Validation of Automated Driving Function Based on the Apollo Platform: A Milestone for Simulation with Vehicle-in-the-Loop Testbed

Abstract

1. Introduction

- Closed-Area Testing: In contrast to open-road testing, closed-area testing is considered a safer alternative. Generally, a GPS-equipped test vehicle drives within a test field and maps its position to the simulation environment in real-time [3]. In the context of ADAS testing, the sensory information generated by the simulated scenario is transmitted in a suitable format to the relevant ECUs or real sensors on the test vehicle to trigger the ADAS functions [4]. As a result, the real-time system must perform optimally and is subdivided into a cloud-based system and an on-board real-time system. For the former, the back-end achieves remote control of the vehicle through communication technology (e.g., LTE-V or 5G) [5,6,7]. However, due to the ease of integration, the majority of the technical implementation is carried out using the on-board real-time system. The in-vehicle system achieves synchronization between the road logic, traffic scenarios and the vehicle’s position, thereby enabling the generation of synthetic sensory data that can trigger actual sensors and elicit appropriate reactions from real vehicles [8,9,10]. Despite the wide usage of closed-area testing, it is not without its limitations. One such limitation is the need for a substantial investment in a large open area. Additionally, high dynamic testing can still pose hazards, and the vehicle under test (VUT) trajectory remains uncontrollable [11].

- Chassis Dynamometer Testing: To compensate for the huge waste of space in closed-area testing and to ensure a certain degree of high dynamic testing, a roller testbed test has been used in several studies. This is essentially a rolling road that measures the power output of the engine while the vehicle’s wheels are turning. For example, a series of groundbreaking investigations are presented in [2,12]. Subsequently, the use of simulation software to create a virtual environment was demonstrated to be a more efficient approach for validation in [13,14,15]. A co-simulation framework has been proposed to enhance the simulation scenario, enabling sensor stimulation on the testbed [16,17]. Although this type of bench was initially designed for emission tests, it has been extended to validate ADAS and can facilitate sensor stimulation due to its cost-effectiveness.

- Powertrain Testbed Testing: A roller testbed is no longer sufficient for achieving highly dynamic manoeuvres; hence, the powertrain testbed was introduced. Powertrain setups connect each wheel hub to a dyno simulating driving resistance at each wheel. To achieve comparable results with a rolling test rig, an additional rolling resistance simulation and an accurate tire simulation are required. For example, a distinctive feature of the test bench described in [18,19] is the integration of the alignment of torque simulation units, which employ wheel actuators to generate the corresponding aligning torque through a mechanical connection. The KS-R2R (road-to-rig) [20] technology differs from current approaches in that it employs complete wheel models instead of solely relying on tire models [21,22]. These models utilize torque as input and speed as an output, aligning more closely with the natural sequence of cause and effect. In the field of ADAS testing, a common approach is to use sensor stimulation as a solution, which has been widely adopted in many works [18,21,23,24,25]. In contrast to previous approaches that utilized sensor stimulation for ADAS validation, [22] provides an abstract representation of real sensors and ADAS functionality. This supports the development of ADAS functionality by demonstrating its feasibility in prototype vehicles during the functional concept phase. Overall, the powertrain testbed is not only capable of achieving highly dynamic manoeuvres but is also highly adaptable to the simulation environment, enabling the validation of ADAS functions and supporting early-stage concept development.

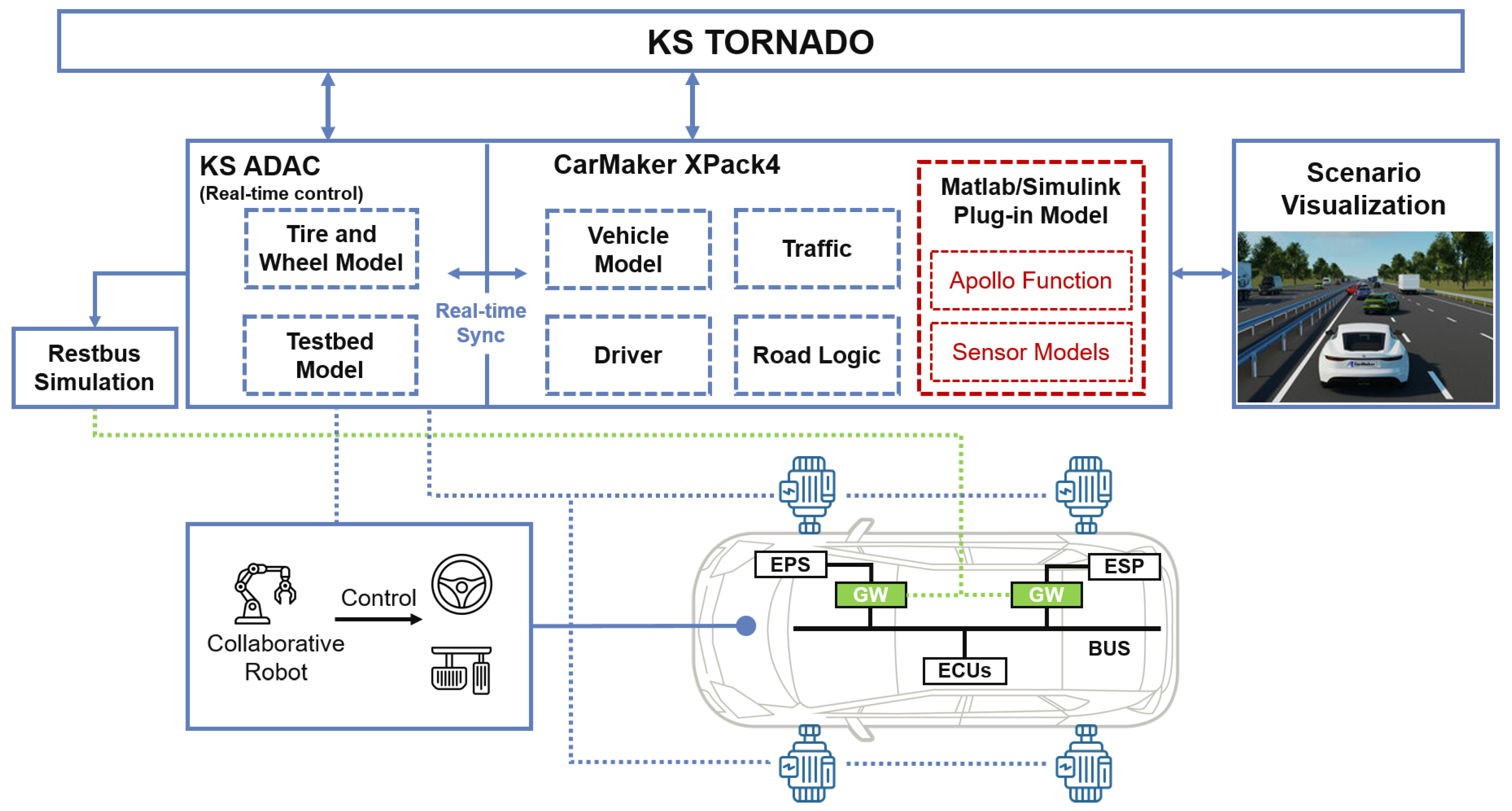

2. System Design

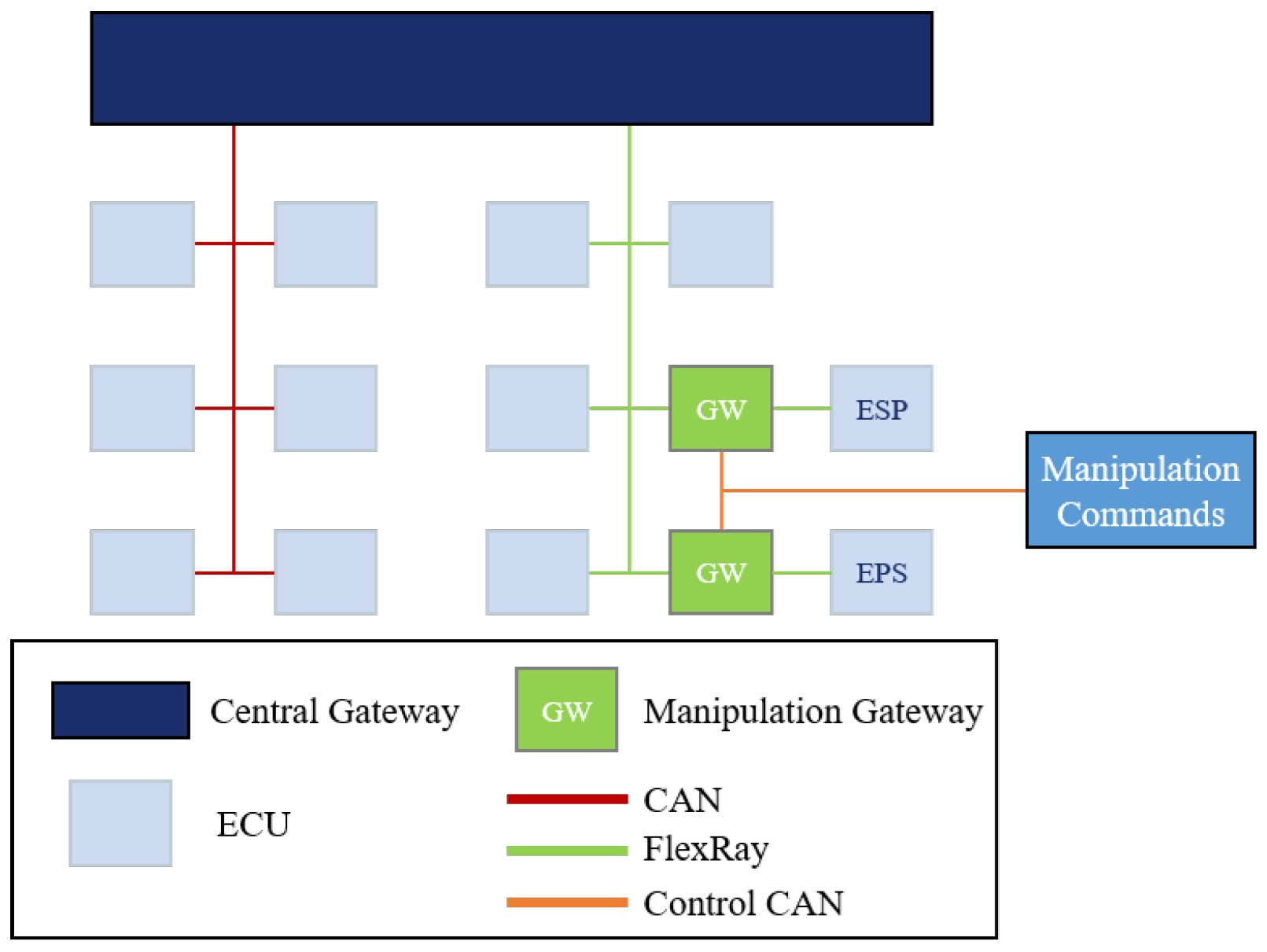

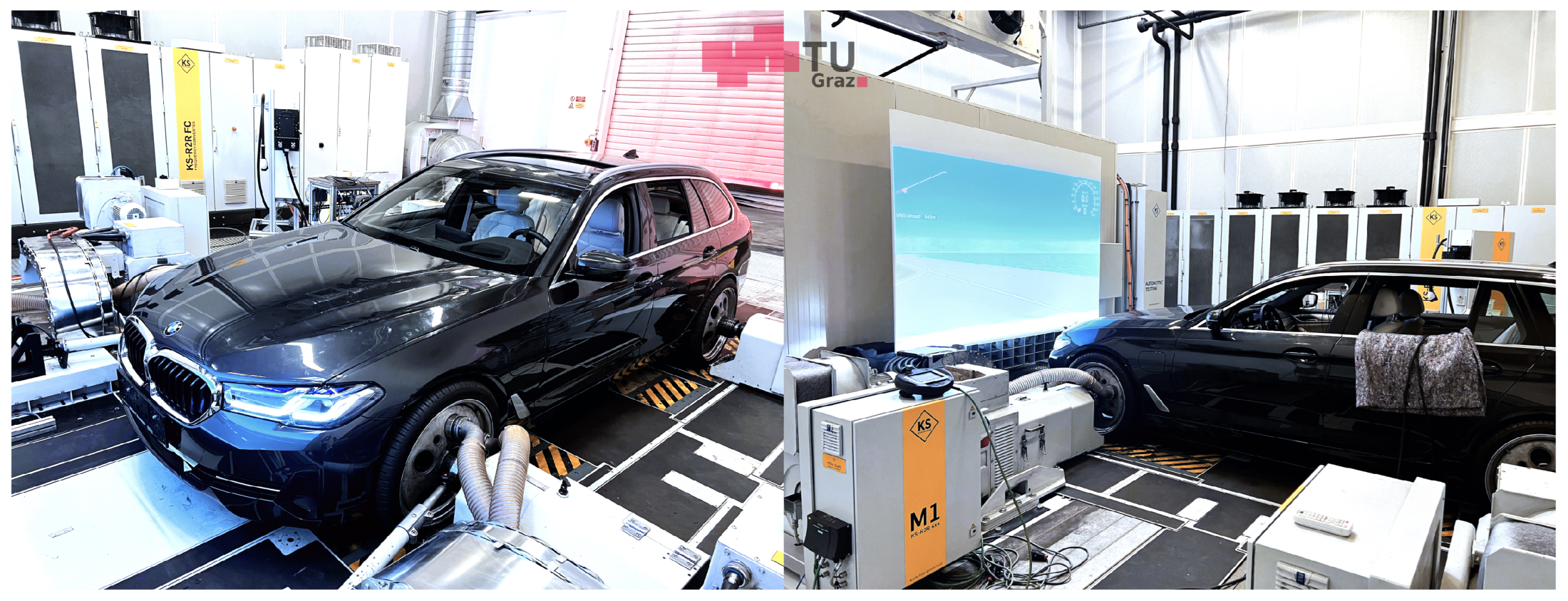

3. Vehicle-in-the-Loop Testbed

3.1. Vehicle under Test

3.2. Testbed Integration

4. Function and Environment Simulation

4.1. Perception Model

4.2. Apollo Platform Integration

4.3. Driving Scenario

5. Case Studies

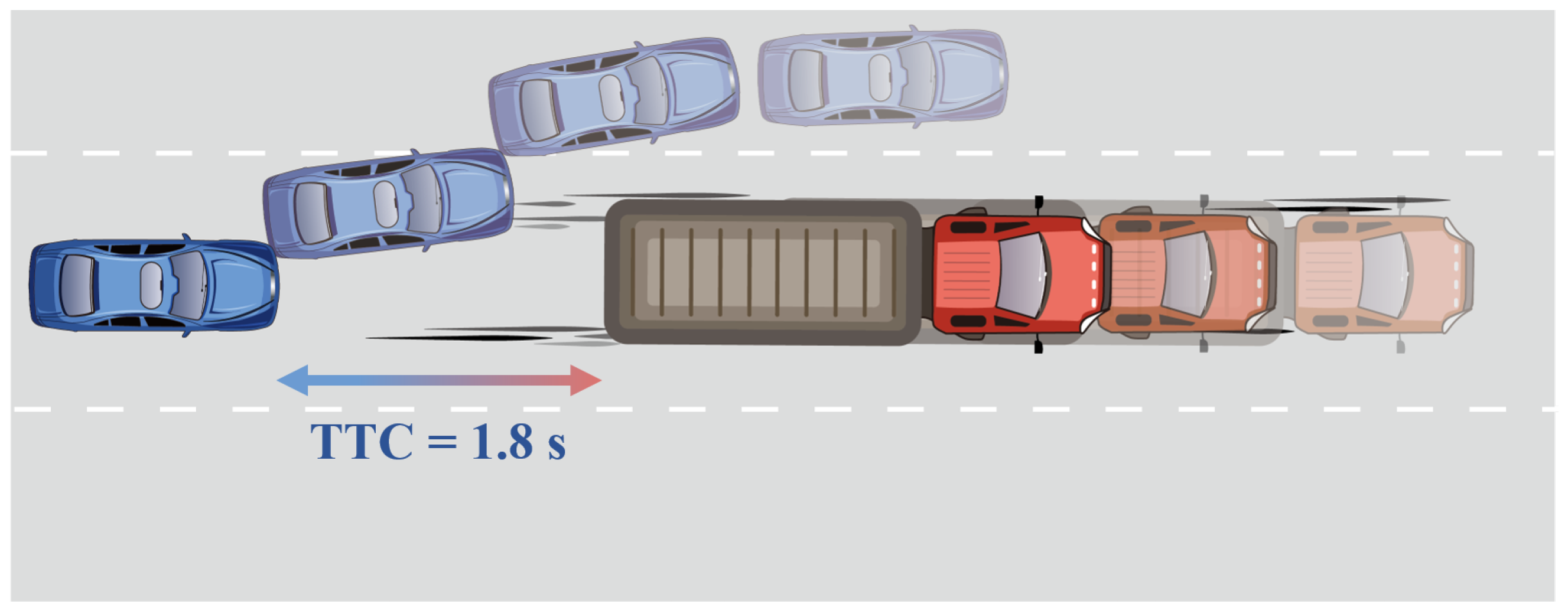

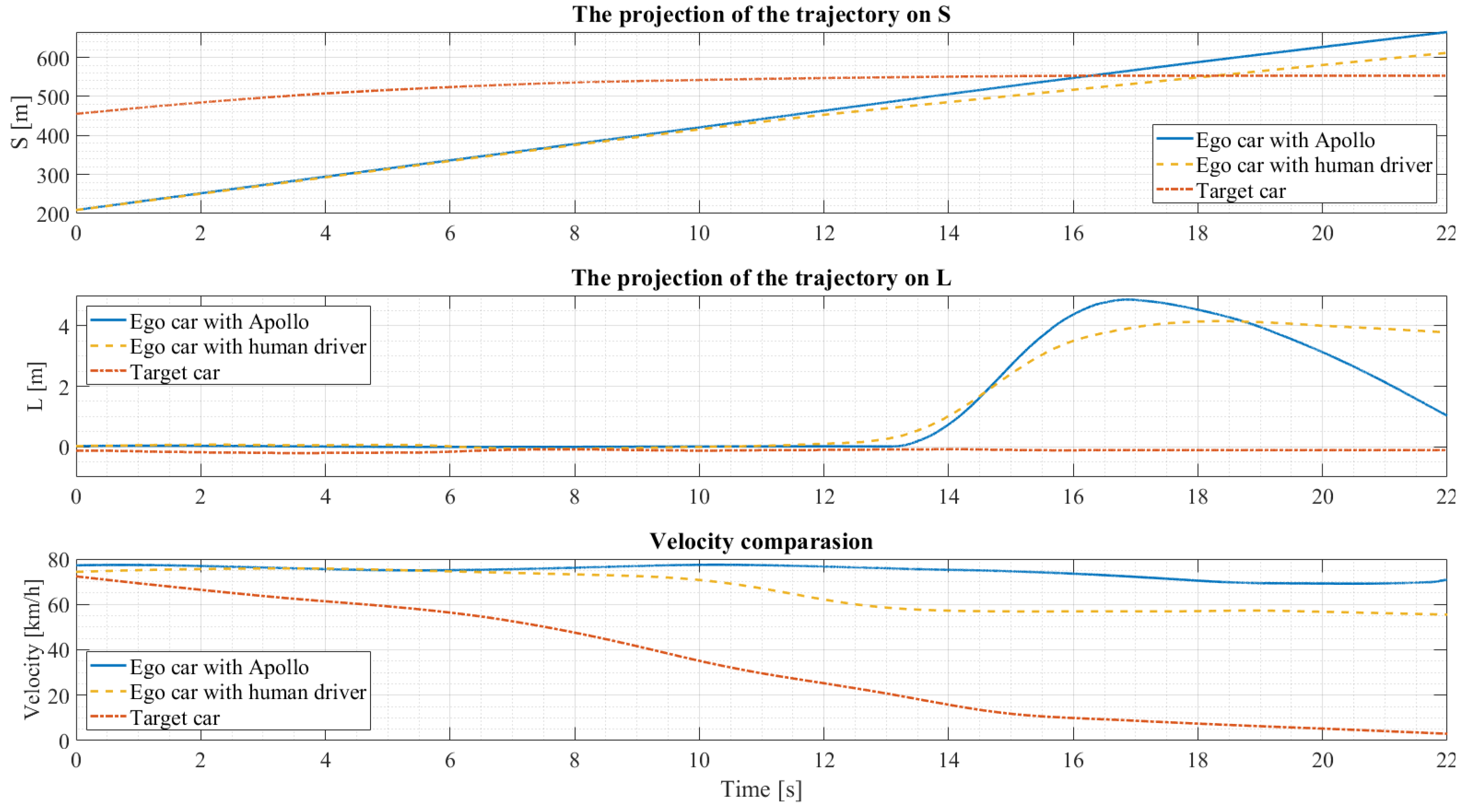

5.1. Evasive Lane Change

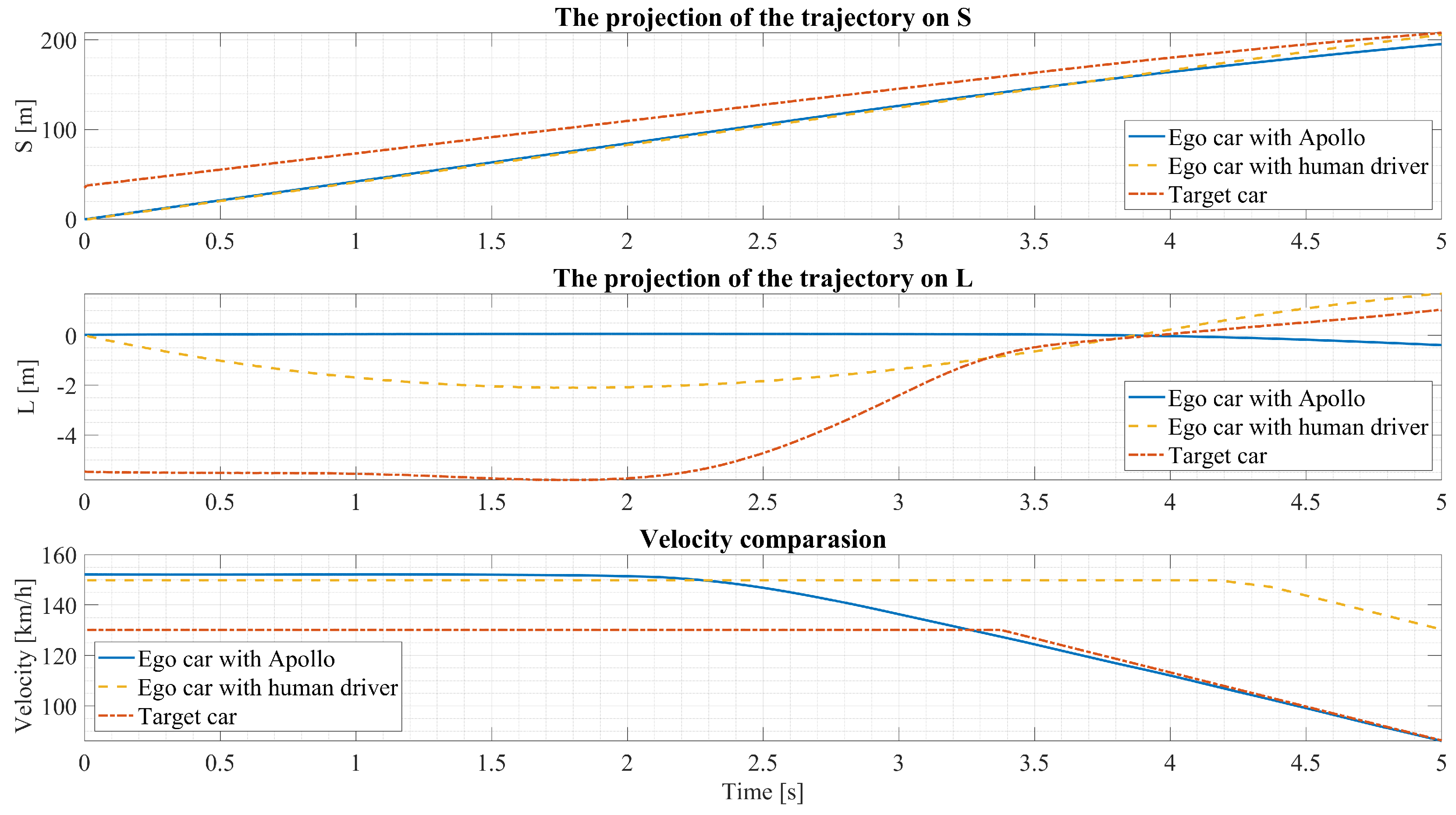

5.2. Preventing Collisions

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Magosi, Z.F.; Li, H.; Rosenberger, P.; Wan, L.; Eichberger, A. A Survey on Modelling of Automotive Radar Sensors for Virtual Test and Validation of Automated Driving. Sensors 2022, 22, 5693. [Google Scholar] [CrossRef] [PubMed]

- Verhoeff, L.; Verburg, D.; Lupker, H.; Kusters, L.J. VEHIL: A full-scale test methodology for intelligent transport systems, vehicles and subsystems. In Proceedings of the IEEE Intelligent Vehicles Symposium 2000 (Cat. No. 00TH8511), Dearborn, MI, USA, 5 October 2000; pp. 369–375. [Google Scholar]

- Bhadani, R.K.; Sprinkle, J.; Bunting, M. The cat vehicle testbed: A simulator with hardware in the loop for autonomous vehicle applications. arXiv 2018, arXiv:1804.04347. [Google Scholar] [CrossRef]

- Miquet, C. New test method for reproducible real-time tests of ADAS ECUs: “Vehicle-in-the-Loop” connects real-worldvehicles 12 with the virtual world. In 5th International Munich Chassis Symposium 2014: Chassis. Tech Plus; Springer: Wiesbaden, Germany, 2014; pp. 575–589. [Google Scholar]

- Che, X.; Li, C.; Zhang, Z. An Open Vehicle-in-the-Loop Test Method for Autonomous Vehicle; EasyChair: Manchester, UK, 2019. [Google Scholar]

- Fayazi, S.A.; Vahidi, A.; Luckow, A. A Vehicle-in-the-Loop (VIL) verification of an all-autonomous intersection control scheme. Transp. Res. Part C Emerg. Technol. 2019, 107, 193–210. [Google Scholar] [CrossRef]

- Gelbal, Ş.Y.; Tamilarasan, S.; Cantaş, M.R.; Güvenç, L.; Aksun-Güvenç, B. A connected and autonomous vehicle hardware-in-the-loop simulator for developing automated driving algorithms. In Proceedings of the 2017 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Banff, AB, Canada, 5–8 October 2017; pp. 3397–3402. [Google Scholar]

- Tettamanti, T.; Szalai, M.; Vass, S.; Tihanyi, V. Vehicle-in-the-loop test environment for autonomous driving with microscopic traffic simulation. In Proceedings of the 2018 IEEE International Conference on Vehicular Electronics and Safety (ICVES), Bogota, Colombia, 14–16 November 2022; pp. 1–6. [Google Scholar]

- Drechsler, M.F.; Sharma, V.; Reway, F.; Schütz, C.; Huber, W. Dynamic vehicle-in-the-loop: A novel method for testing automated driving functions. SAE Int. J. Connect. Autom. Veh. 2022, 5, 367–380. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, S.; Xiao, T.; Zhang, S.; Hou, Q.; Zheng, N. Mixed test environment-based vehicle-in-the-loop validation-a new testing approach for autonomous vehicles. In Proceedings of the 2020 IEEE Intelligent Vehicles Symposium (IV), Las Vegas, NV, USA, 19 October–13 November 2020; pp. 1283–1289. [Google Scholar]

- Ferguson, D.; Howard, T.M.; Likhachev, M. Motion planning in urban environments. In The DARPA Urban Challenge: Autonomous Vehicles in City Traffic; Springer: Berlin/Heidelberg, Germany, 2009; pp. 61–89. [Google Scholar]

- Verbürg, D.; van der Knaap, A.C.; Ploeg, J. Developing and testing intelligent vehicles. In Proceedings of the IEEE Intelligent Vehicle Symposium (IV’2002), Versailles, France, 18–20 June 2002; pp. 1–8. [Google Scholar]

- Gietelink, O.; Ploeg, J.; Schutter, B.; Verhaegen, M. Testing advanced driver assistance systems for fault management with the VEHIL test facility. In Proceedings of the 7th International Symposium on Advanced Vehicle Control, Arnhem, The Netherlands, 23–27 August 2004; pp. 579–584. [Google Scholar]

- Albers, A.; Düser, T. A new process for configuration and application of complex validation environments using the example of vehicle-in-the-loop at the roller test bench. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Vancouver, BC, Canada, 12–18 November 2010; Volume 44489, pp. 807–816. [Google Scholar]

- Albers, A.; Düser, T. Implementation of a vehicle-in-the-loop development and validation platform. In Proceedings of the FISITA World Automotive Congress, Budapest, Hungary, 30 May–4 June 2010; Volume 2010. [Google Scholar]

- Solmaz, S.; Holzinger, F. A novel testbench for development, calibration and functional testing of ADAS/AD functions. In Proceedings of the 2019 IEEE International Conference on Connected Vehicles and Expo (ICCVE), Graz, Austria, 4–8 November 2019; pp. 1–8. [Google Scholar]

- Qin, Y.; Tang, A.; Jia, J.; Wan, L.; Zhao, H.; Long, Y. Research on Radiated Immunity Test Methods for ADAS Functions Considering Vehicle In-the-Loop. World Electr. Veh. J. 2022, 13, 211. [Google Scholar] [CrossRef]

- Diewald, A.; Kurz, C.; Kannan, P.V.; Gießler, M.; Pauli, M.; Göttel, B.; Kayser, T.; Gauterin, F.; Zwick, T. Radar target simulation for vehicle-in-the-loop testing. Vehicles 2021, 3, 257–271. [Google Scholar] [CrossRef]

- Rautenberg, P.; Kurz, C.; Gießler, M.; Gauterin, F. Driving Robot for Reproducible Testing: A Novel Combination of Pedal and Steering Robot on a Steerable Vehicle Test Bench. Vehicles 2022, 4, 727–743. [Google Scholar] [CrossRef]

- R2R Road to Rig—KS Engineers—ksengineers.com. Available online: https://www.ksengineers.com/en/Automotive-Testing/Testing-equipment/R2R-Road-to-Rig (accessed on 19 May 2023).

- Wipfler, M.; Pressl, B.; Piecha, P. Range Prediction with the Support of an Integration Test Bench. In Proceedings of the 43rd Internationales Wiener Motorensymposium, Vienna, Austria, 27–29 April 2022. [Google Scholar]

- Li, H.; Nalic, D.; Makkapati, V.; Eichberger, A.; Fang, X.; Tettamanti, T. A real-time co-simulation framework for virtual test and validation on a high dynamic vehicle test bed. In Proceedings of the 2021 IEEE Intelligent Vehicles Symposium (IV), Nagoya, Japan, 11–17 July 2021; pp. 1132–1137. [Google Scholar]

- Siegl, S.; Ratz, S.; Düser, T.; Hettel, R. Vehicle-in-the-Loop at Testbeds for ADAS/AD Validation. ATZelectron. Worldw. 2021, 16, 62–67. [Google Scholar] [CrossRef]

- Schyr, C.; Brissard, A. Drivingcube—A novel concept for validation of powertrain and steering systems with automated driving. In Advanced Vehicle Control AVEC’16; CRC Press: Boca Raton, FL, USA, 2016; pp. 79–84. [Google Scholar]

- Schyr, C.; Inoue, H.; Nakaoka, Y. Vehicle-in-the-Loop Testing-a Comparative Study for Efficient Validation of ADAS/AD Functions. In Proceedings of the 2022 International Conference on Connected Vehicle and Expo (ICCVE), Lakeland, FL, USA, 7–9 March 2022; pp. 1–8. [Google Scholar]

- Tornado Software Suite—KS Engineers—ksengineers.com. Available online: https://www.ksengineers.com/en/Automotive-Testing/Management-and-automation-tools/Tornado-Software-Suite (accessed on 19 May 2023).

- Jansen, D.; Buttner, H. Real-time Ethernet: The EtherCAT solution. Comput. Control. Eng. 2004, 15, 16–21. [Google Scholar] [CrossRef]

- Bauer, R. New Methodology for Dynamic Drive Train Testing; Technical Report, SAE Technical Paper; SAE: Warrendale, PA, USA, 2011. [Google Scholar]

- Li, H.; Kanuric, T.; Eichberger, A. Automotive Radar Modeling for Virtual Simulation Based on Mixture Density Network. IEEE Sens. J. 2022, 23, 11117–11124. [Google Scholar] [CrossRef]

- Li, H.; Bamminger, N.; Magosi, Z.F.; Feichtinger, C.; Zhao, Y.; Mihalj, T.; Orucevic, F.; Eichberger, A. The Effect of Rainfall and Illumination on Automotive Sensors Detection Performance. Sustainability 2023, 15, 7260. [Google Scholar] [CrossRef]

- Baidu. Apollo Auto. Available online: https://github.com/ApolloAuto/apollo.git (accessed on 26 September 2022).

- Wong, V. Automated-Driving-Control. Available online: https://github.com/VincentWong3 (accessed on 4 December 2022).

- Krolicki, K. Baidu, Pony.ai start driverless robotaxi tests in Beijing. Reuters, 30 December 2022. [Google Scholar]

- Fan, H.; Zhu, F.; Liu, C.; Zhang, L.; Zhuang, L.; Li, D.; Zhu, W.; Hu, J.; Li, H.; Kong, Q. Baidu apollo em motion planner. arXiv 2018, arXiv:1807.08048. [Google Scholar]

- Pivtoraiko, M.; Kelly, A. Efficient constrained path planning via search in state lattices. In Proceedings of the International Symposium on Artificial Intelligence, Robotics, and Automation in Space, Munich, Germany, 5–8 September 2005; pp. 1–7. [Google Scholar]

- Feng, M.; Zhang, H. Application of Baidu Apollo open platform in a course of control simulation experiments. Comput. Appl. Eng. Educ. 2022, 30, 892–906. [Google Scholar] [CrossRef]

- Magosi, Z.F.; Wellershaus, C.; Tihanyi, V.R.; Luley, P.; Eichberger, A. Evaluation Methodology for Physical Radar Perception Sensor Models Based on On-Road Measurements for the Testing and Validation of Automated Driving. Energies 2022, 15, 2545. [Google Scholar] [CrossRef]

- Krajewski, R.; Bock, J.; Kloeker, L.; Eckstein, L. The highD Dataset: A Drone Dataset of Naturalistic Vehicle Trajectories on German Highways for Validation of Highly Automated Driving Systems. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; pp. 2118–2125. [Google Scholar] [CrossRef]

- Wang, C.; Popp, C.; Winner, H. Acceleration-Based Collision Criticality Metric for Holistic Online Safety Assessment in Automated Driving. IEEE Access 2022, 10, 70662–70674. [Google Scholar] [CrossRef]

- Tomasch, E.; Steffan, H. ZEDATU—Zentrale Datenbank tödlicher Unfälle in Österreich—A Central Database of Fatalities in Austria. In Proceedings of the 2nd International Conference on ESAR “Expert Symposium on Accident Research”, Hannover, German, 1–2 September 2006. [Google Scholar]

- Tomasch, E.; Steffan, H.; Darok, M. Retrospective accident investigation using information from court. In Proceedings of the Transport Research Arena Europe 2008 (TRA), Ljubljana, Slovenia, 21–24 April 2008. [Google Scholar]

- Burckhardt, M.; Burg, H.; Gnadler, R.; Schiemann, G. Die Bremsreaktionsdauer von Pkw-Fahrern. Der Verkehrsunfall 1981, 19, 224–227. [Google Scholar]

- Burckhardt, M.; Burg, H.; Gnadler, R.; Näumann, E.; Schiemann, G. Die Brems-Reaktionsdauer von Pkw-Fahrern. 1981. Available online: https://trid.trb.org/view/1043508 (accessed on 26 September 2022).

- Hugemann, W. Driver Reaction Times in Road Traffic. In Proceedings of the Annual EVU Meeting, Edinburgh, UK, 11–12 July 2002; Europäische Vereinigung für Unfallforschung und Unfallanalyse e.V.: Portorož, Slovenia, 2002. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Makkapati, V.P.; Wan, L.; Tomasch, E.; Hoschopf, H.; Eichberger, A. Validation of Automated Driving Function Based on the Apollo Platform: A Milestone for Simulation with Vehicle-in-the-Loop Testbed. Vehicles 2023, 5, 718-731. https://doi.org/10.3390/vehicles5020039

Li H, Makkapati VP, Wan L, Tomasch E, Hoschopf H, Eichberger A. Validation of Automated Driving Function Based on the Apollo Platform: A Milestone for Simulation with Vehicle-in-the-Loop Testbed. Vehicles. 2023; 5(2):718-731. https://doi.org/10.3390/vehicles5020039

Chicago/Turabian StyleLi, Hexuan, Vamsi Prakash Makkapati, Li Wan, Ernst Tomasch, Heinz Hoschopf, and Arno Eichberger. 2023. "Validation of Automated Driving Function Based on the Apollo Platform: A Milestone for Simulation with Vehicle-in-the-Loop Testbed" Vehicles 5, no. 2: 718-731. https://doi.org/10.3390/vehicles5020039

APA StyleLi, H., Makkapati, V. P., Wan, L., Tomasch, E., Hoschopf, H., & Eichberger, A. (2023). Validation of Automated Driving Function Based on the Apollo Platform: A Milestone for Simulation with Vehicle-in-the-Loop Testbed. Vehicles, 5(2), 718-731. https://doi.org/10.3390/vehicles5020039