Abstract

Gravitational water vortex turbines (GWVTs) are favored over fuel-based power plants due to its lower head requirements and smaller flow rates, making it an economically viable energy source. Different process parameters such as flow rate, cone angle, blade position, and blade type directly affect the torque generation and ultimately the efficiency of GWVTs. The objective of this research is to analyze the impact of different process parameters on torque generation and to determine the optimal efficiency by optimizing the controlling parameters through Design of Experiments (DOE) in combination with Taguchi analysis. This study involved fabricating an accurate experimental setup and conducting experiments on various parameter combinations. The results obtained showed that the blade type has a major influence on the response factor (torque). This research holds potential for advancements in renewable energy.

1. Introduction

The gravitational water vortex turbine (GWVT) is an invention by Austrian inventor Franz Zotlöterer, which utilizes circular water flow to generate green and renewable electricity. Its low head requirements and smaller flow rates make it suitable for supplying power to millions in Pakistan, addressing the electricity crisis. GWVT systems contribute to sustainable power generation, reducing greenhouse gas emissions and minimizing environmental impacts compared to other renewable energy technologies [1]. The literature contains studies on the performance parameters and their influence on the efficiency of gravitational water vortex turbines. Rizwan ullah et al. [2] performed experimental research on the effects of runner design parameters on vortex turbine performance. Tauqir Khan et al. [3] investigated the effects of the number of blades and different blade parameters along with different design parameters. Ajay et al. [4] carried out an assessment of a gravity hydro vortex hydroelectric power plant in Nepal. They varied the head and flow rates of the gravity vortex turbine to observe the output in kilowatts. The proposed research goes beyond the studies conducted by the aforementioned researchers by conducting a more comprehensive parametric study [5]. In the proposed study, numerous variables were used to thoroughly analyze their influence on torque generation in GWVTs. The main objective of this research was to examine the combined effect of these parameters and identify the optimal combination that maximizes torque production. By conducting extensive experiments and utilizing Minitab software for data analysis, this research aimed to optimize the experimental results and identify the best parameter settings for enhanced torque generation.

2. Methodology

2.1. Experimental Apparatus and Method

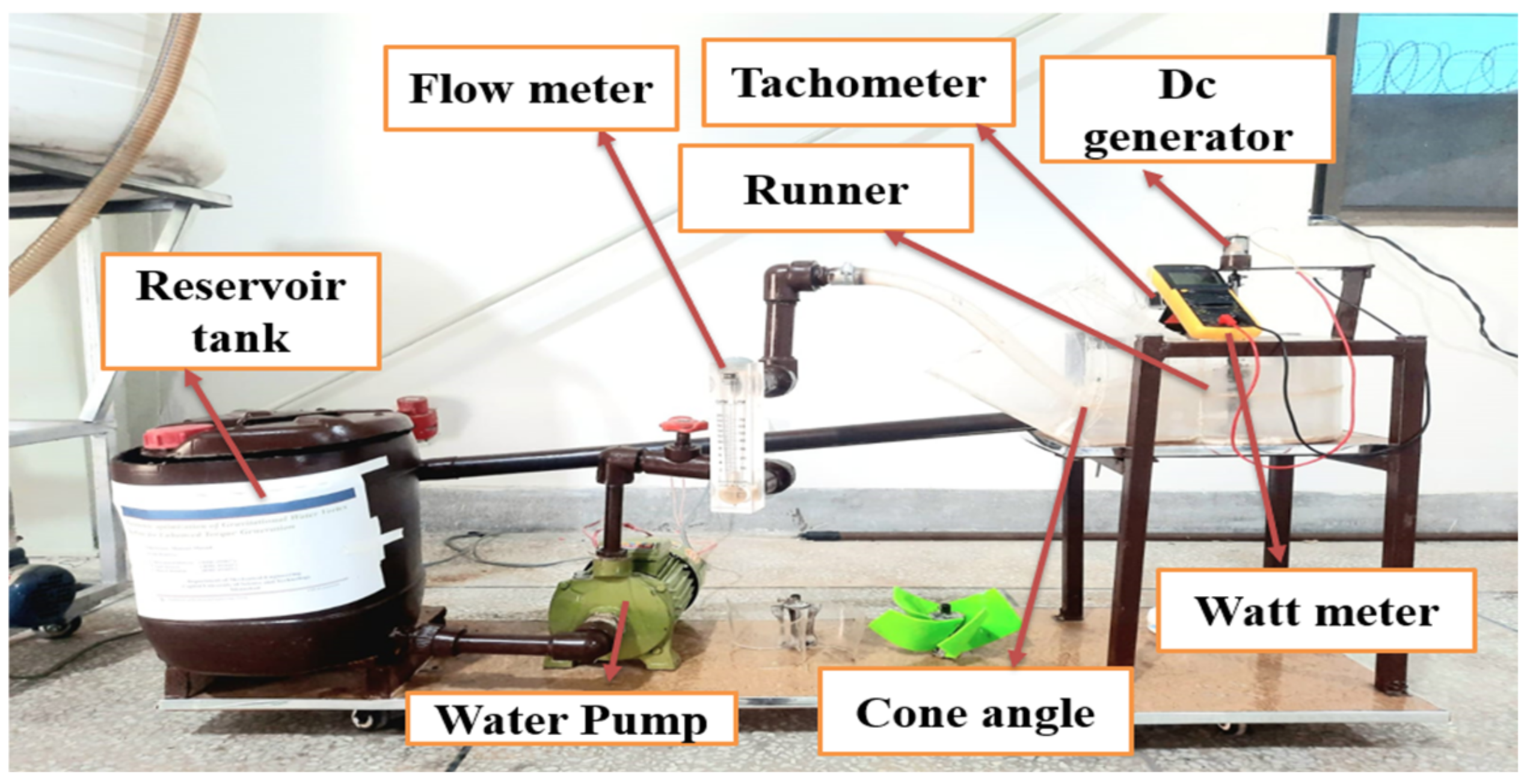

Figure 1 shows a view of the manufactured experimental apparatus. Four parameters were selected for the investigation of their effects on the torque generation. The parameters include flow rate, cone angle, blade position, and blade type. The experiments were conducted at three flow rates (35 LPM, 45 LPM, and 45LPM), three cone angles (25°, 40°, and 55°), three blade positions (P1, P2, and P3) and three blade types (B1, B2, and B3). Water was circulated using a 0.50 horsepower water pump manufactured by Super Aisa, Pakistan, and the flow rates were set using the globe valve. The flowrates were measured in liters per minute (LPM) using a panel mound-type flowmeter (manufactured by Dwyer) and has a minimum capacity of 10 LPM and a maximum capacity of 90 LPM. Three different blades runners were fabricated using acrylic material. The blades were designed in such a way that they yielded the best results in terms of torque generation. In this experiment, a mini non-contact tachometer (Lutron DT-2234) and DC generator were installed to measure the torque. A Deek-Robot Wattmeter (0 to 500 watts) was also installed in the experimental setup to measure the power.

Figure 1.

Experimental setup of gravitational water vortex turbine.

2.2. Design of Experiments

Design of Experiments (DOE) is a systematic statistical method used to determine how input factors impact a process. In this study, anticipated alterations to the input variables of a system or process were prepared and tested using structured tests. To assess the process’s outcome, four process parameters were chosen. The steps in the DOE encompass factor selection, choosing the response variable, defining factor levels, conducting experiments, optimization, and the confirmatory test. Table 1 presents the parameters (factors) and their corresponding levels utilized in the DOE process. Among the crucial steps in DOE is the selection of the orthogonal array (OA). There were 4 factors with 3 levels for each factor. The Taguchi design was utilized, specifically the 3-level design, for the type of design. Four factors were selected for the Taguchi design, and two options were available: L9 runs and L27 runs. In this research, the decision was made to perform L27 runs due to their potential to yield better results and minimize human error as shown in Table 1. Additionally, Table 1 contains the measured response variable (torque) for the 27 experiments.

Table 1.

L27 experimental design and the measured response variable (torque).

3. Results and Discussion

Taguchi analysis was used to improve the process parameters listed in Table 1 in order to identify the factor that has the greatest impact on torque generation. Additionally, Taguchi analysis was performed to forecast the ideal combination of the chosen elements, and then the confirmatory test was utilized to verify the findings. The results of the response with respect to the approach are summarized in Table 2.

Table 2.

Torque response table.

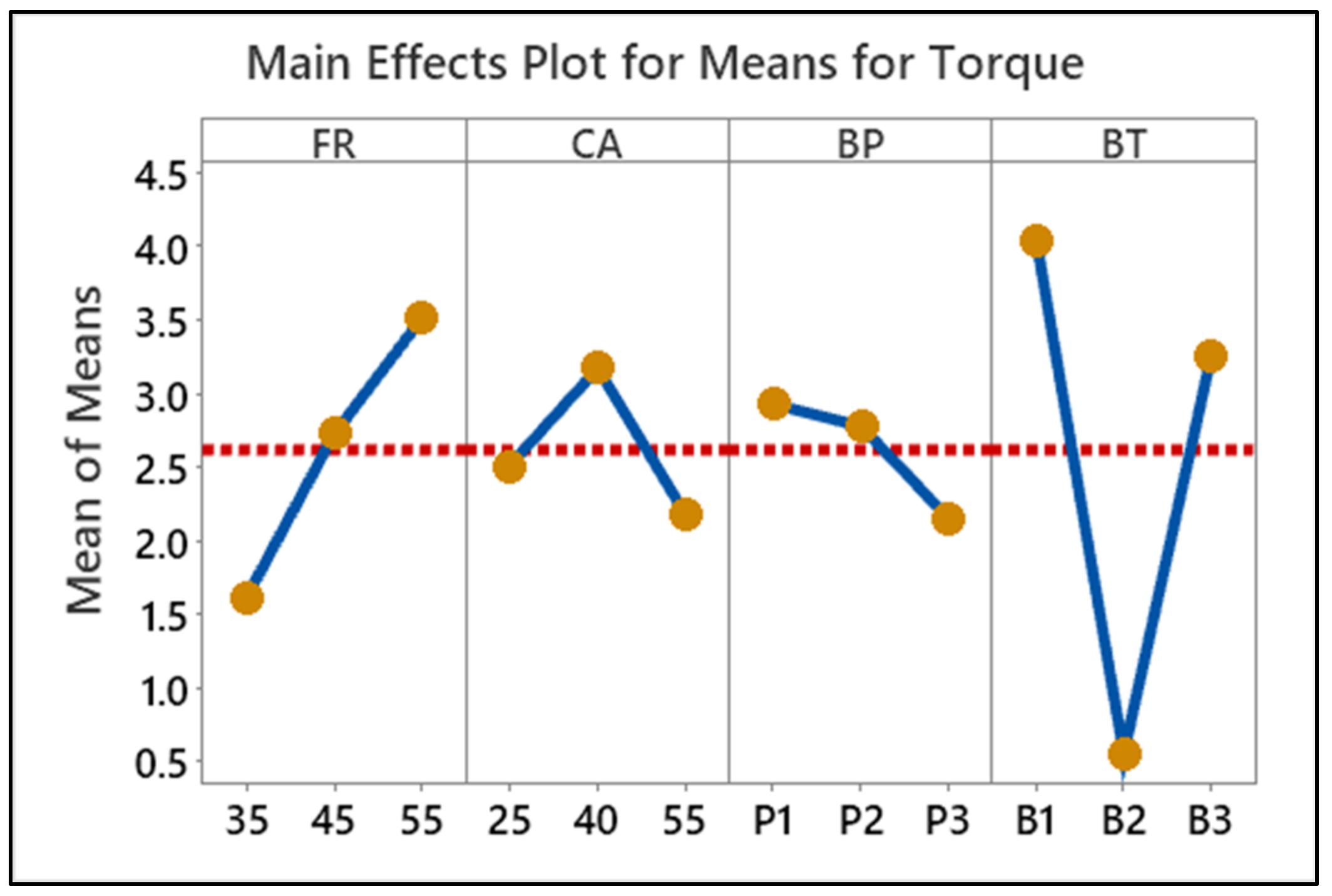

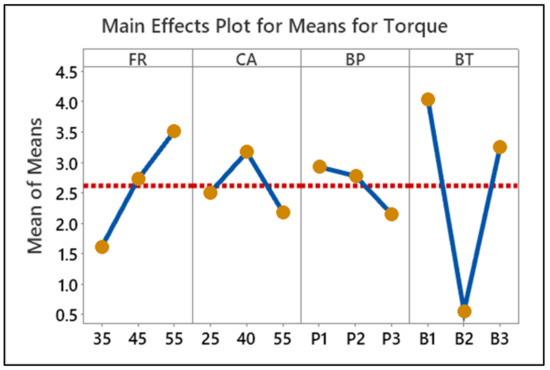

According to Table 2’s delta and rank values, the blade type has the greatest impact on torque generation, followed by flow rate, cone angle, and blade location. Figure 2 displays the mean torque values versus each input parameter as a graph.

Figure 2.

Mean torque vs. the input parameters.

From the analysis of the main effects plots for torque in Figure 2, it was concluded that the optimized parameters are 55 LPM for flow rate, 40° for cone angle, P1 for blade position, and B1 for blade type. Later, the torque results for the ideal combination—5.788 Nm—were predicted using Taguchi analysis. An experimental test was conducted to confirm the validity of the Taguchi analysis findings. As a consequence of the confirmatory test, a torque measurement was made, and a value of 5.76 Nm was recorded. When the results of the confirmatory test and Taguchi analysis were compared, the percentage error was 0.3%, which is noticeably low.

This particular study develops GWVT technology for better torque generation in the production of sustainable energy, boosting confidence in using the ideal combination. The findings demonstrated how crucial careful experimentation and statistical analysis are to maximizing GWVT performance, expanding the possibilities for renewable energy and fostering a more environmentally friendly and sustainable future.

4. Conclusions

A gravitational water vortex turbine was fabricated and optimized using Minitab software to investigate torque. After conducting experiments and analyzing the data, the optimal combination of factor levels for maximum torque was determined to be a 55 LPM for flow rate, 40° for cone angle, curved incline Blade B1as the blade type, and P1 as the blade position. Minitab predicted the torque to be 5.788 Nm for this combination. Subsequent confirmatory tests on an experimental set-up confirmed that the maximum torque was indeed achieved with this combination. The study’s findings provide conclusive evidence and valuable guidance for future implementations of these turbines. The systematic approach, including experimentation and data analysis, has successfully enhanced torque generation and improved turbine efficiency. This research contributes to the advancement of water vortex turbines for sustainable energy applications.

Author Contributions

Conceptualization, M.M. (Manzar Masud); methodology, M.M. (Manzar Masud) and S.R.; software, M.M. (Muhammad Mobeen), S.J. and A.A.; validation, M.M. (Manzar Masud) and S.R.; formal analysis, M.M. (Muhammad Mobeen), S.J. and A.A.; investigation, M.M. (Muhammad Mobeen), S.J., A.A. and S.R.; data curation, M.M. (Manzar Masud) and S.R.; writing—original draft preparation, M.M. (Muhammad Mobeen), S.J. and A.A.; writing—review and editing, M.M. (Manzar Masud) and S.R.; supervision, M.M. (Manzar Masud); project administration, M.M. (Manzar Masud). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bajracharya, T.R.; Shakya, S.R.; Timilsina, A.B.; Dhakal, J.; Neupane, S.; Gautam, A.; Sapkota, A. Effects of Geometrical Parameters in Gravitational Water Vortex Turbines with Conical Basin. J. Renew. Energy 2020, 2020, 5373784. [Google Scholar] [CrossRef]

- Ullah, R.; Cheema, T.A. Experimental Investigation of Runner Design Parameters on the Performance of Vortex Turbine. Eng. Proc. 2022, 23, 14. [Google Scholar]

- Khan, T.; Asif, M.M.; Ahmed, H.; Islam, M.; Harun, Z. Design and Development of a Vortex Turbine for the Hilly Regions of Bangladesh. In Proceedings of the 2nd International Seminar of Science and Applied Technology (ISSAT 2021), Video Conference, 12 October 2021. [Google Scholar]

- Jha, A.K.; Subedi, D.U.; Timilsina, A.B. Assessment of Gravitational Water Vortex Hydropower Plant in Nepal. Int. Res. J. Eng. Technol. 2018, 5, 2679–2691. [Google Scholar]

- Nishi, Y.; Suzuo, R.; Sukemori, D.; Inagaki, T. Loss Analysis of Gravitation Vortex Type Water Turbine and Influence of Flow Rate on the Turbine’s Performance. Renew. Energy 2020, 155, 1103–1117. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).