Abstract

This study investigates the friction-reducing potential of “micro surface texturing” on H-13 steel metal surfaces. Tribological tests were performed on a ball-on-plate reciprocating tribometer using SAE30 oil. Circular micro textures with a 0.1 mm diameter and 5–8 µm depth were applied at varying area densities (5%, 10%, and 15%). The results were compared to identify the most effective area density for the micro textures. A friction reduction of 37.95% was observed compared to the untextured sample at 15% area density. The average friction for all the textures is reduced, which shows the effectiveness of laser surface texturing on tribological performance.

1. Introduction

Tribology, the study of friction, wear, and lubrication, is of the utmost importance in engineering applications. The efficient management of friction not only extends the lifespan of machines and components but also improves the overall system efficiency while reducing energy consumption [1]. One effective approach to minimize friction and enhance tribological performance is surface texturing. Surface texturing involves the creation of micro-scale features, such as dimples, ridges, or grooves, on material surfaces. These features have demonstrated the potential to reduce friction between contacting metal surfaces by promoting enhanced lubricant retention, load distribution, and surface roughness [2]. By decreasing the contact area and adhesion between the surfaces, surface texturing contributes to lower friction and wear rates [3].

This study focuses on investigating the impact of micro-surface texturing on the friction reduction between two metal surfaces. We conducted tribological tests using a ball-on-plate reciprocating tribometer, employing SAE30 oil as the lubricant [4,5]. The metal surfaces were modified with circular micro textures, and different area densities (5%, 10%, and 15%) were examined. Through a systematic comparison of the friction coefficients for each area density, our aim is to identify the most effective micro-texture configuration. This research contributes to the growing body of knowledge on surface texturing and its potential to optimize tribological behavior in engineering applications. Surface texturing has emerged as a promising approach to enhance mechanical efficiency, minimize wear, and extend component lifespan. By exploring the influence of textured surfaces on friction and wear characteristics, this study provides valuable insights into designing and implementing tribological systems with improved performance [6,7].

This current research work is focused on the study of the effect of surface texture area density on friction reduction. The surface textures in this work have been produced using a 20 W fiber laser engraver, which required additional iterative processes to create optimal texture design, followed by post-surface cleaning processes.

2. Methodology

H-13 (chromium-molybdenum hot work steel) steel base plate (60 mm × 30 mm × 4 mm) prepared by cutting and filing. Laser engraving with the “X700” laser engraver and “ezcad” software for precise micro-scale patterns. Rigorous calculations determined the number of dimples for each area density (5%, 10%, and 15%). The surface texture diameter is kept less than contact area so that hydrodynamic pressure is created, and surface area densities are selected on the basis of the literature that proved its effectiveness in this range. Texturing is executed with meticulous attention to detail using “ezcad” software. Plate is cleaned using silicon carbide abrasive paper for surface preparation. The laser engraver parameters and required texture details are given in Table 1.

Table 1.

Laser engraver parameters and required texture details.

Diamond slurry and the Metkon Gripo 2 V Grinder-Polisher achieved exceptional surface quality.

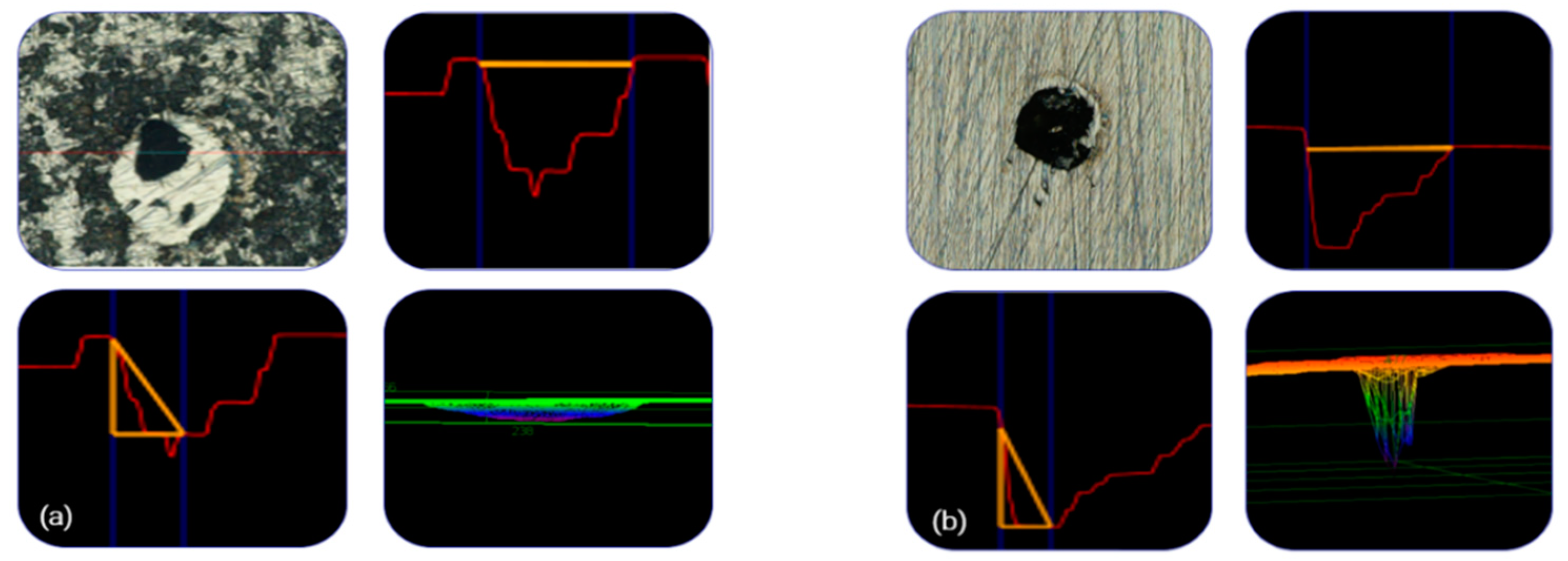

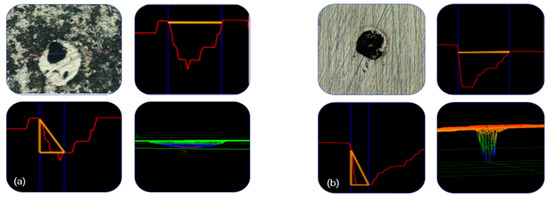

The DSX1000 digital microscope provided detailed insights into the texture’s unique characteristics shown in Figure 1. The schematic diagram of the LST is shown in Figure 2.

Figure 1.

Laser surface texturing: (a) surface texture before grinding/polishing; (b) surface texture after grinding/polishing.

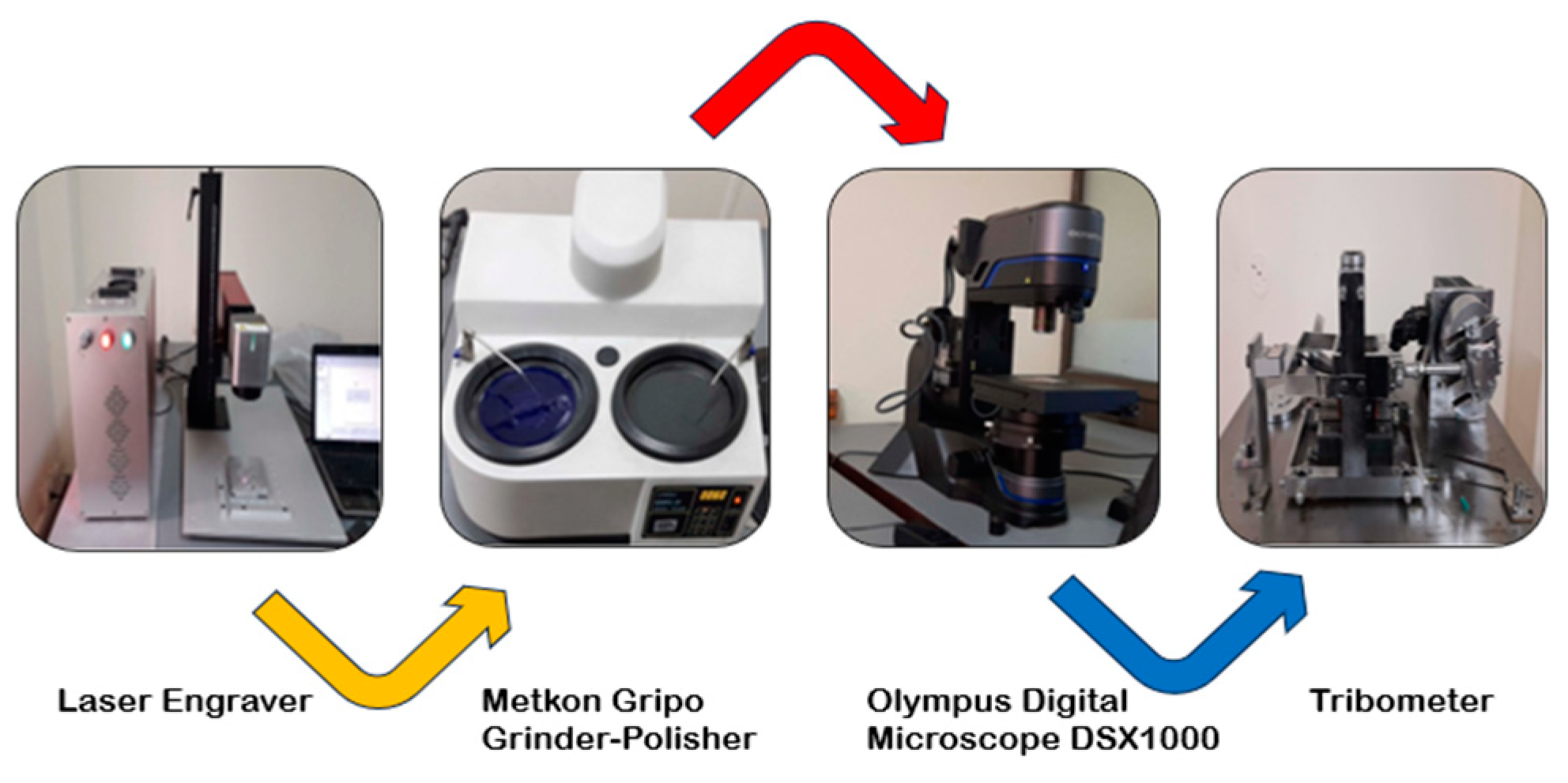

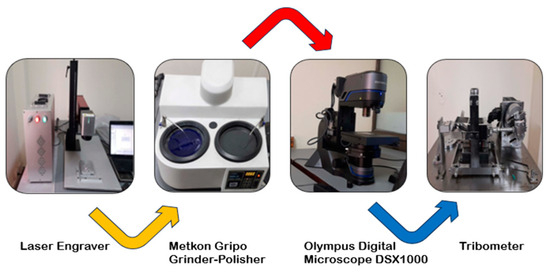

Figure 2.

Schematic of experimental setup.

Laser engraving involved fine-tuning key parameters to create textured surfaces with dimple depth of 5–8 µm, dimple diameter of 0.1 mm, and densities of 5%, 10%, and 15%. The textured plate’s properties were validated via tribometer testing. Testing parameters are given in Table 2.

Table 2.

Testing parameters of tribo-testing.

3. Results and Discussion

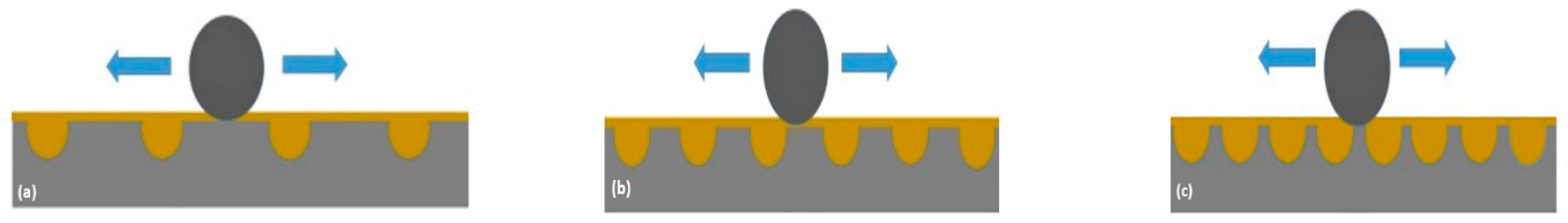

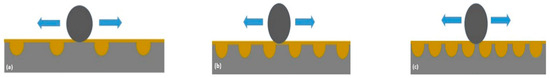

The untextured sample exhibited a higher friction compared to the textured samples. As the texture density increased from 5% to 10% and then to 15%, the friction was significantly reduced by 23.5%, 41.39%, and 37.95%, respectively. The introduction of micro-scale roughness and enhanced lubricant retention contributed to smoother sliding and minimized adhesion, resulting in the observed friction reduction [8]. With 15% texture density, diminishing returns may occur as closely spaced features limit the lubricant’s effectiveness. The ball and textured plates contact visualization is shown in Figure 3.

Figure 3.

Visualization of contact between ball and textured plate (a) 5% area density; (b) 10% area density; (c) 15% area density.

Comparative Analysis and Discussion

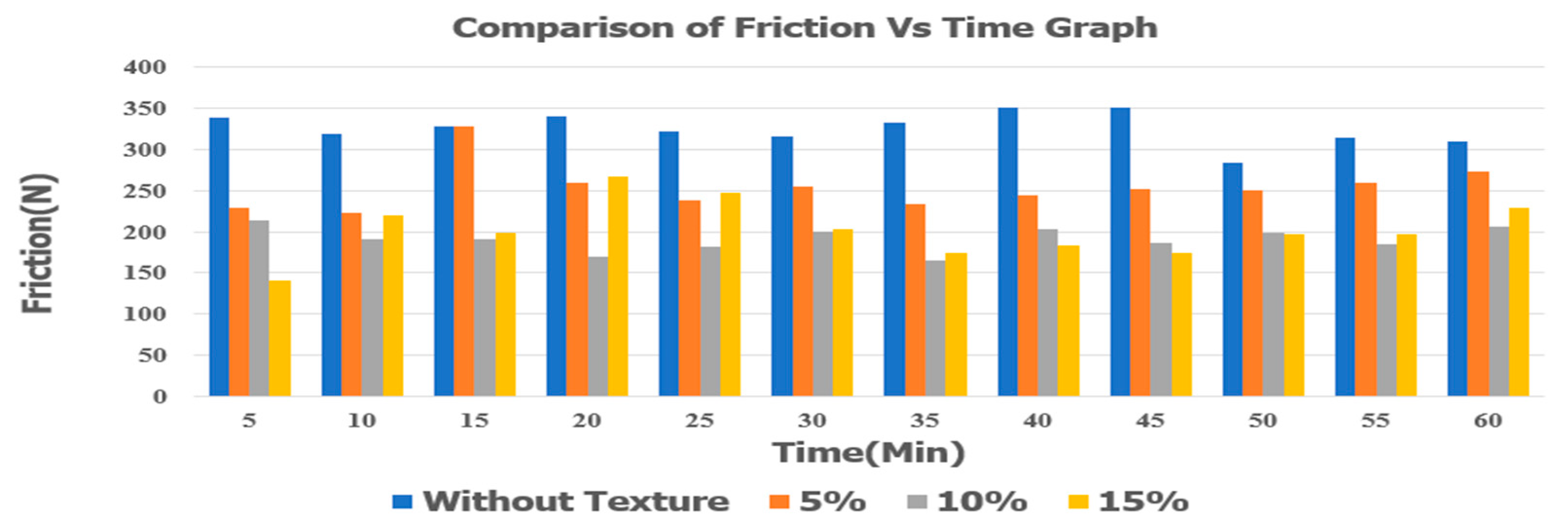

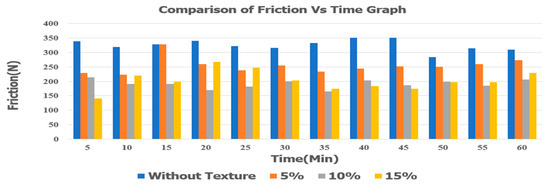

The graph in Figure 4 shows decreasing friction with increasing texture density. A lower density of 5% provides a noticeable reduction, while a higher 10% offers a more substantial decrease. A potential plateau effect of 15% may result from the limitations in hydrodynamic layer formation. The integration of advanced software aids in informed decision making.

Figure 4.

Comparison of friction between untextured and textured samples for 5%, 10%, and 15%. These findings hold promise for engineering applications with reduced friction, increased efficiency, and prolonged component life.

4. Conclusions

Surface texturing proved highly effective in substantially reducing friction within the ball-on-plate reciprocating system. The 5% texture sample achieved a remarkable 23.5% friction reduction, while the 10% texture resulted in approximately 41.39% reduction. At 15% texture density, the reduction was around 37.95%, indicating an optimal range for texture density selection. A careful consideration of the texture parameters is vital for optimizing tribological performance.

Author Contributions

Conceptualization, R.S.; Experimentation and results, W.A., M.S. and M.U.; Technical support, M.A.A.; Proofreading, M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting this study’s findings are available from the corresponding author upon reasonable request.

Acknowledgments

The authors acknowledge the technical support provided by the National University of Sciences & Technology Islamabad and the administrative support provided by the Capital University of Sciences & Technology Islamabad for the present study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zou, H.; Yan, S.; Shen, T.; Wang, H.; Li, Y.; Chen, J.; Meng, Y.; Men, S.; Zhang, Z.; Sui, T.; et al. Efficiency of surface texturing in the reducing of wear for tests starting with initial point contact. Wear 2021, 482–483, 203957. [Google Scholar] [CrossRef]

- Li, J.; Zeng, S.; Liu, S.; Zhou, N.; Qing, T. Tribological properties of textured stator and PTFE-based material in travelling wave ultrasonic motors. Friction 2020, 8, 301–310. [Google Scholar] [CrossRef]

- Goti, E.; Mazza, L.; Mura, A.; Zhang, B. An early method for the technical diagnosis of pin-on-disk tribometers by reference friction measurements in EHL conditions. Measurement 2020, 166, 108169. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Erdemir, A.; Ajayi, O.O.; Etsion, I. Tribological Behavior of Oil-Lubricated Laser Textured Steel Surfaces in Conformal Flat and Non-Conformal Contacts. Mater. Perform. Charact. 2017, 6, 1–23. [Google Scholar] [CrossRef]

- Joshi, G.S.; Putignano, C.; Gaudiuso, C.; Stark, T.; Kiedrowski, T.; Ancona, A.; Carbone, G. Effects of the micro surface texturing in lubricated non-conformal point contacts. Tribol. Int. 2018, 127, 296–301. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, F.; Yan, L.; Jiang, Z.; Xu, X. A novel ultrahigh-speed ball-on-disc tribometer. Tribol. Int. 2021, 157, 106901. [Google Scholar] [CrossRef]

- Patil, A.S.; Shirsat, U.M. Effect of laser textured dimples on tribological behavior of piston ring and cylinder liner contact at varying load. Mater. Today Proc. 2021, 44, 1005–1020. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).