GA Optimization for Regression Modeling of Electromagnetic Performances Predicted by a Subdomain Model for SMPMSM in an Electric Vehicle †

Abstract

:1. Introduction

2. The Framework of the Regression Method in SMPMSM

3. Result and Analysis

4. Conclusions

Funding

Acknowledgments

References

- Hong, G.; Wei, T.; Ding, X. Multi-Objective Optimal Design of Permanent Magnet Synchronous Motor for High Efficiency and High Dynamic Performance. IEEE Access 2018, 6, 23568–23581. [Google Scholar] [CrossRef]

- Wang, S.; Li, H. Reduction of Electromagnetic Vibration and Noise in Permanent Magnet Motor for EVs by Optimizing Design of Rotor Based on GPR-PSO Model. J. Electr. Eng. Technol. 2020, 15, 1231–1243. [Google Scholar] [CrossRef]

- Zuo, S.; Lin, F.; Wu, X. Noise Analysis, Calculation, and Reduction of External Rotor Permanent-Magnet Synchronous Motor. IEEE Trans. Ind. Electron. 2015, 62, 6204–6212. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Qiao, D.; Pei, Y.; Jung, S.Y. Reducing cogging torque in surface-mounted permanent-magnet motors by nonuniformly distributed teeth method. IEEE Trans. Magn. 2011, 47, 2231–2239. [Google Scholar] [CrossRef]

- Tiang, T.L.; Ishak, D.; Lim, C.P.; Kamarol, M. A Novel Analytical Method Using Virtual PM Blocks to Optimize Magnet Segmentations in Surface-Mounted PM Synchronous Machines. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; pp. 4–9. [Google Scholar]

- Liu, Z.J.; Li, J.T. Analytical solution of air-gap field in permanent-magnet motors taking into account the effect of pole transition over slots. IEEE Trans. Magn. 2007, 43, 3872–3883. [Google Scholar] [CrossRef]

- Lubin, T.; Mezani, S.; Rezzoug, A. Two-dimensional analytical calculation of magnetic field and electromagnetic torque for surface-inset permanent-magnet motors. IEEE Trans. Magn. 2012, 48, 2080–2091. [Google Scholar] [CrossRef]

- Tiang, T.L.; Ishak, D.; Lim, C.P.; Jamil, M.K.M. A comprehensive analytical subdomain model and its field solutions for surface-mounted permanent magnet machines. IEEE Trans. Magn. 2015, 51, 1–14. [Google Scholar] [CrossRef]

| Design | Preliminary Design | Optimal Design | Improvement (%) |

|---|---|---|---|

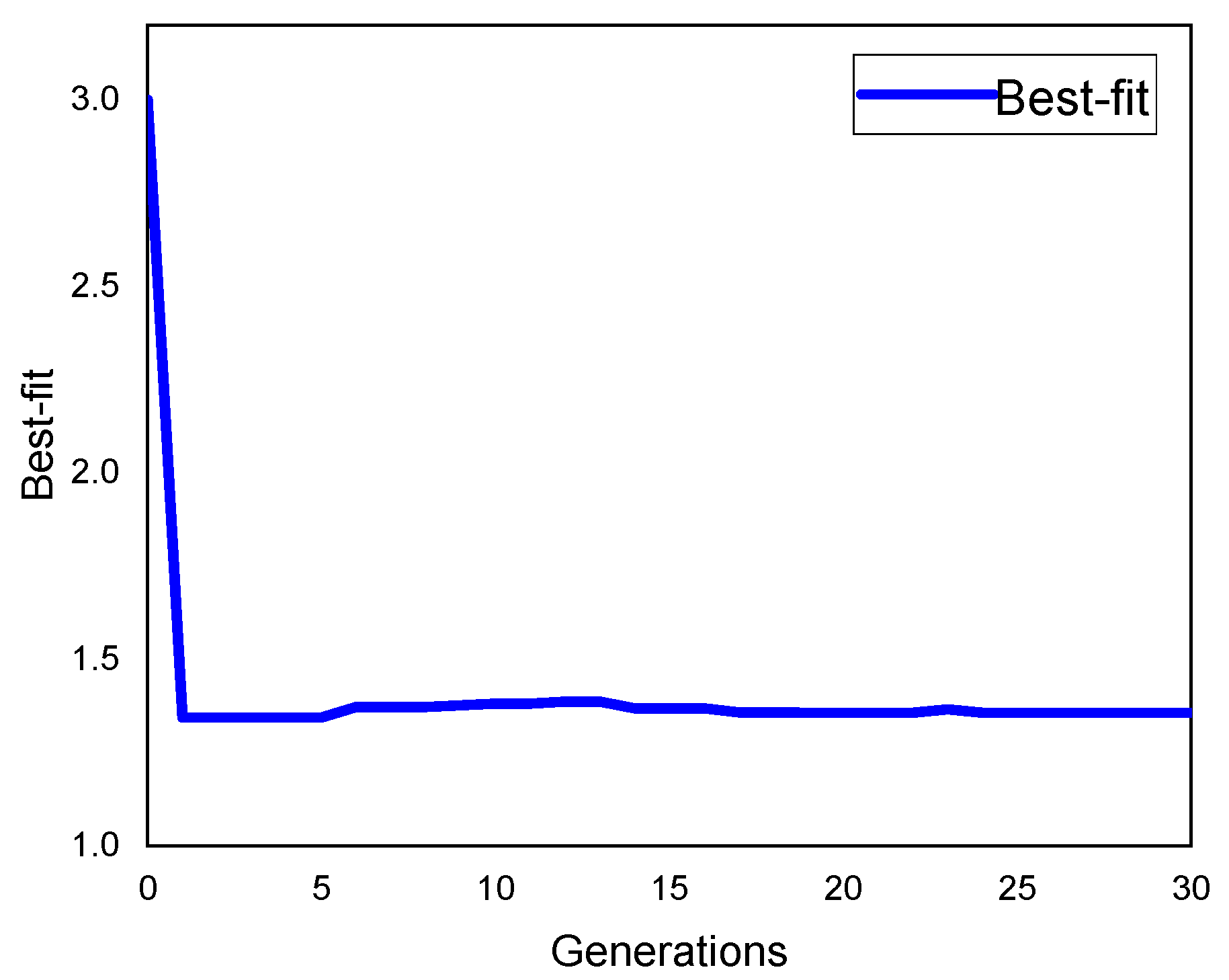

| Generations | - | 2 | - |

| Best-fit | - | 1.3438 | - |

| αp (elec. deg.) | 180 | 127.31 | −29.27 |

| boa (mech. deg.) | 5.50 | 8.01 | - |

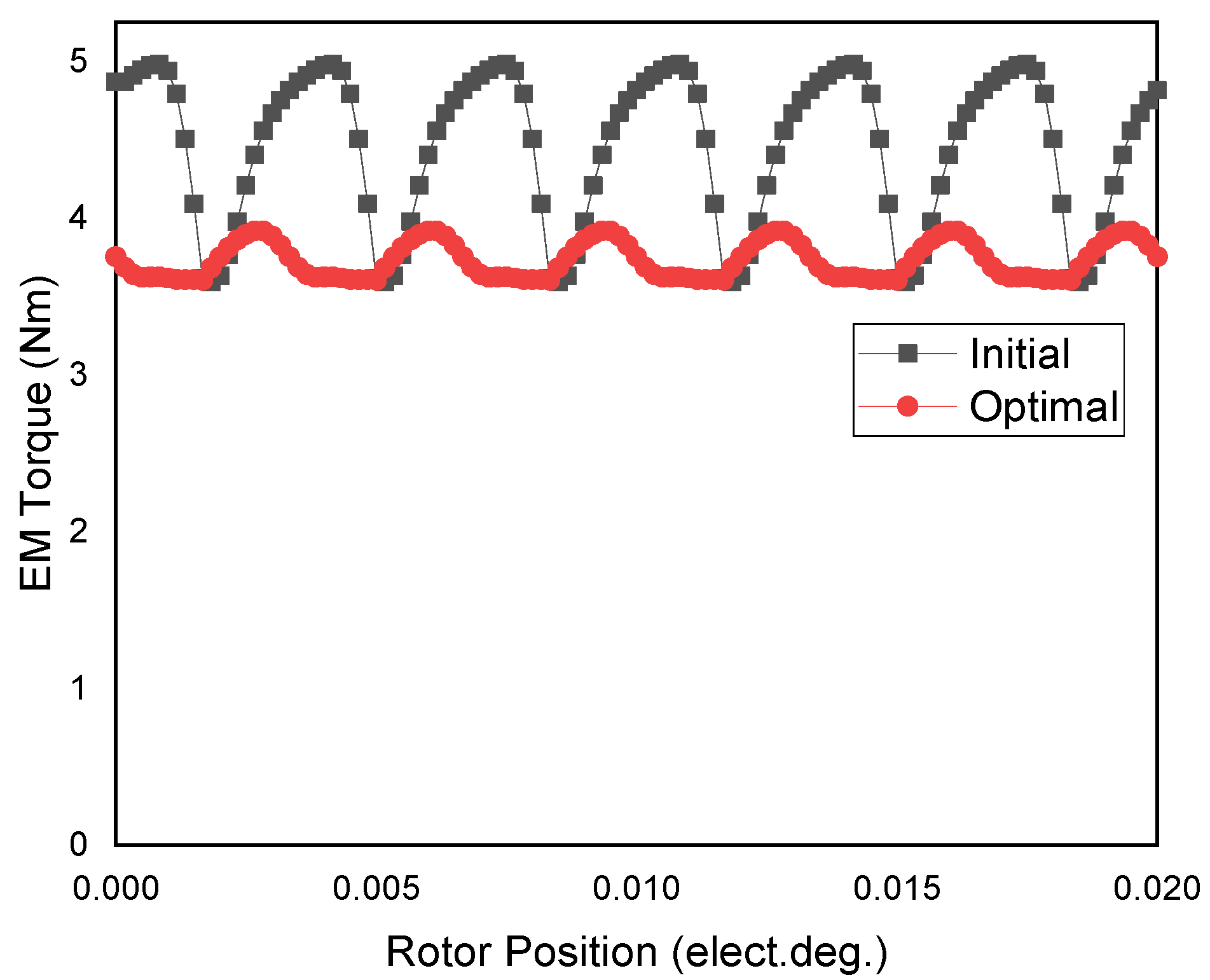

| Average EM Torque (Nm) | 4.46 | 3.73 | −16.37 |

| EM Torque Ripple (%) | 31.17 | 8.40 | −73.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd-Shafri, S.A.; Tiang, T.L.; Tan, C.J.; Ishak, D.; Ahmad, M.S. GA Optimization for Regression Modeling of Electromagnetic Performances Predicted by a Subdomain Model for SMPMSM in an Electric Vehicle. Eng. Proc. 2021, 12, 73. https://doi.org/10.3390/engproc2021012073

Mohd-Shafri SA, Tiang TL, Tan CJ, Ishak D, Ahmad MS. GA Optimization for Regression Modeling of Electromagnetic Performances Predicted by a Subdomain Model for SMPMSM in an Electric Vehicle. Engineering Proceedings. 2021; 12(1):73. https://doi.org/10.3390/engproc2021012073

Chicago/Turabian StyleMohd-Shafri, Syauqina Akmar, Tow Leong Tiang, Choo Jun Tan, Dahaman Ishak, and Mohd Saufi Ahmad. 2021. "GA Optimization for Regression Modeling of Electromagnetic Performances Predicted by a Subdomain Model for SMPMSM in an Electric Vehicle" Engineering Proceedings 12, no. 1: 73. https://doi.org/10.3390/engproc2021012073

APA StyleMohd-Shafri, S. A., Tiang, T. L., Tan, C. J., Ishak, D., & Ahmad, M. S. (2021). GA Optimization for Regression Modeling of Electromagnetic Performances Predicted by a Subdomain Model for SMPMSM in an Electric Vehicle. Engineering Proceedings, 12(1), 73. https://doi.org/10.3390/engproc2021012073