Concept for an Electromechanical Connection and Steering Joint for a Small Off-Road Electric Vehicle

Abstract

:1. Introduction

2. Materials and Methods

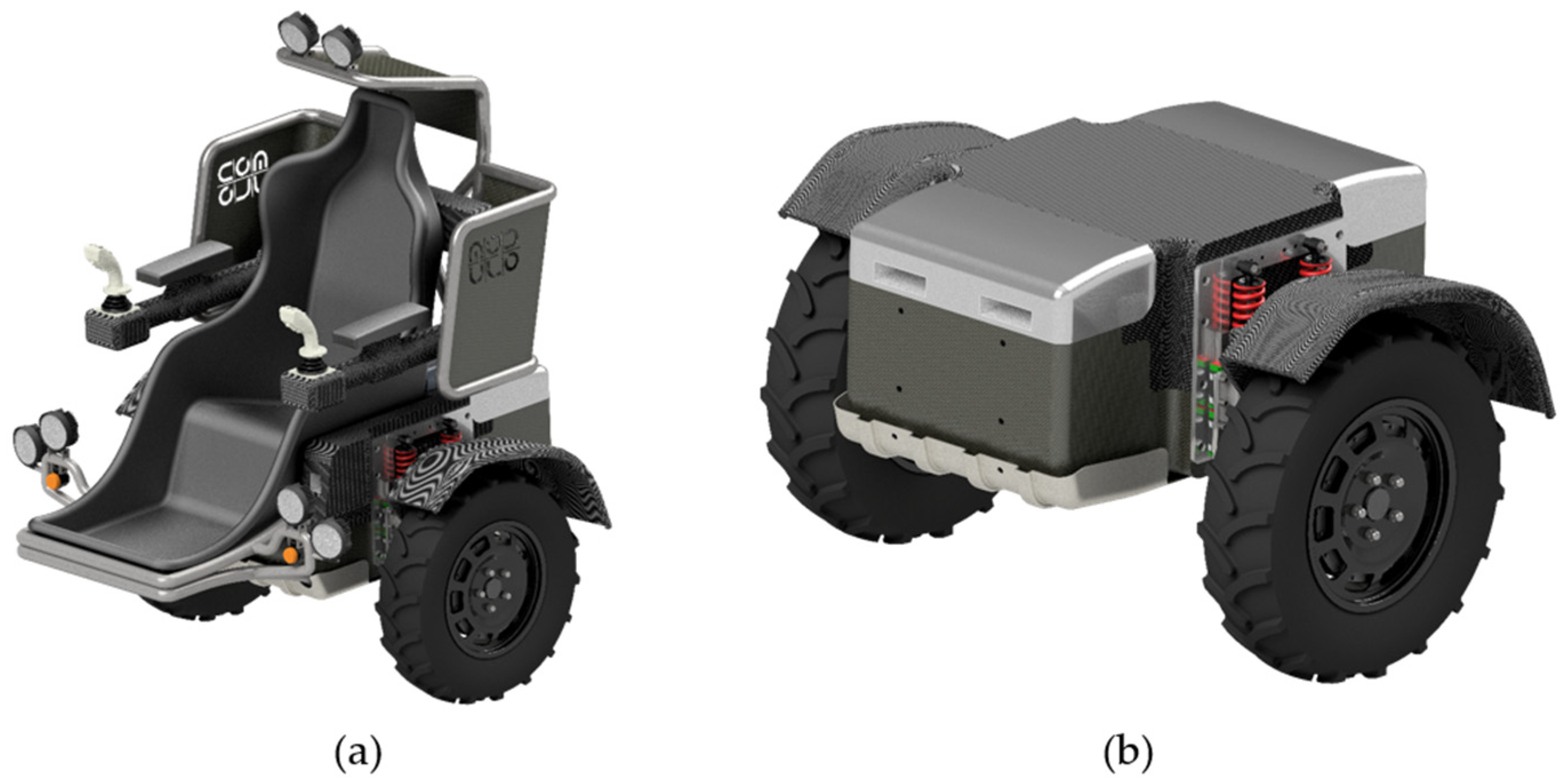

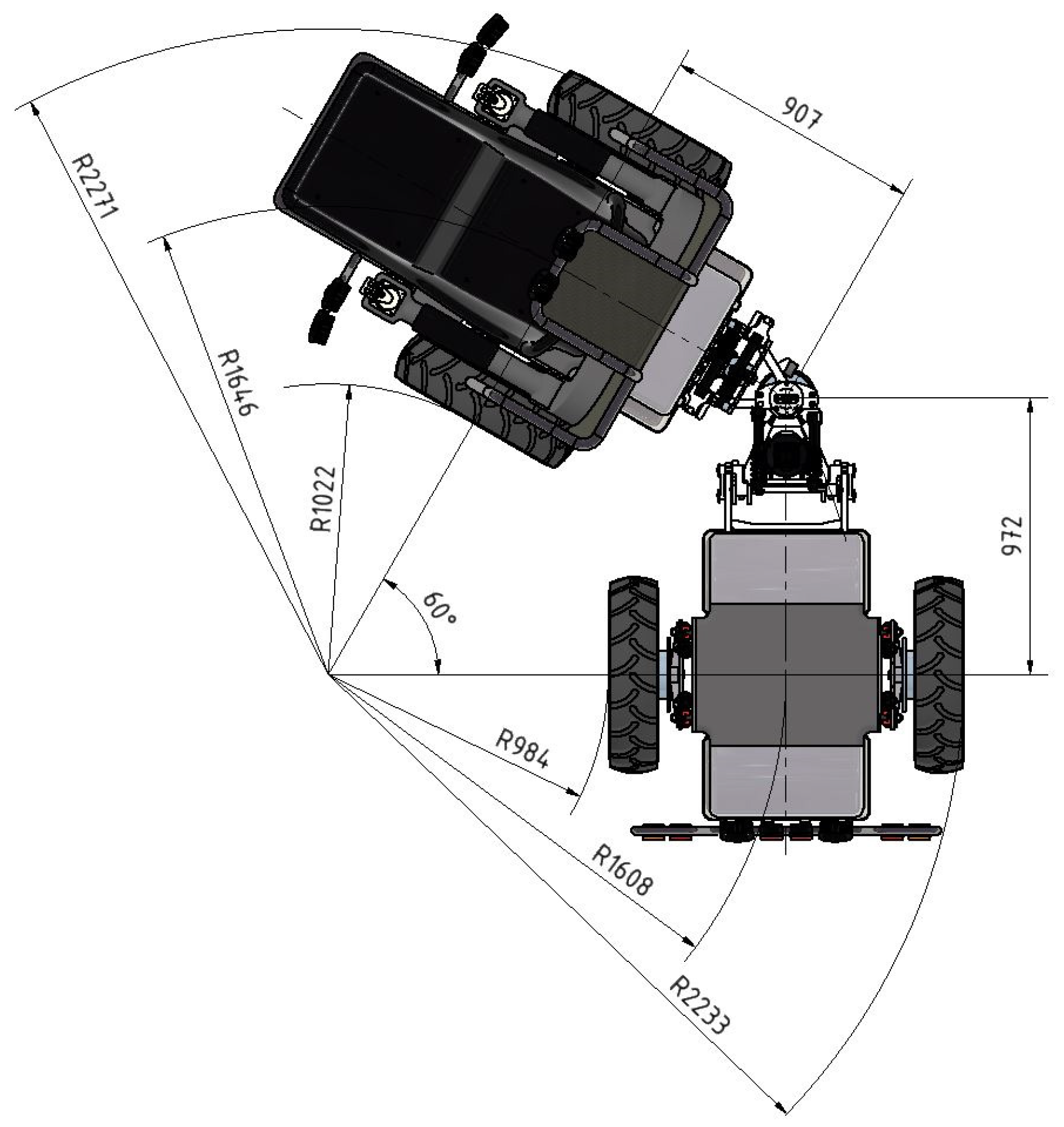

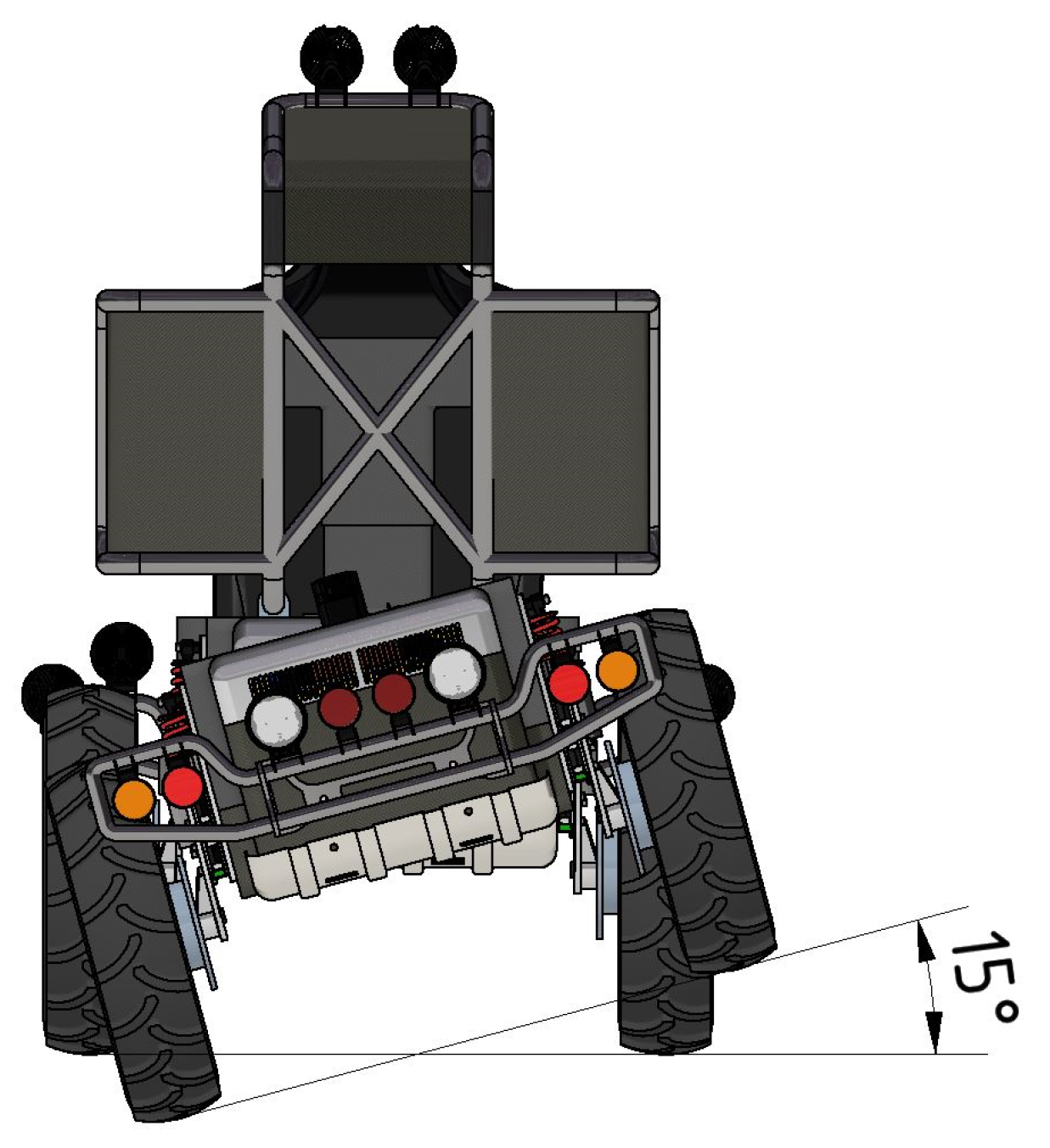

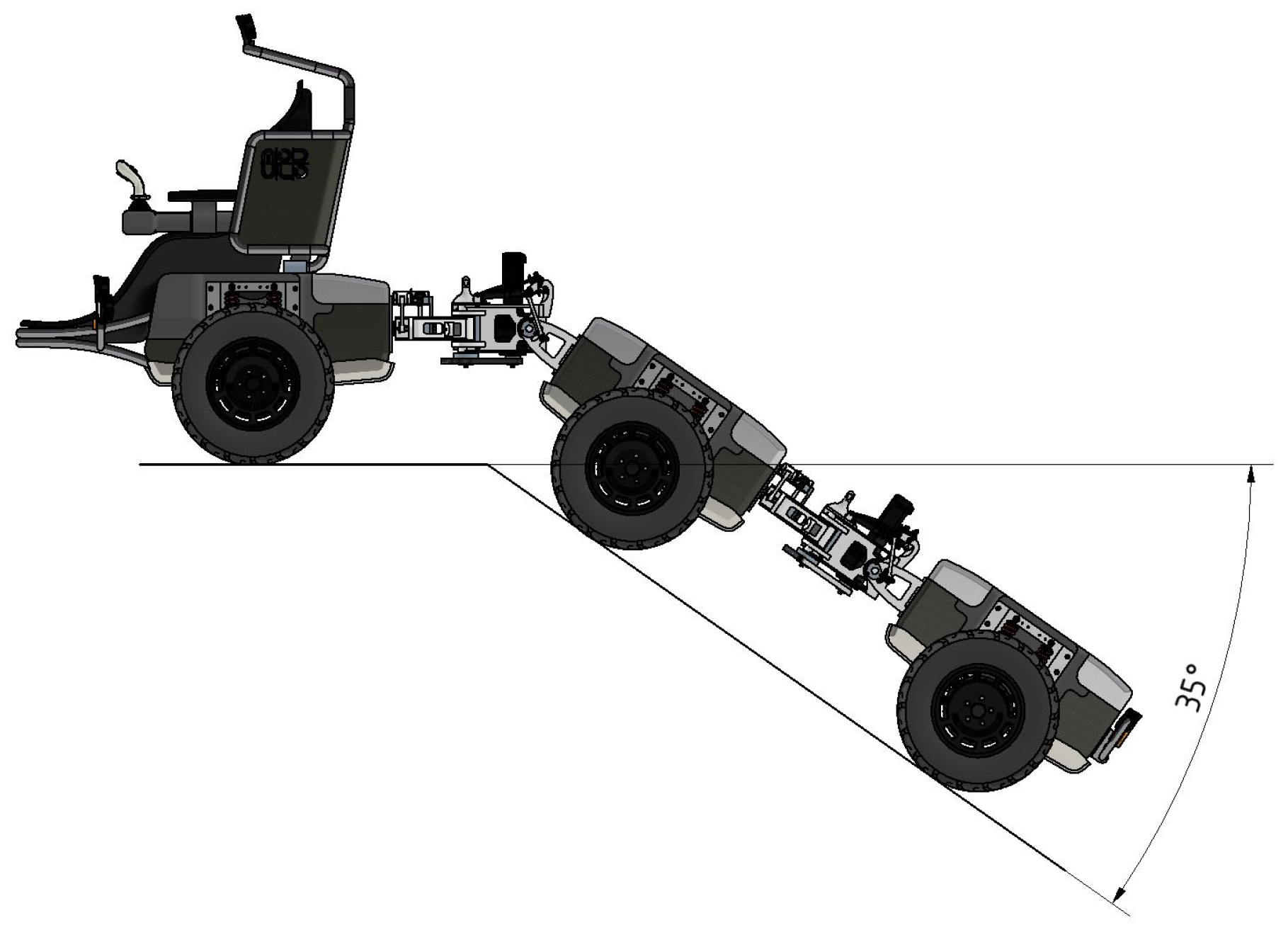

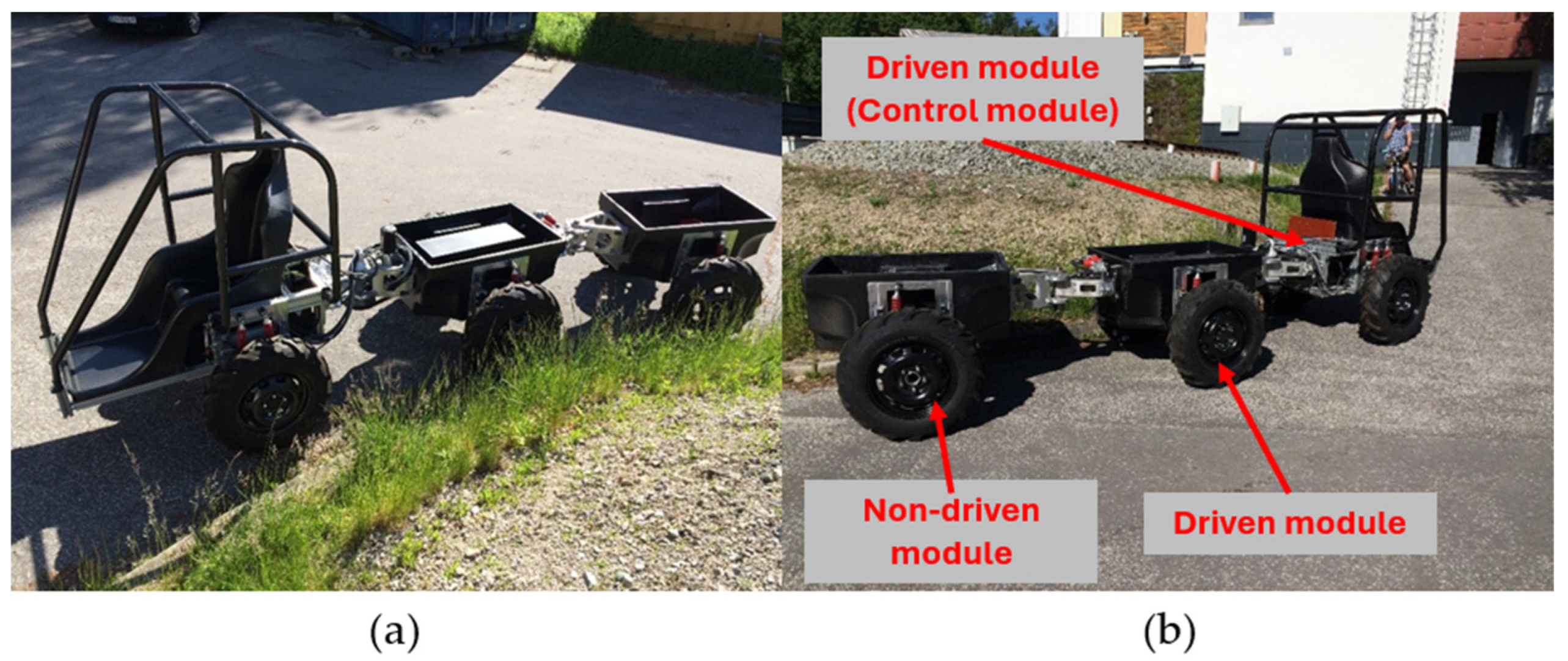

2.1. Design of a Small Off-Road Electric Vehicle

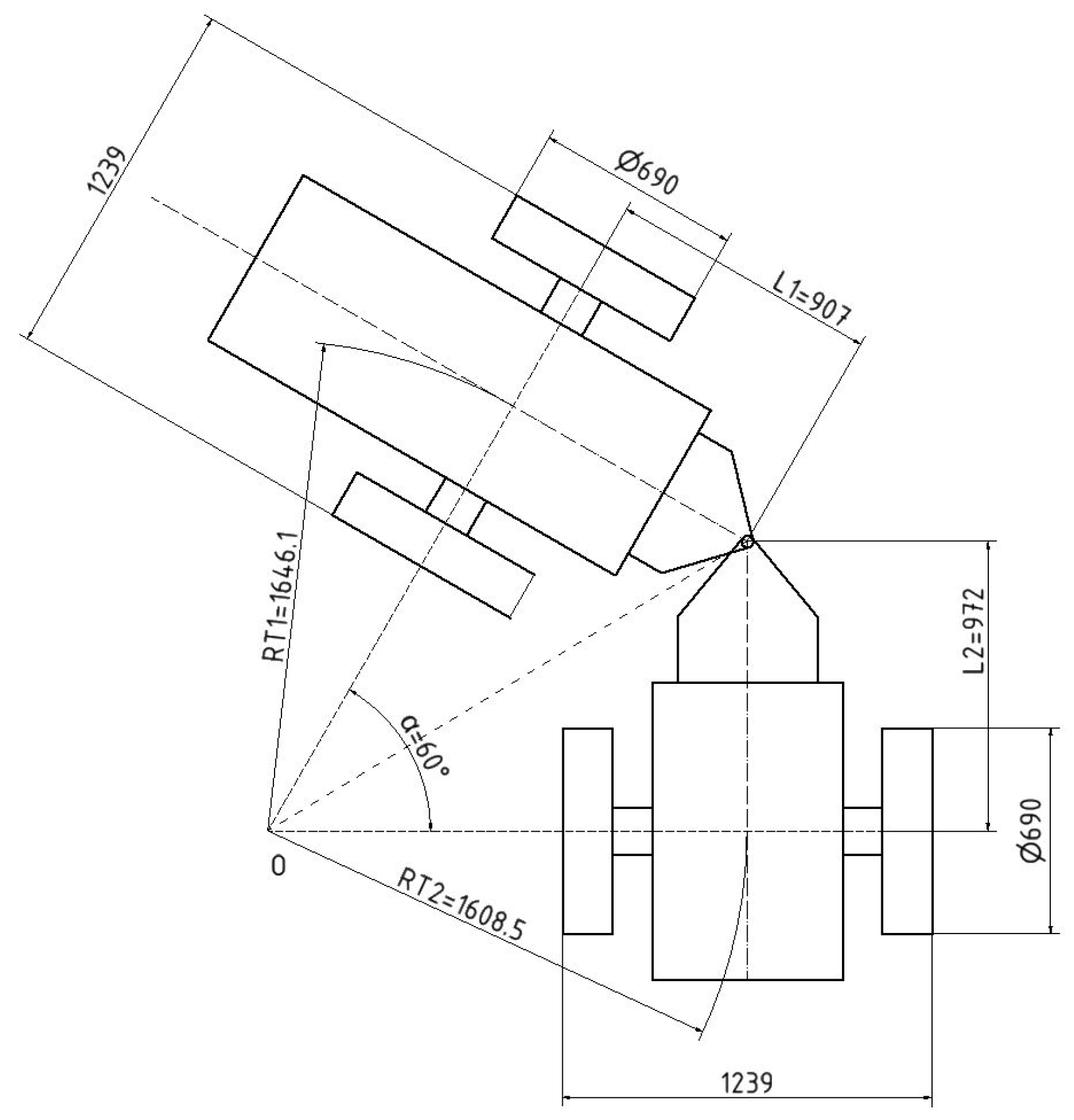

2.2. Requirements for the Design of the Electromechanical Connection and Steering Joint

- Mechanical connection of two standard modules or the connection of a control module and a standard module;

- Steering the vehicle’s direction by rotating the joint. The joint rotation must be achieved electrically using a servo drive and additional reduction gears;

- Powering the steering servo drive from the vehicle’s traction batteries;

- Ensuring sufficient space in the proposed design for housing the steering servo drive and routing electrical cables to the servo drive;

- Enabling the mutual lateral tilt of two connected modules;

- Enabling the mutual longitudinal tilt of two connected modules;

- Modular construction, allowing the arrangement of the connection and steering joint to be customized according to the needs of the end user.

2.3. Concept Development

2.4. Reflection on Developed Concepts

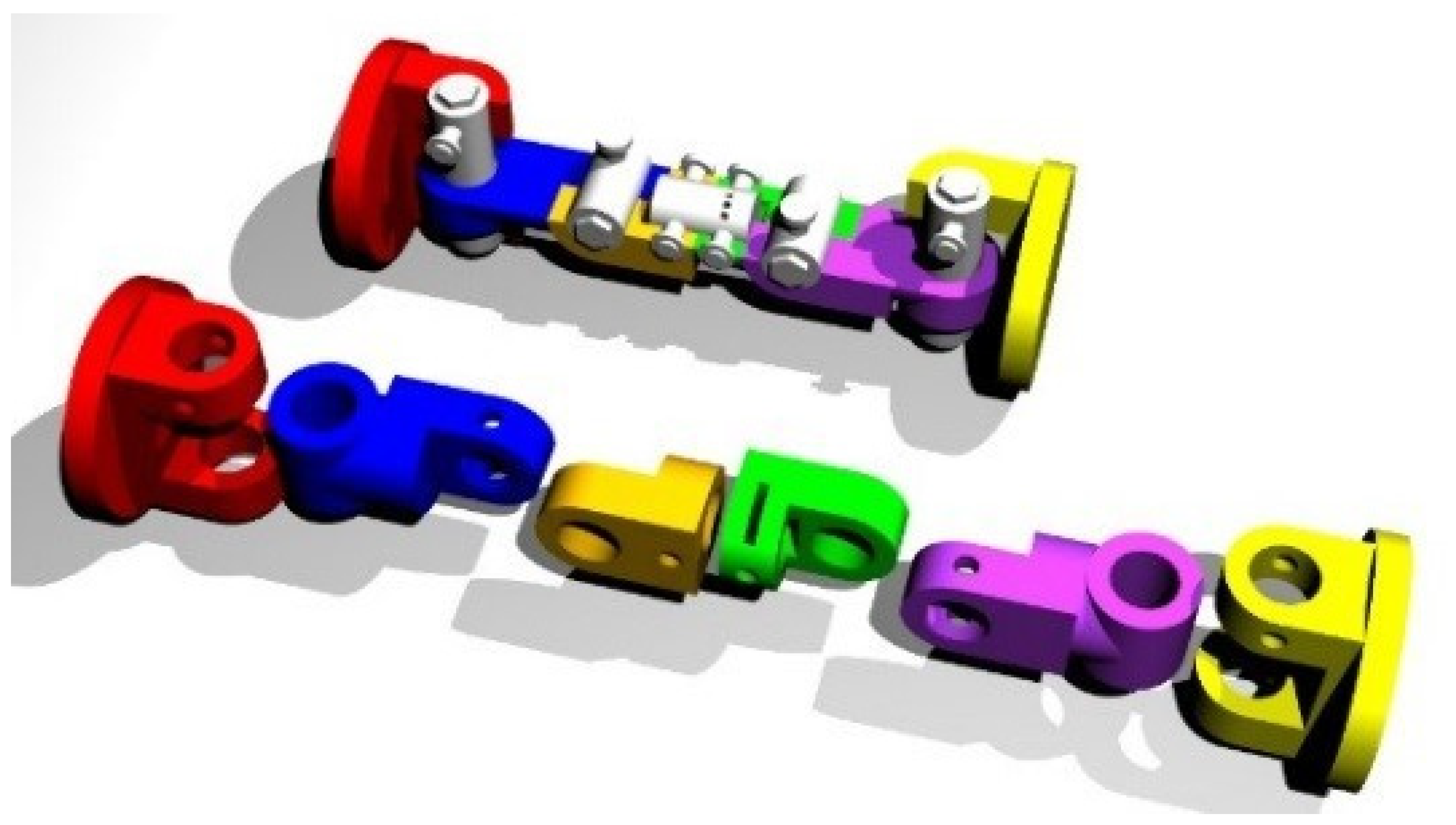

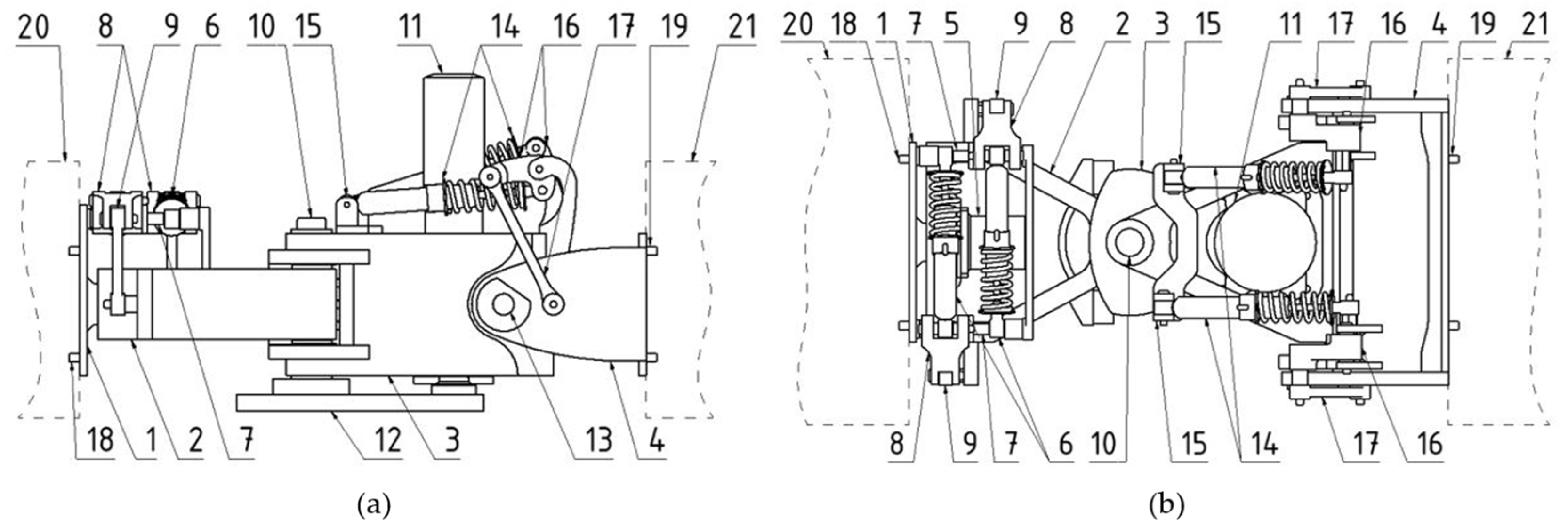

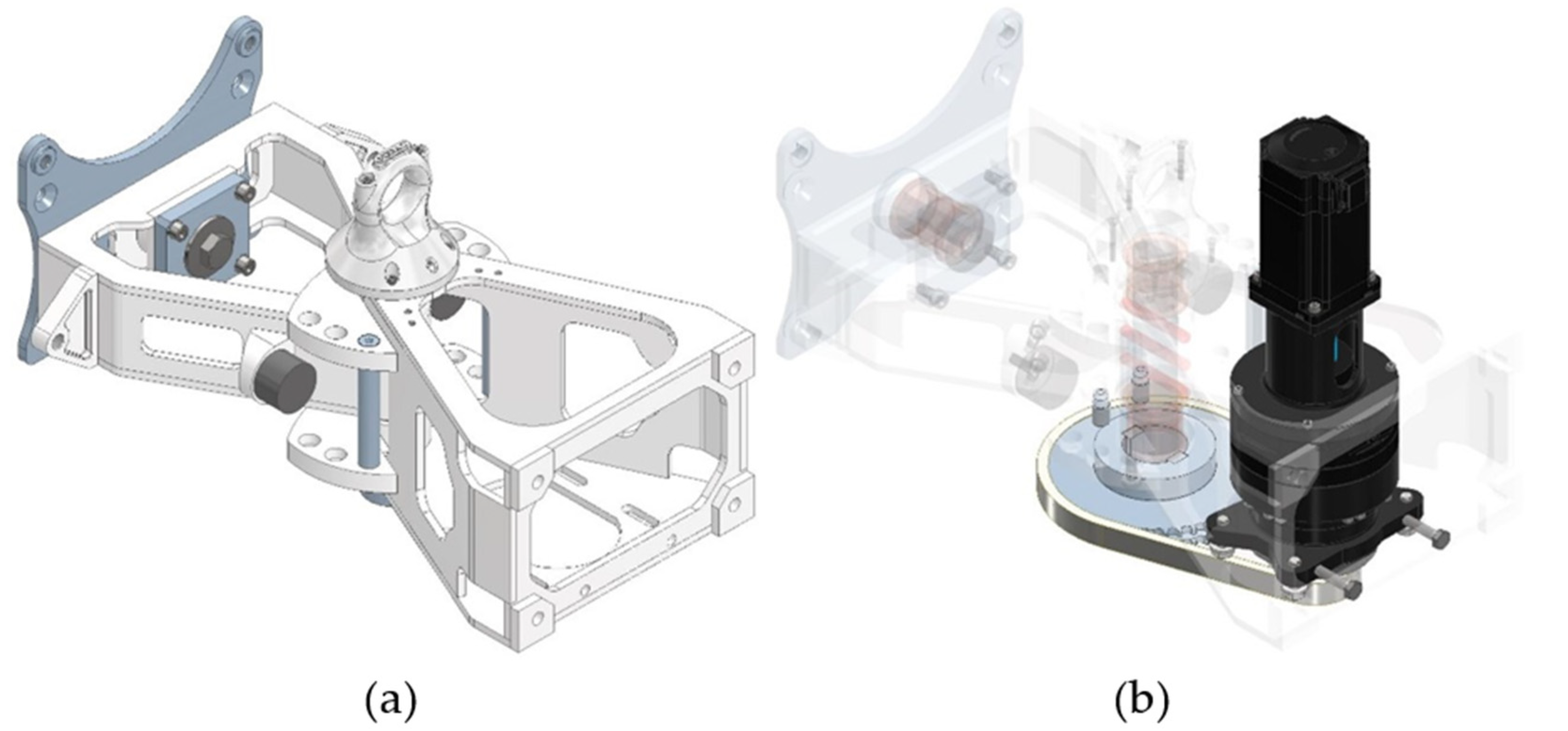

2.5. Design of the Electromechanical Connection and Steering Joint

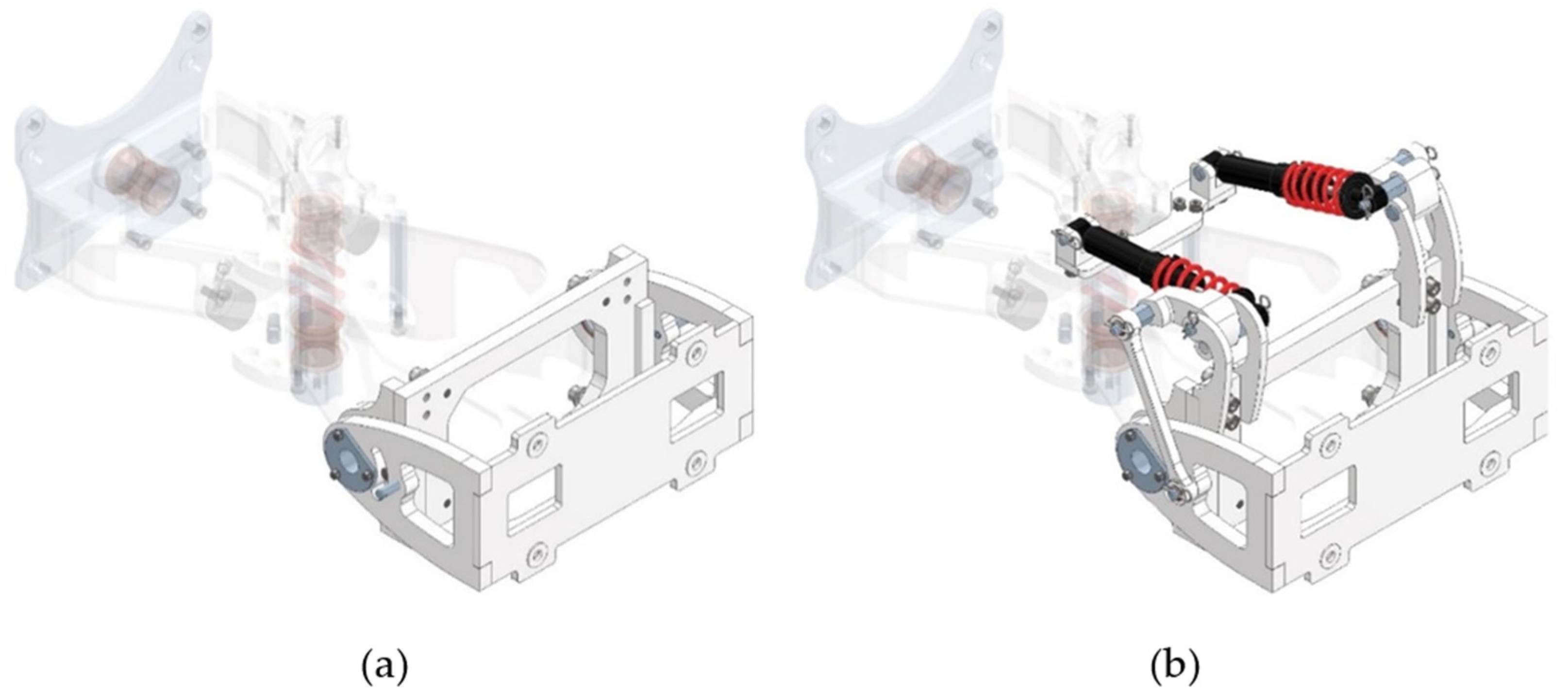

- Base Module: It is the main connecting element of two standard vehicle modules. It is also the supporting module to which all the other modules are attached.

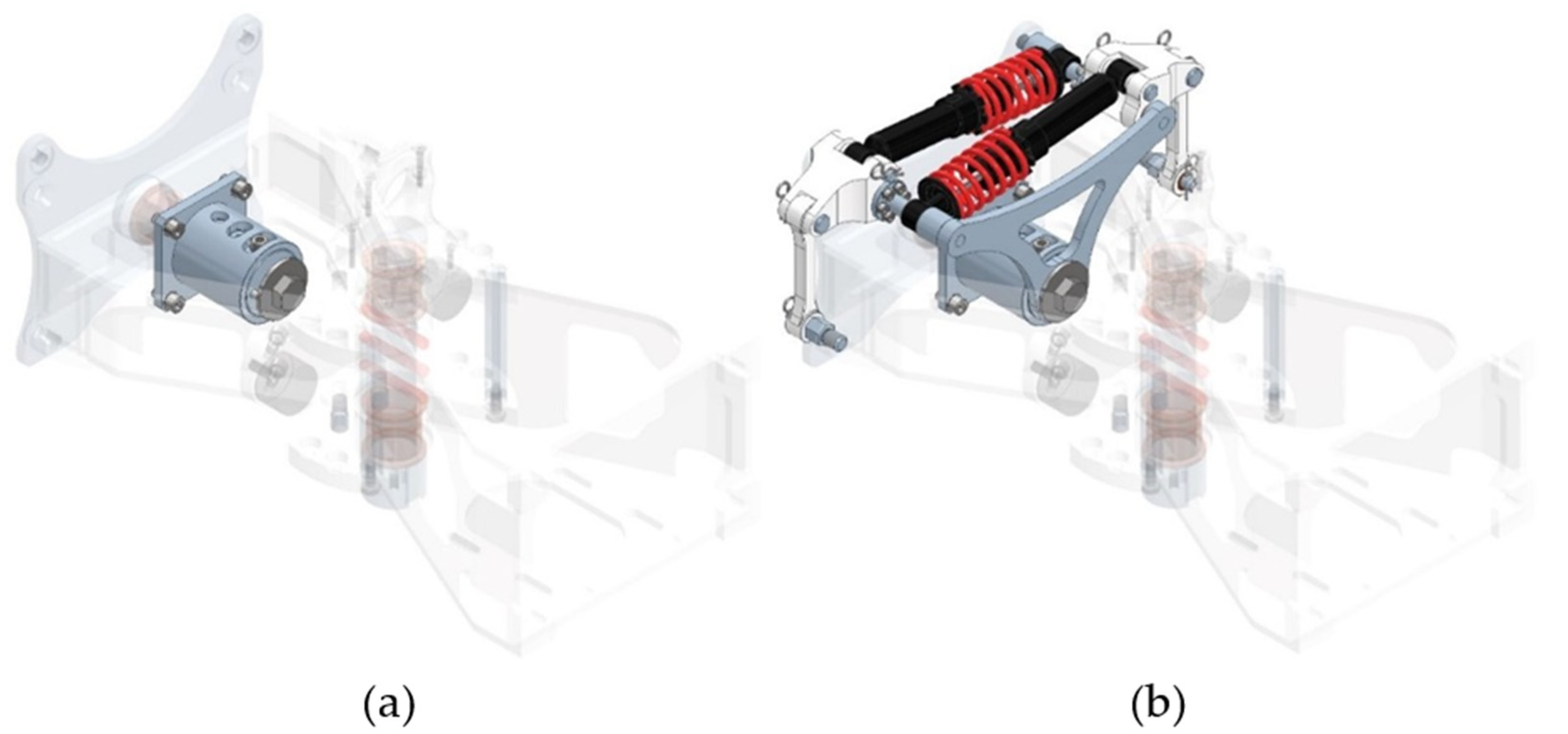

- Steering Module: Composed of a motor assembly with a cycloidal gearbox and a chain drive. It serves to control the direction of the vehicle.

- Lateral Tilt Module: Allows the mutual lateral tilting of two consecutive standard vehicle modules.

- Lateral Tilt Damping Module: An additional module for the lateral tilt module. It serves to dampen shocks from lateral tilting. Its use is particularly beneficial when driving at higher speeds on uneven terrain.

- Longitudinal Tilt Module: Allows the mutual longitudinal tilting of two consecutive standard vehicle modules.

- Longitudinal Tilt Damping Module: An additional module for the longitudinal tilt module. It serves to dampen shocks from longitudinal tilting. Its use is particularly beneficial when driving at higher speeds on uneven terrain.

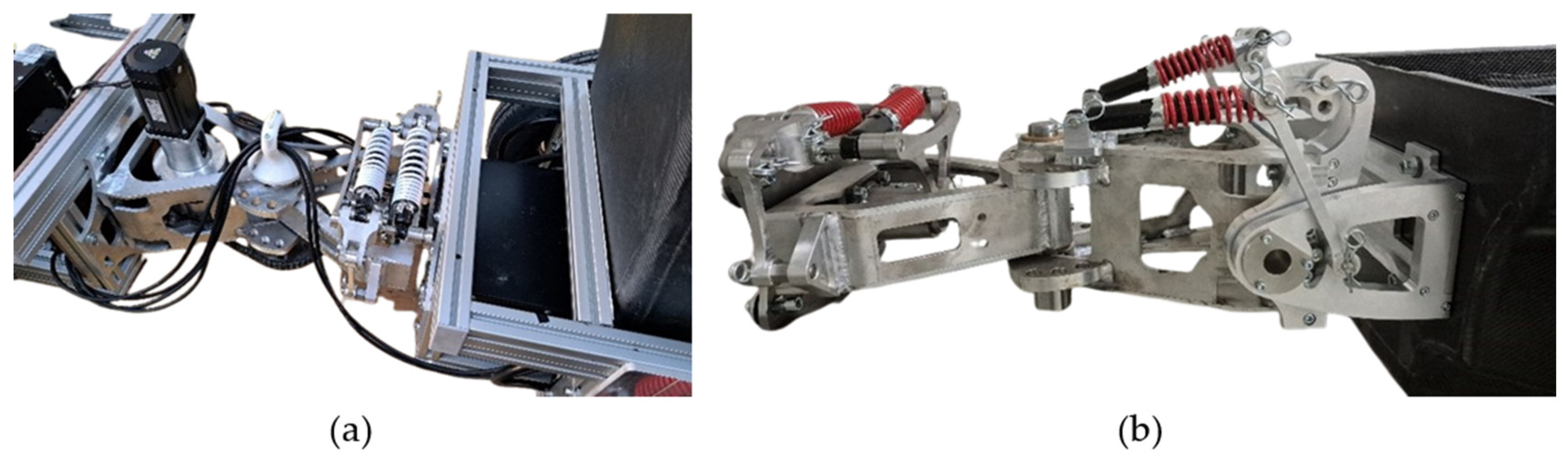

3. Prototype Manufacturing

4. Driving Tests

5. Discussion

6. Conclusions

7. Patents and Utility Models

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, J.; Wang, G.; Zhao, H.; Sun, K. Study on electromechanical performance of steering of the electric articulated tracked vehicles. J. Mech. Sci. Technol. 2019, 33, 3171–3185. [Google Scholar]

- Trancossi, M.; Pascoa, J.; Xisto, C. Design of an innovative off road hybrid vehicle by energy efficiency criteria. Int. J. Heat Technol. 2016, 34, S387–S395. [Google Scholar]

- Tong, Z.-M.; Miao, J.-Z.; Li, Y.-S.; Tong, S.-G.; Zhang, Q.; Tan, G.-R. Development of electric construction machinery in China: A review of key technologies and future directions. J. Zhejiang Univ. Sci. A 2021, 22, 245–264. [Google Scholar]

- Wei, F.; Walls, W.; Zheng, X.; Li, G. Evaluating environmental benefits from driving electric vehicles: The case of Shanghai, China. Transp. Res. Part D Transp. Environ. 2023, 119, 103749. [Google Scholar] [CrossRef]

- Ajanovic, A.; Haas, R. On the environmental benignity of electric vehicles. J. Sustain. Dev. Energy Water Environ. Syst. 2019, 7, 416–431. [Google Scholar] [CrossRef]

- Ivković, N. An Analysis of the Environmental Impact of Electric Vehicles. Put I Saobraćaj 2022, 68, 43–50. [Google Scholar]

- Hawkins, T.R.; Gausen, O.M.; Strømman, A.H. Environmental impacts of hybrid and electric vehicles—A review. Int. J. Life Cycle Assess. 2012, 17, 997–1014. [Google Scholar]

- Hernandez, M.; Messagie, M.; Hegazy, O.; Marengo, L.; Winter, O.; Van Mierlo, J. Environmental impact of traction electric motors for electric vehicles applications. Int. J. Life Cycle Assess. 2017, 22, 54–65. [Google Scholar]

- Ghobadpour, A.; Monsalve, G.; Cardenas, A.; Mousazadeh, H. Off-road electric vehicles and autonomous robots in agricultural sector: Trends, challenges, and opportunities. Vehicles 2022, 4, 843–864. [Google Scholar] [CrossRef]

- Un-Noor, F.; Wu, G.; Perugu, H.; Collier, S.; Yoon, S.; Barth, M.; Boriboonsomsin, K. Off-road construction and agricultural equipment electrification: Review, challenges, and opportunities. Vehicles 2022, 4, 780–807. [Google Scholar] [CrossRef]

- Poullikkas, A. Sustainable options for electric vehicle technologies. Renew. Sustain. Energy Rev. 2015, 41, 1277–1287. [Google Scholar]

- Kim, Y.-H. Study on Modularization of Components for Cost Reduction of Sail Yacht Steering System. J. Ocean Eng. Technol. 2020, 34, 469–474. [Google Scholar] [CrossRef]

- He, X.; Jiang, Y. Review of hybrid electric systems for construction machinery. Autom. Constr. 2018, 92, 286–296. [Google Scholar]

- Huang, X.; Huang, Q.; Cao, H.; Yan, W.; Cao, L.; Zhang, Q. Optimal design for improving operation performance of electric construction machinery collaborative system: Method and application. Energy 2023, 263, 125629. [Google Scholar] [CrossRef]

- Lin, T.; Lin, Y.; Ren, H.; Chen, H.; Chen, Q.; Li, Z. Development and key technologies of pure electric construction machinery. Renew. Sustain. Energy Rev. 2020, 132, 110080. [Google Scholar]

- Quan, Z.; Ge, L.; Wei, Z.; Li, Y.W.; Quan, L. A survey of powertrain technologies for energy-efficient heavy-duty machinery. Proc. IEEE 2021, 109, 279–308. [Google Scholar]

- Huang, X.; Yan, W.; Cao, H.; Chen, S.; Tao, G.; Zhang, J. Prospects for purely electric construction machinery: Mechanical components, control strategies and typical machines. Autom. Constr. 2024, 164, 105477. [Google Scholar]

- Gao, J.; Qi, X. Handling performance analysis and optimization of a vehicle with considering the influence of steering shaft parameters. J. Mech. Sci. Technol. 2023, 37, 569–582. [Google Scholar]

- Skurjat, A. The effect of steering axis inclination on the dynamic stability of vehicles with an articulated steering. Sci. Rep. 2025, 15, 676. [Google Scholar]

- Shi, G.; Zhao, Q.; Wang, J.; Dong, X. Research on reinforcement learning based on PPO algorithm for human-machine intervention in autonomous driving. Electron. Res. Arch. 2024, 32. [Google Scholar] [CrossRef]

- Łopatka, M.J.; Rubiec, A. Concept and preliminary simulations of a driver-aid system for transport tasks of articulated vehicles with a hydrostatic steering system. Appl. Sci. 2020, 10, 5747. [Google Scholar] [CrossRef]

- Xu, T.; Shen, Y.; Huang, Y.; Khajepour, A. Study of hydraulic steering process for articulated heavy vehicles based on the principle of the least resistance. IEEE ASME Trans. Mechatron. 2019, 24, 1662–1673. [Google Scholar]

- Zhang, Q.; Wang, X.; Tong, Z.; Cheng, Z.; Liu, X. Experimental Study on Structure Optimization and Dynamic Characteristics of Articulated Steering for Hydrogen Fuel Cell Engineering Vehicles. World Electr. Veh. J. 2024, 15, 306. [Google Scholar] [CrossRef]

- Tesar, J.S.; Cohen, C.J.; Obermark, J. Articulated joint for a high-mobility modular vehicle. In Unmanned Ground Vehicle Technology III; SPIE: Bellingham, WA, USA, 2001; pp. 97–104. [Google Scholar]

- Yanda, S.; Murali, G.B.; Raju, S.S.; Duckworth, B.J.; Sen, C.; Chadha, S.S. Design optimization of universal joints for all-terrain vehicles. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; p. 012012. [Google Scholar]

- Spofford, J.R.; Herron, J.B.; Anhalt, D.J.; Morgenthaler, M.K.; DeHerrera, C. Off-road perception testbed vehicle design and evaluation. In Unmanned Ground Vehicle Technology V; SPIE: Bellingham, WA, USA, 2003; pp. 347–357. [Google Scholar]

- Christensen, T.B. Modularised eco-innovation in the auto industry. J. Clean. Prod. 2011, 19, 212–220. [Google Scholar] [CrossRef]

- Rushton, G.J.; Zakarian, A. Modular vehicle architectures: A systems approach. Insight 2000, 3, 23–27. [Google Scholar]

- Martin, L.; Dominik, M.; Russo, S.P. Impact of electromobility on automotive architectures. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), IEEE, Barcelona, Spain, 17–20 November 2013; pp. 1–8. [Google Scholar]

- Stopka, M.; Kohar, R.; Weis, P.; Šteininger, J. Concept of modular 3D printer construction. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012092. [Google Scholar]

- Cecutti, C.; Agius, D. Ecotoxicity and biodegradability in soil and aqueous media of lubricants used in forestry applications. Bioresour. Technol. 2008, 99, 8492–8496. [Google Scholar]

- Müller-Zermini, B.; Gaule, G. Environmental approach to hydraulic fluids. Lubr. Sci. 2013, 25, 287–296. [Google Scholar]

- Morledge, R.; Jackson, F. Reducing environmental pollution caused by construction plant. Environ. Manag. Health 2001, 12, 191–206. [Google Scholar] [CrossRef]

- Mobarak, H.; Mohamad, E.N.; Masjuki, H.; Kalam, M.; Al Mahmud, K.; Habibullah, M.; Ashraful, A. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar]

- Xin, Z.; Jiang, Q.; Zhu, Z.; Shao, M. Design and optimization of a new terrain-adaptive hitch mechanism for hilly tractors. Int. J. Agric. Biol. Eng. 2023, 16, 134–144. [Google Scholar]

- Adebayo, R.; Ogundipe, O.B.; Bolarinwa, O.G. Development of a motorcycle trailer hitch for commercial purposes. Int. J. Eng. Appl. Sci. Technol. 2021, 6, 17–23. [Google Scholar] [CrossRef]

- Skyba, R.; Hrček, S.; Smetánka, L.; Majchrák, M. Strength analysis of slewing bearings. Transp. Res. Procedia 2019, 40, 891–897. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, G.; Cheng, F.; Miao, Z.; Zhou, S. Design and optimization of the steering system of transport vehicle for large-scale wind turbine blade. In Proceedings of the 2011 International Conference on Fluid Power and Mechatronics, IEEE, Beijing, China, 17–20 August 2011; pp. 1–5. [Google Scholar]

- García, P.L.; Crispel, S.; Saerens, E.; Verstraten, T.; Lefeber, D. Compact gearboxes for modern robotics: A review. Front. Robot. AI 2020, 7, 103. [Google Scholar] [CrossRef]

- Majchrák, M.; Kohár, R.; Hrček, S.; Brumerčík, F. The comparison of the amount of backlash of a harmonic gear system. Teh. Vjesn. 2021, 28, 771–778. [Google Scholar]

- Semjon, J.; Hajduk, M.; Jánoš, R.; Tuleja, P. Procedure selection bearing reducer twinspin for robotic arm. Appl. Mech. Mater. 2013, 245, 261–266. [Google Scholar] [CrossRef]

- Kočiško, M.; Baron, P.; Paulišin, D. Research of Dynamic Characteristics of Bearing Reducers of the TwinSpin Class in the Start-Up Phase and in the Initial Operating Hours. Machines 2023, 11, 595. [Google Scholar] [CrossRef]

- Belorit, M.; Hrcek, S.; Gajdosik, T.; Steininger, J. Description of the bearing check program for countershaft gearboxes. In Proceedings of the 58th International Conference of Machine Design Departmens (ICDM), Prague, Czech Republic, 6–8 September 2017; pp. 32–35. [Google Scholar]

| Layout Variant | Basic Module | Steering Module | Lateral Tilting Module | Lateral Tilting Damping Module | Longitudinal Tilting Module | Longitudinal Tilting Damping Module |

|---|---|---|---|---|---|---|

| 1 | Yes | X | X | X | X | X |

| 2 | Yes | Yes | X | X | X | X |

| 3 | Yes | X | Yes | X | X | X |

| 4 | Yes | Yes | Yes | X | X | X |

| 5 | Yes | X | Yes | X | Yes | X |

| 6 | Yes | Yes | Yes | X | Yes | X |

| 7 | Yes | X | Yes | Yes | X | X |

| 8 | Yes | Yes | Yes | Yes | X | X |

| 9 | Yes | X | Yes | Yes | Yes | X |

| 10 | Yes | Yes | Yes | Yes | Yes | X |

| 11 | Yes | X | Yes | Yes | Yes | Yes |

| 12 | Yes | Yes | Yes | Yes | Yes | Yes |

| 13 | Yes | X | X | X | Yes | X |

| 14 | Yes | Yes | X | X | Yes | X |

| 15 | Yes | X | X | X | Yes | Yes |

| 16 | Yes | Yes | X | X | Yes | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gajdošík, T.; Gajdáč, I.; Madaj, R.; Vereš, M. Concept for an Electromechanical Connection and Steering Joint for a Small Off-Road Electric Vehicle. Vehicles 2025, 7, 30. https://doi.org/10.3390/vehicles7020030

Gajdošík T, Gajdáč I, Madaj R, Vereš M. Concept for an Electromechanical Connection and Steering Joint for a Small Off-Road Electric Vehicle. Vehicles. 2025; 7(2):30. https://doi.org/10.3390/vehicles7020030

Chicago/Turabian StyleGajdošík, Tomáš, Igor Gajdáč, Rudolf Madaj, and Matúš Vereš. 2025. "Concept for an Electromechanical Connection and Steering Joint for a Small Off-Road Electric Vehicle" Vehicles 7, no. 2: 30. https://doi.org/10.3390/vehicles7020030

APA StyleGajdošík, T., Gajdáč, I., Madaj, R., & Vereš, M. (2025). Concept for an Electromechanical Connection and Steering Joint for a Small Off-Road Electric Vehicle. Vehicles, 7(2), 30. https://doi.org/10.3390/vehicles7020030