Impact of Bio-Ethanol, Bio-ETBE Addition on the Volatility of Gasoline with Oxygen Content at the Level of E10

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Base Fuels

2.1.2. Oxygenates

2.2. Samples and Methods

2.2.1. Vapor Pressure Measurements

2.2.2. Distillation Measurements

2.2.3. Calculation of VLI

3. Results and Discussion

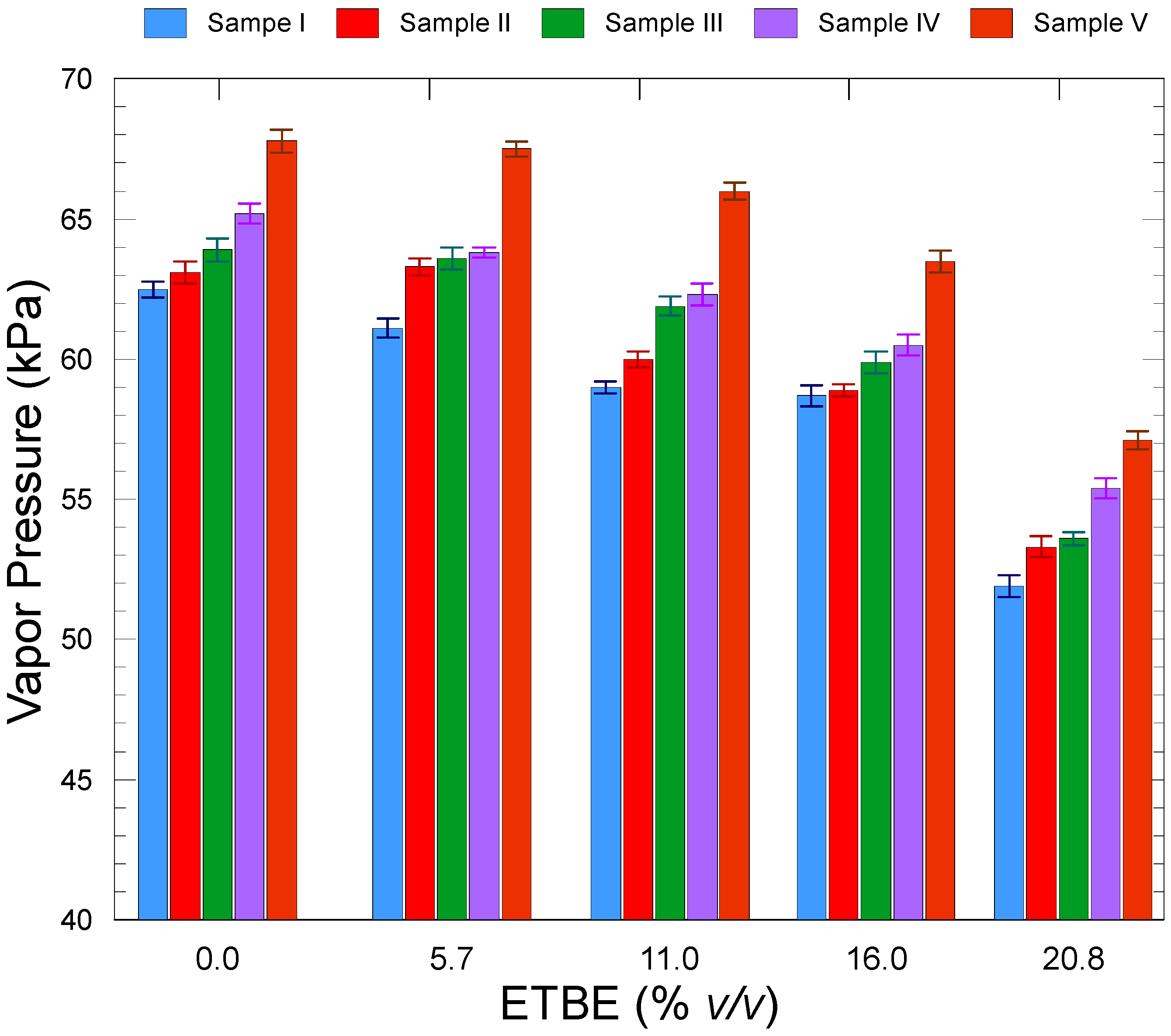

3.1. Vapor Pressure Measurements

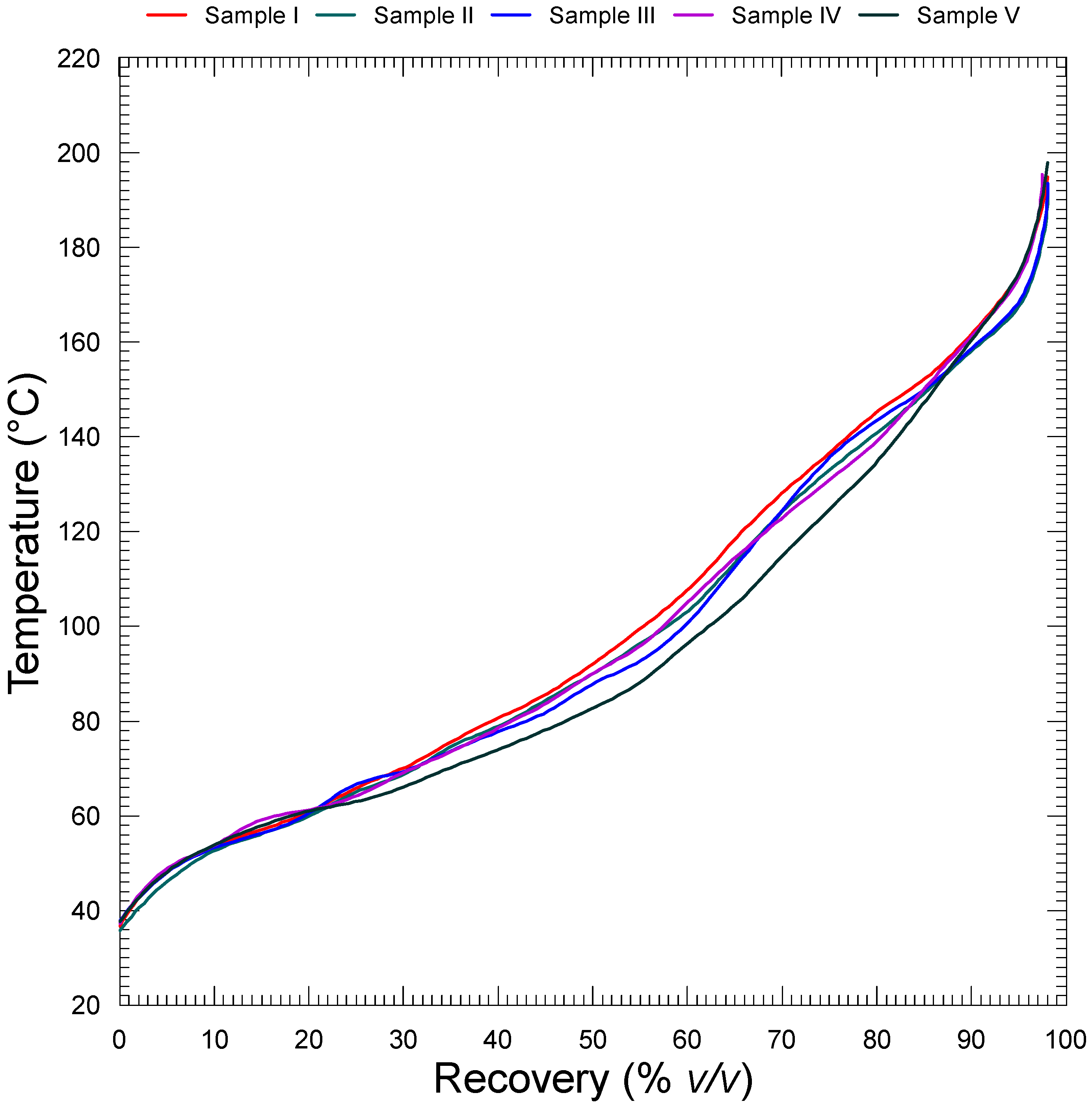

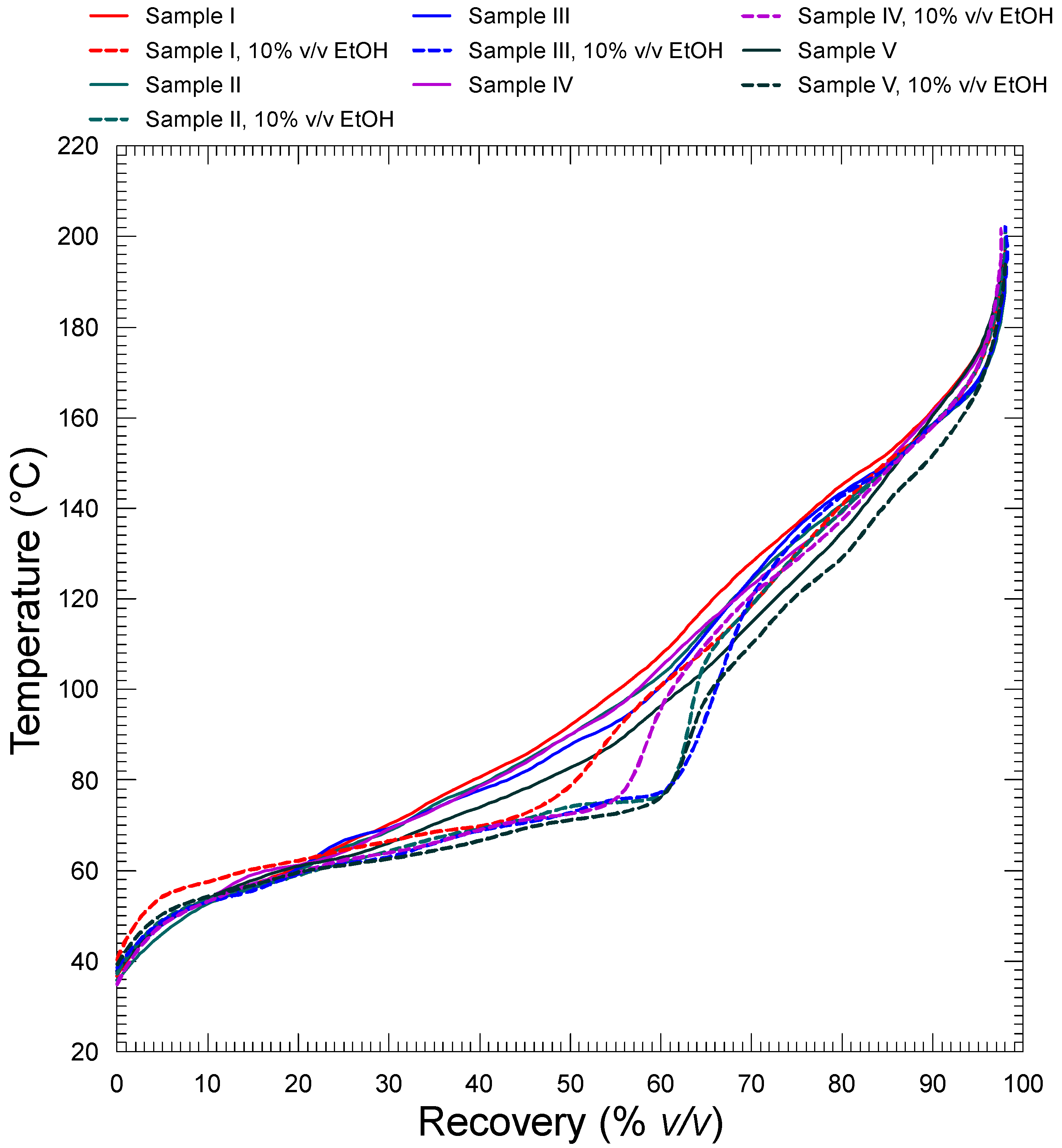

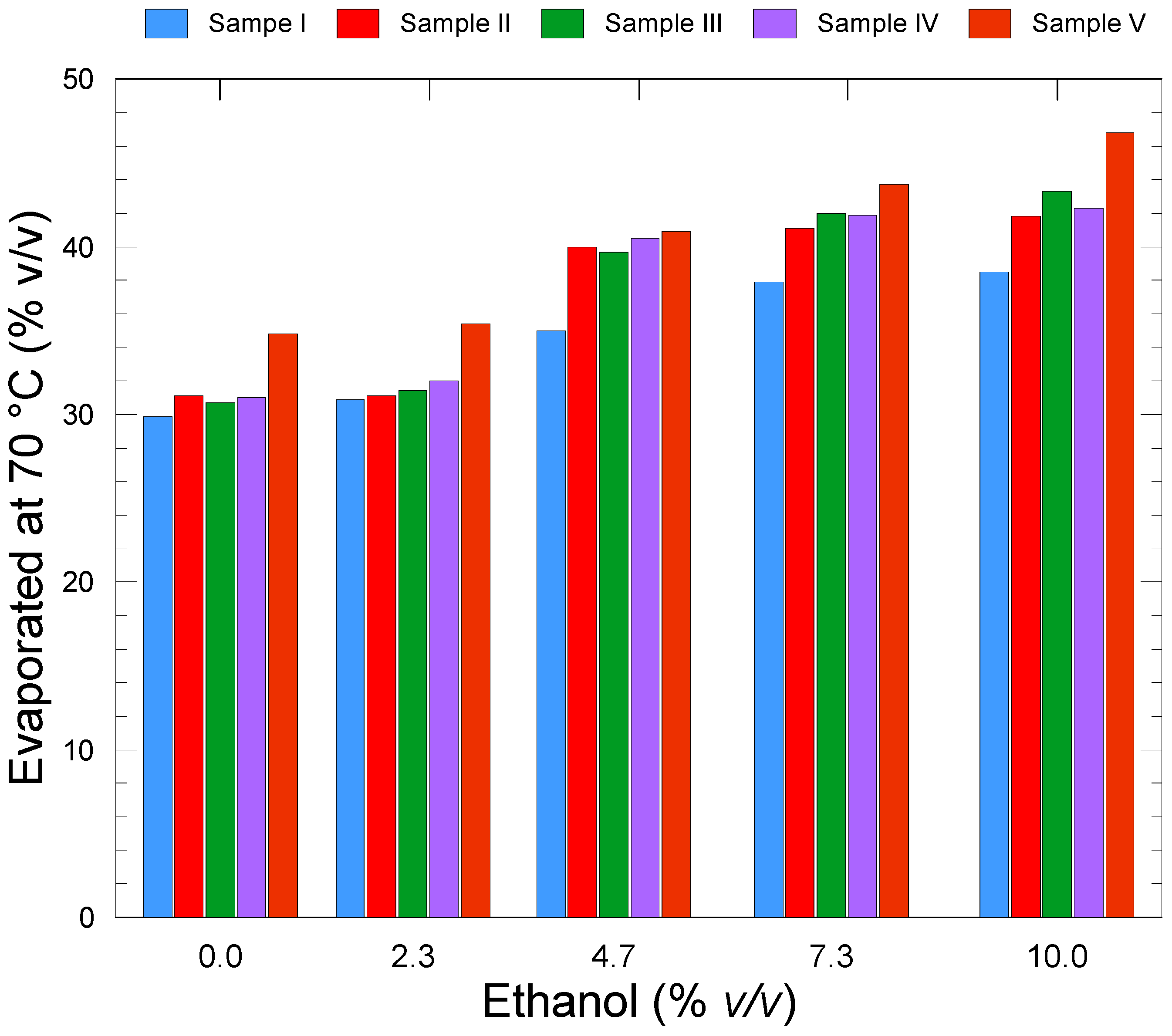

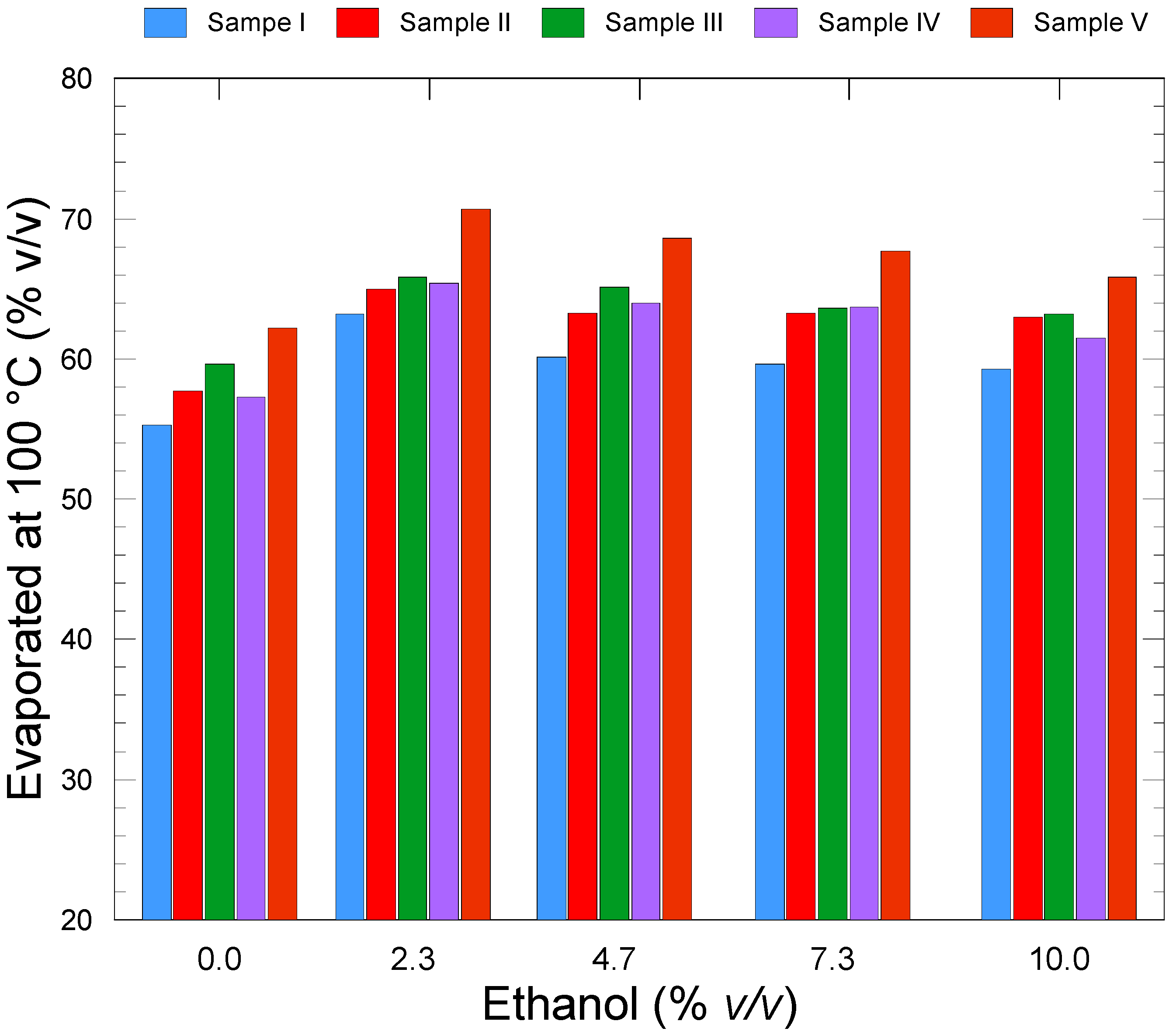

3.2. Distillation Measurements

3.3. Vapor Lock Index (VLI)

4. Conclusions

- In the base fuels to which only bio-ethanol had been added to the maximum allowable content (10% v/v), the vapor pressure was higher than the value of the specifications for “summer” gasoline.

- The addition of bio-ethanol/bio-ETBE set all of the samples within the EN 228 specification limits.

- The vapor pressure values of the samples with both bio-ethanol and bio-ETBE were between the vapor pressure of the samples to which only bio-ethanol or bio-ETBE had been added. The change in the vapor pressure was similar for all samples.

- The five base fuels showed similar changes of their distillation characteristics for the same level of bio-ethanol and bio-ETBE in the blend.

- As for the vapor pressure value and distillation characteristics (E70 and E100), Sample V (with increased C5 and C6 iso-paraffins) showed higher values than the other four base fuels at all oxygenate contents.

- Sample I shows the lowest vapor pressure as well as the lowest E70 and E100 values in all of the cases where bio-ethanol/bio-ETBE was added in different concentrations. The high content of aromatic hydrocarbons, most of which had seven or eight carbon atoms, and the low percentage of volatile iso-paraffins justify the low volatility characteristics seen for Sample I.

- As for the VLI, this was lower than the upper limit for gasoline class C1 according to the EN 228 standard. The VLI achieved its maximum value when the bio-ethanol concentration was 10% v/v and when the bio-ETBE had not been added. As the bio-ETBE content increases, the VLI is reduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DVPE | dry vapor pressure equivalent |

| E70 | evaporated at 70 °C |

| E100 | evaporated at 100 °C |

| E150 | evaporated at 150 °C |

| EN | European norm |

| ETBE | ethyl tert butyl ether |

| EU | European Union |

| FBP | final boiling point |

| FCC | fluid catalytic cracking |

| GHG | greenhouse gases |

| IBP | initial boiling point |

| MON | motor octane number |

| RON | research octane number |

| VLI | vapor lock index |

References

- European Union. Directive 2015/1513 of the European parliament and of the Council of 9 September 2015 amending directive 98/70/EC relating to the quality of petrol and diesel fuels and amending directive 2009/28/EC on the promotion of the use of energy from renewable sources, L 239/1 EN. Off. J. Eur. Union. 2015, 58, 1–29. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32015L1513 (accessed on 26 September 2021).

- European Union. Directive 2009/28/EC of the European Parliament and of The Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC, L 140/16 EN. Off. J. Eur. Union. 2009, 5, 16–62. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32009L0028 (accessed on 13 September 2021).

- European Union. Directive 2009/30/EC of the European Parliament and of The Council of 23 April 2009 amending Directive 98/70/EC as regards the specification of petrol, diesel and gas–oil and introducing a mechanism to monitor and reduce greenhouse s emissions and amending Council Directive 1999/32/EC as regards the specification of fuel used by inland waterway vessels and repealing Directive 93/12/EEC, L 140/88 EN. Off. J. Eur. Union 2009, 52, 88–113. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32009L0030 (accessed on 15 September 2021).

- EN 228:2012+A1:2017 Automotive Fuels—Unleaded Petrol—Requirements and Test Methods; Irish Standard: Dublin, Ireland, 2017.

- EN 590:2013+A1:2017 Automotive Fuels—Diesel—Requirements and Test Methods; Slovakia Standard: Bratislava, Slovakia, 2017.

- Rodríguez-Antón, L.M.; Hernández-Campos, M.; Sanz-Pérez, F. Experimental determination of some physical properties of gasoline, ethanol and ETBE blends. Fuel 2013, 112, 178–184. [Google Scholar] [CrossRef]

- Weber de Menezes, E.; Cataluña, R.; Samios, D.; Da Silva, R. Addition of an azeotropic ETBE/ethanol mixture in eurosupertype gasolines. Fuel 2006, 85, 2567–2577. [Google Scholar] [CrossRef]

- Karonis, D.; Anastopoulos, G.; Lois, E.; Stournas, S. Impact of simultaneous ETBE and ethanol addition on motor gasoline properties. SAE Int. J. Fuels Lubr. 2009, 1, 1584–1594. [Google Scholar] [CrossRef]

- AlRamadan, A.S.; Sarathy, S.M.; Badra, J. Unraveling the octane response of gasoline/ethanol blends: Paving the way to formulating gasoline surrogates. Fuel 2021, 299, 120882. [Google Scholar] [CrossRef]

- Magnusson, R.; Nilsson, C. The influence of oxygenated fuels on emissions of aldehydes and ketones from a two-stroke spark ignition engine. Fuel 2011, 90, 1145–1154. [Google Scholar] [CrossRef]

- Yücesu, S.H.; Topgül, T.; Çinar, C.; Okur, M. Effect of ethanol–gasoline blends on engine performance and exhaust emissions in different compression ratios. Appl. Therm. Eng. 2006, 26, 2272–2278. [Google Scholar] [CrossRef]

- CONCAWE. Gasoline Volatility and Vehicle Performance. CONCAWE Review; Report No. 2/12, February 2012. Available online: https://www.concawe.eu/wp-content/uploads/2017/01/rpt_12-2-2012-00657-01-e.pdf (accessed on 15 July 2021).

- EN 228:2008 Automotive Fuels—Unleaded Petrol—Requirements and Test Methods; Slovakia Standard: Bratislava, Slovakia, 2008.

- Myung, C.L.; Choi, K.; Cho, J.; Kim, K.; Baek, S.; Lim, Y.; Park, S. Valuation of regulated, particulate, and BTEX emissions inventories from a gasoline direct injection passenger car with various ethanol blended fuels under urban and rural driving cycles in Korea. Fuel 2020, 262, 116406. [Google Scholar] [CrossRef]

- Zhang, M.; Ge, Y.; Wang, X.; Thomas, D.; Su, S.; Hu, L. An assessment of how bio-E10 will impact the vehicle-related ozone contamination in China. Energy Rep. 2020, 6, 572–581. [Google Scholar] [CrossRef]

- CONCAWE. Volatility and Vehicle Drivability Performance of Ethanol/Gasoline Blends. CONCAWE Review; Report No. 8/09, October 2009. Available online: https://www.concawe.eu/wp-content/uploads/2017/01/rpt_09-8-2009-05087-01-e.pdf (accessed on 20 July 2021).

- Anderson, V.F.; Anderson, J.E.; Wallington, T.J.; Mueller, S.A.; Nielsen, O.J. Distillation Curves for Alcohol−Gasoline Blends. Energy Fuels 2010, 24, 2683–2691. [Google Scholar] [CrossRef]

- Hirshfeld, D.S.; Kolb, J.A.; Anderson, J.E.; Iqbal, A.; Moore, M.E.; Studzinski, W.M.; Sutherland, I. Refining Economics of Higher Octane Sensitivity, Research Octane Number and Ethanol Content for U.S. Gasoline. Energy Fuels 2021, 35, 14816–14827. [Google Scholar] [CrossRef]

- ETBE Technical Product Bulletin. European Fuel Oxygenates Association. ETBE Technical Product Bulletin. June 2006. Available online: https://www.petrochemistry.eu/wp-content/uploads/2018/01/ETBE-Product-Bulletin-Jun-2006.pdf (accessed on 15 June 2021).

- Petre, M.; Rosca, P.; Dragomir, R.E. The effect of bio-ethers on the volatility properties of oxygenated gasoline. Rev. Chim. 2011, 62, 567–574. Available online: https://www.revistadechimie.ro/Articles.asp?ID=2987 (accessed on 15 June 2021).

- Dubois, T.; Abiad, L.; Caine, P. Investigating the Impact of Ethanol on the Lubricity of Gasoline and on the Lubricity Improvers Efficiency. In SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2017; Volume 1. [Google Scholar] [CrossRef]

- Khuong, L.S.; Masjuki, H.H.; Zulkifli, N.W.M.; Mohamad, E.N.; Kalam, M.A.; Alabdulkarem, A.; Arslan, A.; Mosarof, M.H.; Syahir, A.Z.; Jamshaid, M. Effect of gasoline–bioethanol blends on the properties and lubrication characteristics of commercial engine oil. RSC Adv. 2017, 7, 15005–15019. [Google Scholar] [CrossRef] [Green Version]

- ACEA. ACEA E10 Compatibility List. ACEA, August 2018. Available online: https://www.acea.auto/files/ACEA_E10_compatibility.pdf (accessed on 26 July 2021).

- Iodice, P.; Senatore, A.; Langella, G.; Amoresano, A. Advantages of ethanol-gasoline blends as fuel substitute for last generation Si engines. Environ. Prog. Sustain. Energy 2017, 36, 1173–1179. [Google Scholar] [CrossRef]

- Iodice, P.; Cardone, M. Ethanol/Gasoline Blends as Alternative Fuel in Last Generation Spark-Ignition Engines: A Review on CO and HC Engine Out Emissions. Energies 2021, 14, 4034. [Google Scholar] [CrossRef]

- Dalli, D.; Lois, E.; Karonis, D. Vapor Pressure and Octane Numbers of Ternary Gasoline–Ethanol–ETBE Blends. J. Energy Eng. 2014, 140, A4014002. [Google Scholar] [CrossRef]

- EN 15376:2014 Automotive Fuels—Ethanol as a Blending Component for Petrol—Requirements and Test Methods; Slovakia Standard: Bratislava, Slovakia, 2014.

- EN 13016-1:2018 Liquid Petroleum Products—Vapour Pressure—Part 1: Determination of Air Saturated Vapour Pressure (ASVP) and Calculated Dry Vapour Pressure Equivalent (DVPE); Slovakia Standard: Bratislava, Slovakia, 2018.

- ISO. EN ISO 3405:2019 Petroleum and Related Products from Natural or Synthetic Sources—Determination of Distillation Characteristics at Atmospheric Pressure; Slovakia Standard: Bratislava, Slovakia, 2019. [Google Scholar]

- ISO. ISO 4259:2017 Petroleum Products—Determination and Application of Precision Data in Relation to Methods of Test; ISO: Geneva Switzerland, 2017. [Google Scholar]

- ISO/IEC. BIMP-ISO/IEC Guide 98-3:2008 Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement (GUM: 1995); ISO/IEC: Geneva, Switzerland, 2008; Available online: http://www.bipm.org/utils/common/documents/jcgm/JCGM_100_2008_E.pdf (accessed on 28 June 2021).

- Da Silva, R.; Cataluna, R.; Weber de Menezes, E.; Samios, D.; Clarisse, M.; Piatnicki, S. Effect of additives on the antiknock properties and Reid vapor pressure of gasoline. Fuel 2005, 84, 951–959. [Google Scholar] [CrossRef]

- Mužíková, Z.; Pospíšil, M.; Šebor, G. Volatility and phase stability of petrol blends with ethanol. Fuel 2009, 88, 1351–1356. [Google Scholar] [CrossRef]

- Pumphrey, J.A.; Brand, J.I.; Scheller, W.A. Vapour pressure measurements and predictions for alcohol–gasoline blends. Fuel 2000, 79, 1405–1411. [Google Scholar] [CrossRef]

- Gaspar, D.J.; Phillips, S.D.; Polikarpov, E.; Albrecht, K.O.; Jones, S.B.; George, A.; Lander, A.; Santos, D.M.; Howe, D.T.; Baldwin, A.J.; et al. Measuring and predicting the vapor pressure of gasoline containing oxygenates. Fuel 2019, 243, 630–644. [Google Scholar] [CrossRef]

- Chilari, D.; Karonis, D. Influence of Ethanol on Vapor Pressure of Refinery Components and Commercial Type Gasoline Blends. J. Appl. Chem. 2017, 10, 19–28. Available online: https://www.iosrjournals.org/iosr-jac/papers/vol10-issue12/Version-1/C1012011928.pdf (accessed on 25 June 2021). [CrossRef]

- Rodriguez-Anton, L.M.; Gutierrez-Martin, F.; Martinez-Arevalo, C. Experimental determination of some physical properties of gasoline, ethanol and ETBE ternary blends. Fuel 2015, 156, 81–86. [Google Scholar] [CrossRef] [Green Version]

- Amine, M.; Awad, E.; Baraka, Y. Volatility criteria of isomerate-enriched gasoline-ethanol blends. Egypt. J. Pet. 2020, 29, 227–233. [Google Scholar] [CrossRef]

- Amine, M.; Awad, E.; Baraka, Y. Reformate-enriched gasoline-ethanol blends: Volatility criteria and azeotrope formation. Egypt. J. Pet. 2019, 28, 377–382. [Google Scholar] [CrossRef]

- CONCAWE. Understanding Volatility of Ethanol/Gasoline Blends. CONCAWE Review; Springer: Berlin/Heidelberg, Germany, 2011. Available online: https://www.concawe.eu/wp-content/uploads/2017/01/concawe_cr201-2011-04592-01-e.pdf (accessed on 18 June 2021).

- Bruno, T.J.; Wolk, A.; Naydich, A. Composition-Explicit Distillation Curves for Mixtures of Gasoline with Four-Carbon Alcohols (Butanols). Energy Fuels 2009, 23, 2295–2306. [Google Scholar] [CrossRef]

| Properties | Unit | Reformate | FCC Gasoline | Alkylate | Isomerate | Dimate | Test Method |

|---|---|---|---|---|---|---|---|

| Density (at 15 °C) | kg/m3 | 788.7 | 734.6 | 704.0 | 653.4 | 689.9 | EN ISO 12185 |

| Vapor Pressure (at 37.8 °C) | kPa | 36.5 | 47.8 | 42.6 | 92.3 | 60.7 | EN 13016-1 |

| n-Paraffins | % v/v | 8.4 | 3.7 | 4.0 | 8.3 | 0.1 | EN ISO 22854 |

| iso-Paraffins | % v/v | 18.2 | 21.7 | 95.8 | 83.3 | 4.2 | EN ISO 22854 |

| Naphthenes | % v/v | 2.8 | 6.6 | 0.1 | 8.3 | 0.1 | EN ISO 22854 |

| Olefins | % v/v | 0.0 | 40.9 | 0.2 | 0.0 | 95.3 | EN ISO 22854 |

| Aromatics | % v/v | 70.7 | 23.0 | 0.0 | 0.1 | 0.2 | EN ISO 22854 |

| Benzene | % v/v | 2.14 | 0.69 | 0.0 | 0.0 | 0.0 | EN ISO 22854 |

| RON | - | 100.4 | 92.5 | 94.7 | 86.4 | 95.1 | EN ISO 5164 |

| MON | - | 88.9 | 80.7 | 92.0 | 83.5 | 80.9 | EN ISO 5163 |

| IBP | °C | 46.7 | 37.5 | 31.4 | 56.7 | 53.7 | EN ISO 3405 |

| E 70 | % v/v | 9.6 | 27.7 | 6.7 | 84.6 | 13.9 | EN ISO 3405 |

| E100 | % v/v | 23.1 | 53.1 | 9.7 | 97.9 | 81.6 | EN ISO 3405 |

| E150 | % v/v | 82.2 | 73.2 | 92.3 | - | 89.8 | EN ISO 3405 |

| FBP | °C | 179.6 | 209.8 | 190.3 | 100.1 | 189.3 | EN ISO 3405 |

| Refinery Fractions | I | II | III | IV | V |

|---|---|---|---|---|---|

| % v/v | |||||

| Reformate | 35 | 40 | 40 | 30 | 25 |

| Alkylate | 5 | 5 | 0 | 10 | 10 |

| FCC Gasoline | 30 | 20 | 20 | 30 | 25 |

| Isomerate | 25 | 30 | 30 | 30 | 35 |

| Dimate | 5 | 5 | 10 | 0 | 5 |

| Properties | Unit | I | II | III | IV | V | Limits EN 228 (O: 3.7% m/m) | Test Method |

|---|---|---|---|---|---|---|---|---|

| Density | kg/m3 | 759.3 | 744.9 | 743.2 | 737.6 | 730.9 | 720.0–775.0 | EN ISO 12185 |

| Vapor Pressure (at 37.8 °C) | kPa | 53.8 | 56.7 | 57.7 | 59.2 | 61.8 | class A: 45.0–60.0 | EN 13016-1 |

| class C/C1: 50.0–80.0 | ||||||||

| n-Paraffins | % v/v | 6.4 | 6.7 | 6.7 | 6.5 | 6.3 | - | EN ISO 22854 |

| Iso-paraffins | %v/v | 40.2 | 41.7 | 43.4 | 47.7 | 50.0 | - | EN ISO 22854 |

| Naphthenes | % v/v | 5.1 | 4.9 | 4.9 | 5.3 | 5.3 | - | EN ISO 22854 |

| Olefins | % v/v | 17.1 | 13.0 | 17.7 | 12.3 | 15.0 | 18.0 max | EN ISO 22854 |

| Aromatics | % v/v | 31.7 | 32.9 | 32.9 | 28.1 | 23.5 | 35.0 max | EN ISO 22854 |

| Benzene | % v/v | 0.96 | 1.00 | 1.00 | 0.86 | 0.72 | 1.00 max | EN ISO 22854 |

| IBP | °C | 36.8 | 35.7 | 37.8 | 37.3 | 37.6 | - | EN ISO 3405 |

| E 70 | % v/v | 29.9 | 31.1 | 30.7 | 31.0 | 34.8 | class A: 22.0–50.0 | EN ISO 3405 |

| class C/C1: 24.0–52.0 | ||||||||

| E100 | % v/v | 55.3 | 57.7 | 59.6 | 57.3 | 62.2 | 46.0–71.0 | EN ISO 3405 |

| E150 | % v/v | 83.5 | 85.5 | 85.1 | 85.0 | 86.1 | 75.0 min | EN ISO 3405 |

| FBP | °C | 194.7 | 191.5 | 193.4 | 195.3 | 197.8 | 210 | EN ISO 3405 |

| Base Fuel (%) | 90.0 | 87.0 | 84.3 | 81.7 | 79.2 |

| bio-ethanol (%) | 10.0 | 7.3 | 4.7 | 2.3 | - |

| bio-ETBE (%) | - | 5.7 | 11.0 | 16.0 | 20.8 |

| I | II | III | IV | V | |

|---|---|---|---|---|---|

| Vapor pressure kPa (EN ISO 13016-1) | 53.8 | 56.7 | 57.7 | 59.9 | 61.8 |

| Reproducibility, R | 2.89 | 2.94 | 2.96 | 3.00 | 3.03 |

| Expanded Uncertainty, U | ±0.37 | ±0.41 | ±0.18 | ±0.37 | ±0.26 |

| Ethanol Content of Blends (%v/v) | Vapor Pressure Waiver Permitted EN 13016-1 (kPa) |

|---|---|

| 0.0 | 0.0 |

| 2.3 | 6.4 |

| 4.7 | 8.0 |

| 7.3 | 7.9 |

| 10.0 | 7.8 |

| Properties | Units | Sample I | Sample II | Sample III | Sample IV | Sample V |

|---|---|---|---|---|---|---|

| E70 | % v/v | 29.9 ± 0.056 | 31.1 ± 0.048 | 30.7 ± 0.057 | 31.0 ± 0.048 | 34.8 ± 0.050 |

| E100 | % v/v | 55.3 ± 0.054 | 57.7 ± 0.053 | 59.6 ± 0.059 | 57.3 ± 0.049 | 62.2 ± 0.059 |

| E150 | % v/v | 83.5 ± 0.026 | 85.5 ± 0.028 | 85.1 ± 0.027 | 85.0 ± 0.029 | 86.1 ± 0.029 |

| FBP | (°C) | 194.7 ± 0.028 | 191.5 ± 0.030 | 193.4 ± 0.029 | 195.3 ± 0.034 | 197.8 ± 0.038 |

| 0% EtOH/ 0% ETBE | 2.3% EtOH/ 16.0% ETBE | 4.7% EtOH/ 11.0%ETBE | 7.3% EtOH/ 5.7% ETBE | 10% EtOH/ 0% ETBE | 0% EtOH/ 20.8% ETBE | |

|---|---|---|---|---|---|---|

| Units | % v/v | |||||

| Sample I | 29.9 ± 0.056 | 30.9 ± 0.065 | 35.0 ± 0.064 | 37.9 ± 0.055 | 38.5 ± 0.062 | 22.9 ± 0.061 |

| Sample II | 31.1 ± 0.048 | 31.1 ± 0.054 | 40.0 ± 0.058 | 41.1 ± 0.054 | 41.8 ± 0.054 | 23.9 ± 0.047 |

| Sample III | 30.7 ± 0.057 | 31.4 ± 0.062 | 39.7 ± 0.054 | 42.0 ± 0.055 | 43.3 ± 0.055 | 23.3 ± 0.058 |

| Sample IV | 31.0 ± 0.048 | 32.0 ± 0.046 | 40.5 ± 0.047 | 41.9 ± 0.048 | 42.3 ± 0.045 | 26.6 ± 0.046 |

| Sample V | 34.8 ± 0.050 | 35.4 ± 0.045 | 40.9 ± 0.045 | 43.7 ± 0.048 | 46.8 ±0.047 | 28.1 ± 0.046 |

| 0% EtOH/ 0% ETBE | 2.3% EtOH/ 16.0% ETBE | 4.7% EtOH/ 11.0%ETBE | 7.3% EtOH/ 5.7% ETBE | 10% EtOH/ 0% ETBE | 0% EtOH/ 20.8% ETBE | |

|---|---|---|---|---|---|---|

| Units | % v/v | |||||

| Sample I | 55.3 ± 0.054 | 63.2 ± 0.050 | 60.1 ± 0.049 | 59.6 ± 0.049 | 59.3 ± 0.058 | 63.8 ± 0.055 |

| Sample II | 57.7 ± 0.053 | 65.0 ± 0.056 | 63.3 ± 0.049 | 63.3 ± 0.055 | 63.0 ± 0.056 | 66.3 ± 0.049 |

| Sample III | 59.6 ± 0.059 | 65.8 ± 0.054 | 65.1 ± 0.053 | 63.6 ± 0.051 | 63.2 ± 0.049 | 66.9 ± 0.055 |

| Sample IV | 57.3 ± 0.049 | 65.4 ± 0.054 | 64.0 ± 0.053 | 62.7 ± 0.051 | 61.5 ± 0.050 | 65.6 ± 0.054 |

| Sample V | 62.2 ± 0.059 | 70.7 ± 0.058 | 68.6 ± 0.056 | 67.7 ± 0.055 | 65.8 ±0.041 | 70.8 ± 0.056 |

| 0% EtOH/ 0% ETBE | 2.3% EtOH/ 16.0% ETBE | 4.7% EtOH/ 11.0%ETBE | 7.3% EtOH/ 5.7% ETBE | 10% EtOH/ 0% ETBE | 0% EtOH/ 20.8% ETBE | |

|---|---|---|---|---|---|---|

| Units | % v/v | |||||

| Sample I | 83.5 ± 0.026 | 86.1 ± 0.024 | 85.3 ± 0.039 | 84.8 ± 0.027 | 84.5 ± 0.025 | 86.3 ± 0.035 |

| Sample II | 85.5 ± 0.028 | 89.0 ± 0.026 | 87.4 ±0.025 | 87.4 ± 0.026 | 85.5 ± 0.026 | 88.9 ± 0.029 |

| Sample III | 85.1 ± 0.027 | 87.3 ± 0.031 | 86.8 ± 0.032 | 86.3 ± 0.026 | 85.5 ± 0.024 | 87.9 ± 0.030 |

| Sample IV | 85.0 ± 0.029 | 89.6 ± 0.028 | 89.5 ± 0.028 | 87.7 ± 0.026 | 85.8 ± 0.026 | 89.4 ± 0.027 |

| Sample V | 86.1 ± 0.029 | 90.2 ± 0.028 | 89.7 ± 0.026 | 89.4 ± 0.027 | 89.2 ± 0.026 | 90.0 ±0.029 |

| 0% EtOH/ 0% ETBE | 2.3% EtOH/ 16.0% ETBE | 4.7% EtOH/ 11.0%ETBE | 7.3% EtOH/ 5.7% ETBE | 10% EtOH/ 0% ETBE | 0% EtOH/ 20.8% ETBE | |

|---|---|---|---|---|---|---|

| Units | % v/v | |||||

| Sample I | 194.7 ± 0.028 | 191.5 ± 0.029 | 193.0 ± 0.027 | 196.5 ± 0.035 | 202.7 ± 0.025 | 191.9 ± 0.035 |

| Sample II | 191.5 ± 0.030 | 185.4 ± 0.029 | 193.5 ± 0.031 | 194.3 ± 0.027 | 201.5 ± 0.028 | 186.4 ± 0.031 |

| Sample III | 193.4 ± 0.029 | 190.0 ± 0.025 | 193.6 ± 0.026 | 197.5 ± 0.025 | 202.1 ± 0.026 | 188.8 ± 0.027 |

| Sample IV | 195.3 ± 0.034 | 185.4 ± 0.035 | 187.0 ± 0.039 | 195.1 ± 0.037 | 201.7 ± 0.035 | 185.8 ± 0.039 |

| Sample V | 197.8 ± 0.038 | 185.2 ± 0.034 | 188.2 ± 0.035 | 195.0 ± 0.035 | 195.0 ± 0.037 | 186.1 ± 0.036 |

| 0% EtOH/ 0% ETBE | 2.3% EtOH/ 16.0% ETBE | 4.7% EtOH/ 11.0%ETBE | 7.3% EtOH/ 5.7% ETBE | 10% EtOH/ 0% ETBE | 0% EtOH/ 20.8% ETBE | |

|---|---|---|---|---|---|---|

| Units | - | |||||

| Sample I | 747.3 | 810.3 | 835 | 876.3 | 894.5 | 679.3 |

| Sample II | 784.7 | 791.3 | 880.0 | 920.7 | 923.6 | 700.3 |

| Sample III | 791.9 | 813.2 | 896.9 | 930.0 | 942.1 | 692.1 |

| Sample IV | 816.0 | 829.0 | 906.5 | 931.3 | 948.1 | 740.2 |

| Sample V | 861.6 | 882.8 | 946.3 | 980.9 | 1005.6 | 767.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michalopoulou, D.-P.; Komiotou, M.; Zannikou, Y.; Karonis, D. Impact of Bio-Ethanol, Bio-ETBE Addition on the Volatility of Gasoline with Oxygen Content at the Level of E10. Fuels 2021, 2, 501-520. https://doi.org/10.3390/fuels2040029

Michalopoulou D-P, Komiotou M, Zannikou Y, Karonis D. Impact of Bio-Ethanol, Bio-ETBE Addition on the Volatility of Gasoline with Oxygen Content at the Level of E10. Fuels. 2021; 2(4):501-520. https://doi.org/10.3390/fuels2040029

Chicago/Turabian StyleMichalopoulou, Dimitra-Panagiota, Maria Komiotou, Ypatia Zannikou, and Dimitrios Karonis. 2021. "Impact of Bio-Ethanol, Bio-ETBE Addition on the Volatility of Gasoline with Oxygen Content at the Level of E10" Fuels 2, no. 4: 501-520. https://doi.org/10.3390/fuels2040029

APA StyleMichalopoulou, D.-P., Komiotou, M., Zannikou, Y., & Karonis, D. (2021). Impact of Bio-Ethanol, Bio-ETBE Addition on the Volatility of Gasoline with Oxygen Content at the Level of E10. Fuels, 2(4), 501-520. https://doi.org/10.3390/fuels2040029