Electric Motor and Transmission Integration for Light-Duty Electric Vehicles: A 2023 Benchmarking Perspective and Component Sizing for a Fleet Approach

Abstract

:1. Introduction

2. Materials and Methods

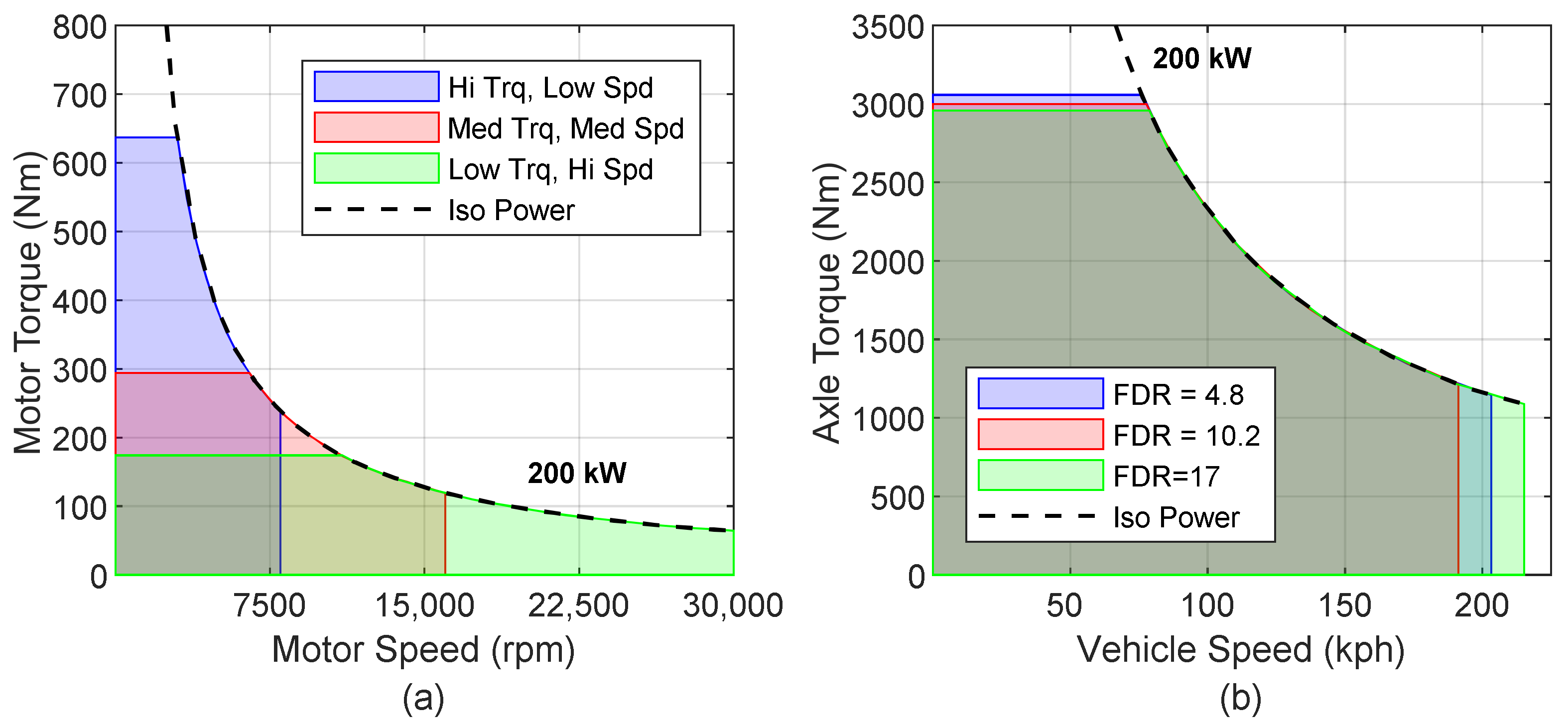

2.1. Electric Machine Performance

2.2. Transmission Design Baiscs

2.3. Propulsion System Requirements and Limitations

2.4. EV Propulsion System Integration Fundamentals

- Worldwide Harmonized Light Vehicles Test Procedure—WLTP

- New European Driving Cycle—NEDC

- Urban Dynamometer Driving Schedule—UDDS

- Highway Fuel Economy Test—HWFET

- Supplemental Federal Test Procedure—US06.

2.5. Review of Electric Motors and Electric Traction Drive Units

2.6. Review of Electric Vehicle Transmissions

2.7. Transmission Design and Parasitic Losses

3. Results

3.1. Light-Duty, Economy Passenger Car

3.2. Light-Duty Performance Car

3.3. Light-Duty Truck

4. Discussion

5. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFPM | Axial Flux Permanent Magnet |

| AWD | All Wheel Drive |

| CVT | Continuously Variable Transmission |

| DC | Direct Current |

| DCT | Dual Clutch Transmission |

| EM | Electric Motor |

| EESM | Externally Excited Synchronous Machine |

| ETDU | Electric Traction Drive Unit—Electric Motor + Transmission |

| EV | Electric Vehicle |

| FDR | Final Drive Ratio |

| FWD | Front Wheel Drive |

| GR | Gear Ratio |

| HV | High Voltage |

| ICE | Internal Combustion Engine |

| IM | Induction Machine |

| NREL | National Renewable Energy Laboratory |

| OEM | Original Equipment Manufacturer |

| PMSM | Permanent Magnet Synchronous Machine |

| PMSRM | Permanent Magnet Synchronous Reluctance Machine |

| RWD | Rear Wheel Drive |

| SRM | Switched Reluctance Machine |

| TPIM | Traction Power Inverter Module |

| TRM | Transmission |

| VDC | Voltage Direct Current |

Appendix A

Appendix B

References

- Conway, G.; Joshi, A.; Leach, F.; Garcia, A.; Senecal, P.K. A Review of Current and Future Powertrain Technologies and Trends in 2020. Transp. Eng. 2021, 5, 100080. [Google Scholar] [CrossRef]

- International Energy Agency. The Role of Critical Minerals in Clean Energy Transitions. 2021. Available online: https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions (accessed on 28 March 2023).

- Castelvecchi, D. Electric Cars and Batteries: How Will the World Produce Enough? Nature 2021, 596, 336–339. [Google Scholar] [CrossRef] [PubMed]

- Machado, F.A.; Kollmeyer, P.J.; Barroso, D.G.; Emadi, A. Multi-Speed Gearboxes for Battery Electric Vehicles: Current Status and Future Trends. IEEE Open J. Veh. Technol. 2021, 2, 419–435. [Google Scholar] [CrossRef]

- El Hadraoui, H.; Zegrari, M.; Chebak, A.; Laayati, O.; Guennouni, N. A Multi-Criteria Analysis and Trends of Electric Motors for Electric Vehicles. World Electr. Veh. J. 2022, 13, 65. [Google Scholar] [CrossRef]

- Mądziel, M.; Campisi, T. Energy Consumption of Electric Vehicles: Analysis of Selected Parameters Based on Created Database. Energies 2023, 16, 1437. [Google Scholar] [CrossRef]

- Chowdhury, S.; Gurpinar, E.; Su, G.-J.; Raminosoa, T.; Burress, T.A.; Ozpineci, B. Enabling Technologies for Compact Integrated Electric Drives for Automotive Traction Applications. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 17–19 June 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Agamloh, E.; von Jouanne, A.; Yokochi, A. An Overview of Electric Machine Trends in Modern Electric Vehicles. Machines 2020, 8, 20. [Google Scholar] [CrossRef]

- Husain, I.; Ozpineci, B.; Islam, S.; Gurpinar, E.; Su, G.-J.; Yu, W.; Chowdhury, S.; Xue, L.; Rahman, D.; Sahu, R. Electric Drive Technology Trends, Challenges, and Opportunities for Future Electric Vehicles. Proc. IEEE 2021, 109, 1039–1059. [Google Scholar] [CrossRef]

- Yang, Z.; Shang, F.; Brown, I.P.; Krishnamurthy, M. Comparative Study of Interior Permanent Magnet, Induction, and Switched Reluctance Motor Drives for EV and HEV Applications. IEEE Trans. Transp. Electrif. 2015, 1, 245–254. [Google Scholar] [CrossRef]

- Woolmer, T.J.; McCulloch, M.D. Analysis of the Yokeless And Segmented Armature Machine. In Proceedings of the 2007 IEEE International Electric Machines & Drives Conference, Antalya, Turkey, 3–5 May 2007; pp. 704–708. [Google Scholar] [CrossRef]

- Schneider, E.; Fickel, F.; Cebulski, B.; Liebold, J. Highly Integrative and flexible Electric Drive Unit for Electric Vehicles. ATZ Worldw. 2011, 113, 10–15. [Google Scholar] [CrossRef]

- Hawkins, S.; Holmes, A.; Ames, D.; Rahman, K.; Malone, R. Design Optimization, Development and Manufacturing of General Motors New Battery Electric Vehicle Drive Unit (1ET35). SAE Int. J. Altern. Powertrains 2014, 3, 213–221. [Google Scholar] [CrossRef]

- Jurkovic, S.; Rahman, K.; Patel, N.; Savagian, P. Next Generation Voltec Electric Machines; Design and Optimization for Performance and Rare-Earth Mitigation. SAE Int. J. Altern. Powertrains 2015, 4, 336–342. [Google Scholar] [CrossRef]

- Liu, J.; Anwar, M.; Chiang, P.; Hawkins, S.; Jeong, Y.; Momen, F.; Poulos, S.; Song, S. Design of the Chevrolet Bolt EV Propulsion System. SAE Int. J. Altern. Powertrains 2016, 5, 79–86. [Google Scholar] [CrossRef]

- Doerr, J.; Attensperger, T.; Wittmann, L.; Enzinger, T. The New Electric Axle Drives from Audi. ATZelektronik Worldw. 2018, 13, 16–23. [Google Scholar] [CrossRef]

- Raminosoa, T.; Wiles, R.; Cousineau, J.E.; Bennion, K.; Wilkins, J. A High-Speed High-Power-Density Non-Heavy Rare-Earth Permanent Magnet Traction Motor. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 61–67. [Google Scholar] [CrossRef]

- Ajamloo, A.M.; Ibrahim, M.N.; Sergeant, P. Design, Modelling and Optimization of a High Power Density Axial Flux SRM with Reduced Torque Ripple for Electric Vehicles. Machines 2023, 11, 759. [Google Scholar] [CrossRef]

- Nitabaru, T.; Okada, H.; Isomura, T.; Kawashima, Y.; Abe, H.; Ogata, H. Drive Control Development of Switched Reluctance Motor for Compact Electric Vehicles. SAE Int. J. Adv. Curr. Pract. Mobil. 2019, 1, 1006–1013. [Google Scholar] [CrossRef]

- Vigneshwar, S.T.; Lenin, N.C. Comparison of Radial Flux PMSM and Axial Flux PMSM for Hybrid Electric Tracked Vehicles. In Emerging Solutions for e-Mobility and Smart Grids; Kamaraj, V., Ravishankar, J., Jeevananthan, S., Eds.; Springer Proceedings in Energy; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Oh, S.C.; Emadi, A. Test and simulation of axial flux-motor characteristics for hybrid electric vehicles. IEEE Trans. Veh. Technol. 2004, 53, 912–919. [Google Scholar] [CrossRef]

- The Drive. Available online: https://www.thedrive.com/news/why-axial-flux-motors-are-a-big-deal-for-evs (accessed on 21 July 2023).

- Yasa Press. Available online: https://www.yasa.com/wp-content/uploads/2018/01/YASA_P400_Product_Sheet.pdf (accessed on 21 July 2023).

- Aiso, K.; Akatsu, K. Performance Comparison of High-Speed Motors for Electric Vehicle. World Electr. Veh. J. 2022, 13, 57. [Google Scholar] [CrossRef]

- Pindoriya, R.M.; Rajpurohit, B.S.; Kumar, R.; Srivastava, K.N. Comparative analysis of permanent magnet motors and switched reluctance motors capabilities for electric and hybrid electric vehicles. In Proceedings of the 2018 IEEMA Engineer Infinite Conference (eTechNxT), New Delhi, India, 13–14 March 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Koenigsegg. Available online: https://www.koenigsegg.com/quark-emotor (accessed on 21 July 2023).

- TheDrive. Available online: https://www.thedrive.com/news/heres-how-koenigseggs-dark-matter-electric-motor-makes-800-hp (accessed on 21 August 2023).

- Koenigsegg. Available online: https://www.koenigsegg.com/technical-specifications-gemera-2023 (accessed on 21 August 2023).

- Lucid Motors Press. Available online: https://lucidmotors.com/media-room/lucid-motors-proprietary-electric-drivetrain-technology-powers-record-setting-performance (accessed on 21 July 2023).

- Lucid Motors Press. Available online: https://ir.lucidmotors.com/news-releases/news-release-details/lucid-unveils-state-art-motorsports-electric-drive-unit-taking (accessed on 21 July 2023).

- Ahssan, M.; Ektesabi, M.; Gorji, S. Electric Vehicle with Multi-Speed Transmission: A Review on Performances and Complexities. SAE Int. J. Altern. Powertrains 2018, 7, 169–181. [Google Scholar] [CrossRef]

- Xu, X.; Dong, P.; Liu, Y.; Zhang, H. Progress in Automotive Transmission Technology. Automot. Innov. 2018, 1, 187–210. [Google Scholar] [CrossRef]

- Green Car Congress. Available online: https://www.greencarcongress.com/2014/11/20141110-gkn.html (accessed on 21 July 2023).

- SAE International, Automotive Engineering. Available online: https://www.sae.org/news/2019/03/gkn-etwinster-bev-e-axle-debut (accessed on 21 July 2023).

- Porsche Media. Available online: https://media.porsche.com/mediakit/taycan/en/porsche-taycan/der-antrieb (accessed on 21 July 2023).

- Jalopnik. Available online: https://jalopnik.com/an-extremely-detailed-look-at-the-porsche-taycans-engin-1837802533 (accessed on 21 July 2023).

- Fang, S.; Song, J.; Song, H.; Tai, Y.; Li, F.; Nguyen, T.S. Design and control of a novel two-speed Uninterrupted Mechanical Transmission for electric vehicles. Mech. Syst. Signal Process. 2016, 75, 473–493. [Google Scholar] [CrossRef]

- Berg, M.; Reimann, W.; Voss, B. DrivePacEV80—Highly Integrative Electric Drive Unit for Electric Vehicles. In Proceedings of the 3rd Aachen Colloquium China Automobile and Engine Technology, Beijing, China, 1 October 2013; pp. 1–32. [Google Scholar]

- Hegger, C.; Maas, J. Automatic Two-Speed Transmission Based on a Combined MRF Coupling Element. IEEE/ASME Trans. Mechatron. 2022, 27, 3019–3028. [Google Scholar] [CrossRef]

- Han, J.-O.; Shin, J.-W.; Kim, J.-C.; Oh, S.-H. Design 2-Speed Transmission for Compact Electric Vehicle Using Dual Brake System. Appl. Sci. 2019, 9, 1793. [Google Scholar] [CrossRef]

- Han, J.-O.; Jeong, W.-H.; Lee, J.-S.; Oh, S.-H. The Structure and Optimal Gear Tooth Profile Design of Two-Speed Transmission for Electric Vehicles. Energies 2021, 14, 3736. [Google Scholar] [CrossRef]

- Gao, B.; Meng, D.; Shi, W.; Cai, W.; Dong, S.; Zhang, Y.; Chen, H. Topology optimization and the evolution trends of two-speed transmission of EVs. Renew. Sustain. Energy Rev. 2022, 161, 112390. [Google Scholar] [CrossRef]

- Ruan, J.; Walker, P.D.; Wu, J.; Zhang, N.; Zhang, B. Development of continuously variable transmission and multi-speed dual-clutch transmission for pure electric vehicle. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- SAE International, Automotive Engineering. Available online: https://www.sae.org/news/2019/07/zf-2-speed-ev-transmission-prototype (accessed on 21 July 2023).

- Campbell, B.; Pomerleau, M.; Govindswamy, K.; Tomazic, D.; Tousignant, T.; Wellman, T. Integrated electric drive units with up to 2 speeds. In Proceedings of the 12th International CTI Symposium, Novi, MI, USA, 14–17 May 2018. [Google Scholar]

- Inmotive. Available online: https://www.inmotive.com/ (accessed on 21 July 2023).

- Bosch Mobility Solutions. Available online: https://www.bosch-mobility-solutions.com/en/solutions/transmission-technology/transmission-cvt4ev/ (accessed on 21 July 2023).

- New Atlas. Available online: https://newatlas.com/antonov-3-speed-transmission-ev/19088/#gallery:1 (accessed on 21 July 2023).

- ZF Press. Available online: https://press.zf.com/press/en/releases/release_10181.html (accessed on 21 July 2023).

- SAE International, Automotive Engineering. Available online: https://www.sae.org/news/2022/12/zf-new-edrive-platform (accessed on 21 July 2023).

- Green Car Congress. Available online: https://www.greencarcongress.com/2019/09/20190924-ricardo.html (accessed on 21 July 2023).

- Bajrami, A.; Palpacelli, M.C. A Proposal for a Simplified Systematic Procedure for the Selection of Electric Motors for Land Vehicles with an Emphasis on Fuel Economy. Machines 2023, 11, 420. [Google Scholar] [CrossRef]

- Ibrahim, M.; Rassõlkin, A.; Vaimann, T.; Kallaste, A. Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System. Sustainability 2022, 14, 601. [Google Scholar] [CrossRef]

- Kown, K.; Lee, J.H.; Lim, S.K. Optimization of Multipseed Transmission for Electric Vehicles based on Electrical and Mechanical Efficiency Analysis. Appl. Energy 2023, 342, 121203. [Google Scholar] [CrossRef]

- Mantriota, G.; Reina, G. Dual-Motor Planetary Transmission to Improve Efficiency in Electric Vehicles. Machines 2021, 9, 58. [Google Scholar] [CrossRef]

- Lu, Z.; Tian, G.; Onori, S. Time-Optimal Coordination Control for the Gear-Shifting Process in Electric-Driven Mechanical Transmission (Dog Clutch) without Impacts. SAE Int. J. Electrified Veh. 2020, 9, 155–168. [Google Scholar] [CrossRef]

- Beaudoin, M.; Boulet, B. Fundamental limitations to no-jerk gearshifts of multi-speed transmission architectures in electric vehicles. Mech. Mach. Theory 2021, 160, 104290. [Google Scholar] [CrossRef]

- Gassmann, T.; Gueth, D.; Haupt, J. Seamless-shift Two-speed Transmission with Torque Vectoring Functionality. ATZ Worldw. 2017, 119, 46–49. [Google Scholar] [CrossRef]

- Wu, P.; Qiang, P.; Pan, T.; Zang, H. Multi-Objective Optimization of Gear Ratios of a Seamless Three-Speed Automated Manual Transmission for Electric Vehicles Considering Shift Performance. Energies 2022, 15, 4149. [Google Scholar] [CrossRef]

- Gillespie, T. Fundamentals of Vehicle Dynamics; Revised Edition; SAE International: Warrendale, PA, USA, 2021; ISBN 978-1-4686-0176-3. [Google Scholar]

- Deiml, M.; Eriksson, T.; Schneck, M.; Tan-Kim, A. High-speed Electric Drive Unit for the Next Generation of Vehicles. ATZ Worldw. 2019, 121, 42–47. [Google Scholar] [CrossRef]

- Doerr, J.; Fröhlich, G.; Stroh, A.; Baur, M. The Electric Drivetrain with Three-motor Layout of the Audi E-tron S. MTZ Worldw. 2020, 81, 16–25. [Google Scholar] [CrossRef]

- Cascadia Motion. Cascadia Motion Catalog, 2022–2023. Available online: https://www.cascadiamotion.com/images/catalog/CascadiaMotionCatalogWeb.pdf (accessed on 2 January 2023).

- CleanTechnica. Available online: https://cleantechnica.com/2022/02/02/koenigsegg-quark-terrier-bring-big-power-in-small-package-to-electric-cars/ (accessed on 21 July 2023).

- GM News. Available online: https://news.gm.com/newsroom.detail.html/Pages/news/us/en/2021/sep/0921-ultium-drive.html (accessed on 21 July 2023).

- Ford Media. Available online: https://media.ford.com/content/fordmedia/feu/en/news/2020/12/09/first-of-a-new-breed--ford-mustang-mach-e-ready-to-accelerate-ze.html (accessed on 21 July 2023).

- Ford Media. Available online: https://media.ford.com/content/fordmedia/fna/us/en/news/2021/11/02/all-electric-f-100-eluminator-concept.html (accessed on 21 July 2023).

- SAE International, Automotive Engineering. Available online: https://www.sae.org/news/2018/04/equipmakes-cool-spoke-motor-technology (accessed on 21 July 2023).

- Steiner, M. Sports Cars from Porsche-Innovations as a Tradition. ATZ Worldw. 2023, 125, 24–29. [Google Scholar] [CrossRef]

- Esmail, E.L.; Pennestrì, E.; Cirelli, M. Power-Flow and Mechanical Efficiency Computation in Two-Degrees-of-Freedom Planetary Gear Units: New Compact Formulas. Appl. Sci. 2021, 11, 5991. [Google Scholar] [CrossRef]

- Roulet, B.; Briec, A. Modeling of Power Losses in Mechanical Gearbox. In Proceedings of the 5th Congress EAEC, Strasbourg, France, 21–23June 1995; pp. 1–12. [Google Scholar]

- Changenet, C.; Oviedo-Marlot, X.; Velex, P. Power Loss Predictions in Geared Transmissions Using Thermal Networks-Applications to Six Speed Manual Gearbox. ASME J. Mech. Des. 2006, 128, 618–625. [Google Scholar] [CrossRef]

- Changenet, C.; Velex, P. A Model for the Prediction of Churning Losses in Gear Transmissions–Preliminary Results. ASME J. Mech. Des. 2007, 129, 128–133. [Google Scholar] [CrossRef]

- Kitabayashi, H.; Li, C.; Hiraki, H. Analysis of the Various Factors Affecting Drag Torque in Multiple-Plate Wet Clutches; SAE Technical Paper 2003-01-1973; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Goszczak, J.; Leyko, J.; Mitukiewicz, G.; Batory, D. Experimental Study of Drag Torque between Wet Clutch Discs. Appl. Sci. 2022, 12, 3900. [Google Scholar] [CrossRef]

- Ford Media. Available online: https://media.ford.com/content/dam/fordmedia/North%20America/US/product/2022/f-150-lightning/pdf/F-150_Lightning_Tech_Specs.pdf (accessed on 21 July 2023).

- GMC Media. Available online: https://media.gmc.com/media/us/en/gmc/vehicles/hummer-ev-pickup/2022.html (accessed on 21 July 2023).

- Basis, D. Modular Motor Gearbox Unit and Drive System. United States Patent US 10,703,201, B2, 7 July 2020. [Google Scholar]

- United States Environmental Protection Agency, Compliance and Fuel Economy Data. Available online: https://www.epa.gov/compliance-and-fuel-economy-data/data-cars-used-testing-fuel-economy (accessed on 19 August 2023).

- CleanTechnica. Available online: https://cleantechnica.com/2023/02/25/us-electric-car-sales-increased-65-in-2022/ (accessed on 19 August 2023).

- Benford, H.; Leising, M. The Lever Analogy: A New Tool in Transmission Analysis; SAE Technical Paper 810102; SAE International: Warrendale, PA, USA, 1981. [Google Scholar] [CrossRef]

- Hall, M.; Dourra, H. Dynamic Analysis of Transmission Torque Utilizing the Lever Analogy; SAE Technical Paper 2009-01-1137; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Attibele, P. A New Approach to Understanding Planetary Gear Train Efficiency and Powerflow. SAE Int. J. Adv. Curr. Pract. Mobil. 2020, 2, 3180–3188. [Google Scholar] [CrossRef]

| Performance Requirements/Targets | Key EV and Propulsion Attributes |

|---|---|

| Vehicle Road Load Torque | Maximum Vehicle Speed (Vmax) |

| Regulatory Drive Cycles | Maximum Torque |

| Gradeability | Electric Motor Base Speed(s) |

| Acceleration—0 to 100 kph | Maximum Torque at Vmax |

| Passing Acceleration(s) | Front and Rear Axle Traction Limits |

| Towing Capacity | System Operating Voltage |

| EM Architecture | DC Voltage (VDC) | Peak Power (kW) | Peak Torque (Nm) | Volume (L) | Mass (kg) | Rotor Diameter (mm) |

|---|---|---|---|---|---|---|

| PMSM | 350 | 150 | 358 | 5.2 | 38 | 204 |

| SCIM | 396 | 165 | 355 | 9.9 | 46 | 156 |

| AFPM | 700 | 160 | 370 | 6.8 | 28 | 294 |

| Parameters | Units | Value |

|---|---|---|

| Vehicle Mass | kg | 1628 |

| F0 | N | 126 |

| F1 | N/(m/s) | 2.025 |

| F2 | N/(m/s2) | 0.434 |

| Weight Dist. (F/R) | % | 56/44 |

| Tire Rolling Radius | m | 0.3234 (P215/50R17) |

| Max Speed | kph | 147 |

| 0–100 kph Target | sec | 7 |

| Base EM | - | 150 kW, 360 Nm max, 9000 rpm max |

| Base Transmission | - | 1 Speed, GR 7.05 |

| Parameters | Units | Value |

|---|---|---|

| Vehicle Mass | kg | 2359 |

| F0 | N | 228 |

| F1 | N/(m/s) | 4.321 |

| F2 | N/(m/s2) | 0.327 |

| Weight Dist. (F/R) | % | 49/51 |

| Front Tire Rolling Radius | m | 0.364 (P245/45R20) |

| Rear Tire Rolling Radius | m | 0.368 (P285/40R20) |

| Max Speed | kph | 260 |

| 0–100 kph Target | sec | <3 |

| Base FWD EM | - | 190 kW, 360 Nm, and 16,000 rpm max |

| Base FWD Transmission | - | 1 Speed, GR 8.05 |

| Base RWD EM | - | 370 kW, 610 Nm, and 16,000 rpm max |

| Base RWD Transmission | - | 2 Speed, GR1 15.5 GR2 8.05 |

| Parameters | Units | Dual EM, ICE Equivalent AWD EV | Tri-EM, Performance AWD EV |

|---|---|---|---|

| Vehicle Mass | kg | 2994 | 4128 |

| F0 | N | 161 | 334 |

| F1 | N/(m/s) | 3.38 | 7.963 |

| F2 | N/(m/s2) | 0.770 | 1.113 |

| Weight Dist. (F/R) | % | 50/50 | 50/50 |

| Front Tire Rolling Radius | m | 0.419 (LT275/60R20) | 0.442 (LT305/70R18) |

| Rear Tire Rolling Radius | m | 0.419 (LT275/60R20) | 0.442 (LT305/70R18) |

| Max Speed | kph | 190 | 190 |

| 0–100 kph Target | sec | ~4 | ~3.2 |

| Base FWD EM | - | 217 kW, 525 Nm, and 11,000 rpm max | 255 kW, 458 Nm, and 15,000 rpm max |

| Base FWD Transmission | - | 1 Speed, GR 9.6 | 1 Speed, GR 13.3 |

| Base RWD EM | - | 217 kW, 525 Nm, and 11,000 rpm max | 510 kW, 990 Nm, and 15,000 rpm max |

| Base RWD Transmission | - | 1 Speed, GR 9.6 | 1 Speed, GR 10.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robinette, D. Electric Motor and Transmission Integration for Light-Duty Electric Vehicles: A 2023 Benchmarking Perspective and Component Sizing for a Fleet Approach. Vehicles 2023, 5, 1167-1195. https://doi.org/10.3390/vehicles5030065

Robinette D. Electric Motor and Transmission Integration for Light-Duty Electric Vehicles: A 2023 Benchmarking Perspective and Component Sizing for a Fleet Approach. Vehicles. 2023; 5(3):1167-1195. https://doi.org/10.3390/vehicles5030065

Chicago/Turabian StyleRobinette, Darrell. 2023. "Electric Motor and Transmission Integration for Light-Duty Electric Vehicles: A 2023 Benchmarking Perspective and Component Sizing for a Fleet Approach" Vehicles 5, no. 3: 1167-1195. https://doi.org/10.3390/vehicles5030065

APA StyleRobinette, D. (2023). Electric Motor and Transmission Integration for Light-Duty Electric Vehicles: A 2023 Benchmarking Perspective and Component Sizing for a Fleet Approach. Vehicles, 5(3), 1167-1195. https://doi.org/10.3390/vehicles5030065