Evaluation of the Environmental Performance of Stevia Glycoside Production Using Precision Agriculture and Green Processing Techniques †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Life Cycle Assessment (LCA) Methodology

2.1.1. Product Systems

2.1.2. Functional Unit

2.1.3. System Boundaries

2.1.4. Inventory Analysis

2.1.5. Impact Assessment Methodology

2.2. Systems Description

2.2.1. System A

2.2.2. System B

2.2.3. System C

2.2.4. System D

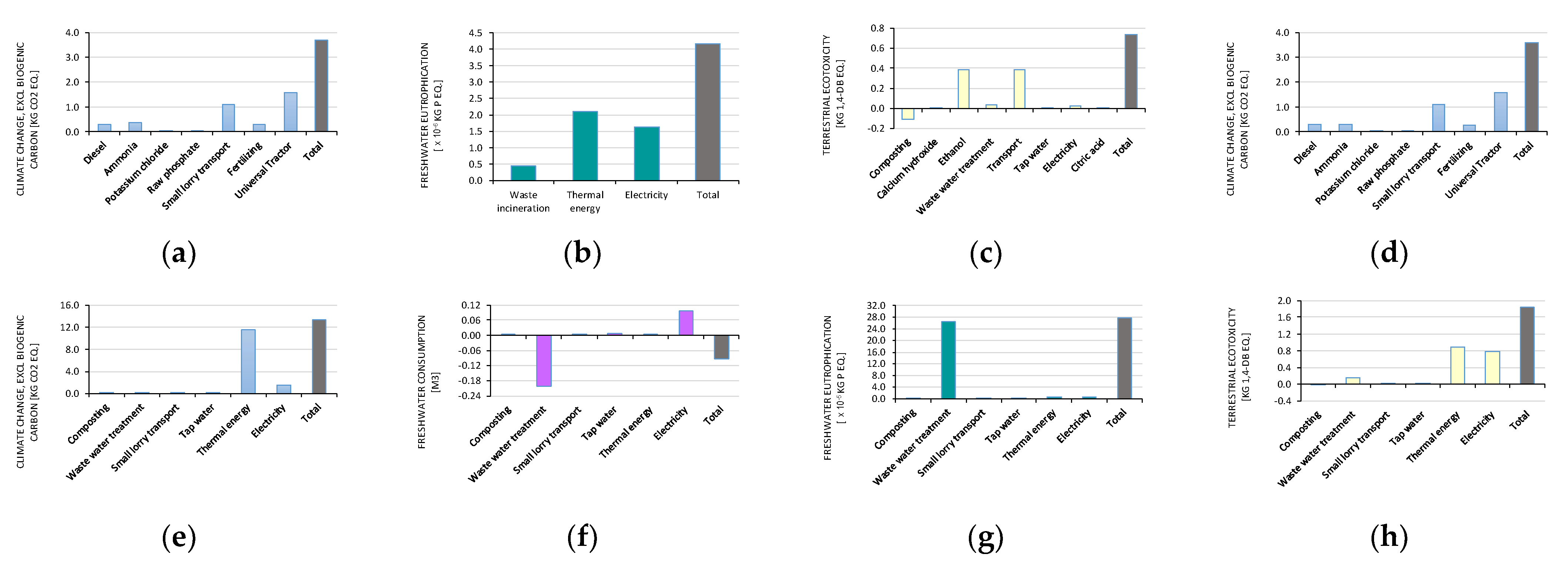

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- López-Carbón, V.; Sayago, A.; González-Domínguez, R.; Fernández-Recamales, A. Simple and Efficient Green Extraction of Steviol Glycosides from Stevia rebaudiana Leaves. Foods 2019, 8, 402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaushik, R.; Narayanan, P.; Vasudevan, V.; Muthukumaran, G.; Usha, A. Nutrient composition of cultivated stevia leaves and the influence of polyphenols and plant pigments on sensory and antioxidant properties of leaf extracts. J. Food Sci. Technol. 2010, 47, 27–33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; Wal, T.V.d.; Soto, I.; Gómez-Barbero, M.; Barnes, A.; Eory, V. Precision Agriculture Technologies Positively Contributing to GHG Emissions Mitigation, Farm Productivity and Economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef] [Green Version]

- Singh, P.; Pandey, P.C.; Petropoulos, G.P.; Pavlides, A.; Srivastava, P.K.; Koutsias, N.; Deng, K.A.K.; Bao, Y. 8—Hyperspectral remote sensing in precision agriculture: Present status, challenges, and future trends. In Hyperspectral Remote Sensing; Pandey, P.C., Srivastava, P.K., Balzter, H., Bhattacharya, B., Petropoulos, G.P., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 121–146. [Google Scholar]

- Yılmaz, F.M.; Görgüç, A.; Uygun, Ö.; Bircan, C. Steviol glycosides and polyphenols extraction from Stevia rebaudiana Bertoni leaves using maceration, microwave-, and ultrasound-assisted techniques. Sep. Sci. Technol. 2021, 56, 936–948. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Chapter Five—Life Cycle Assessment. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 57–75. [Google Scholar]

- Huijbregts, M.; Steinmann, Z.; Elshout, P.; Stam, G.; Verones, F.; Vieira, M.; Van Zelm, R. ReCiPe2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess 2017, 22, 138–147. [Google Scholar] [CrossRef]

| Endpoints | System A | System B | System C | System D |

|---|---|---|---|---|

| Damage to Human Health [DALY] | 1.06 × 10−4 | 1.05 × 10−4 | 6.48 × 10−5 | 6.44 × 10−5 |

| Damage to Ecosystems [species.yr] | 7.61 × 10−6 | 7.61 × 10−6 | 7.83 × 10−6 | 7.82 × 10−6 |

| Damage to Resource Availability [USD] | 4.81 | 4.81 | 2.16 | 2.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gantelas, C.; Boukouvalas, C.; Oikonomopoulou, V.; Eleni, P.; Krokida, M. Evaluation of the Environmental Performance of Stevia Glycoside Production Using Precision Agriculture and Green Processing Techniques. Chem. Proc. 2022, 10, 7. https://doi.org/10.3390/IOCAG2022-12315

Gantelas C, Boukouvalas C, Oikonomopoulou V, Eleni P, Krokida M. Evaluation of the Environmental Performance of Stevia Glycoside Production Using Precision Agriculture and Green Processing Techniques. Chemistry Proceedings. 2022; 10(1):7. https://doi.org/10.3390/IOCAG2022-12315

Chicago/Turabian StyleGantelas, Constantinos, Christos Boukouvalas, Vasiliki Oikonomopoulou, Panagiota Eleni, and Magdalini Krokida. 2022. "Evaluation of the Environmental Performance of Stevia Glycoside Production Using Precision Agriculture and Green Processing Techniques" Chemistry Proceedings 10, no. 1: 7. https://doi.org/10.3390/IOCAG2022-12315

APA StyleGantelas, C., Boukouvalas, C., Oikonomopoulou, V., Eleni, P., & Krokida, M. (2022). Evaluation of the Environmental Performance of Stevia Glycoside Production Using Precision Agriculture and Green Processing Techniques. Chemistry Proceedings, 10(1), 7. https://doi.org/10.3390/IOCAG2022-12315