Abstract

Washing Bay effluent contains several organic and inorganic pollutants that require effective treatment techniques. The new trend of utilizing plant-based coagulants for treating washing bay effluent can help overcome drawbacks associated with chemical coagulants such as large sludge volumes, health risks, and high costs. Hence, this study evaluates the comparative performance of C. arietinum and alum coagulants in continuous feed bench-scale experiments for treating washing bay effluents. The multi-criteria decision analysis (MCDA) was performed using the Simple Additive Weighting (SAW) method to determine a sustainable coagulant material based on the established criteria. The results showed that the C. arietinum bio-coagulant produced a higher utility value than alum; hence it could be a preferable alternative in the C/F/S treatment of washing bay effluent based on the selected criteria and weights.

1. Introduction

The rapid growth of the global automobile industry has unavoidably led to the establishment of wash bays across towns and cities. Wastewater generated from these washing centers contains several pollutants, such as surfactants, detergents, oil-grease, sand, phosphates, and organic matter, which may harm the environment once discharged without proper treatment [1,2].

The coagulation/flocculation (C/F) process is an extensively applied physicochemical technique for treating real washing bay effluents due to its advantages: effectiveness, versatility, low investment costs, and simplicity [3]. The process commonly utilizes metal salts (Al or Fe (III)) as coagulants, owing to their great ability to destabilize particles through sweep flocculation and charge neutralization mechanisms. However, they produce large volumes of toxic sludge and high metal residual concentrations in the treated effluents, causing adverse health implications on humans and various environmental-related concerns [4]. Hence, the recent trend of applying eco-friendly natural-based coagulants to substitute chemical coagulants in treating washing bay effluent could assist in overcoming the aforementioned challenges [5,6].

Continuous-flow treatment systems offer distinct benefits related to the possibility of full-scale applications with higher flow rates, preventing dead times associated with batch assays and guaranteeing a continuous yield of treated effluent. Moreover, the coagulation/flocculation/sedimentation (C/F/S) processes for treating washing bay effluent are often based on the Jar Tests [1,4], which do not consider the hydrodynamic characteristics for continuous-flow treatment. Moreover, bench-scale continuous flow experimentations constitute an intermediary stage between the lab-scale batch process (jar test), helpful in establishing the optimal parameters, and real-scale plants. A previous study by Suarez et al. [7] concerning the C/F pre-treatment of hospital wastewater under continuous feed revealed that the system was typical for full-scale treatment operations. To date, C/F studies for treating washing bay wastewater are generally performed in batches, yet its main application at full-scale is performed in continuous mode. Thus, the novelty of the present study lies in the realization of a laboratory bench-scale system under a continuous feed as a proof of concept for full-scale operationalization. In particular, the objectives of this study are threefold: (1) evaluate the C/F treatment performance of washing bay effluent using C. arietinum and alum coagulants; (2) determine the economic and environmental aspects of applying the two coagulants; and (3) determine the sustainable coagulant material using the Simple Additive Weighting (SAW) method based on the established criteria.

2. Materials and Methods

2.1. Effluent Collection and Characterization

Washing bay effluent was collected from an automobile cleaning station in Borg El-Arab city, Egypt. The physicochemical characteristics of the sampled effluent, determined following APHA [8] standard protocols, are presented in Table 1.

Table 1.

Characterization of raw washing bay effluents.

2.2. Coagulant Materials and Choice of Optimal Dosage and pH

C. arietinum was used as a natural-based coagulant while alum was used as a conventional chemical-based coagulant. The choice for optimal dosages and pH selection derives from our previous results in a batch C/F/S treatment performed on the same type of wastewater [5]. In particular, the system was operated (i) without any chemical/coagulant additions (blank); (ii) using 2.255 g/L of C. arietinum; and (iii) using 0.138 g/L of alum.

2.3. Continuous Feed Bench-Scale Studies

2.3.1. Design and Layout

A bench-scale treatment system (C/F/S) was designed for continuous feed operations with 12 L/h. Optimized operational conditions (i.e., hydraulic retention time and mixing speeds) from batch experimentations of our previous study were used to develop the design criteria for the system [5]. The volume (V) for individual treatment units/compartments was computed using Equation (1).

where, Q is the hourly flow for washing bay effluent (L/h), and HRT is the reaction time (min).

2.3.2. System Set-Up

During bench-scale pilot tests, washing bay wastewater was continuously pumped through system compartments at 12 L/h. All treatment tanks were built from plastic material, including a 120 L storage tank, a coagulation tank (1 L), a flocculation tank (6 L), and a sedimentation tank (36 L) to allow settling. The coagulation and flocculation tanks were installed with overhead stirrers operating at 162 rpm and 30 rpm, respectively. The coagulation chamber was supplied with raw effluent through the storage tank by gravity (Figure S1). After 10 min of continuous operation, the effluent was sampled after C/F and C/F/S stages to analyze various pollutant concentrations.

2.4. Performance Comparison and Prioritization of Coagulants

The pollutant removal efficiencies ( expressed as %), after operations of the C/F and/or C/F/S, were calculated using Equation (2).

where, and are the pollutant concentration (turbidity, surfactants, oil-grease, and COD) in the raw and treated washing bay effluent.

The effective coagulant was selected based on the analysis of variance (ANOVA, Fisher’s test) of treatments (coagulant type), considering a significance level of 1% (α = 0.01).

The prioritization of coagulant alternatives was based on the Simple Additive Weighting (SAW) method for multi-attribute decision-making (MADM). The optimum alternative (A*) was determined following Equations (3) and (4) [9].

where, is the utility value for the alternative (for = 1, 2), represents the assigned weights for the criterion (, …, n), and is the normalized performance rating value of the alternative with respect to the criterion, computed using Equation (5) [9].

where, is the rating value for the alternative with respect to the criterion.

3. Results and Discussion

3.1. Treatment Performance of the Continuous Feed Bench-Scale System

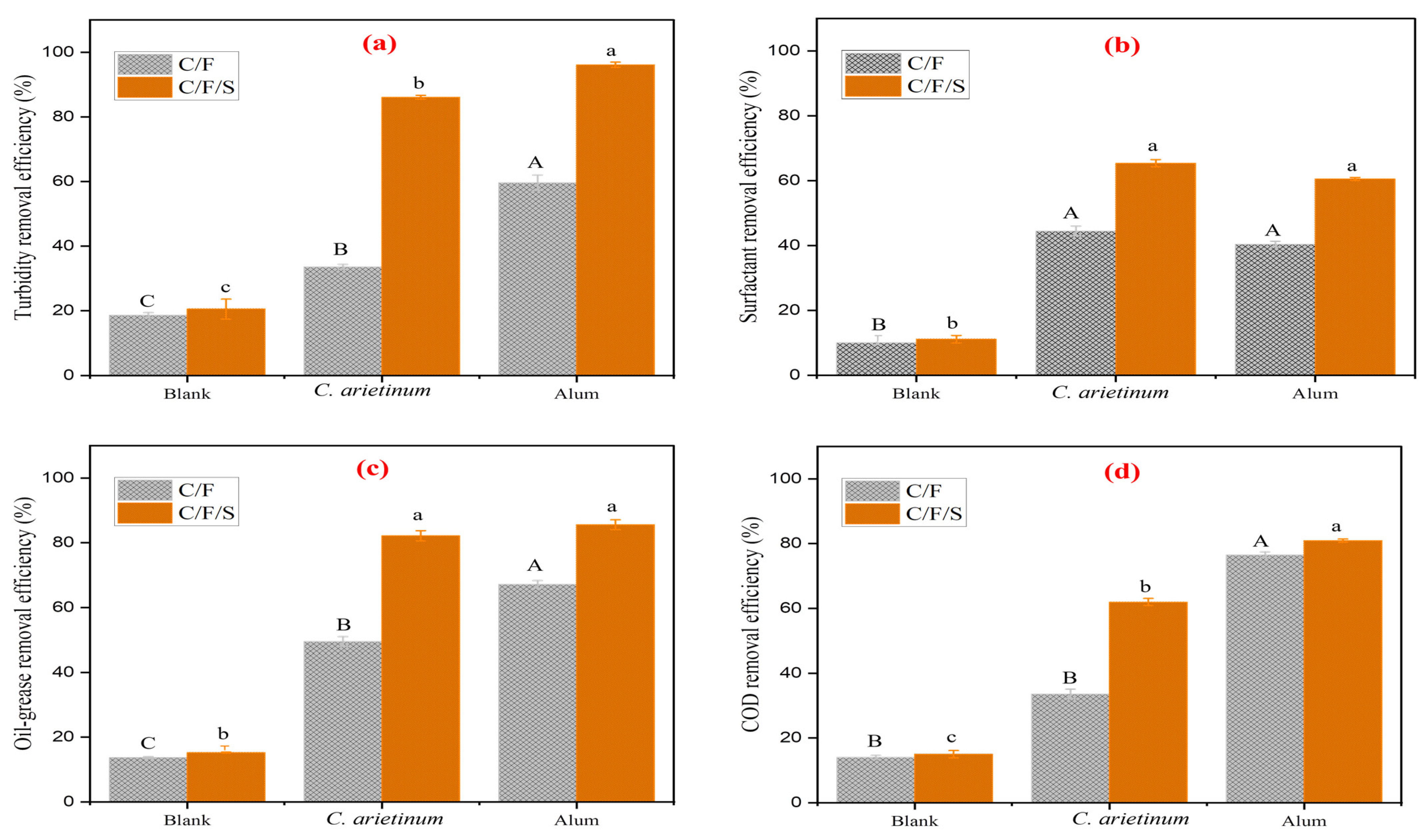

The performance of the continuous bench-scale (C/F/S) treatment system for washing bay effluent was investigated for different pollutants of turbidity, surfactants, oil-grease, and COD on two coagulants (C. arietinum and alum) and the blank. The turbidity removal efficiencies were significantly increased from 33.6 ± 1.1 to 86.1 ± 2.6% for C. arietinum, from 59.7 ± 2.3 to 96.2 ± 1.8% for alum after undergoing C/F/S treatment stages, as shown in Figure 1a. The ANOVA and Fisher’s tests presented p-values < 0.01 for all coagulant types (treatments), indicating a statistical significance under all treatment conditions. This result demonstrated that the sedimentation stage is a system’s backbone towards turbidity removal.

Figure 1.

Variation of removal efficiencies of (a) turbidity, (b) surfactants, (c) oil-grease, and (d) COD for C. arietinum bio-coagulant, alum coagulant, and the blank. (Same letters indicate a statistically insignificant difference between means of removal efficiencies (p > 0.01, Fisher’s test)).

The surfactant removal efficiencies were significantly enhanced from 44.5 ± 2.5 to 65.4 ± 3.4% for C. arietinum, from 40.3 ± 1.9 to 60.5 ± 1.5% for alum, respectively, after the C/F/S stage (Figure 1b). On the other hand, the blank elimination rates remained steady at both stages. The Fisher’s test indicated the removal rates for both coagulants had a statistically insignificant difference (p-value > 0.01). In both cases, surfactant concentration levels were above the maximum limit set by Egyptian authorities, requiring further treatment.

The oil-grease percentage removals were expressively increased from 13.8 ± 1.4 to 15.3 ± 1.1%, 48.6 ± 1.5 to 82.4 ± 1.6%, and 66.5 ± 2.2 to 85.5 ± 1.5% for the blank, C. arietinum, and alum, respectively, after C/F/S treatment stages (Figure 1c). Moreover, there was an insignificant difference between the values for oil-grease removal by C. arietinum and alum treatments (p > 0.01). This result indicates that the treatment performance of C. arietinum was significantly improved during the sedimentation stage compared to alum. Since oil-grease values after applying C/F/S (10.5 ± 0.8 mg/L for C. arietinum and 8.61 ± 0.5 mg/L for alum) were above the local Egyptian threshold value of 5 mg/L [10], pre-treatment processes such as skimmers and aeration to minimize oil-grease content in washing bay effluent before the C/F/S stage [6,11].

The COD elimination rates 14.3 ± 1.1%, 61.3 ± 2.8%, and 80.6 ± 2.7% were achieved for the blank, C. arietinum, and alum treatments, respectively, after applying the C/F/S process (Figure 1d). ANOVA results indicated the removal rates for both coagulants had a statistically significant difference (p-value < 0.01), assigned to the addition of soluble organic groups (in the C. arietinum) to the solution during stirring. In general, the pollutant removal rates achieved by continuous bench-scale C/F/S system are in good agreement with those reported for batch treatment of the same type of wastewater [5], confirming the possibility of up-scaling the proposed layout in real-scale plants for treating washing bay effluent under similar operating conditions.

3.2. pH Variation and Alkalinity Consumption

C/F with alum reduced pH values to less than 6, while C. arietinum slightly increased by 1.6. On the other hand, variations in alkalinity expressed in mg/L as CaCO3 were a six unit reduction for C. arietinum and 38 unit reduction for alum. Alum addition consumes alkalinity and acidifies the water pH value due to the release of the H+ proton into the water [11]. The property of pH stability is a competitive edge for C. arietinum since no alkalization is needed.

3.3. Aspects of Environmental Sustainability

To enrich the environmental aspects of the proposed system using natural- and chemical-based coagulants, an objective analysis based on: (i) the volume of deposited sludge and (ii) residual concentrations of aluminum was performed. As previously reported, sludge volumes were measured using a plastic graduated cylinder after settling for 24 h [12]. The volume of generated sludge with alum (30 mL/L) was three times greater than that from the treated sample using C. arietinum (10 mL/L). Since post-coagulation sludge contains a mixture of hazardous organic and inorganic compounds [4], a high volume generated by alum would impose severe human health and environmental problems on disposal in the environment compared to the low-volume biodegradable sludge produced by C. arietinum. The residual aluminum concentration in the treated alum effluent (0.95 mg/L) was significantly higher than with the C. arietinum powder (0.062 mg/L). Accordingly, C. arietinum demonstrated an advantage over alum since low residual aluminum levels would alleviate its adverse effects on humans and living organisms.

3.4. Cost Evaluation Analysis

The cost evaluation was based on the optimal dosages. Considering the market price of raw C. arietinum seeds (0.58 USD/kg), the total production cost of the bio-coagulant material is 1.45 USD/kg. Accordingly, the costs of C. arietinum and alum coagulants for operating the bench-scale system per m3 were computed as 3.26 and 1.13 USD, respectively (Table S1).

3.5. Selection of Best Coagulant

The best coagulant was selected based on the decision-making matrix in Table 2. Then, weights were assigned considering the relative importance of each criterion. For each alternative, scores between 1–10 were assigned based on experimental results and cost evaluation analysis. C. arietinum exhibited the highest utility value and was selected as an optimal coagulating material.

Table 2.

Results of SAW analysis for choosing the best coagulant for washing bay effluent treatment “equal weights of criteria”.

4. Conclusions

This study assessed the performance of C. arietinum and alum coagulants in a bench-scale continuous feed coagulation/flocculation/sedimentation treatment of washing bay effluents. Results showed that C. arietinum and alum achieved comparable pollutant removal efficiencies. Furthermore, the variations in alkalinity, pH and generated sludge volume were lower using the bio-coagulant compared to alum. The cost of C. arietinum (3.26 USD/m3) for treatment was higher than for alum (1.13 USD/m3). A multi-criteria analysis based on the SAW method revealed that C. arietinum could be considered a preferable option to alum coagulant in aspects of environmental sustainability.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/ECP2023-14693/s1, Figure S1: Continuous bench-scale plant consisting of C/F/S stages for treating washing bay effluent; Table S1: Computation of C. arietinum and alum coagulant costs.

Author Contributions

D.D.: Methodology, formal analysis, writing—original draft; M.N., M.F. and M.G.I.: supervision, conceptualization, visualization, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially supported by TICAD7, Egypt-Japan University of Science and Technology (E-JUST) and Japan International Cooperation Agency (JICA).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available within the article and/or its Supplementary Materials.

Acknowledgments

The first author is very grateful to the TICAD7 for providing financial support in the form of an MSc. scholarship. Also, thanks to JICA-Japan International Cooperation Agency for providing all facilities and equipment to accomplish this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Veréb, G.; Gayır, V.E.; Santos, E.N.; Fazekas, Á.; Kertész, S.; Hodúr, C.; László, Z. Purification of Real Car Wash Wastewater with Complex Coagulation/Flocculation Methods Using Polyaluminum Chloride, Polyelectrolyte, Clay Mineral and Cationic Surfactant. Water Sci. Technol. 2020, 80, 1902–1909. [Google Scholar] [CrossRef] [PubMed]

- Priya, M.; Jeyanthi, J. Removal of COD, Oil and Grease from Automobile Wash Water Effluent Using Electrocoagulation Technique. Microchem. J. 2019, 150, 104070. [Google Scholar] [CrossRef]

- Dadebo, D.; Ibrahim, M.G.; Fujii, M.; Nasr, M. Transition towards Sustainable Carwash Wastewater Management: Trends and Enabling Technologies at Global Scale. Sustainability 2022, 14, 5652. [Google Scholar] [CrossRef]

- Veit, M.T.; Novais, Í.G.V.; Juchen, P.T.; Palácio, S.M.; Gonçalves, G.D.C.; Zanette, J.C. Automotive Wash Effluent Treatment Using Combined Process of Coagulation/Flocculation/Sedimentation–Adsorption. Water. Air. Soil Pollut. 2020, 231, 494. [Google Scholar] [CrossRef]

- Dadebo, D.; Nasr, M.; Fujii, M.; Ibrahim, M.G. Bio-Coagulation Using Cicer Arietinum Combined with Pyrolyzed Residual Sludge-Based Adsorption for Carwash Wastewater Treatment: A Techno-Economic and Sustainable Approach. J. Water Process Eng. 2022, 49, 103063. [Google Scholar] [CrossRef]

- Al-Gheethi, A.A.; Mohamed, R.M.S.R.; Rahman, M.A.A.; Johari, M.R.; Kassim, A.H.M. Treatment of Wastewater from Car Washes Using Natural Coagulation and Filtration System. IOP Conf. Ser. Mater. Sci. Eng. 2016, 136, 012046. [Google Scholar] [CrossRef]

- Suarez, S.; Lema, J.M.; Omil, F. Pre-Treatment of Hospital Wastewater by Coagulation-Flocculation and Flotation. Bioresour. Technol. 2009, 100, 2138–2146. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for Examination of Water and Wastewater, 21st ed.; American Public Health Association/American Water Works Association/Water Environment Federation: Washington, DC, USA, 2005. [Google Scholar]

- Tzeng, G.-H.; Huang, J.-J. Multiple Attribute Decision Making Methods and Applications; Chapman and Hall/CRC: New York, NY, USA, 2011. [Google Scholar]

- MWRI. Environmental Pollution and Legislative Regulations. Available online: https://www.mwri.gov.eg (accessed on 1 May 2021).

- Bhatti, Z.A.; Mahmood, Q.; Raja, I.A.; Malik, A.H.; Khan, M.S.; Wu, D. Chemical Oxidation of Carwash Industry Wastewater as an Effort to Decrease Water Pollution. Phys. Chem. Earth 2011, 36, 465–469. [Google Scholar] [CrossRef]

- Andrade, P.V.; Palanca, C.F.; de Oliveira, M.A.C.; Ito, C.Y.K.; dos Reis, A.G. Use of Moringa Oleifera Seed as a Natural Coagulant in Domestic Wastewater Tertiary Treatment: Physicochemical, Cytotoxicity and Bacterial Load Evaluation. J. Water Process Eng. 2021, 40, 101859. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).