Abstract

The main focus of this research is on building an economical setup for the packaging of a variety of products using the thermoforming technique. Three different sheets of polyethylene terephthalate (PET) were used during experimentation with a vacuum forming machine. The sheet with 0.15 mm thickness took less heating time compared with the other two sheets of 0.2 mm and 0.3 mm thickness. Better results are obtained in such a scenario when sheets are heated perfectly, and proper suction is applied. The sheet with 0.2 mm thickness gave the required results with a heating time of 245 s and temperature of 218 °C.

1. Introduction

Vacuum shaping, regularly known as vacuum forming, is a rendition of thermoforming, whereby a sheet of plastic is warmed to a shaping temperature, extended onto or into a solitary surface form, and held against the form by applying a vacuum between the form and surface and the sheet. The interaction time in thermoforming is shortened with a lessening in the number of steps during thermoforming [1]. The component molding temperature was found to be the major influencing limit of divider thickness course in thermoforming movement using a complex plastic material [2]. Shrinkage is the joined impact of primary pressure amassing because of extending, and warm pressure gathering because of compelled cooling. Heating temperature also plays an important role in shrinkage prediction [3]. The break of polymeric sheets is an issue occurring during plug help thermoforming. We see that the ecstasy happens as a result of the disappointment of holding quick to particular rules in the fitting assistance measure, for instance, lacking warming of the sheet and rapid connection, and unsound properties of the applied polymeric materials, for instance, inflexibility, manageable modulus, and loosening up time [4]. Multi-step thermoforming was similarly applied to lessen the waiting pressing factor totaled during the molding cycle, and was found to be significant in the reduction in the wrappage and wrinkling of the outlined film, due to the midway loosening up of bending in each period of forming [5]. Thermoforming is the best shaping method for thin plastic sheets, used for a wide range of purposes, from showers to customized doorways. A further purpose of the work was to increase our understanding of the genuine parts of curving of the sheet during the different periods of the cycle. It would be entirely expected that the sheet would be more straightforward to deform with rising temperature [6]. Thermoforming is also carried out by applying a vacuum on the top surface of the warmed plastic, causing the plastic sheet structure to inflate, and a short time later the structure is moved, after which a vacuum is applied underneath the sheet [7]. This technique is used for speedy prototyping. Other shaping techniques use powder or tar as a starting material for thermoforming use, removing plastic. This strategy is an extremely compelling cycle for suitable high-capability large-scale manufacturing. The aftereffect of this technique is a strong, solid, lightweight and open arrangement of shapes [8]. The skin packaging is conducted with the help of a lower mechanical assembly on packaging-forming machines. The lower gadget contains a body base and an upper level surface and is planned in the trim station of a packaging machine. The packaging creation in the upper level surface that supports the level base of the bundling. The lower gadget fits adequately into a lower instrument holder of the packaging machine. The vacuum pressure is applied through an upper level surface [9].

2. Materials and Methods

2.1. Major Components for Economical Packing Machine

- Rod heater: Two heaters of 1000 Watts each are utilized for warming the sheet to a necessary temperature.

- K-Type thermocouple: K thermocouple gives the broadest working temperature range. K-Type thermocouples of W1209 are utilized in this venture.

- REXC-700 temperature controller: A module related to Arduino UNO R3 to record the temperature readings is utilized.

- Molds: Molds create different kinds of shapes. The molds are made of aluminum. These molds will be placed on suction box. The variety of packing shapes are easily made by this setup.

- Plastic sheets: The sheets utilized are acrylic (polyethylene terephthalate) plastic sheets to make diverse shapes. This material is clear and transparent in appearance. It is manufactured effectively, is accessible in sway-adjusted grades and furthermore comes in many tones.

- Vacuum chamber: The vacuum chamber is on the bottom of the mold. A vacuum pump is attached to the vacuum chamber. The pump will suck until the desired vacuum pressure is achieved. The working pressure for the vacuum chamber is 14 psi.

2.2. Experimental Methodology

The experimentation is performed by placing a sheet in a clamping frame in such a way that it does not have any kind of air leakage. The sheet is heated by turning on the heater, up to the heating temperature range for the sheet. Turning on the suction pump can suck the sheet to make desired shapes of molds. Figure 1 shows shapes obtained by different molds.

Figure 1.

The shapes obtained by different molds.

3. Results

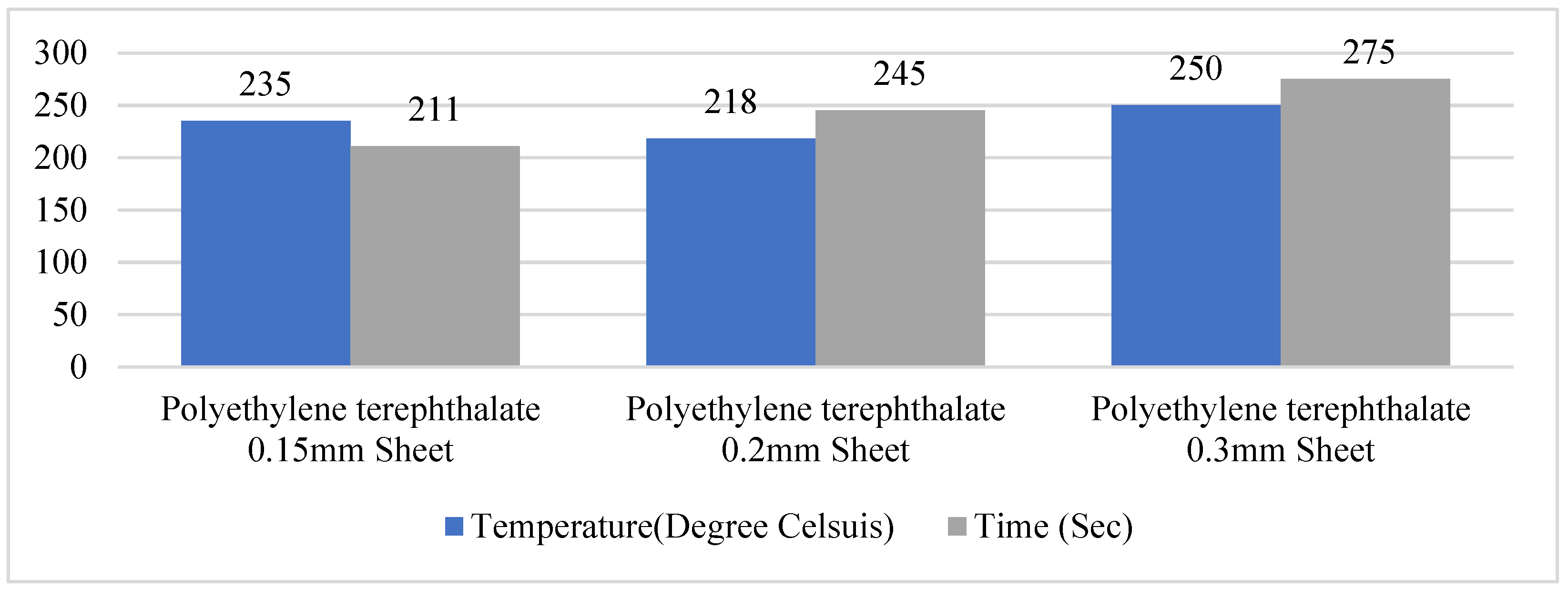

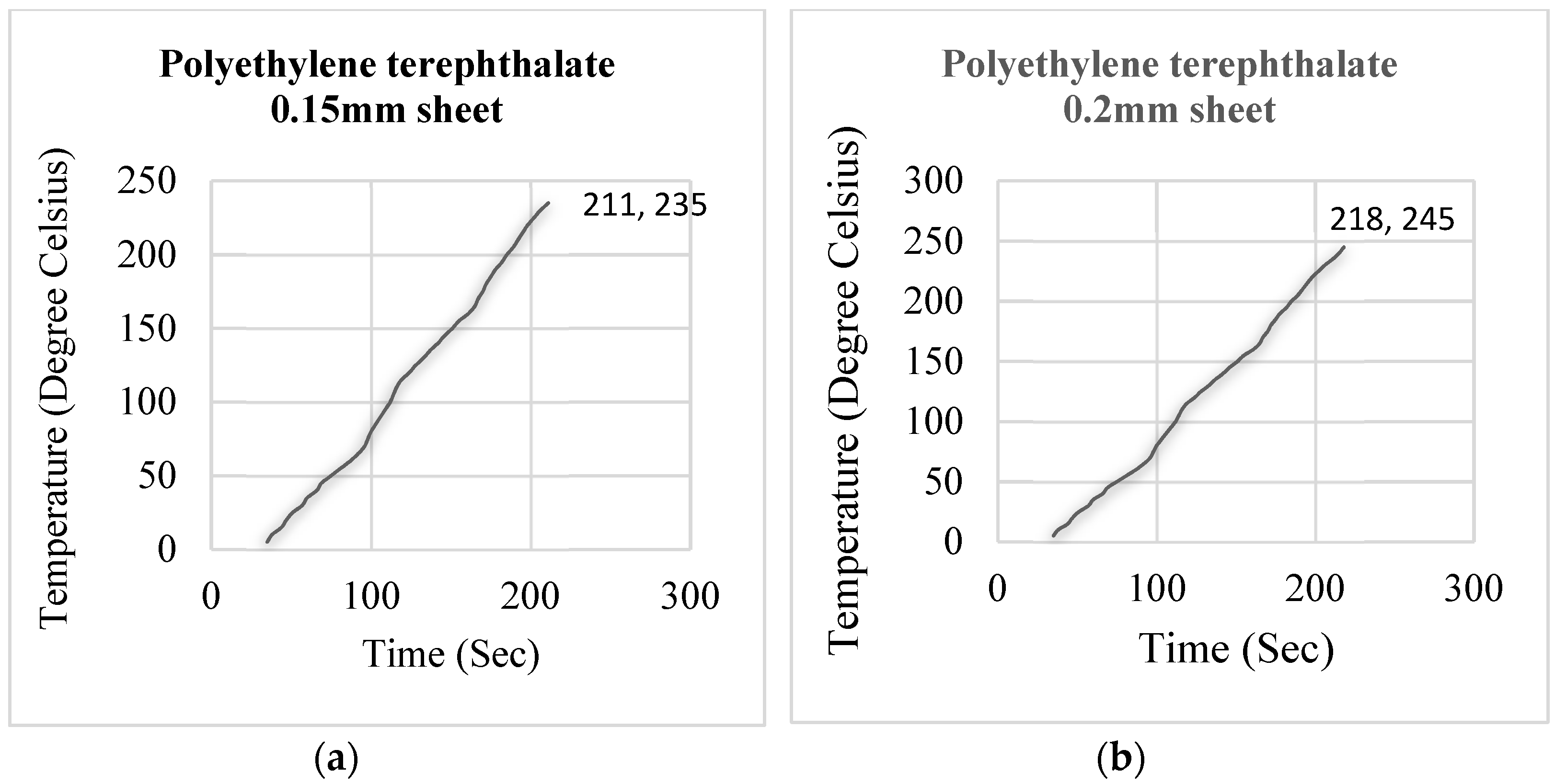

Figure 2 shows the three different polyethylene terephthalate (PET) sheets in different temperature. The results are obtained according to the requirements. As show in Figure 3a the sheet with 0.15 mm thickness takes less heating time compared with the other two sheets of 0.2 mm and 0.3 mm thickness. By varying suction pressure and temperature, the results are affected. Better results are obtained in such a scenario when sheets are heated perfectly, and proper suction is applied. Figure 3a shows the effect of temperature on 0.15 mm PET sheet w.r.t. time and Figure 3b shows the effect of temperature on 0.2 mm sheet w.r.t. time.

Figure 2.

Polyethylene terephthalate 0.15 mm sheet: The sheet is heated up to a temperature of 211 °C and for 235 s. The effect of temperature on sheets with respect to time is mentioned in Table 1. Polyethylene terephthalate 0.2 mm sheet: Molded product shapes obtained from this 0.2 mm sheet were much better compared with the other two sheets. Polyethylene terephthalate 0.3 mm sheet: This sheet is not feasible for thermoforming on this machine because of its thickness, as we heated it up to 250 °C but required more heat.

Figure 3.

(a) Effect of temperature on 0.15 mm thickness sheet (b) Effect of temperature on 0.2 mm thickness sheet.

4. Discussion

Plastic, print and bundling enterprises are among the main areas in the economy of Pakistan, having a high development potential. In Pakistan there are a few modern issues which require the knowledge of an expert specialist for better execution and item quality. The vacuum forming technique is one of the economical methods for manufacturing a variety of shapes for the packaging industry. Vacuum shaping, regularly known as vacuum forming, is a type of thermoforming whereby we use the phenomena of heating and suction to make our desired product. The setup of a vacuum forming machine is built on the basis of the principle of vacuum forming. The heating time for a sheet depends on type of material and the thickness of the sheet. The sheet obtained the shape of the mold after suction. The suction time is very important for achieving a perfect shape of the product.

5. Conclusions

Overall, the packing machine worked very well. This economical setup is suitable for the manufacturing of a variety of packing shapes. For the manufacturing of a better quality of packing, we must know about the technicalities. The frame must be airtight using insulation so that no air leakage occurs. The sheet should not be heated so much that it is converted to liquid form. The sheet should not be removed from the molds when it is too hot. It must be checked if the source sheet is formable or not.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rosen, S.R. Thermoforming: Improving Process Performance, 1st ed.; Society of Manufacturing Engineers: Southfield, MI, USA, 2002; pp. 67–73. [Google Scholar]

- Ayhan, Z.; Zhang, H. Wall thickness distribution in thermoformed food containers produced by a Benco aseptic packaging machine. Polym. Eng. Sci. 2000, 40, 1–10. [Google Scholar] [CrossRef]

- Xu, H.; Kazmer, D. Thermoforming Shrinkage Prediction. Polym. Eng. Sci. 2001, 41, 1553–1563. [Google Scholar] [CrossRef]

- Hosseini, H.; Berdyshev, B.V. A Solution for the Rupture of Polymeric Sheets in Plug-Assist Thermoforming. J. Polym. Res. 2006, 13, 329–334. [Google Scholar] [CrossRef]

- Chen, S.; Huang, S.; Lin, M.; Chien, R. Study on the thermoforming of PC films used for in-mold decoration. Int. Commun. Heat Mass Transf. 2008, 35, 967–973. [Google Scholar] [CrossRef]

- McCool, R.; Martin, P.J. The Role of Process Parameters in Determining Wall Thickness Distribution in Plug-Assisted Thermoforming. Polym. Eng. Sci. 2010, 50, 1923–1934. [Google Scholar] [CrossRef]

- Sreedhara, V.S.M.; Mocko, G. Control of thermoforming process parameters to increase quality of surfaces using pin-based tooling. In Proceedings of the ASME International Design Engineering Technical Conference, Boston, MA, USA, 2–5 August 2015; pp. 1–8. [Google Scholar]

- Prakash, M.; Mahadeo, P.S.; Vitthal, N.G.; Ramesh, D.R.; Ashok, G.P. Design & development of vaccum forming machine & die. Spec. Issue Int. J. Theor. Appl. Res. Mech. Eng. (IJTARME) 2016, 5, 20–24. [Google Scholar]

- GmbH, B.; Huber, C. Lower Tool for Vacuum Skin Packaging. U.S. Patent 16/786,534, 10 February 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).