.9.X, Part. Number 200-793. February 2020. Available online: https://ro.scribd.com/document/459696225/828-series-Instruction-Manual-V2-9-x-February-2020-200-793-pdf (accessed on 23 June 2024).

- Available online: https://standards.iteh.ai/catalog/standards/iso/ (accessed on 28 November 2023).

- Available online: https://standards.iteh.ai/catalog/standards/cen/930377f4-91d8-4a42-8067-2bffe88626e0/cen-ts-15414-1-2010 (accessed on 28 November 2023).

- Available online: https://www.en-standard.eu/din/ (accessed on 28 November 2023).

- Available online: https://www.pine-environmental.com/products/niton_xl3t_xrf_soil_analyser (accessed on 28 May 2023).

- Horf, M.; Gebber, R.; Vogel, S.; Ostermann, M.; Piepel, M.-F.; Olfs, H.-W. Determination of nutrients in liquid manures and biogas digestates by portable energy-dispersive X-ray fluorescence spectrometry. Sensors 2021, 21, 3892. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.thermofisher.com/order/catalog/product/10131166 (accessed on 28 May 2023).

- Pang, B.; Wu, S.; Yu, Z.; Liu, Y.; Li, J.; Zheng, L.; Chen, H.; Li, X.; Shi, G. Rapid Exploration Using pXRF Combined with Geological Connotation Method (GCM): A Case Study of the Nuocang Cu Polymetallic District, Tibet. Minerals 2022, 12, 514. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Z.; Wang, Y. Optimizing the amount of pig manure in the vermicomposting of spent mushroom (Lentinula) substrate. PeerJ 2020, 8, e10584. [Google Scholar] [CrossRef] [PubMed]

- Mutungwazi, A.; Ijoma, G.N.; Ogola, H.J.O.; Matambo, T.S. Physico-chemical and metagenomic profile analyses of animal manures routinely used as inocula in anaerobic digestion for biogas production. Microorganisms 2022, 10, 671. [Google Scholar] [CrossRef]

- Al-mamouri, A.K.; Jassim, H. Improving of biogas production using different pretreatment of rice husk inoculated with ostrich dung. J. Eng. Res. 2021, 18, 1–11. [Google Scholar] [CrossRef]

- Goldan, E.; Nedeff, V.; Barsan, N.; Culea, M.; Panainte-Lehadus, M.; Mosnegutu, E.; Tomezei, C.; Chitimus, D.; Irimia, O. Assessment of manure compost used as soil amendment—A review. Processes 2023, 11, 1167. [Google Scholar] [CrossRef]

- Available online: https://www.carryoncomposting.com/443725801.html (accessed on 27 November 2023).

- Akhter, P.; Khan, Z.I.; Hussain, M.I.; Ahmad, K.; Farooq Awan, M.U.; Ashfaq, A.; Chaudhry, U.K.; Fahad Ullan, M.; Abideen, Z.; Almaary, K.S.; et al. Assessment of heavy metal accumulation in soil and garlic influenced by waste-derived organic amendments. Biology 2022, 11, 850. [Google Scholar] [CrossRef] [PubMed]

- Vukobratovic, M.; Vukobratovic, Z.; Loncaric, Z.; Kerovac, D. Heavy metals in animal manure and effects of composting on it. Acta Hortic. 2014, 1034, 591–597. [Google Scholar] [CrossRef]

- Shah, G.M.; Farooq, U.; Shabbir, Z.; Guo, J.; Dong, R.; Bakhat, H.F.; Wakeel, M.; Siddique, A.; Shahid, N. Impact of Cadmium contamination on fertilizer value and associated health risks in different soil types following anaerobic digestate application. Toxics 2023, 11, 1008. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A01986L0278-20220101 (accessed on 28 February 2024).

- Available online: https://lege5.ro/Gratuit/gu2tkmjz/norma-tehnica-privind-protectia-mediului-si-in-special-a-solurilor-cand-se-utilizeaza-namoluri-de-epurare-in-agricultura-din-14012004?pid=24686366#p-24686366 (accessed on 29 February 2024).

- Available online: https://bpcinstruments.com/wp-content/uploads/2022/02/2022_Gas-Endeavour-Manual.pdf (accessed on 24 November 2023).

| Factors Influencing Anaerobic Digestion | Description | References |

|---|---|---|

| Temperature | It influences microbial growth and the degradation of organic matter. Low temperature reduces biogas production. Variable temperature affects biogas production. Higher temperature inhibits ammonia, and to avoid this, the C/N ratio must be higher. Recommended: (i) it must not be higher than 1 °C/day (ii) maintained at temperatures lower than 0.6 °C/day. | [19,20,21,22,23,24,25] |

| pH-ul | The pH indicates the concentration of hydrogen ions. It contributes to the activity of microorganisms. The range of 5.5 and 8.5 is optimal. Recommended: to be higher in the second stage. Adding an alkaline substance and ORL control can maintain the pH at the desired value. | [26,27,28,29,30,31] |

| C/N ratio | The C/N ratio contributes to the efficiency of anaerobic digestion (microbial growth, process stability). It influences the production of biogas& the quality of the compost. A high C/N ratio indicates a low nitrogen content. A low ratio leads to the accumulation of ammonia (leads to inhibition of the process). Recommended C/N ratio is 20–30. Lower ratios of 10–20 have led to good results. A ratio of 20 inhibits the process. A ratio greater than 30 decreases the biogas yield. The optimal ratio is influenced by the chemical composition and biodegradability of the substrate. Good results were obtained with a C/N ratio of 20 or lower, 12.7. In other studies, large amounts were obtained in the range of 15.5/1 to 19/1. A 16/1 ratio ensures process stability. | [23,26,27,29,32,33,34,35,36,37,38,39,40,41,42,43] |

| Organic loading rate (ORL) | The organic loading rate indicates the amount of organic matter that must be introduced daily into the digester (can positively or negatively influence the process of anaerobic digestion). The high loading rate of the digester leads to the accumulation of (VFA) and low pH, and the low rate affects the microorganisms through the lack of nutrients. In the organic material there are volatile solids (these can be digested) and fixed solids. Knowing ORL offers the possibility to monitor the methane yield. | [44,45,46,47,48] |

| Hydraulic retention time (HRT) | HRT is the average time that the soluble compound remains inside the digester. For animal manure longer retention time (20–30 days), food waste has a shorter retention time (15 days). | [49,50,51] |

| Heavy metal (HM)concentration | HM induces toxicity and is non-biodegradable in nature. Effect: inhibitory effect on methanogens. HM end up in animal waste through animal feed. HM has a higher density than water, and HM scattered on the field affects the soil and water and can lead to the burning of plant roots. The HM amount in organic matter should not be ignored, It inhibits the anaerobic digestion process (affects methane production). HM is not destroyed by anaerobic digestion. HM concentrating must be known before spreading manure/digestate on the ground (fields). | [52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68] |

| Sample Designation | Total Carbon (g) | Total Nitrogen (g) | C/N |

|---|---|---|---|

| Sample A | 23.4 | 3.4 | 6.8 |

| Sample B | 47.1 | 3.4 | 13.8 |

| Sample C | 40.1 | 2.4 | 16.7 |

| Sample D | 45 | 4 | 11.2 |

| Sample E | 39.6 | 2.4 | 16.5 |

| Sample F | 45.3 | 1.5 | 30.2 |

| Sample G | 33 | 4.9 | 6.7 |

| Sample H | 27.6 | 1.8 | 15.3 |

| Sample I | 44 | 2 | 22 |

| Sample | Total Carbon | Total Hydrogen | Organic Hydrogen | Total Nitrogen | Unit |

|---|---|---|---|---|---|

| Sample A | 0.8 | 11 | 0.1 | 0.1 | % by mass |

| Sample B | 15.1 | 9.6 | 2 | 1.1 | % by mass |

| Sample C | 11.3 | 9.6 | 1.6 | 0.7 | % by mass |

| Sample D | 23 | 8.7 | 3.2 | 2 | % by mass |

| Sample E | 5.4 | 10.4 | 0.7 | 0.3 | % by mass |

| Sample F | 6.0 | 10.4 | 0.9 | 0.2 | % by mass |

| Sample G | 22.6 | 6.6 | 3.1 | 3.4 | % by mass |

| Sample H | 9.3 | 8.6 | 1.2 | 0.6 | % by mass |

| Sample I | 9.6 | 10 | 1.2 | 0.4 | % by mass |

| Sample | Zinc (Zn) | Copper (Cu) | Iron (Fe) | Manganese (Mn) | Calcium (Ca) | Potassium (K) | Arsenic (As) |

|---|---|---|---|---|---|---|---|

| Sample A | 376 ± 24 ppm | 88 ± 11 ppm | 767 ± 39 ppm | 227 ± 36 ppm | 0.92 ± 37% | 7.51 ± 1.01% | <2 ppm |

| Sample B | 363 ± 12 ppm | 39 ± 7 ppm | 0.27 ± 0.01% | - | 1.12 ± 0.37% | 4.81 ± 0.59% | <1 ppm |

| Sample C | 0.79 ± 0.01% | 581 ± 20 ppm | 0.62 ± 0.01% | 0.12 ± 0.01% | 10.66 ± 0.28% | 3.80 ± 0.24% | <2 ppm |

| Sample D | 0.17 ± 0.01% | 237 ± 12 ppm | 0.19 ± 0.01% | 517 ± 37 ppm | 3.64 ± 1.08% | 3.54 ± 1.19% | <1 ppm |

| Sample E | 85 ± 6 ppm | 16 ± 7 ppm | 0.79 ± 0.01% | 220 ± 30 ppm | 4.05 ± 0.07% | 1.64 ± 0.06% | <2 ppm |

| Sample F | 106 ± 6 ppm | - | 0.32 ± 0.01% | 186 ± 26 ppm | - | - | <1 ppm |

| Sample G | 878 ± 21 ppm | 233 ± 15 ppm | 0.17 ± 0.01% | 0.12 ± 0.01% | 14.47 ± 0.36% | 8.96 ± 0.36% | <2 ppm |

| Sample H | 633 ± 17 ppm | 82 ± 11 ppm | 1.03 ± 0.01% | 522 ± 46 ppm | 8.94 ± 0.80% | 2.48 ± 0.64% | <4 ppm |

| Sample I | 249 ± 10 ppm | 50 ± 8 ppm | 2.22 ± 0.01% | - | 7.67 ± 0.10% | 6.79 ± 0.11% | <2 ppm |

| Heavy Metals (HMs) | Limit Values in Romanian Regulation (kg/ha/year) | Limit Values in European Legislation (kg/ha/year) |

|---|---|---|

| Cadmium | 0.5 | 0.15 |

| Copper | 12 | 12 |

| Nickel | 3 | 3 |

| Lead | 15 | 15 |

| Zinc | 30 | 30 |

| Mercury | 0.1 | 0.1 |

| Chromium | 12 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Halmaciu, I.-A.; Ionel, I.; Miutescu, M.-C.; Grecu, E. Novel Specifications Regarding Biogas Production from Agriengineering Activities in Romania. AgriEngineering 2024, 6, 3602-3617. https://doi.org/10.3390/agriengineering6040205

Halmaciu I-A, Ionel I, Miutescu M-C, Grecu E. Novel Specifications Regarding Biogas Production from Agriengineering Activities in Romania. AgriEngineering. 2024; 6(4):3602-3617. https://doi.org/10.3390/agriengineering6040205

Chicago/Turabian StyleHalmaciu, Ioana-Ancuta, Ioana Ionel, Maria-Cristina Miutescu, and Eugenia Grecu. 2024. "Novel Specifications Regarding Biogas Production from Agriengineering Activities in Romania" AgriEngineering 6, no. 4: 3602-3617. https://doi.org/10.3390/agriengineering6040205