Abstract

In a circular economy, strategies for product recovery, such as reuse, recycling, and remanufacturing, play an important role at the end of a product’s life. A sustainability model was developed to solve the problem of sequence-dependent robotic disassembly line balancing. This research aimed to assess the viability of the model, which was optimised using the Multi-Objective Bees Algorithm in a robotic disassembly setting. Two industrial gear pumps were used as case studies. Four objectives (maximising profit, energy savings, emissions reductions and minimising line imbalance) were set. Several product recovery scenarios were developed to find the best recovery plans for each component. An efficient metaheuristic, the Bees Algorithm, was used to find the best solution. The robotic disassembly plans were generated and assigned to robotic workstations simultaneously. Using the proposed sustainability model on end-of-life industrial gear pumps shows the applicability of the model to real-world problems. The Multi-Objective Bees Algorithm was able to find the best scenario for product recovery by assigning each component to recycling, reuse, remanufacturing, or disposal. The performance of the algorithm is consistent, producing a similar performance for all sustainable strategies. This study addresses issues that arise with product recovery options for end-of-life products and provides optimal solutions through case studies.

Keywords:

Bees Algorithm; disassembly; end-of-life; product recovery; recycle; remanufacture; reuse; sustainability 1. Introduction

The United Nations’ Sustainable Development Goal 12 states that unsustainable production and consumption are the root causes of climate change, biodiversity loss, and pollution []. The circular economy is a way to address these problems by keeping products and materials in use for longer []. This is different from the linear economy, in which products are made from raw materials, then used, and finally thrown away. There are four main options in a circular economy: recycling, remanufacturing, repair and reuse. Recycling is the outermost loop in the circular economy technical cycle []. Recycling should be considered the last option at the end of a product’s life [] because it consumes more energy, generates waste, and causes pollution [,,] when compared to other options, the aim of which is to extend the product’s life span. Remanufacturing is expected to become an increasingly significant component of the future manufacturing sector, as it has the potential to generate an EU market of €90 billion by 2030 [] and is considered the backbone of a circular economy [,,]. Remanufacturing is a process of transforming an end-of-life (EoL) product to its original performance with a warranty that it is the same or better than a new product [,,,,,,]. Remanufacturing benefits the environment as it reduces waste, raw material usage, CO2 emissions, energy consumption and the need for landfill space [,,,,,,,,,,].

Disassembly is the first activity in remanufacturing [,,,,,,,,,], and due to complexities in EoL products, disassembly has generally to be kept a manual activity [,,]. However, technological developments in the current era of Industry 4.0 have facilitated the shift from human labour to automated processes. To ensure future success and be competitive, remanufacturing companies have to embrace automation []. Research interest in disassembly automation is reflected in the number of publications on that subject since 2014. Disassembly sequence planning and line balancing are two important research lines that promise to improve remanufacturing plant efficiency and productivity. Previous research in robotic disassembly has shown that it is important to consider the interconnection of sequence planning and line balancing, which are intertwined problems [,,,]. To reflect this, the term “sequence-dependent line balancing” is used in the majority of previous publications in this area, as it will be throughout the remainder of this article. Disassembly problems are NP-complete, meaning that the solution time grows exponentially as the number of components increases [,]. Previous research reports that a metaheuristic can find the optimal solution efficiently using a multi-objective approach when there are conflicting objectives [,,,,,,,,,]. The Bees Algorithm (BA) is a robust metaheuristic that can find the optimal solution to a complex problem, such as those involved in robotic disassembly [,,,]. Hence, a Multi-Objective Bees Algorithm (MOBA) was used as an optimisation tool for this study.

Most previous research on disassembly line balancing has been oriented toward maximising profit [,,,,,], the same with robotic disassembly line balancing. However, recent developments in robotic disassembly line balancing have incorporated sustainability as one of the objectives. This research was motivated by the need to expand the focus beyond profitability and address sustainability concerns. Sustainability was defined by the United Nations in 1987 as meeting the current needs without undermining the needs of future generations []. Sustainability is also described as the intersection of economic, social, and environmental factors—the-so-called triple bottom line []. A total of 35 articles on robotic disassembly line balancing published between 2014 and 2023 were found using the Scopus search engine. However, only 17 of those articles had sustainability as one of their objectives. Of those 17 articles, 10 focus on reduction of energy consumption [,,,,,,,,,], while two articles target the reduction of carbon emissions [,]. The present study contributes to the development of a sustainability model to fill a gap in robotic disassembly line balancing research, whereas prior studies have only focused on environmental aspects of sustainability. The model considers four objectives, namely, maximising profit, energy savings and environmental benefits and minimising line imbalance. In addition, this study provides a recovery path for each part such as recycling, reusing, or remanufacturing, and the last option of disposal if the parts cannot be recovered, which previous research did not address. This article considers optimal recovery options overlooked in previous research to propose a model for end-of-life products, taking real industrial products as examples. Four sustainability scenarios were developed, and the optimal solutions are presented. The scenarios are based on the characteristics of each component and developed after discussion with remanufacturers in England and Spain. In the REC (recycling) scenario, most of the components are recycled. In the REU (reuse) and REM (remanufacturing) scenarios, most of the components are reused or remanufactured, respectively. Unlike in previous work, the product recovery was optimised for each component by the algorithm in the OPT (optimal) scenario. The proposed model was applied to two industrial gear pumps under these four sustainability scenarios. Industrial gear pumps were chosen for their low wear, making them excellent subjects for studying complete disassembly sequence planning (DSP) without destruction. A hypervolume indicator was used to evaluate the optimal results found by the MOBA and to assess the performance of the algorithm.

The paper is structured as follows. The next section describes relevant previous work, the research steps, the proposed sustainability model, the case studies and the MOBA. The results obtained are then presented and analysed. The final section discusses the significance of the findings, summarises the main conclusions, outlines the study’s strengths and limitations, and suggests future research directions.

2. Relevant Work

As previously highlighted, the impact of disassembly sequences on line balancing is beginning to emerge. Existing research has shown that sequence-dependent manual disassembly line balancing [,,,,,,,,] is an increasingly significant phenomenon. Recent scholarly work, outlined in Table 1, further underscores the central role of sequence dependency in the field of robotic disassembly line balancing. Table 1 presents relevant publications in robotic disassembly line balancing.

Table 1.

Overview of Robotic Disassembly Line Balancing Research.

3. Methods

The first step in this research was to create a sustainability model for the sequence-dependent robotic disassembly line balancing (RDLBSD) problem. In the second step, input data for experiments and product recovery scenarios are prepared. In the final step, the optimisation algorithm used to find the optimal solution is described.

3.1. Sustainability Model for RDLBSD

The approach used in this research was to aggregate the first three objectives (profit, energy savings, and environmental benefits) and treat them as one goal and then use the non-dominated approach for the aggregated goal and the fourth objective (unbalanced line) using MOBA. This approach was used because the first three objectives have the same unit of measure, Euros (or dollars, or another currency), and the aim is maximisation. In contrast, the fourth objective measures imbalance in the disassembly line and aims to minimise it. The objective is expressed in Equation (1).

For these three objectives, a scalar approach was adopted using an aggregation method by adding the objective function in a linear way []. This is expressed in Equation (2). The objectives are to maximise profit, save energy and reduce environmental impact (see Equations (3)–(5)). The fourth objective is to minimise the unbalanced lines, as presented in Equation (6). This equation will result in zero if the disassembly line is in the perfect balance state []. Table 2, Table 3, Table 4 and Table 5 describe the variables for each objective.

Table 2.

Description of variables for economic profit.

Table 3.

Description of variable for energy savings.

Table 4.

Description of variables for environmental benefits.

Table 5.

Description of variables for unbalanced line.

Equation (3) assesses the economic profit of the whole disassembly process, obtained as the disassembly gains minus the disassembly costs. Disassembly gains include the revenues obtained from the components to be reused or remanufactured, and the revenues from the components to be recycled. Disassembly costs consist of the disposal costs of the components to be thrown away, the costs involved in the disassembly operations, the costs involved in the moving path of the robot, the recovery costs of the components to be reused or remanufactured, the overhead costs of the company, and the depreciation costs of the machinery (robotic cells).

Equation (4) defines the energy savings obtained in the whole disassembly process, obtained as the reclaimed energy from the components to be reused or remanufactured less the energy consumption in the disassembly process. Energy consumption includes the energy consumption of the robot in the disassembly of the components, the energy consumption of the robot in the movement between the position of disassembly and the magazine tools, the energy consumption of the robot in the tool change, the energy consumption of the robot in the movement between the magazine tools and the disassembly position, the energy consumption of the robot in the movement between disassembly points, the energy consumption involved in recovering the components to be reused, remanufactured, recycled or disposed of.

Equation (5) assesses the environmental benefit obtained in the whole disassembly process, expressed as the reclaimed environmental impact from components being reused or remanufactured, less the environmental impact caused by the disassembly operations and the recovery of the components, which includes the environmental impact in the recovering process, the environmental impact in the disassembly operations, and the environmental impact produced by the movement of the robot between disassembly operations.

The constraints are expressed in Equations (7)–(10). Equation (7) ensures that there is only one doable way to retrieve each component, either recycle, remanufacture, reuse, or dispose. Equation (8) ensures that each part has been completely taken apart. Equation (9) is needed to ensure that the precedence sequence is adhered to. Equation (10) ensures that the total number of removed components is lower than the product’s total number of components.

The model is based on several underlying assumptions. First, it presupposes that complete disassembly of all components is feasible. Second, it relies on the assumption that task times are both known and deterministic. Third, the model is founded on the premise that the remanufacturing company operates for 220 days annually, with 8-h shifts each day. Additionally, it takes into account an initial investment cost of 150,000 euros for the robotic cell and an hourly operating cost of 120 euros. Furthermore, the model considers the expected lifetime of the robotic cell.

3.2. Case Study

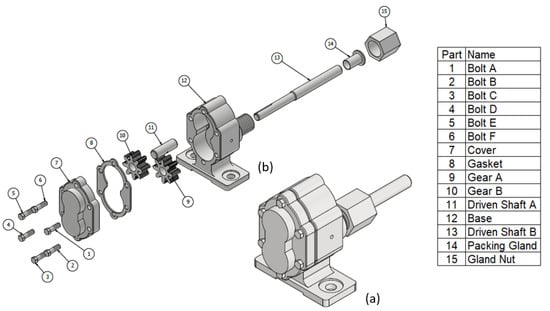

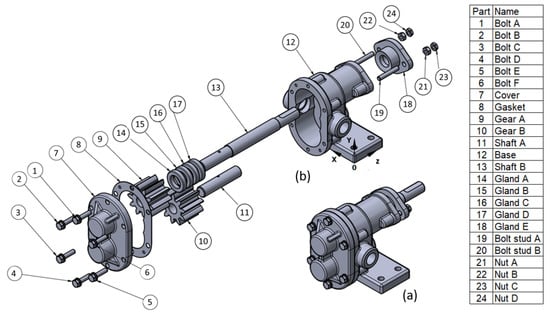

Two industrial gear pumps were chosen as case studies (see Figure 1 and Figure 2). The Bill of Materials (BOM) is provided in Table 6 and Table 7. The input data were prepared as follows. Data on the CAD model, component materials, gear pump properties, and disassembly tools were gathered. The space interference matrix was designed to represent the disassembly precedence in directions Y+ and Y−, as the gear pumps could only be dismantled in these two directions. These matrices considered the fastener and the so-called modified feasible solution generation (MFSG). The interested reader is referred to the article by Liu et al. [] on the development of MFSGs.

Figure 1.

Gear pump A: (a) assembled view; (b) exploded view. Source: Liu et al. [].

Figure 2.

Gear pump B: (a) assembled view; (b) exploded view. Source: Ramírez et al. [].

Table 6.

BOM for Gear Pump A.

Table 7.

BOM for Gear Pump B.

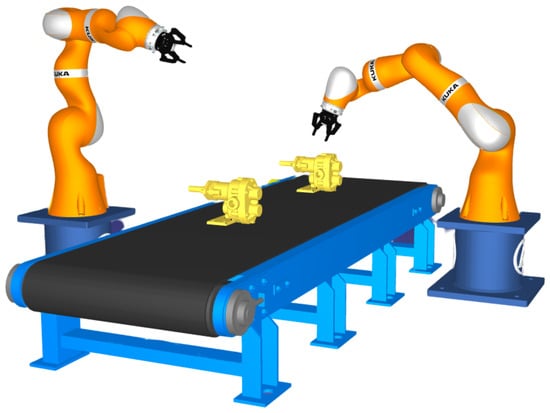

The KUKA LBR-iiwa 14 R820 robot was chosen for this study. Information about the robot was obtained from the manufacturer’s technical data sheet. Information and other data were collected from recycling and remanufacturing companies in the United Kingdom and Spain. As described earlier, the product recovery scenarios REC, REM, REU, and OPT for gear pumps were developed and are shown in Table 8 and Table 9. Figure 3 depicts a robotic disassembly line using two KUKA robots to disassemble a gear pump.

Table 8.

The product recovery options for the case study gear pump A.

Table 9.

The product recovery options for the case study gear pump B.

Figure 3.

Robotic disassembly line.

3.3. Multiobjective Bees Algorithm

As mentioned in the introduction, the disassembly problem is an NP-complete problem [,]. This designation indicates that it would take a significant amount of time to find the optimal solutions, making it inappropriate for real-world problems that require prompt solutions. In the past two decades, metaheuristic algorithms have been utilised by the majority of researchers as a method for acquiring optimal solutions more quickly, with this strategy being suitable for complex problems such as disassembly.

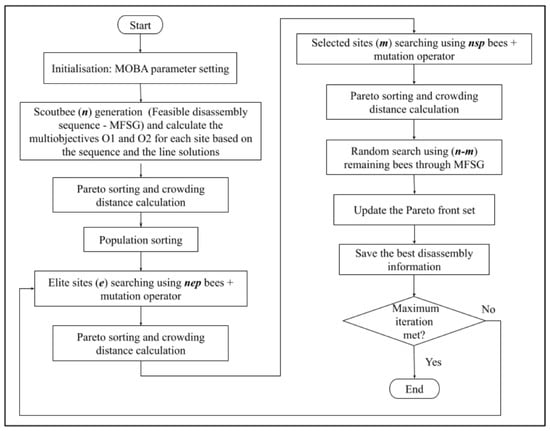

The Bees Algorithm is a population-based metaheuristic inspired by the foraging behaviour of bees, which can find sources of nectar by exploring the solution space and exploiting abundant nectar sources therin []. Recent research in remanufacturing applications that used the Bees Algorithm (BA) shows that it is a robust algorithm [,,]. In addition, it has been demonstrated that the BA outperforms other algorithms in the robotic disassembly line balancing problem [,]. A hybrid MOBA combining the aggregate and non-dominated approaches, as previously mentioned, was developed for this RDLBSD problem. Figure 4 depicts a flowchart of the hybrid MOBA.

Figure 4.

Hybrid MOBA flowchart.

The setting parameters for MOBA are as follows: number of elite sites (e) = 1, number of selected sites (m) = 5, number of recruited bees around elite sites () = 10, and number of recruited bees around selected sites () = 5 []. The maximum number of iterations and population size are varied to evaluate the algorithm’s performance under different parameter settings. The iteration was set to 100 and increased by 100 until 500, whereas the bees population was set to 50 and increased by 10 until 80. The experiments were run 50 times in MATLAB 2020a on the University of Birmingham’s BEAR Cloud Service.

4. Results

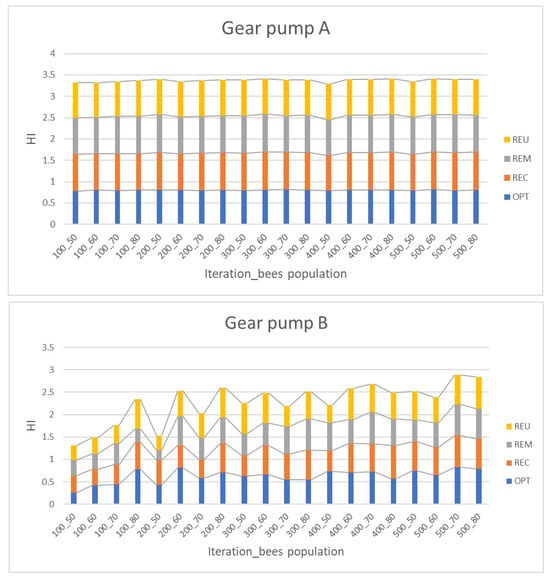

The hypervolume indicator (HI), which has become a standard, was the most widely used method for evaluating the performance of multiobjective algorithms []. Higher HI values are better because they show that the set of Pareto optimal solutions (POSs) is more diverse []. The indicator measures convergence and diversity [,]. The HI for both gear pumps is presented in Figure 5. The diagram demonstrates that for gear pump A, the HI in each scenario is reasonably similar. This indicates that the MOBA performs consistently. On the other hand, the HI for gear pump B is lower when a lower number of iterations and a smaller bee population are utilised. It becomes more consistent after 300 iterations. This is logical considering that gear pump A has fewer components than gear pump B.

Figure 5.

Hypervolume Indicator.

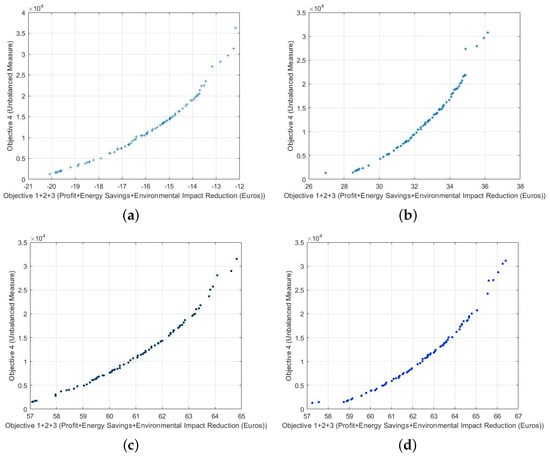

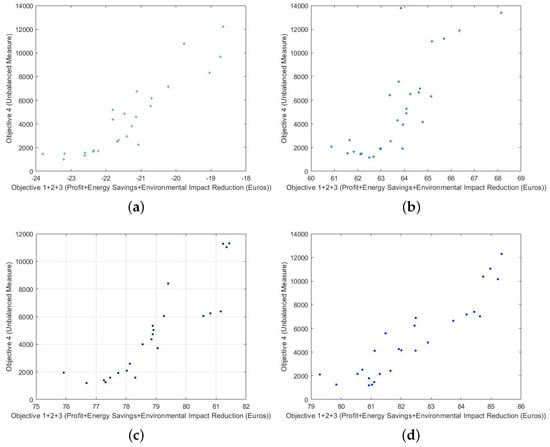

The following figures and tables show the output of the highest HI for each scenario. The Pareto optimal solutions are depicted in Figure 6 and Figure 7. The four scenarios show similar results; the difference can be seen in the x-axis, which measures the monetary goals.

Figure 6.

Plot of gear pump A best solutions under four sustainability scenarios (a) REC scenario; (b) REM scenario; (c) REU scenario; (d) OPT scenario.

Figure 7.

Plot of gear pump B best solutions under four sustainability scenarios (a) REC scenario; (b) REM scenario; (c) REU scenario; (d) OPT scenario.

The best outputs of the experiments are presented in Table 10 and Table 11, showing the disassembly sequence, the disassembly direction, the product recovery for each component, the disassembly tool, the robotic workstation, and the value of the objectives for the case study.

Table 10.

Example output of Gear Pump A under four scenarios.

Table 11.

Example output of Gear Pump B under four scenarios.

5. Discussion

The proposed sustainable product recovery model was implemented using the Bees Algorithm to optimise the integration of robotic disassembly sequence planning and disassembly line balancing, with two industrial gear pumps as case studies. The MOBA was able to find the best solutions for the proposed four strategies of REC (recycling), REM (remanufacturing), REU (reuse), and OPT (optimal). Comparing the four strategies, the REU and OPT show similar results, which is logical given that if the parts are retained and reused in remanufacturing, they will yield higher profit, energy savings and environmental benefits. The difference is that OPT, which is the strategy generated by the MOBA, outperforms the REC, REM and REU strategies, producing higher Euro values.

The maximum value was generated by the OPT scenario for both gear pumps A and B. This scenario is the best recovery option for each part and yields the maximum value for the first three objectives, which use Euros as the unit of measurement. As has been seen, the REC scenario results in negative monetary values as the activities involving recycling demand a greater amount of energy and other resources. Recycling presents greater challenges than the other product recovery options, including the separation of EoL product materials to achieve a higher quality of material, energy consumption, and environmental impact. This finding supports the notion that recycling should be the last product recovery option. The proposed model could be adopted by industries to extend the life of resources and environmental benefits, allowing them to make the best product recovery decisions.

Although the sustainability model and product recovery options presented in this study show good results, a limitation is that it assumes that the EoL product can be completely disassembled and is in good condition. However, it is known that the condition of an incoming EoL product is uncertain. It might be worn out or corroded or have missing parts and other problems. This should be investigated in the future.

Nonetheless, the encouraging results obtained should motivate academic researchers and companies to investigate the possibility of incorporating the proposed model, given that doing so would increase productivity, efficiency, and monetary value while simultaneously making a positive contribution to the environment.

6. Conclusions

The viability of the sustainability model was demonstrated on real EoL products by optimising it using the Multi-Objective Bees Algorithm. This demonstrated that the model could be applied to a robotic disassembly cell. The recovery strategies show that recycling should be the final option, which is consistent with the circular economy’s goals. Since robotic disassembly is emerging research while manual disassembly has matured, future work should consider tools in manual disassembly research, such as machine learning (including deep learning), that could also be used to investigate robotic disassembly. Additionally, other metaheuristic optimisation algorithms could be added as benchmarks. Furthermore, future studies will involve other more complex EoL products to demonstrate the versatility of this method. Finally, further studies could be conducted on the impact of incoming product uncertainty on disassembly.

Author Contributions

Conceptualization, D.T.P. and F.J.R.; methodology, D.T.P., F.J.R. and N.H.; software, N.H.; validation, D.T.P., F.J.R. and N.H.; formal analysis, N.H.; investigation, D.T.P., F.J.R. and N.H.; resources, D.T.P. and F.J.R.; data curation, D.T.P., F.J.R. and N.H.; writing—original draft preparation, N.H., F.J.R. and D.T.P.; writing—review and editing, D.T.P., F.J.R. and N.H.; visualization, N.H.; supervision, D.T.P. and F.J.R.; project administration, D.T.P.; funding acquisition, D.T.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Engineering and Physical Sciences Research Council (EPSRC), UK grant no. EP/N018524/1. Natalia Hartono’s doctoral study is supported by the Indonesian Endowment Fund for Education (LPDP), Ministry of Finance, Republic of Indonesia, grant no. 201908222215155 under the BUDI LN scheme.

Data Availability Statement

The data presented in this study are available in http://etheses.bham.ac.uk//id/eprint/14384/ (accessed on 25 November 2023).

Acknowledgments

The authors would like to thank the University of Birmingham for providing flexible resources for intensive computational work to the University of Birmingham’s research community through the BEAR Cloud Service.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| BA | Bees Algorithm |

| CAD | Computer-Aided Design |

| EoL | End-of-Life |

| HI | Hypervolume Indicator |

| MFSG | Modified Feasible Solution Generation |

| MO | Multi-objective |

| MOBA | Multi-Objective Bees Algorithm |

| MCDM | Multiple-criteria Decision-making |

| NP | Non-Deterministic Polynomial |

| OPT | Optimal |

| POSs | Pareto Optimal Solutions |

| REC | Recycling |

| REM | Remanufacturing |

| REU | Reuse |

| RDLBSD | Sequence-Dependent Robotic Disassembly Line Balancing |

References

- Goal 12 Ensure Sustainable Consumption and Production Patterns. Available online: https://sdgs.un.org/goals/goal12 (accessed on 2 February 2023).

- Circular Economy Introduction. Available online: https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed on 2 February 2023).

- Anil Kumar, G.; Bahubalendruni, M.; Prasad, V.; Sankaranarayanasamy, K. A multi-layered disassembly sequence planning method to support decision making in de-manufacturing. Sādhanā 2021, 46, 102. [Google Scholar] [CrossRef]

- King, A.; Burgess, S.; Ijomah, W.; McMahon, C. Reducing waste: Repair, recondition, remanufacture or recycle? Sustain. Dev. 2006, 14, 257–267. [Google Scholar] [CrossRef]

- Ijomah, W. The application of remanufacturing in sustainable manufacture. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2006, 163, 157–163. [Google Scholar] [CrossRef]

- The European Remanufacturing Network. Available online: https://www.remanufacturing.eu/ (accessed on 2 February 2023).

- Supporting Remanufacturing—The Backbone of the Circular Economy. Available online: https://www.remancouncil.eu/ (accessed on 2 February 2023).

- Kurilova-Palisaitiene, J.; Sundin, E.; Poksinska, B. Remanufacturing challenges and possible lean improvements. J. Clean. Prod. 2018, 172, 3225–3236. [Google Scholar] [CrossRef]

- Jensen, J.; Prendeville, S.; Bocken, N.; Peck, D. Creating sustainable value through remanufacturing: Three industry cases. J. Clean. Prod. 2019, 218, 304–314. [Google Scholar] [CrossRef]

- BS 8887-220; Design for Manufacture, Assembly, Disassembly and End-of-Life Processing (MADE). The Process of Remanufacture. Specification. British Standard Institution: London, UK, 2010. [CrossRef]

- Steinhilper, R. Recent trends and benefits of remanufacturing: From closed loop businesses to synergetic networks. In Proceedings of the Second International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 11–15 December 2001; pp. 481–488. [Google Scholar]

- Matsumoto, M.; Ijomah, W. Remanufacturing. In Handbook of Sustainable Engineering; Kauffman, J., Ed.; Springer: Dordrech, The Netherlands, 2013. [Google Scholar] [CrossRef]

- What Is Remanufacturing? Available online: https://www.remancouncil.org/educate/remanufacturing-information/what-is-remanufacturing (accessed on 1 September 2023).

- Hamzaoui-Essoussi, L.; Linton, J. Offering branded remanufactured/recycled products: At what price? J. Remanuf. 2014, 4, 1–15. [Google Scholar] [CrossRef]

- Hormozi, A. Parts remanufacturing in the automotive industry. Prod. Inventory Manag. J. 1997, 38, 26. [Google Scholar]

- Singhal, D.; Tripathy, S.; Jena, S. Remanufacturing for the circular economy: Study and evaluation of critical factors. Resour. Conserv. Recycl. 2020, 156, 104681. [Google Scholar] [CrossRef]

- Ciptomulyono, U.; Mustajib, M.; Karningsih, P.; Anggrahini, D.; Basuki, S. A new multi-criteria method based on DEMATEL, ANP and grey clustering for quality sorting of incoming cores in remanufacturing systems under epistemic uncertainty: A case study of heavy-duty equipment. Cogent Eng. 2022, 9, 2099056. [Google Scholar] [CrossRef]

- Sutherland, J.; Adler, D.; Haapala, K.; Kumar, V. A comparison of manufacturing and remanufacturing energy intensities with application to diesel engine production. CIRP Ann. 2008, 57, 5–8. [Google Scholar] [CrossRef]

- Chiodo, J.D.; Ijomah, W.L. Use of active disassembly technology to improve remanufacturing productivity: Automotive application. Int. J. Comput. Integr. Manuf. 2014, 27, 361–371. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, M.; Zhang, H.; Jiang, Z.; Liu, C.; Cai, W. A review on energy, environment and economic assessment in remanufacturing based on life cycle assessment method. J. Clean. Prod. 2020, 255, 120160. [Google Scholar] [CrossRef]

- Zhuang, X.; Song, X.; Yang, H.; Zhao, D.; Wu, W.; Zhao, J. The energy saving and GHG mitigation benefits assessment of product remanufacturing from a multi-life cycle perspective: A case study of spark plug. Environ. Impact Assess. Rev. 2023, 99, 107018. [Google Scholar] [CrossRef]

- Li, K.; Zhang, L.; Fu, H.; Liu, B. The effect of intelligent manufacturing on remanufacturing decisions. Comput. Ind. Eng. 2023, 178, 109114. [Google Scholar] [CrossRef]

- Xia, X.; Lu, M.; Wang, W. Emission reduction and outsourcing remanufacturing: A comparative study under carbon trading. Expert Syst. Appl. 2023, 227, 120317. [Google Scholar] [CrossRef]

- Liao, H.; Deng, Q.; Wang, Y.; Guo, S.; Ren, Q. An environmental benefits and costs assessment model for remanufacturing process under quality uncertainty. J. Clean. Prod. 2018, 178, 45–58. [Google Scholar] [CrossRef]

- Jiang, Z.; Ding, Z.; Zhang, H.; Cai, W.; Liu, Y. Data-driven ecological performance evaluation for remanufacturing process. Energy Convers. Manag. 2019, 198, 111844. [Google Scholar] [CrossRef]

- Peng, S.; Ping, J.; Li, T.; Wang, F.; Zhang, H.; Liu, C. Environmental benefits of remanufacturing mechanical products: A harmonized meta-analysis of comparative life cycle assessment studies. J. Environ. Manag. 2022, 306, 114479. [Google Scholar] [CrossRef] [PubMed]

- Diener, D.; Tillman, A. Component end-of-life management: Exploring opportunities and related benefits of remanufacturing and functional recycling. Resour. Conserv. Recycl. 2015, 102, 80–93. [Google Scholar] [CrossRef]

- Wang, K.; Gao, L.; Li, X.; Li, P. Energy-efficient robotic parallel disassembly sequence planning for end-of-life products. IEEE Trans. Autom. Sci. Eng. 2021, 19, 1277–1285. [Google Scholar] [CrossRef]

- Liu, J.; Wang, S. Balancing disassembly line in product recovery to promote the coordinated development of economy and environment. Sustainability 2017, 9, 309. [Google Scholar] [CrossRef]

- Ma, Y.; Jun, H.; Kim, H.; Lee, D. Disassembly process planning algorithms for end-of-life product recovery and environmentally conscious disposal. Int. J. Prod. Res. 2011, 49, 7007–7027. [Google Scholar] [CrossRef]

- Vongbunyong, S.; Kara, S.; Pagnucco, M. Learning and revision in cognitive robotics disassembly automation. Robot. Comput. Integr. Manuf. 2015, 34, 79–94. [Google Scholar] [CrossRef]

- Vongbunyong, S.; Vongseela, P.; Sreerattana-aporn, J. A process demonstration platform for product disassembly skills transfer. Procedia CIRP 2017, 61, 281–286. [Google Scholar] [CrossRef]

- McGovern, S.; Gupta, S. Disassembly Line: Balancing and Modeling; McGraw-Hill Education: New York, NY, USA, 2011. [Google Scholar]

- Seidi, M.; Saghari, S. The balancing of disassembly line of automobile engine using genetic algorithm (GA) in fuzzy environment. Ind. Eng. Manag. Syst. 2016, 15, 364–373. [Google Scholar] [CrossRef]

- Kose, Y.; Cevikcan, E.; Ertemel, S.; Murat, M. Game theory-oriented approach for disassembly line worker assignment and balancing problem with multi-manned workstations. Comput. Ind. Eng. 2023, 181, 109294. [Google Scholar] [CrossRef]

- Priyono, A.; Ijomah, W.; Bititci, U. Disassembly for remanufacturing: A systematic literature review, new model development and future research needs. J. Ind. Eng. Manag. (JIEM) 2016, 9, 899–932. [Google Scholar] [CrossRef]

- Priyono, A.; Ijomah, W.; Bititci, U. Strategic operations framework for disassembly in remanufacturing. J. Remanuf. 2015, 5, 1–16. [Google Scholar] [CrossRef]

- Wang, G.; Wu, H.; Xiao, J. A Genetic Algorithm-Based Optimization Approach for Disassembly Tool Selections toward Electric Vehicle Battery Disassembly. In Proceedings of the 2023 9th International Conference On Mechatronics And Robotics Engineering (ICMRE), Shenzhen, China, 10–12 February 2023; pp. 192–196. [Google Scholar]

- Liu, J.; Zhou, Z.; Pham, D.T.; Xu, W.; Ji, C.; Liu, Q. Collaborative optimization of robotic disassembly sequence planning and robotic disassembly line balancing problem using improved discrete Bees algorithm in remanufacturing. Robot. Comput. Integr. Manuf. 2020, 61, 101829. [Google Scholar] [CrossRef]

- Harper, G.; Kendrick, E.; Anderson, P.; Mrozik, W.; Christensen, P.; Lambert, S.; Greenwood, D.; Das, P.; Ahmeid, M.; Milojevic, Z. Others Roadmap for a sustainable circular economy in lithium-ion and future battery technologies. J. Physics: Energy 2023, 5, 021501. [Google Scholar]

- Poschmann, H.; Brueggemann, H.; Goldmann, D. Disassembly 4.0: A review on using robotics in disassembly tasks as a way of automation. Chem. Ing. Tech. 2020, 92, 341–359. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Z.; Pham, D.T.; Xu, W.; Yan, J.; Liu, A.; Ji, C.; Liu, Q. An improved multi-objective discrete bees algorithm for robotic disassembly line balancing problem in remanufacturing. Int. J. Adv. Manuf. Technol. 2018, 97, 3937–3962. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Q.; Feng, Y.; Zheng, H.; Zheng, B.; Tan, J. An energy-saving optimization method of dynamic scheduling for disassembly line. Energies 2018, 11, 1261. [Google Scholar] [CrossRef]

- Chen, Q.; Yao, B.; Pham, D.T. Sequence-dependent robotic disassembly line balancing problem considering disassembly path. Int. Manuf. Sci. Eng. Conf. 2020, 84263, V002T07A019. [Google Scholar]

- Cevikcan, E.; Aslan, D.; Yeni, F.B. Disassembly line design with multi-manned workstations: A novel heuristic optimisation approach. Int. J. Prod. Res. 2020, 58, 649–670. [Google Scholar] [CrossRef]

- Guo, J.; Pu, Z.; Du, B.; Li, Y. Multi-objective optimisation of stochastic hybrid production line balancing including assembly and disassembly tasks. Int. J. Prod. Res. 2022, 60, 2884–2900. [Google Scholar] [CrossRef]

- Fang, Y.; Liu, Q.; Li, M.; Laili, Y.; Pham, D.T. Evolutionary many-objective optimization for mixed-model disassembly line balancing with multi-robotic workstations. Eur. J. Oper. Res. 2019, 1, 160–174. [Google Scholar] [CrossRef]

- Fang, Y.; Wei, H.; Liu, Q.; Li, Y.; Zhou, Z.; Pham, D.T. Minimizing energy consumption and line length of mixed-model multirobotic disassembly line systems using multi-objective evolutionary optimization. In Proceedings of the ASME 2019 14th International Manufacturing Science and Engineering Conference, Erie, PA, USA, 10–14 June 2019. [Google Scholar]

- Fang, Y.; Ming, H.; Li, M.; Liu, Q.; Pham, D.T. Multi-objective evolutionary simulated annealing optimisation for mixed-model multi-robotic disassembly line balancing with interval processing time. Int. J. Prod. Res. 2020, 58, 846–862. [Google Scholar] [CrossRef]

- Fang, Y.; Xu, H. Constraint Handling Methods for Resource-Constrained Robotic Disassembly Line Balancing Problem. J. Phys. Conf. Ser. 2020, 1576, 012039. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Fang, Y.; Laili, Y.; Luo, P.; Pham, D.T. Many-objective best-order-sort genetic algorithm for mixed-model multi-robotic disassembly line balancing. Procedia CIRP 2019, 83, 14–21. [Google Scholar] [CrossRef]

- Dong, C.; Liu, P.; Guo, X.W.; Qi, L.; Qin, S.; Xu, G. Multi-objective ant lion optimizer for stochastic robotic disassembly line balancing problem subject to resource constraints. J. Phys. Conf. Ser. 2021, 2024, 012014. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, L.; Guo, X.; Liu, S.; Qi, L.; Qin, S.; Tang, Y.; Zhao, Z. Multi-objective multi-verse optimizer for multi-product partial U-shaped disassembly line balancing problem. In Proceedings of the 2021 IEEE International Conference on Networking, Sensing and Control (ICNSC), Xiamen, China, 3–5 December 2021. [Google Scholar]

- Zhou, B.; Bian, J. Multi-mechanism-based modified bi-objective Harris Hawks optimization for sustainable robotic disassembly line balancing problems. Eng. Appl. Artif. Intell. 2022, 116, 105479. [Google Scholar] [CrossRef]

- Yin, T.; Zhang, Z.; Zhang, Y.; Wu, T.; Liang, W. Mixed-integer programming model and hybrid driving algorithm for multi-product partial disassembly line balancing problem with multi-robot workstations. Robot. Comput. Integr. Manuf. 2022, 73, 102251. [Google Scholar] [CrossRef]

- Laili, Y.; Wang, Y.; Fang, Y.; Pham, D.T. Robotic disassembly sequence re-planning. In Optimisation of Robotic Disassembly for Remanufacturing; Pham, D.T., Ed.; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2022; pp. 131–142. [Google Scholar]

- Hartono, N.; Ramírez, F.J.; Pham, D.T. Optimisation of robotic disassembly sequence plans for sustainability using the multi-objective Bees Algorithm. In Intelligent Production and Manufacturing Optimisation—The Bees Algorithm Approach; Pham, D.T., Hartono, N., Eds.; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2022; pp. 337–363. [Google Scholar]

- Ren, Y.; Yu, D.; Zhang, C.; Tian, G.; Meng, L.; Zhou, X. An improved gravitational search algorithm for profit-oriented partial disassembly line balancing problem. Int. J. Prod. Res. 2017, 55, 7302–7316. [Google Scholar] [CrossRef]

- Singh, R.; Singh, A.; Yadav, R. A balanced-quantum inspired evolutionary algorithm for solving disassembly line balancing problem. Appl. Soft Comput. 2023, 132, 109840. [Google Scholar] [CrossRef]

- Xi, G.; Wang, J.; Guo, X.; Liu, S.; Qin, S.; Qi, L. Hybrid Disassembly Line Optimization with Reinforcement Learning. In Proceedings of the 2023 32nd Wireless And Optical Communications Conference (WOCC), Newark, NJ, USA, 5–6 May 2023; pp. 1–5. [Google Scholar]

- Bentaha, M.; Battaïa, O.; Dolgui, A. Chance constrained programming model for stochastic profit-oriented disassembly line balancing in the presence of hazardous parts. In Proceedings of the Advances In Production Management Systems. Sustainable Production And Service Supply Chains: IFIP WG 5.7 International Conference, APMS 2013, State College, PA, USA, 9–12 September 2013; Proceedings, Part I. pp. 103–110. [Google Scholar]

- Bentaha, M.; Battala, O.; Dolgui, A. A decomposition method for stochastic partial disassembly line balancing with profit maximization. In Proceedings of the 2013 IEEE International Conference On Automation Science And Engineering (CASE), Madison, WI, USA, 17–20 August 2013; pp. 404–409. [Google Scholar]

- Altekin, F.; Kandiller, L.; Ozdemirel, N. Profit-oriented disassembly-line balancing. Int. J. Prod. Res. 2008, 46, 2675–2693. [Google Scholar] [CrossRef]

- Sustainability. Available online: https://www.un.org/en/academic-impact/sustainability (accessed on 7 January 2023).

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Ming, H.; Liu, Q.; Pham, D.T. Multi-robotic disassembly line balancing with uncertain processing time. Procedia CIRP 2019, 83, 71–76. [Google Scholar] [CrossRef]

- Mei, K.; Fang, Y. Multi-robotic disassembly line balancing using deep reinforment learning. In Proceedings of the ASME 2021 16th International Manufacturing Science and Engineering Conference, MSEC 2021, Virtual, Online, 21–25 June 2021; Volume 2. [Google Scholar]

- Kalayci, C.; Gupta, S. A particle swarm optimization algorithm with neighborhood-based mutation for sequence-dependent disassembly line balancing problem. Int. J. Adv. Manuf. Technol. 2013, 69, 197–209. [Google Scholar] [CrossRef]

- Kalayci, C.; Gupta, S. Ant colony optimization for sequence-dependent disassembly line balancing problem. J. Manuf. Technol. Manag. 2013, 24, 413–427. [Google Scholar] [CrossRef]

- Kalayci, C.; Gupta, S. Artificial bee colony algorithm for solving sequence-dependent disassembly line balancing problem. Expert Syst. Appl. 2013, 40, 7231–7241. [Google Scholar] [CrossRef]

- Kalayci, C.; Gupta, S. Balancing a sequence-dependent disassembly line using simulated annealing algorithm. Appl. Manag. Sci. 2013, 16, 81–103. [Google Scholar]

- Kalayci, C.; Gupta, S. River formation dynamics approach for sequence-dependent disassembly line balancing problem. In Reverse Supply Chains; CRC Press: Boca Raton, FL, USA, 2013; pp. 289–312. [Google Scholar] [CrossRef]

- Kalayci, C.; Gupta, S. Simulated annealing algorithm for solving sequence-dependent disassembly line balancing problem. IFAC Proc. Vol. 2013, 46, 93–98. [Google Scholar] [CrossRef]

- Kalayci, C.; Gupta, S. A tabu search algorithm for balancing a sequence-dependent disassembly line. Prod. Plan. Control. 2014, 25, 149–160. [Google Scholar] [CrossRef]

- Kalayci, C.; Polat, O.; Gupta, S. A hybrid genetic algorithm for sequence-dependent disassembly line balancing problem. Ann. Oper. Res. 2016, 242, 321–335. [Google Scholar] [CrossRef]

- Jia, L.; Shuwei, W. A proposed multi-objective optimization model for sequence-dependent disassembly line balancing problem. In Proceedings of the 2017 3rd International Conference on Information Management (ICIM), Chengdu, China, 21–23 April 2017; pp. 421–425. [Google Scholar]

- Radaschin, A.; Filipescu, A.; Minzu, V.; Minca, E. Adaptive disassembly sequence control by using mobile robots and system information. In Proceedings of the 15th International Conference on System Theory, Control and Computing, Sinaia, Romania, 14–16 October 2011; pp. 1–6. [Google Scholar]

- Minca, E.; Filipescu, A.; Voda, A. Modelling and control of an assembly/disassembly mechatronics line served by mobile robot with manipulator. Control. Eng. Pract. 2014, 31, 50–62. [Google Scholar] [CrossRef]

- Minca, E.; Coanda, H.; Dragomir, F.; Dragomir, O.; Filipescu, A. Cycle time optimization of a reversible A/DML served by a mobile robotic system. In Proceedings of the 2015 19th International Conference on System Theory, Control and Computing (ICSTCC), Cheile Gradistei, Romania, 14–16 October 2015; pp. 99–104. [Google Scholar]

- Filipescu, A.; Filipescu, A.; Voda, A.; Minca, E. Hybrid modeling, balancing and control of a mechatronics line served by two mobile robots. In Proceedings of the 2016 20th International Conference on System Theory, Control and Computing, ICSTCC 2016—Joint Conference of SINTES 20, SACCS 16, SIMSIS 20—Proceedings, Sinaia, Romania, 13–15 October 2016; pp. 234–239. [Google Scholar]

- Alshibli, M.; ElSayed, A.; Kongar, E.; Sobh, T.; Gupta, S. A Robust Robotic Disassembly Sequence Design using Orthogonal arrays and Task Allocation. Robotics 2019, 8, 20. [Google Scholar] [CrossRef]

- Octavian, D.; Gurgu, V.; Minca, E.; Filipescu, A.; Dragomir, F.; Dragomir, O. Optimal control of the complete assembly/disassembly cycle for a mechatronics line prototype. In Proceedings of the 2019 23rd International Conference On System Theory, Control And Computing, ICSTCC 2019—Proceedings, Sinaia, Romania, 9–11 October 2019; pp. 620–625. [Google Scholar]

- Çil, Z.; Mete, S.; Serin, F. Robotic Disassembly Line Balancing Problem: A Mathematical model and Ant Colony Optimization Approach. Appl. Math. Model. 2020, 86, 335–348. [Google Scholar] [CrossRef]

- Fang, Y.; Xu, H.; Liu, Q.; Pham, D. Evolutionary optimization using epsilon method for resource-constrained multi-robotic disassembly line balancing. J. Manuf. Syst. 2020, 56, 392–413. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, H.; Liu, Q.; Zhou, Z.; Yao, B.; Pham, D. Interval multi-objective evolutionary optimization for disassembly line balancing with uncertain task time. In Proceedings of the ASME 2020 15th International Manufacturing Science And Engineering Conference, MSEC 2020, Virtual, Online, 3 September 2020; Volume 2. [Google Scholar]

- Lei, S.; Guo, X.; Zhou, M.; Wang, J.; Qi, L.; Qin, S. A Constrained Decomposition Grid Approach to Disassembly Line Balancing Problems. In Proceedings of the 2021 International Conference on Advanced Mechatronic Systems (ICAMechS), Tokyo, Japan, 9–12 December 2021; pp. 162–167. [Google Scholar]

- Tseng, H.; Chang, C.; Chung, T. Applying Improved Particle Swarm Optimization to Asynchronous Parallel Disassembly Planning. IEEE Access 2022, 10, 80555–80564. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhang, Z.; Yin, T.; Zheng, H. Robotic disassembly line balancing and sequencing problem considering energy-saving and high-profit for waste household appliances. J. Clean. Prod. 2022, 381, 135209. [Google Scholar] [CrossRef]

- Laili, Y.; Wang, Y.; Fang, Y.; Pham, D.; Laili, Y.; Wang, Y.; Fang, Y.; Pham, D. Solutions for Mixed-Model Disassembly Line Balancing with Multi-robot Workstations. In Optimisation Of Robotic Disassembly For Remanufacturing; Springer: Cham, Switzerland, 2022; pp. 153–180. [Google Scholar]

- Zhang, S.; Liu, P.; Guo, X.; Wang, J.; Qin, S.; Tang, Y. An Improved Tabu Search Algorithm for Multi-robot Hybrid Disassembly Line Balancing Problems. In Proceedings of the 2022 International Conference On Cyber-Physical Social Intelligence (ICCSI), Nanjing, China, 18–21 November 2022; pp. 315–320. [Google Scholar]

- Zhang, S.; Guo, X.; Wang, J.; Liu, S.; Qin, S.; Zhao, Z. An Improved Multi-objective Multi-verse Optimization Algorithm for Multifunctional Robotic Parallel Disassembly Line Balancing Problems. In Proceedings of the 2022 IEEE International Conference On Systems, Man, And Cybernetics (SMC), Prague, Czech Republic, 9–12 October 2022; pp. 562–567. [Google Scholar]

- Laili, Y.; Wang, Y.; Fang, Y.; Pham, D.; Laili, Y.; Wang, Y.; Fang, Y.; Pham, D. Solutions for Robotic Disassembly Line Balancing. In Optimisation Of Robotic Disassembly For Remanufacturing; Springer: Cham, Switzerland, 2022; pp. 143–151. [Google Scholar]

- Xu, G.; Zhang, Z.; Li, Z.; Guo, X.; Qi, L.; Liu, X. Multi-Objective Discrete Brainstorming Optimizer to Solve the Stochastic Multiple-Product Robotic Disassembly Line Balancing Problem Subject to Disassembly Failures. Mathematics 2023, 11, 1557. [Google Scholar] [CrossRef]

- Qin, S.; Zhang, S.; Wang, J.; Liu, S.; Guo, X.; Qi, L. Multi-objective Multi-verse Optimizer for Multi-robotic U-shaped Disassembly Line Balancing Problems. IEEE Trans. Artif. Intell. 2023. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Q.; Zhou, Z.; Pham, D.; Xu, W.; Fang, Y. Collaborative Optimisation of Robotic Disassembly Planning Problems using the Bees Algorithm. In Intelligent Production And Manufacturing Optimisation—The Bees Algorithm Approach; Springer: Cham, Switzerland, 2023; pp. 305–335. [Google Scholar]

- Talbi, E. Metaheuristics: From Design to Implementation; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- McGovern, S.; Gupta, S.M. Greedy algorithm for disassembly line scheduling. In Proceedings of the 2003 IEEE International Conference on Systems, Man and Cybernetics, Washington, DC, USA, 8 October 2003. [Google Scholar]

- Ramírez, F.J.; Aledo, J.A.; Gamez, J.A.; Pham, D.T. Economic modelling of robotic disassembly in end-of-life product recovery for remanufacturing. Comput. Ind. Eng. 2020, 142, 106339. [Google Scholar] [CrossRef]

- Pham, D.T.; Ghanbarzadeh, A.; Koç, E.; Otri, S.; Rahim, S.; Zaidi, M. The Bees Algorithm—A novel tool for complex optimisation problems. In Intelligent Production Machines and Systems; Elsevier: Oxford, UK, 2006. [Google Scholar]

- Kerin, M.; Hartono, N.; Pham, D.T. Optimising remanufacturing decision-making using the bees algorithm in product digital twins. Sci. Rep. 2023, 13, 701. [Google Scholar] [CrossRef] [PubMed]

- Zitzler, E.; Knowles, J.; Thiele, L. Quality Assessment of Pareto Set Approximations. In Multiobjective Optimization: Interactive and Evolutionary Approaches; Branke, J., Deb, K., Miettinen, K., Słowiński, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 373–404. [Google Scholar]

- Halim, A.H.; Ismail, I.; Das, S. Performance assessment of the metaheuristic optimization algorithms: An exhaustive review. Artif. Intell. Rev. 2020, 54, 2323–2409. [Google Scholar] [CrossRef]

- Cao, Y.; Smucker, B.; Robinson, T.J. On using the hypervolume indicator to compare Pareto fronts: Applications to multi-criteria optimal experimental design. J. Stat. Plan. Inference 2015, 160, 60–74. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).