Abstract

Water–copper is one of the most common combinations of working fluid and heating surface in high-performance cooling systems. Copper is usually selected for its high thermal conductivity and water for its high heat transfer coefficient, especially in the two-phase regime. However, copper tends to suffer oxidation in the presence of water and thus the heat flux performance is affected. In this research, an experimental investigation was conducted using a cooper bare surface as a heating surface under a constant mass flux of 600 kg·m·s of deionized water at a subcooled inlet temperature of 70 K under atmospheric pressure conditions on a closed-loop. To confirm the heat transfer deterioration, the experiment was repeated thirteen times. On the flow boiling region after thirteen experiments, the results show an increase in the wall superheat of approximately 26% and a reduction in the heat flux of approximately 200 kW·m. On the other hand, the effect of oxidation on the single phase is almost marginal.

1. Introduction

Subcooled flow boiling is a common technique used in cooling systems due to its high heat flux removal ability. One of the most common combinations in heat exchangers are the water as working fluid and copper as heating surface, due to their high heat transfer coefficient. This combination has a reported heat flux of higher than 2500 kW·m under atmospheric pressure conditions [1,2,3]. In addition, researchers have reported an increment in the heat flux on modified surfaces such as porous materials, coating surfaces, rough surfaces, micro-channeled structures, etc. They have reported a flow boiling heat transfer enhancement that is approximately 2 times higher than the non-treated heating surfaces and the effects of the nucleation sites density (NSD) [4,5]. However, the influence of the oxidation on the heating surface affects the heat transfer performance, especially during the boiling operation, as an oxide layer is formed on the heating surface and the characteristic color of the copper changes; thus, the hydrophilic characteristics also change, particularly the bubble static contact angle which presents an increment [6,7,8]. Kim et al. [9] investigated the heat transfer coefficient and the critical heat flux on smart TiO- and ZnO-coated smart surfaces. They found an increment in the heat transfer coefficient (HTC) and a reduction in the CHF under low mass fluxes due to the effect of the wettability and the contact angle of the working fluid with the heating surface. Copper surfaces are stable in pure water; nevertheless, if oxygen is added to the working fluid, copper oxide I (CuO) or copper oxide II (CuO) is formed on the copper surface. The amount of copper oxide on the surface depends on the electrochemical potential and the concentration of oxygen in the water [10,11]. A copper oxidation layer on flow boiling process consists of a four-step process: (I) formation of small particles of oxide; (II) release, the particles detached from the surface; (III) migration, particles swept along by the water flow; and (IV) copper oxide particles suffer from a re-deposition forming an oxide layer [12,13]. In 1990, Moliere et al. [14] reported a decrement in the cooling efficiency of electric turbo-generators. The heat flux removal is affected by copper oxidation clogging in the hollow strands. They found that if the oxygen concentration in the water is approximately 2–3 mg/L O, an oxidation layer (CuO) is formed on the surface in approximately 200 h. On the other hand, if the oxygen concentration is lower, approximately 20 μg/L O many of the copper oxidation layers are removed by the working fluid flow which produces clogging in the system. Vlachou et al. [15] reported a reduction in the heat flux by 10% for the aged surface after 24 h of boiling operation in comparison with the fresh and polished heating surface, for which they also reported that there was an increment in the bubble angle contact on the aged surface. In 2019, Jayaramu et al. [16] conducted a flow boiling experiment in a copper microchannel using three different heating surfaces: a freshly machined surface, an aged surface (the first surface after oxidation), and finally, a cleaned surface (the second surface after cleaning it with 0.1 M hydrochloric acid). They reported that an increment in the roughness induces more active nucleation sites, resulting an increment in the boiling heat transfer. However, the aged surface presented a reduction in the heat flux, and an increment in the wall superheat in comparison with the other two surfaces. This effect is attributed to the increased wettability caused by copper oxidation. In addition, the onset nucleation boiling depends on the size of cavity holes, the shape of the cavity holes, and the surface wettability. In general, the aged surfaces present lower wettability than the freshly machined surfaces due to the high surface energy of the copper oxide layer [17,18]. Kim et al. [17] conducted experimental research using a roughness superhydrophilic aluminum surface and roughness copper surface and the results show the degradation of the heat transfer coefficient in comparison with the copper surfaces. They highlighted the flooding of the scratch, holes, or cavities—as well as the higher wettability between the surfaces and the water higher the contact area. Wang et al. [19,20,21] performed different experiments to analyze the effects of surface oxidation on the heat flux in pool boiling. They found a gradual oxidation process that promotes a deterioration on the heat transfer performance. Recently, researchers have focused on the influence of the oxide layer on heat transfer performance. Takemura et al. [22] studied the effect of the oxide layer on a warmed copper surface, analyzed the deposition of nanoscopic warm oxidation particles and concluded that the oxidation layer contained a hydrophilic compound. This effect increases the contact angle and reduces the wettability. Aromma et al. [23] analyzed the cooper oxidation as a function of the time at low air temperatures between 60 °C and 100 °C. They found an abrupt increment in oxidation at 80 °C and higher, and thus the risk of corrosion also increases. The effect of the oxidation on the critical heat flux (CHF) was experimentally analyzed by Trojer et al. [24]. An increment in the CHF up to 70% was found, an enhancement which was attributed to the super-hydrophilic surface created by the oxidized low carbon steel reactor pressure vessel.

Although previous researchers have focused on copper oxidation and its effects on heat transport phenomena, the oxidation layer effects on subcooled flow boiling need to be considered in the design of high-performance cooling systems. The present research presents the effect of the copper oxide layer on the heat transfer performance in both the single-phase and two phases regions. The results of a subcooled flow boiling experiment which was repeatedly conducted to verify the heat flux of a polished copper surface and an aged (oxidized) surface, for a total of approximately 52 heating hours are discussed subsequently.

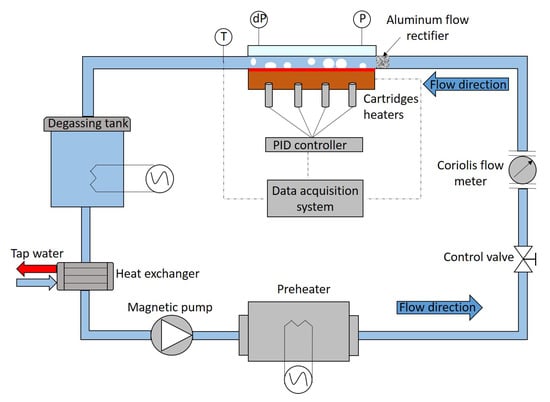

2. Experimental Setup for Flow Boiling

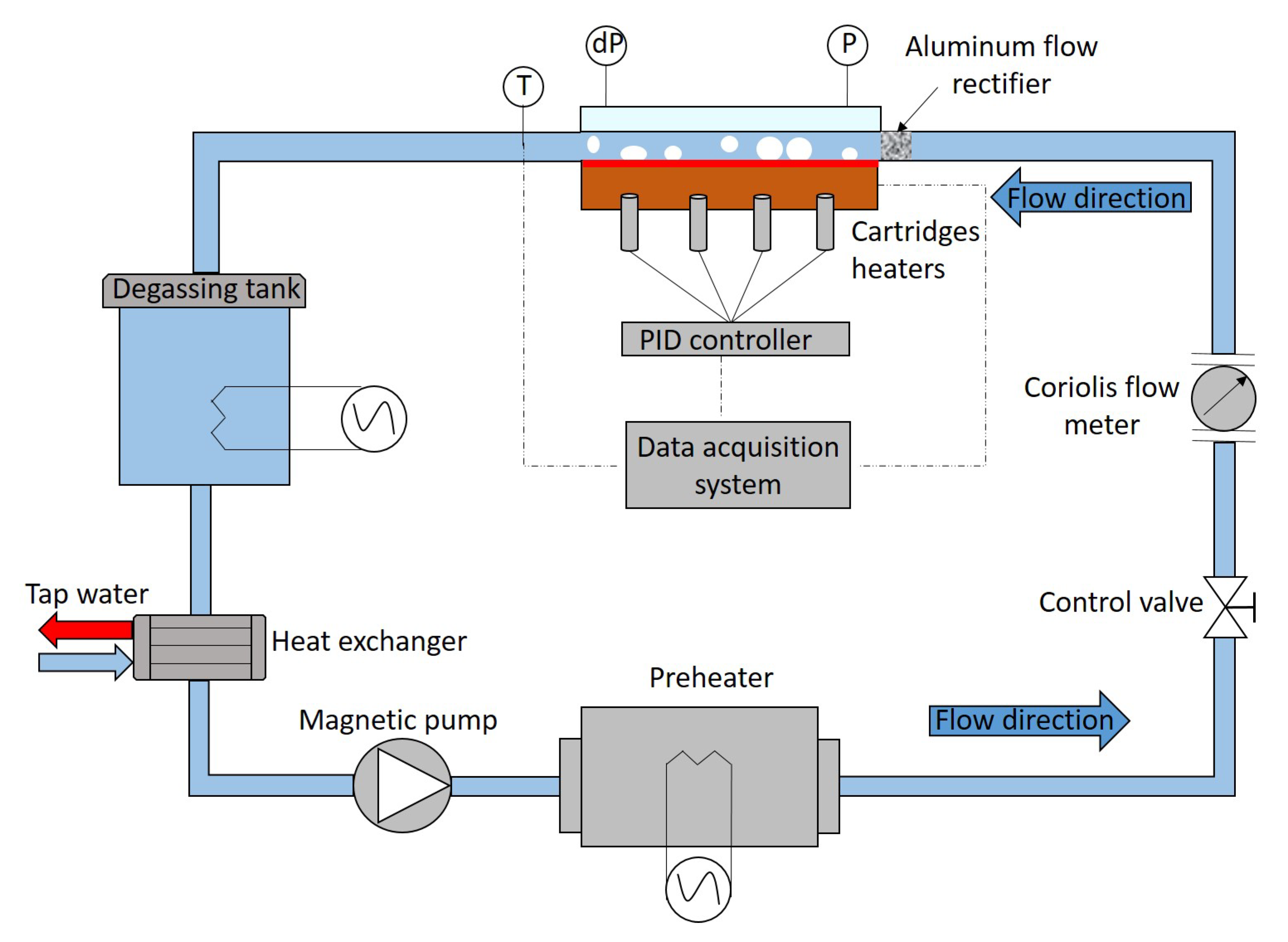

In order to investigate the effect of the copper oxide layer in the horizontal subcooled flow boiling heat flux, the experimental apparatus used in the present research has the same setup to that used in [25,26]. To analyze the effect of the oxidation on the heat flux, high inlet subcooling temperature and high mass flux were selected. Figure 1 shows the experimental apparatus where deionized water was used as working fluid. A 40 L tank was installed to perform the degassing of the working fluid. To reduce the temperature of the deionized water after the degassing process, a 20 cooling tubes heat exchanger with a maximum capacity of 40 l/s was used. A magnetic pump “IWAKI” was used to circulate the working fluid through the test loop. Just after the magnetic pump, a preheater was used to control the inlet subcooling temperature. In the present research, the inlet subcooling temperature was set in K. The mass flux was measured by a Coriolis flow meter and regulated using a control valve installed at the inlet part of the flow meter. Then, the water flowed into the test section, where at the inlet part, an aluminum flow rectifier was used to mix the bulk temperature, rectify the flow, as well as prevent impurities in the heating section. A group of 12 cartridges heaters was inserted in a copper block; the cartridges were controlled and monitored by a PID controller that was also connected to the data acquisition system. The maximum heat flux provided by the cartridges was approximately 2200 kW·m. At the inlet and outlet part of the test section, pressure gages and differential pressure gages were installed. All the data were collected using a data logger MX100 and analyzed in real time. The working fluid returned to the degassing tank and the cycle started again until the maximum capacity of the copper block was reached or the safety operation temperature condition reached 580 °C (approximately 2200 kW·m). Detailed information of the experimental conditions are given in Table 1.

Figure 1.

Experimental apparatus.

Table 1.

Experimental conditions.

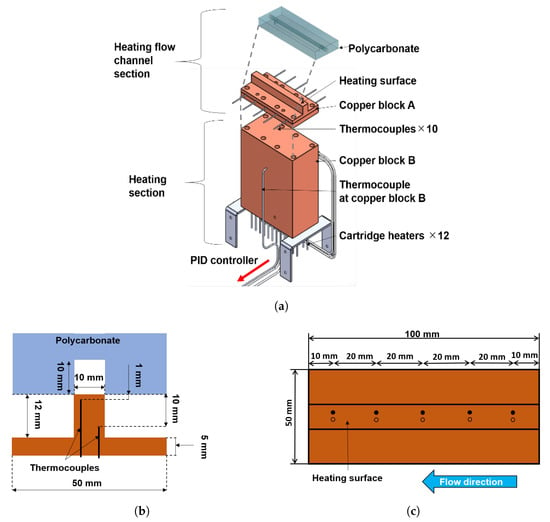

2.1. Test Section

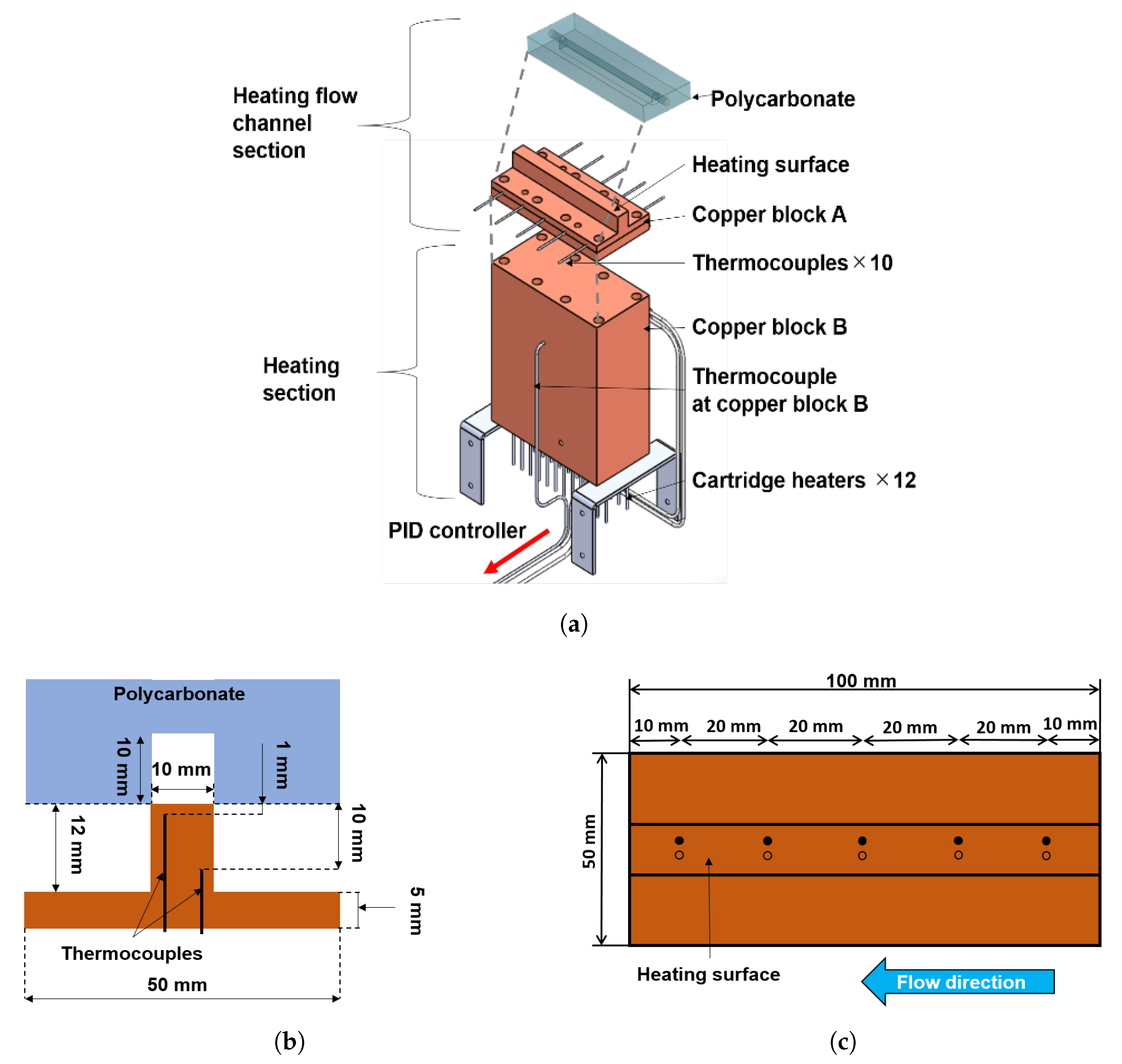

The test section consists of a group of two copper blocks. Figure 2a shows the copper block B where the group of 12 cartridge heaters is installed. The heat is transferred from copper block B to copper block A. This last copper block consists of two pieces of copper, between which a total of 10 thermocouples K-type are inserted to measure the local temperature, which are divided into 5 groups of 2. The distance between each group is 20 mm and the heating surface is a 10 mm × 100 mm area as shown in Figure 2c. The heating surface was covered with a polycarbonate that enables the visualization of the flow and bubble pattern. The flow channel formed between the heating surface and the polycarbonate is 10 mm × 10 mm × 100 mm. The distance between each group of two thermocouples was measured in 9 mm as shown in Figure 2b.

Figure 2.

Test section details: (a) test section (heating copper block); (b) flow channel; and (c) heating surface.

2.2. Experimental Procedure

In order to clarify the influence of the copper oxidation layer on the heat flux and wall superheat, a total of 13 experiments (around 52 heating hours using the same experimental loop) were performed under the same experimental conditions using a polished bare surface. The experiment was conducted under sea-level atmospheric pressure conditions. Deionized water was used as the working fluid. To ensure the absence of micro bubbles in the working fluid, two-hour degassing was conducted before each experiment. After the degassing process, the tap water flowed into the heat exchanger to reduce the water temperature. The pump is activated and the mass flux and inlet subcooling temperature were adjusted. To analyze the effect of the oxide layer on the heat flux in the single-phase and two-phase flow, the temperature of the copper block B was heated to 60 °C. After reaching stable conditions, the data were recorded for three minutes, and then the temperature of the copper block B was increased in steps of 40 °C and the step was repeated. To avoid damage to the experimental apparatus, the experiment was stopped when the copper block B temperature reached 580 °C or if the maximum heat flux of 2200 kW·m is reached.

2.3. Uncertainty Analysis

In this experiment, two kinds of thermocouples were used to measure the temperature. The ten thermocouples inserted in copper block A have a measurement error of 0.05 K; on the other hand, the thermocouple inserted in the copper block B has a measurement error of 0.2 K. The total error on the distance measurement is 0.02 mm. In general, the heat flux in the test section was calculated by the temperature measured on each pair of thermocouples and the distance difference between each pair of them, using a one dimensional Fourier law as shown in Equation (1), where is the distance between each thermocouple, is the temperature difference, is the copper thermal conductivity and q the heat flux. The total amount of heat flux was determined by the average of the five pairs of thermocouples. The uncertainty analysis of the heat flux was calculated by Equation (2):

The experimental heat flux error was calculated in approximately 3% at low heat fluxes and 1% at heat fluxes of 500 kW·m and above. Otomo et al. and Galicia et al. [25,26] provided extensive details on the data acquisition and experimental setup and its instrumentation.

3. Results

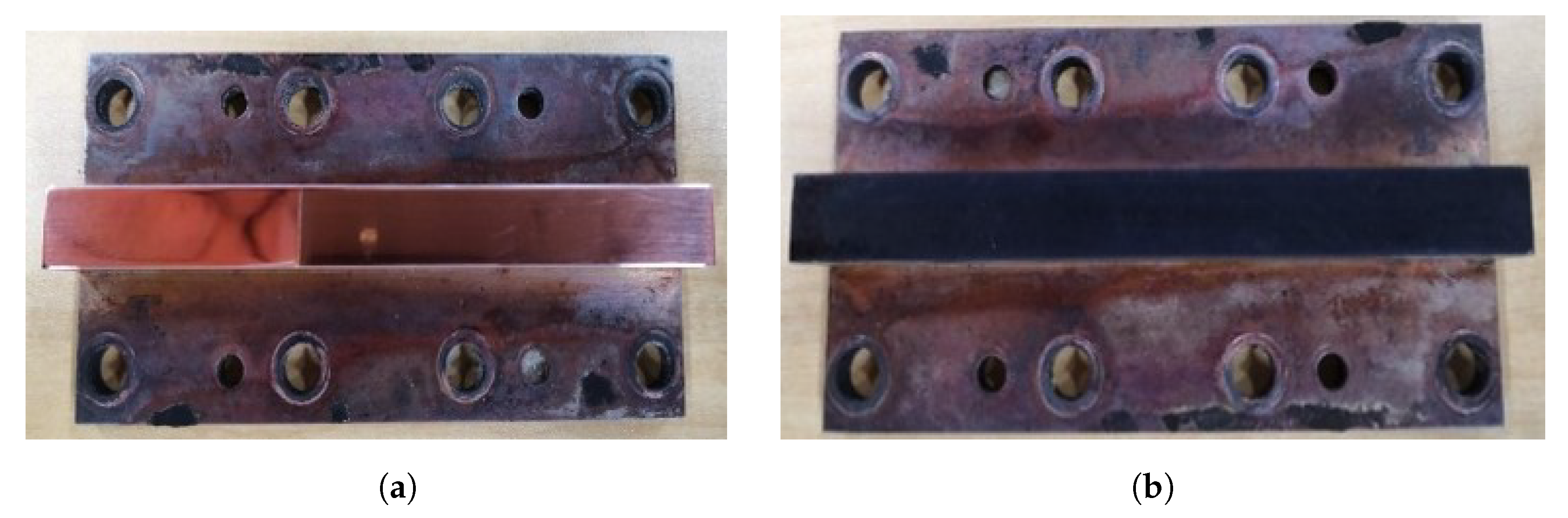

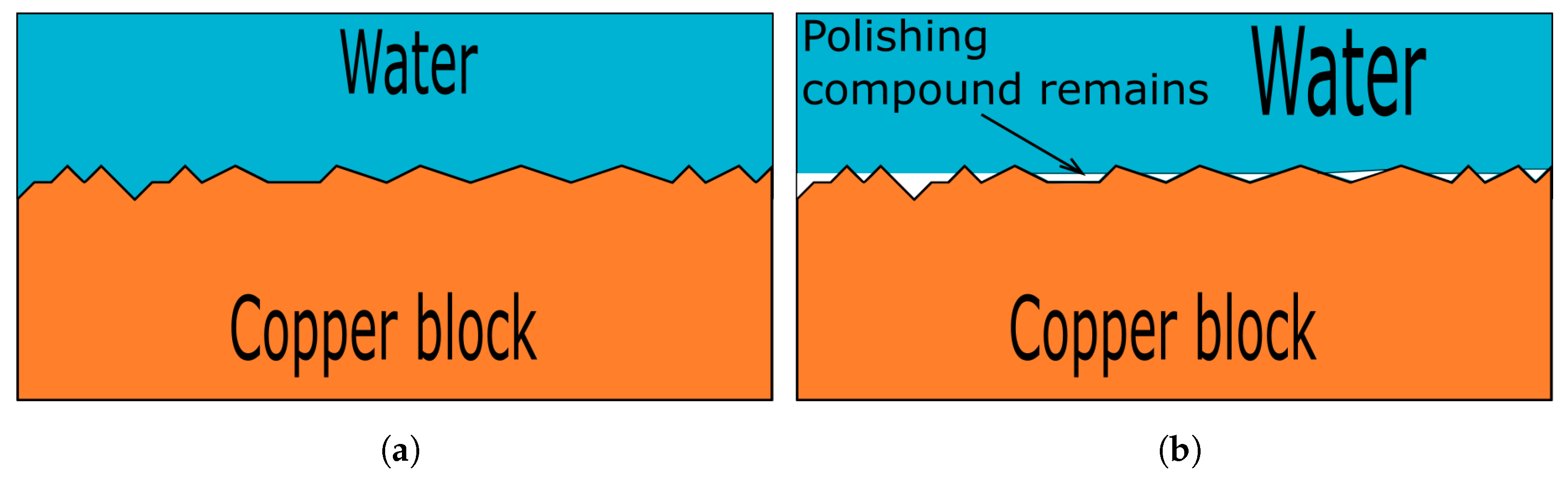

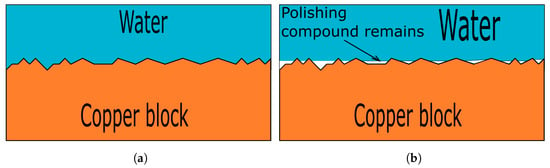

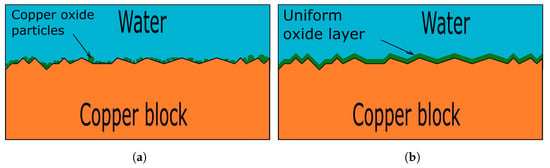

After performing 13 experiments, a black copper layer oxidation was clearly formed by the deposition on the heating surface. Figure 3a shows the polished copper surface before the experiments, and on the other hand, Figure 3b shows the oxidized surface after 13 experiments under the same conditions. The polished surface was polished with a Tamiya polishing compound in its three presentations: coarse, fine, and finally with the finish compound. The color of the surface copper block showed a considerable change in the color and the surface rugosity. A small oxidation layer is formed on the heated surface covering nucleation sites and scratches on the surface, and it increases with the number of experiments. A reduction in the heat transfer coefficient was confirmed.

Figure 3.

Copper surface before and after the formation of the oxide layer: (a) polished copper surface; and (b) oxidized surface after 13 experiments.

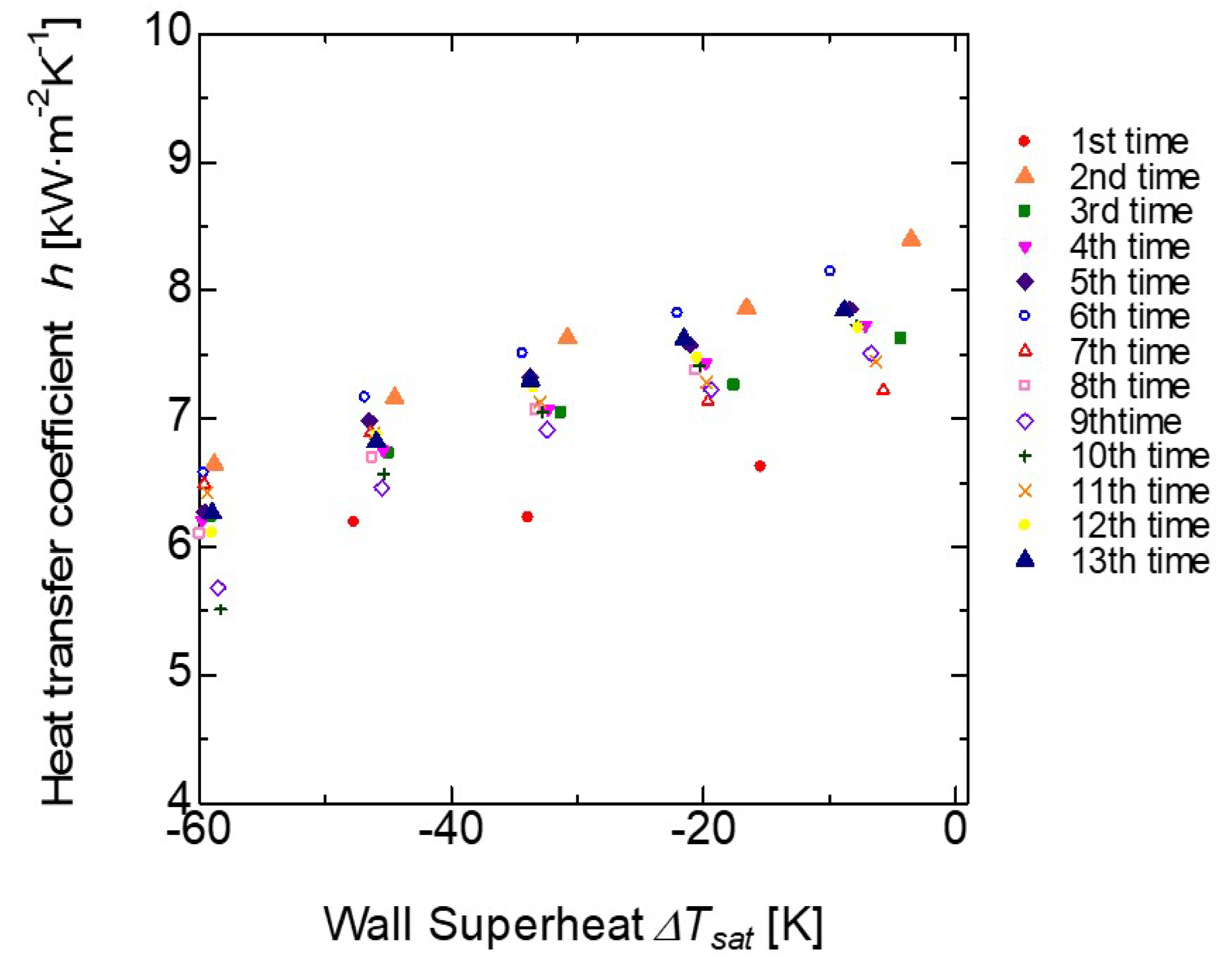

3.1. Single-Phase Heat Flux

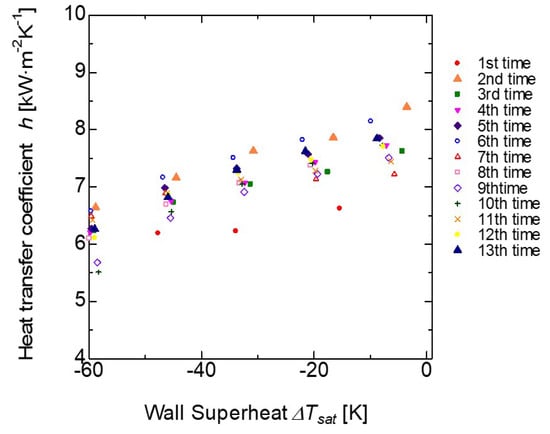

The copper oxidation effect on the heat flux in the single-phase regime is shown in Figure 4. For its easy comprehensibility, the single-phase region was considered when K. The influence of the oxidation on the heat flux is minimal in the single-phase region due to the absence of bubbles, despite the nucleation site density (NSD) being lower for the oxidized surface, it does not have a notable influence over the heat flux performance. The first experiment showed a slight reduction in the heat flux at the same wall superheat temperature, a phenomenon which is attributed to the polishing compound remains; as shown in Figure 5a,b, these remains are removed by the vigorous bubble activity in the flow boiling during the first experiment. This phenomenon was confirmed with the analysis of the heat transfer coefficient, as shown in Figure 6. The first experiment shows the lowest heat transfer coefficient h (approximately 7 kW·m−2K−1), and the HTC increases if the NSD also increases due to the absence of polishing compound remains on the heating surface. An increment in the HTC in the second experiment of approximately 20% in comparison with the first experiment was confirmed. However, from the second experiment to the thirteenth experiment, the heat transfer coefficient did not show significant variation. Despite the oxide layer formed on the surface, the HTC and heat flux variation can be neglected due to the absence of bubble activity. Each experiment took approximately 4 h heating, thus after the 13 experiments, it could be considered a heated surface under 52 h of oxidation approximately. To reduce the oxidation produced by the water during the non-heating time, water was removed by compressed air and all the experiments were finished within 3 days.

Figure 4.

Heat flux in the single-phase region.

Figure 5.

Fresh machined and polished surface comparison: (a) fresh machined surface; and (b) polished surface.

Figure 6.

Heat transfer coefficient in the single-phase region.

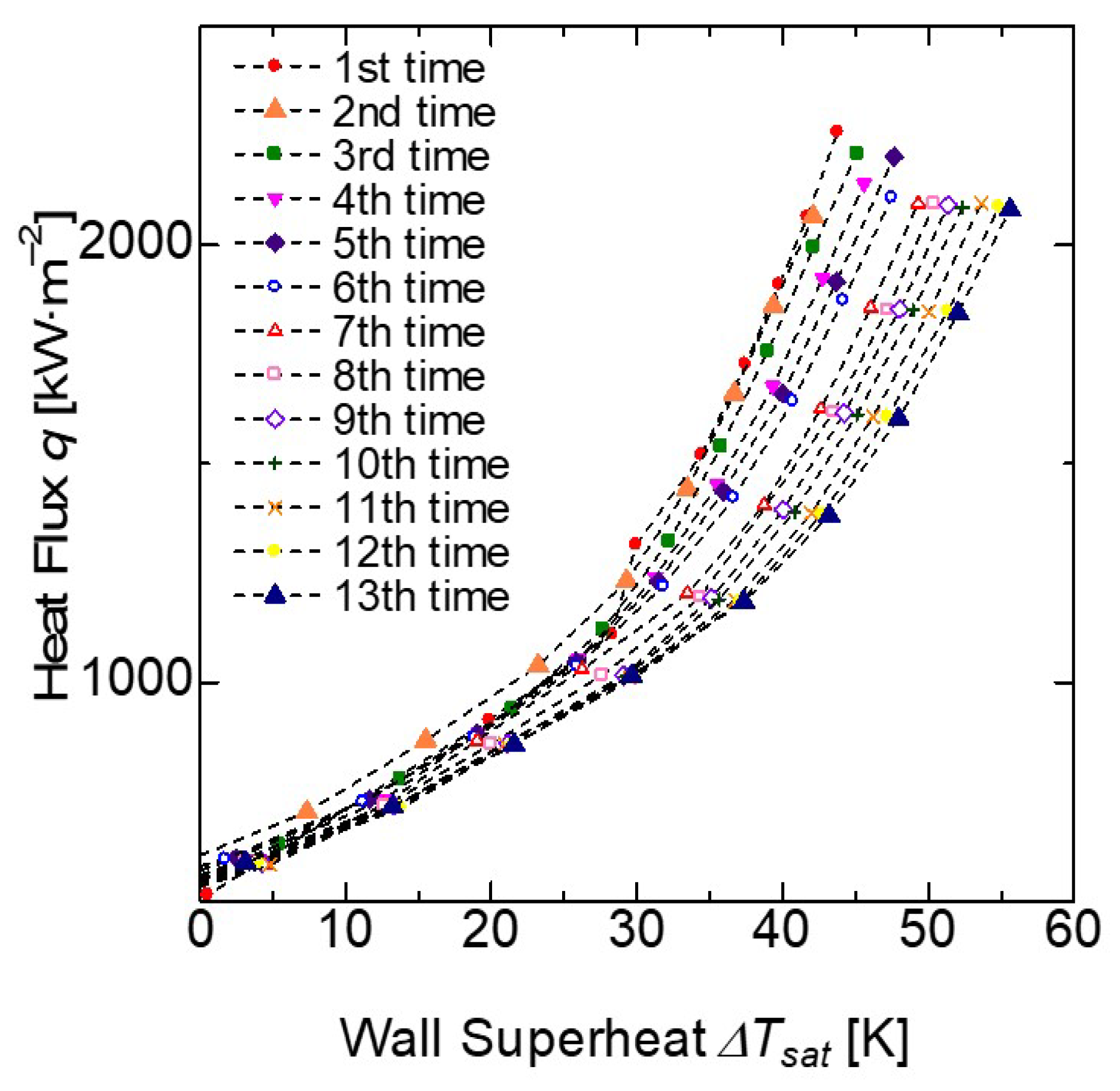

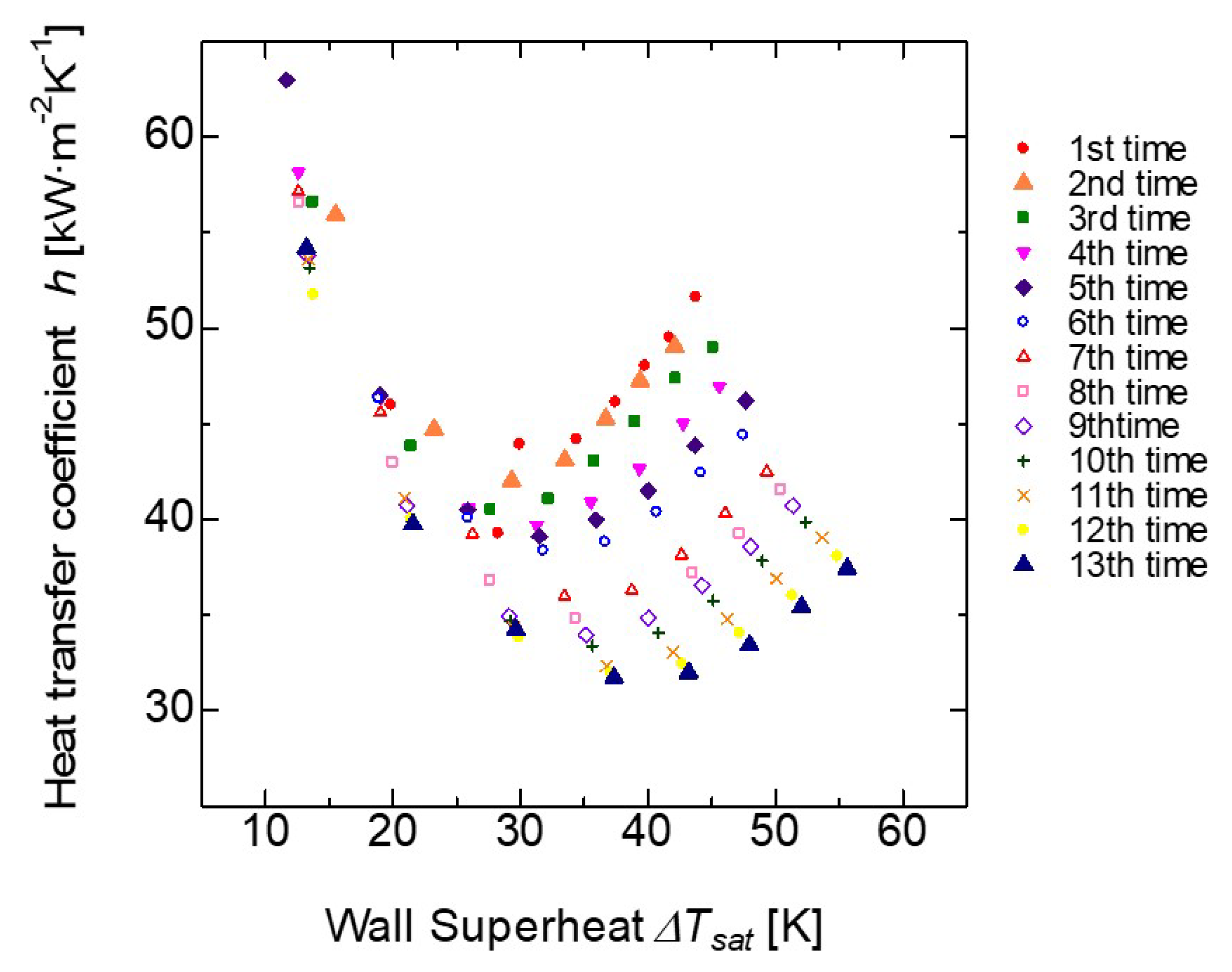

3.2. Two-Phase Heat Flux

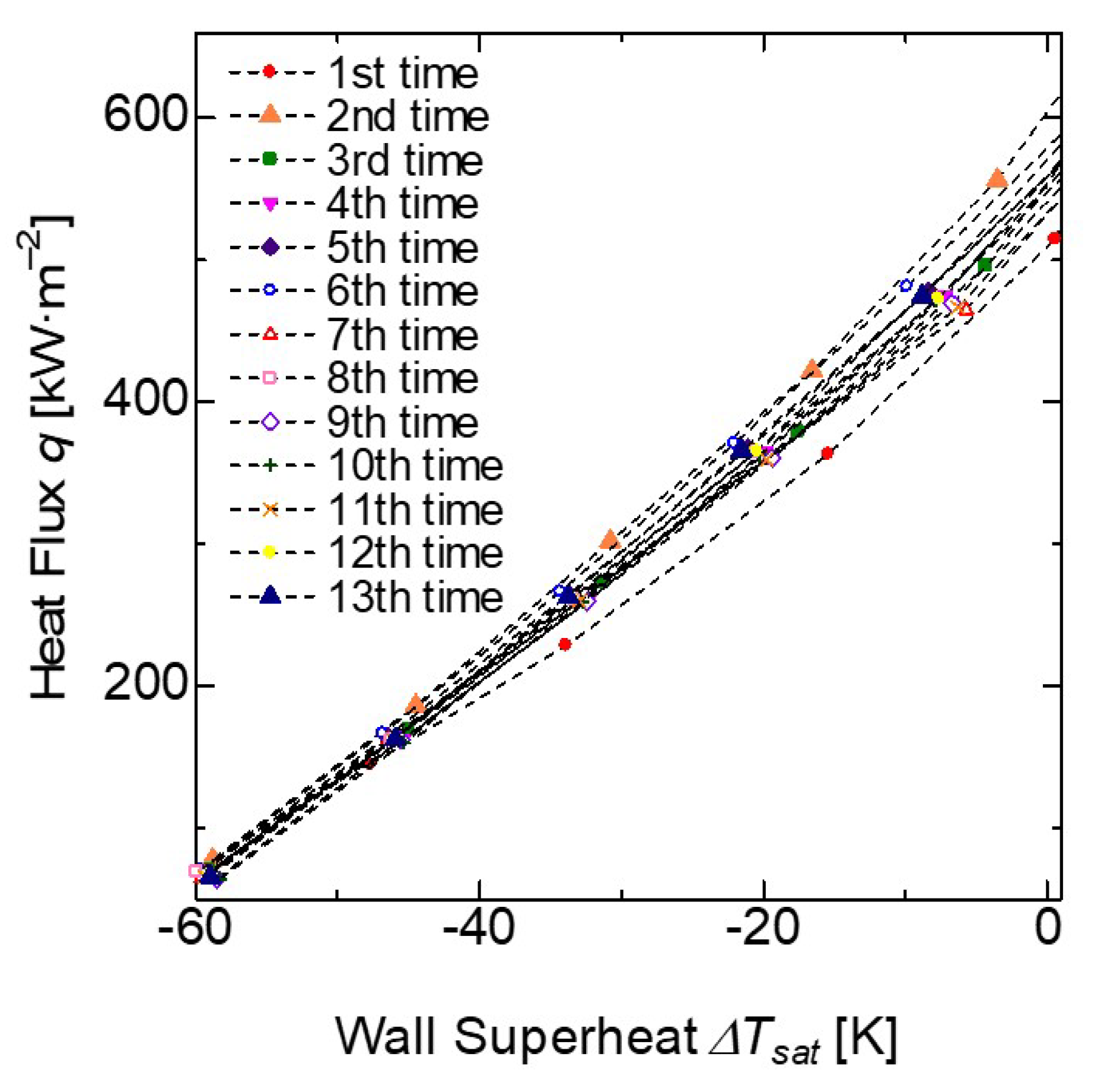

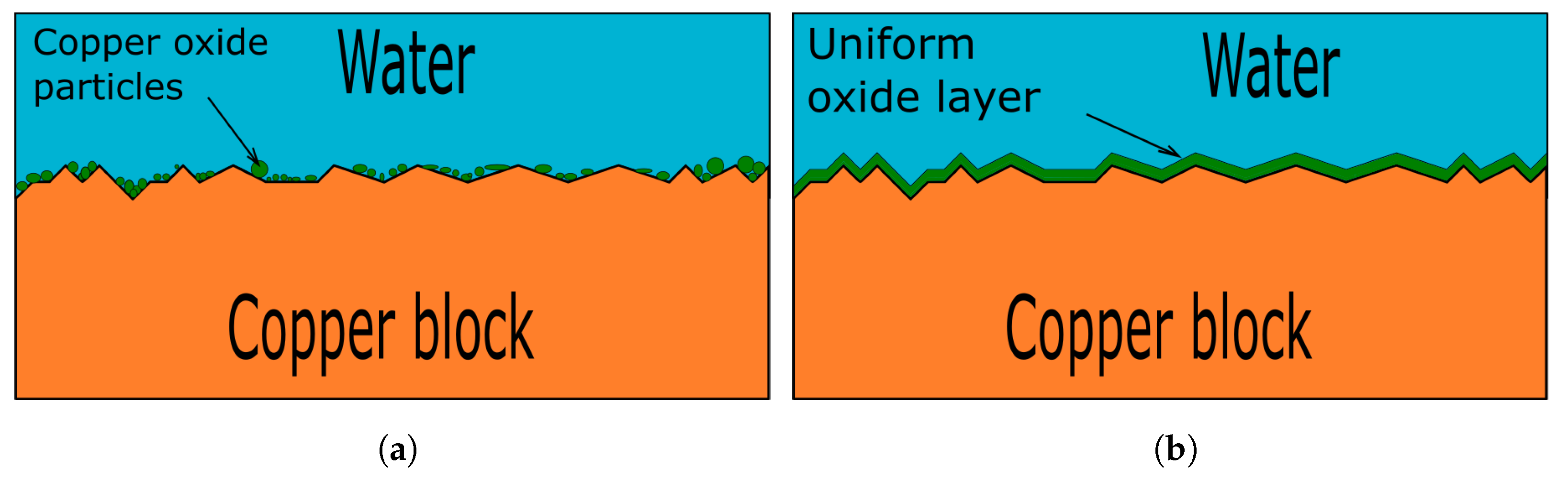

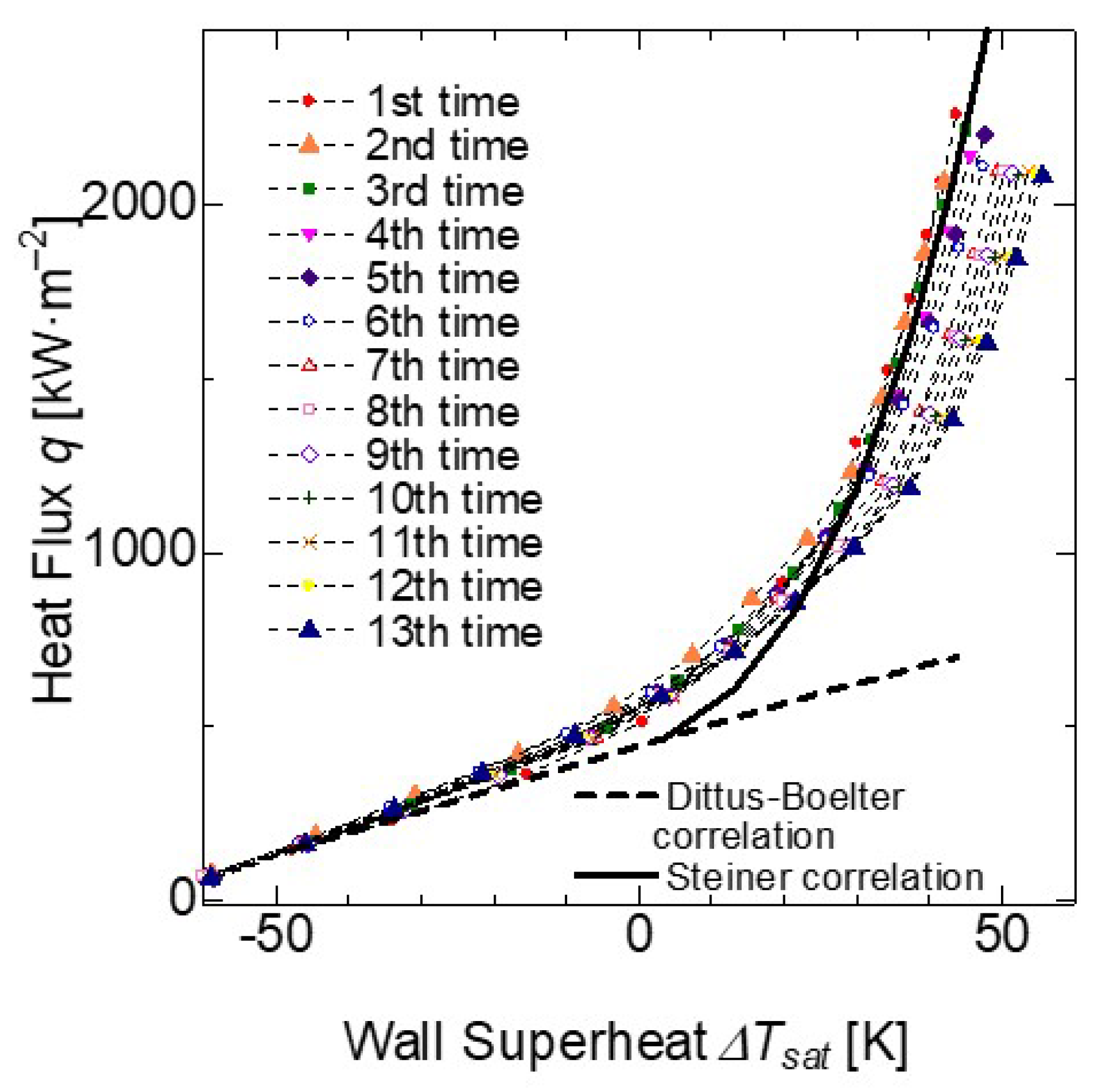

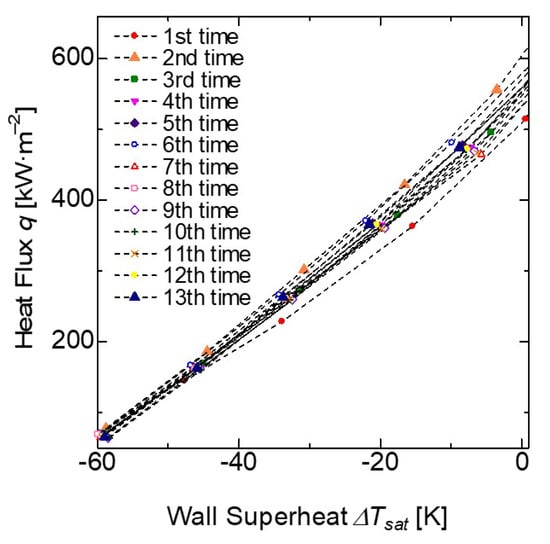

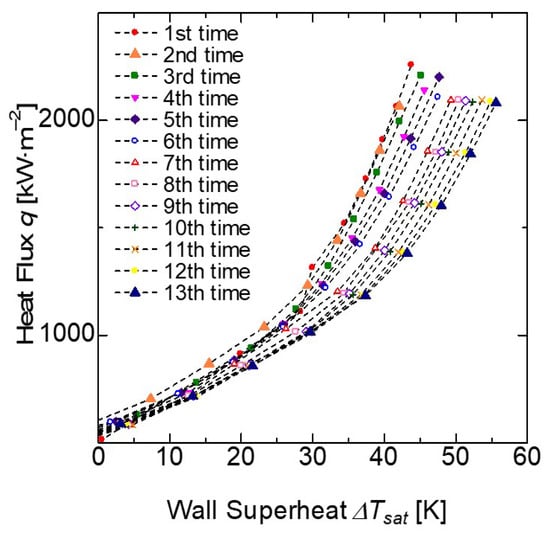

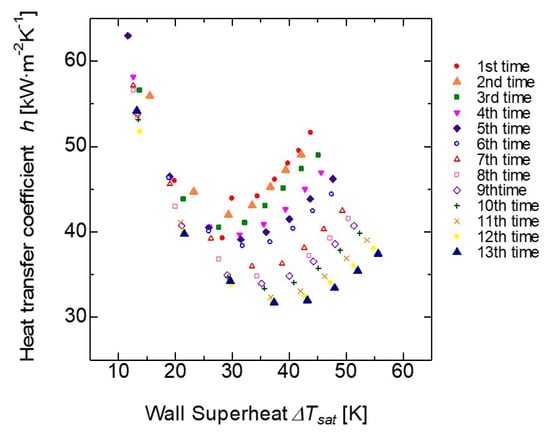

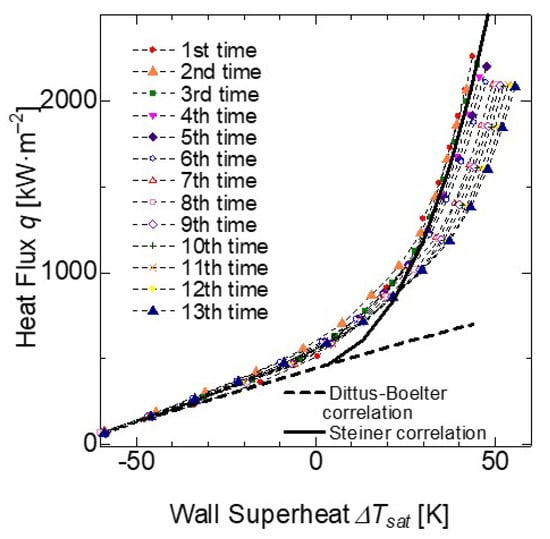

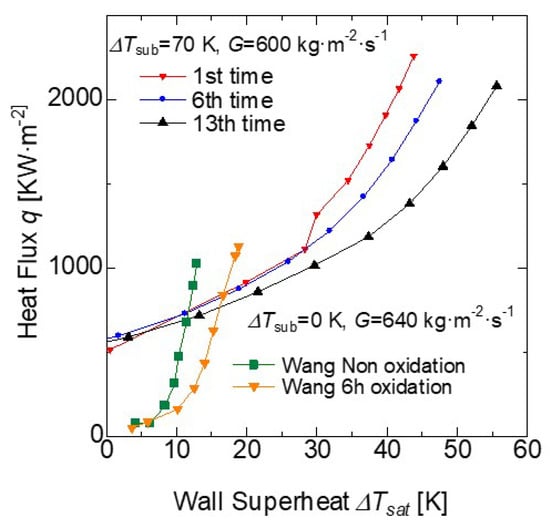

Figure 7 and Figure 8 show the heat flux and the heat transfer coefficient of the thirteen experiments, respectively. The effect of the copper oxide layer is clearly noticeable; the heat flux decreased and the wall superheat gradually increased after each experiment. This effect is attributed to the oxidation layer that increases its thickness and it gradually covers more nucleation sites. From the first experiment to the sixth experiment, the wall superheat increases by approximately 5.5 K, and the heat flux presented a small variation s between 2259 and 2081 kW·m−2. This variation is caused by the formation of copper oxide particles on different points of the surface, as shown in Figure 9a. From the seventh experiment to the last experiment, an increment in the wall superheat of 7 K was found, however, the heat flux presented a minor variation. This phenomenon is attributed to the formation of a uniform oxide layer that completely covers the surface, as shown in Figure 9b. It can be seen that the oxidation effect is reduced after each experiment; the heat flux and wall superheat in the 12th and 13th experiment are similar and the difference in the boiling curve is marginal. In general, the boiling curve conserves the same inclination on the flow boiling area, however, the wall superheat increased by approximately 12.5 K from the first to the last experiment, representing an increment of approximately 26%. The increment in the wall superheat is attributed to the reduction in the number of nucleation sites. These nucleation sites are covered by the oxidation layer and the water supply is reduced on the heating surface. On the other hand, the heat flux presented a reduction of approximately 8% as a result of the effect of the oxide layer. Researchers have proposed correlations to predict the subcooled flow boiling heat flux in pipes. However, these correlations present a variation between the predicted and the experimental heat flux. This variation is due to the fact that the correlation considers a circular heated channel, while the present research uses a single heated face in a square flow channel. In order to tackle this problem and to confirm the accuracy of the experimental results, they were compared with the modified Dittus–Boelter correlation [27] proposed by Hua et al. [28] for the calculation of the heat flux in the single-phase region and the correlation proposed by Steiner et al. [29] corresponding to the heat flux in the subcooled flow boiling. Both correlations are proposed as a modified correlation for subcooled flow boiling using a one side heated surface. Figure 10 shows the comparison of the experimental heat flux and the heat flux calculated by the correlations proposed in [28,29]. In the flow boiling region, good agreement was found between the experimental heat flux and the calculated heat flux during the first three experiments; however, after the fourth experiment, the wall superheat presented a noticeable increment of approximately 10 K.

Figure 7.

Heat flux in the two-phase region.

Figure 8.

Heat transfer coefficient in the two-phase region.

Figure 9.

Oxidation process on the copper surface: (a) formation of copper oxide particles during the first heating hours; and (b) formation of the uniform oxide layer that covers the heating area.

Figure 10.

Experimental heat flux and calculated heat flux comparison. Predicted heat flux by the Dittus-Boelter correlation for single-phase [27,28], and the Steiner correlation [29] for two-phase flow boiling.

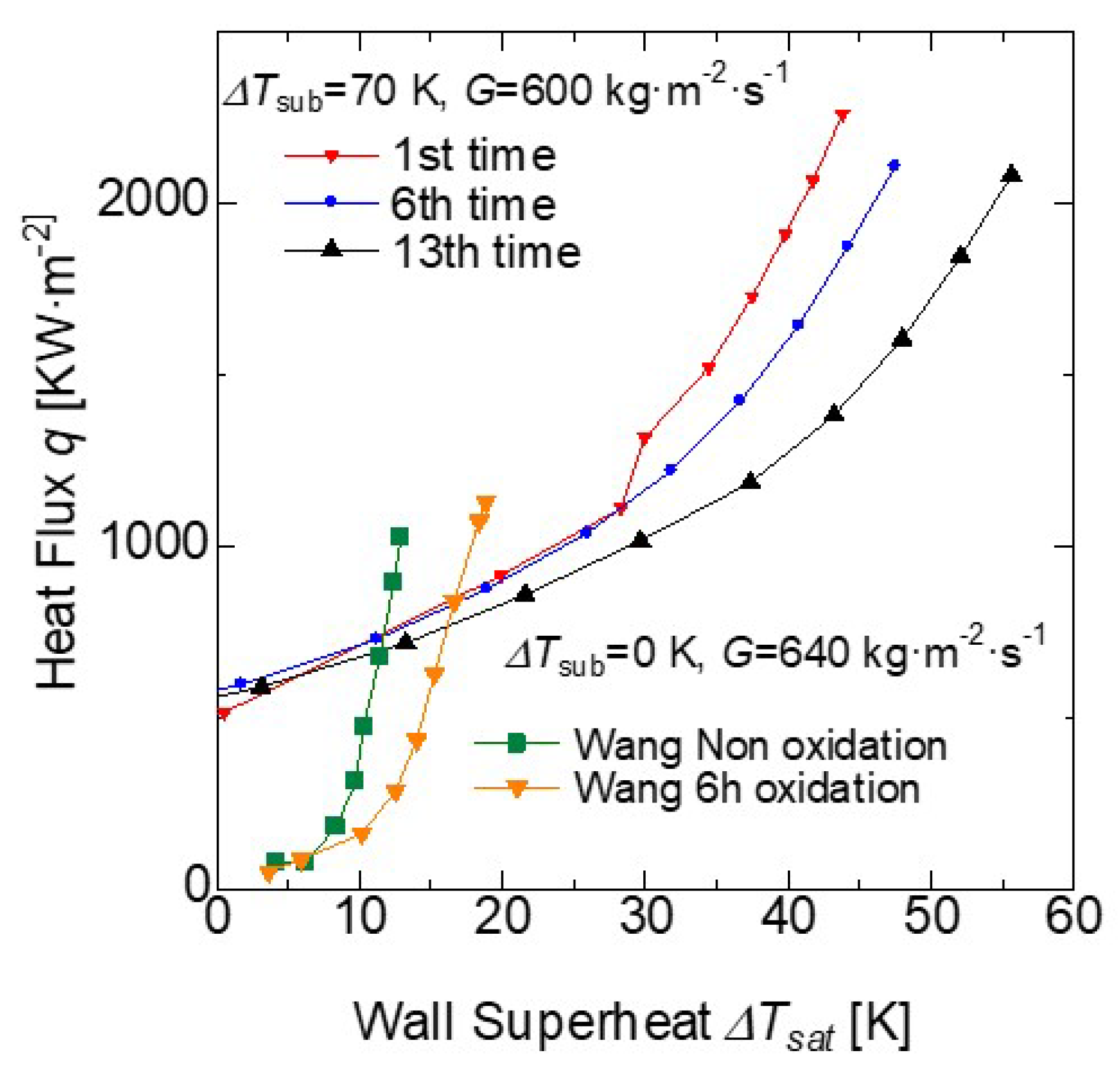

Wang et al. [20] reported the same effect under different mass fluxes and different copper surface oxidation times. They used water as a working fluid at saturation temperature. The number of bubbles formed on the heating surface is proportional to the number of nucleation sites, and the bubble contact angle is lower for the oxidized surface. The heat flux is reduced and the wall superheat increased proportionally to the heating hours as shown in Figure 11. The oxidation effect on the heat flux is independent of the degree of the working fluid subcooling temperature. The ONB also shifted to a higher wall superheat for the subcooled flow boiling, however, the increment in the wall superheat follows the same pattern. Since the oxide layer effect is gradually reduced at the longer heating time, Vlachou et al. [15] demonstrated a limit on the copper oxide layer influence. They tested an aged surface for 24 h under subcooled flow boiling, compared it with a freshly machined surface, and reported stable heat flux conditions on the 24 h aged surface. The present research tested the surface for a total of 52 heating hours.

Figure 11.

Comparison of the copper oxide layer effect on the subcooled flow boiling and the experimental results of saturated flow boiling obtained by Wang et al. [21].

4. Conclusions

The copper oxide layer formed on the surface and its effect on the heat transfer coefficient under subcooled flow boiling was analyzed by repeating the same experiment thirteen times. A significant influence of the oxidation layer on the single-phase region due to the absence of bubble activity was not found. On the other hand, in the two-phase flow regime, a direct relationship was found between the oxide layer promoted by the heating time of the copper surface and the heat transfer performance. The oxidation layer covers a high number of nucleation sites affecting the bubble formation on the two-phase region. The wettability increases with the heating time; nevertheless, the nucleation sites are covered and thus the bubble activity is reduced, promoting an increment in the wall superheat. As a consequence of the increment in the wall superheat, a reduction in the heat transfer coefficient was also found, an effect which is only appreciated in the two-phase regime due to the bubble activity that promotes the working fluid evaporation and condensation. The following conclusions were obtained:

- An influence on the wall superheat temperature was found at the same heat flux in the flow boiling regime, however, for the single-phase regime, the oxidation layer effect is almost negligible.

- The oxidation layer formed on the copper surface covers a large number of nucleation sites and thus the water. supply ability is reduced; as a result, the same heat flux, which is an increment in the wall superheat, was found after the onset nucleate boiling.

- The oxidation layer has a limit effect on the heat flux. For longer oxidation times, there is less of an effect on the wall superheat temperature at the same heat flux.

Author Contributions

Data curation, E.S.G. and K.E.; funding acquisition, K.E.; investigation, E.S.G. and K.E.; project administration, K.E.; visualization, E.S.G.; writing—original draft, E.S.G.; writing—review and editing, E.S.G., T.K., O.S.O., K.E., T.S., K.T. and K.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data openly available in a public repository that issues datasets with DOIs.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mori, S.; Okuyama, K. Enhancement of the critical heat flux in saturated pool boiling using a honeycomb porous media. Int. J. Multiph. Flow 2009, 35, 946–951. [Google Scholar] [CrossRef]

- Benjan, A.; Kraus, A.D. Heat Transfer Handbook; Wiley: Hoboken NJ, USA, 2003. [Google Scholar]

- Chu, K.-H.; Zhu, Y.; Miljkovic, N.; Nam, Y.; Enright, R.; Wang, E.N. Enhanced boiling heat transfer with copper oxide hierarchical surfaces. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems, Barcelona, Spain, 16–20 June 2013; pp. 2272–2275. [Google Scholar]

- Leong, K.; Ho, J.; Wong, K. A critical review of pool and flow boiling heat transfer of dielectric fluids on enhanced surfaces. Appl. Therm. Eng. 2017, 122, 999–1019. [Google Scholar] [CrossRef]

- Ahn, H.S.; Kim, J.M.; Kim, M.H. Experimental study of the effect of a reduced graphene oxide coating on critical heat flux enhancement. Int. J. Heat Mass Transf. 2013, 60, 763–771. [Google Scholar] [CrossRef]

- Walunj, A.; Sathyabhama, A. Influence of surface roughness on pool boiling heat transfer. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012081. [Google Scholar] [CrossRef]

- Jo, H.S.; An, S.; Park, H.G.; Kim, M.-W.; Al-Deyab, S.S.; James, S.C.; Choi, J.; Yoon, S.S. Enhancement of critical heat flux and superheat through controlled wettability of cuprous-oxide fractal-like nanotextured surfaces in pool boiling. Int. J. Heat Mass Transf. 2017, 107, 105–111. [Google Scholar] [CrossRef]

- Kim, J.; Jun, S.; Laksnarain, R.; You, S.M. Effect of surface roughness on pool boiling heat transfer at a heated surface having moderate wettability. Int. J. Heat Mass Transf. 2017, 101, 992–1002. [Google Scholar] [CrossRef]

- Kim, J.M.; Kang, S.H.; Yu, D.I.; Park, H.S.; Moriyama, K.; Kim, M.H. Smart surface in flow boiling: Spontaneous change of wettability. Int. J. Heat Mass Transf. 2016, 105, 992–1002. [Google Scholar] [CrossRef]

- Du, J.; Chen, Z.; Ye, S.; Wiley, B.J.; Meyer, T.J. Copper as a robust and transparent electrocatalyst for water oxidation. Angew. Chem. Int. 2015, 54, 2073–2078. [Google Scholar] [CrossRef]

- Yu, F.; Li, F.; Zhang, B.; Li, H.; Sun, L. Efficient electrocatalytic water oxidation by a copper oxide thin film in borate buffer. Am. Chem. Catal. 2014, 5, 627–630. [Google Scholar] [CrossRef]

- Svoboda, R.; Palmer, D.A. Behaviour of copper in generator stator cooling-water systems. In Proceedings of the 15th International Conference on the Properties of Water and Steam, Berlin, Germany, 8–11 September 2008. [Google Scholar]

- Limkrailassiri, K. Copper oxide by thermal oxidation for electrochemical cells and gas sensor. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2013. [Google Scholar]

- Moliere, M.; Verdier, Y.; Leymonie, C. Oxidation of copper in high purity water at 70 °C: Application to electric generator operator. Corros. 1990, 30, 183–188. [Google Scholar] [CrossRef]

- Vlachou, M.; Lioumbas, J.; David, K.; Chasapis, D.; Karapantsios, T. Effect of channel height and mass flux on highly subcooled horizontal flow boiling. Exp. Therm. Fluid Sci. 2017, 83, 157–168. [Google Scholar] [CrossRef]

- Jarayumu, P.; Gedupudi, S.; Das, S. Influence of heating surface characteristics on flow boiling in a copper microchannel: Experimental investigation and assessment of correlations. Int. J. Heat Mass Transf. 2019, 128, 290–318. [Google Scholar] [CrossRef]

- Kim, J.; Jun, S.; Lee, J.; Godinez, J.; You, S.M. Effect of surface roughness on pool boiling heat transfer of water on a superhydrophilic aluminum surface. J. Heat Transf. 2017, 139, 101501.1–101501.9. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, K.M.; Bang, I.C. Study on flow boiling critical heat flux enhancement of graphene oxide/water nanofluid. Int. J. Heat Mass Transf. 2013, 65, 348–356. [Google Scholar] [CrossRef]

- Wang, K.; Erkan, N.; Gong, H.; Okamoto, K. Effects of carbon steel surface oxidation on critical heat flux in downward-face pool boiling. Int. J. Heat Mass Transf. 2019, 136, 470–485. [Google Scholar] [CrossRef]

- Wang, K.; Erkan, N.; Okamoto, K. Oxidation effect of copper on the downward-facing flow boiling chf under atmospheric pressure. Int. J. Heat Mass Transf. 2020, 156, 119866. [Google Scholar] [CrossRef]

- Wang, K.; Erkan, N.; Okamoto, K. A study on the effect of oxidation on critical heat flux in flow boiling with downward-faced carbon steel. Int. J. Heat Mass Transf. 2020, 147, 118966. [Google Scholar] [CrossRef]

- Takemura, A.; Yuki, K.; Sadayuki, A. Influence of Warm Oxide Layer on Wettability and Contact Angle for Heat Transport Devices. J. Mech. Eng. Autom. 2017, 7, 341–347. [Google Scholar] [CrossRef]

- Aromaa, J.; Kekkonen, M.; Mousapour, M.; Jokilaakso, A.; Lundström, M. The Oxidation of Copper in Air at Temperatures Up to 100 °C. Corros. Mater. Degrad. 2021, 2, 625–640. [Google Scholar] [CrossRef]

- Trojer, M.; Azizian, R.; Paras, J.; McKrell, T.; Atkhen, K.; Bucci, M.; Buongiorno, J. A margin missed: The effect of surface oxidation on CHF enhancement in IVR accident scenarios. Nucl. Eng. Des. 2018, 335, 140–150. [Google Scholar] [CrossRef]

- Galicia, E.S.; Otomo, Y.; Saiwai, T.; Takita, K.; Orito, K.; Enoki, K. Subcooled flow boiling heat flux enhancement using high porosity sintered fiber. Appl. Sci. 2021, 11, 5883. [Google Scholar] [CrossRef]

- Otomo, Y.; Galicia, E.S.; Enoki, K. Enhancement of subcooled flow boiling heat transfer with high porosity sintered fiber metal. Appl. Sci. 2021, 11, 1237. [Google Scholar] [CrossRef]

- Dittus, F.W.; Boelter, L.M.K. Heat Transfer in Automobile Radiators of the Tubular Type; University of California Press; University of California Publications in Engineering: Berkeley, CA, USA, 1930; Volume 2, pp. 443–461. [Google Scholar]

- Hua, S.; Huang, R.; Li, Z.; Zhou, P. Experimental study on the heat transfer characteristics of subcooled flow boiling with cast iron heating surface. Appl. Therm. Eng. 2015, 77, 180–191. [Google Scholar] [CrossRef]

- Steiner, H.; Kobor, A.; Gebhard, L. A wall heat transfer model for subcooled boiling flow. Int. J. Heat Mass Transf. 2005, 48, 4161–4173. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).