Abstract

This work reports an encapsulated and flexible solid-state AIC screen printed on top of a polyester–cotton textile. The proposed zinc-ion capacitor (ZIC) arrays were fabricated on top of a polymer-coated polyester–cotton textile with solution-based processes and inexpensive electrodes and electrolyte materials. This battery achieved an energy density of 0.47 μWh·cm−2 (per device area) or 0.51 mWh·cm−2 (per active material area) in a galvanostatic cycling test between 0.1 V and 1.8 V.

1. Introduction

An e-textile is a combination of electrical and electronic devices with textiles; it can be applied for personal electronics, healthcare, or emergency applications. In an e-textile system [1], its electrical and electronic functions require a mechanically flexible, cost-effective, and portable power supply and/or buffer device such as a printed solid-state zinc-ion capacitor (ZIC).

A ZIC is an asymmetrical energy storage device. It stores electrical energy via both electrical double-layer and redox charge transfer storage mechanisms. A ZIC is made with a cathode of conductive and porous electrode such as carbon, a zinc metal anode, and a charge separator filled with an ionic conductive electrolyte that transports metal ions, triggering a faradic reaction [2]. It can be fabricated in the air at room temperature, allowing for reduced fabrication complexity. A ZIC is an improved electrical energy device for wearable electronics without occupying an excessive physical area. Previously, Gibertini et al. [3] presented an inkjet-printed solid-state capacitor array on a polyurethane-coated textile. It was fabricated with Ti3C2 MXene as the electrode and current collector and a LiCl half-aqueous half-organic gel polymer film as the electrolyte and encapsulation, achieving areal capacitance of 0.89 mF.cm−2 and areal energy density of 0.08 μWh·cm−2, but both values decreased to 61.7% after 140 charge/discharge cycles due to the reaction between Ti3C2 MXene and the water in the electrolyte. Zeng et al. [4] demonstrated a fully printed ZIC array on a polyamide substrate with an alkaline-activated carbon cathode and zinc anode on a sputter-coated gold collector pattern. It achieved an energy density of 8.2 μWh·cm−2 with a hydrogel electrolyte. The fundamental challenges of this device are the use of hydrogel electrolytes that will degrade the device’s cycling stability, and the use of sputter-coated gold as the device collector limits its scalability and design versatility. Yong et al. [5] presented a zinc-ion capacitor fabricated on a polyester–cotton textile in which a polymer separator membrane was present. The flexible encapsulated ZIC achieved an area capacitance of 33mF·cm−2, an energy density of 8.5 μWh·cm−2, a power density of 1.22 mW·cm−2, and good bending stability. In this work, the use of a half-aqueous/half-organic electrolyte is a potential drawback for energy storage design in e-textiles; the water in the electrolyte will increase the encapsulation complexity and is the source of zinc anode dendrite issues that reduce the ZIC’s lifetime.

In this work, a flexible ZIC array was achieved on top of a polyester–cotton textile surface. All material layers including the polymer interface, cathode anode, and current collector were fabricated via the screen-printing technique. The ZIC was covered with a full organic polymer electrolyte and encapsulated with a polymer film for energy storage performance characterization.

2. Material and Fabrication Processes

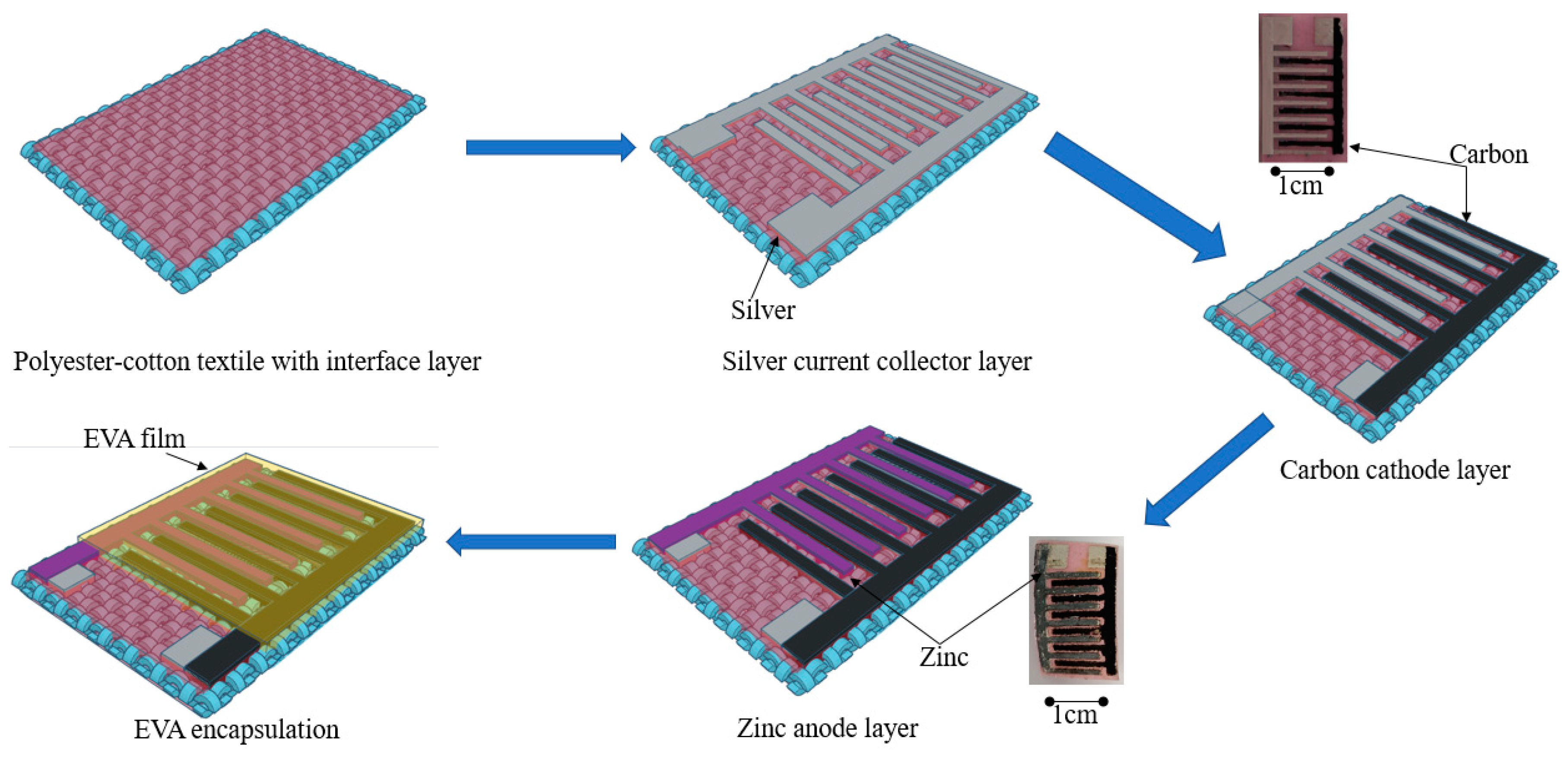

The proposed ZICs were fabricated using solution-based processes and inexpensive materials on polyester–cotton textiles (Figure 1). Firstly, a polyurethane layer followed by an ethylene–vinyl alcohol copolymer (EVOH) layer was deposited on the textile (thickness of 250 μm) using the screen-printing process; these layers act as the interface layers to smooth the textile’s uneven surface. Then, a silver current collector layer (Smart Fabric Inks Ltd., Southampton, United Kingdom TC-C4001) was printed on top of the interface layer and cured in a box oven (10 min at 120 °C). Both the carbon and zinc layers were screen-printed onto the silver current collector layer and cured in a box oven (10 min at 100 °C). The carbon pastes contained activated carbon/carbon black powder (14.5 wt%), binder (EVOH (8 wt%), and the solvent DMSO (78.5 wt%). The zinc paste contained zinc powder (50 wt%), binder EVOH (5 wt%), and the solvent DMSO (45 wt%). Finally, a PEVA film was mechanically compressed on top of the ZIC array with heat as part of the device encapsulation process.

Figure 1.

Fabrication process of the encapsulated ZIC on the textile.

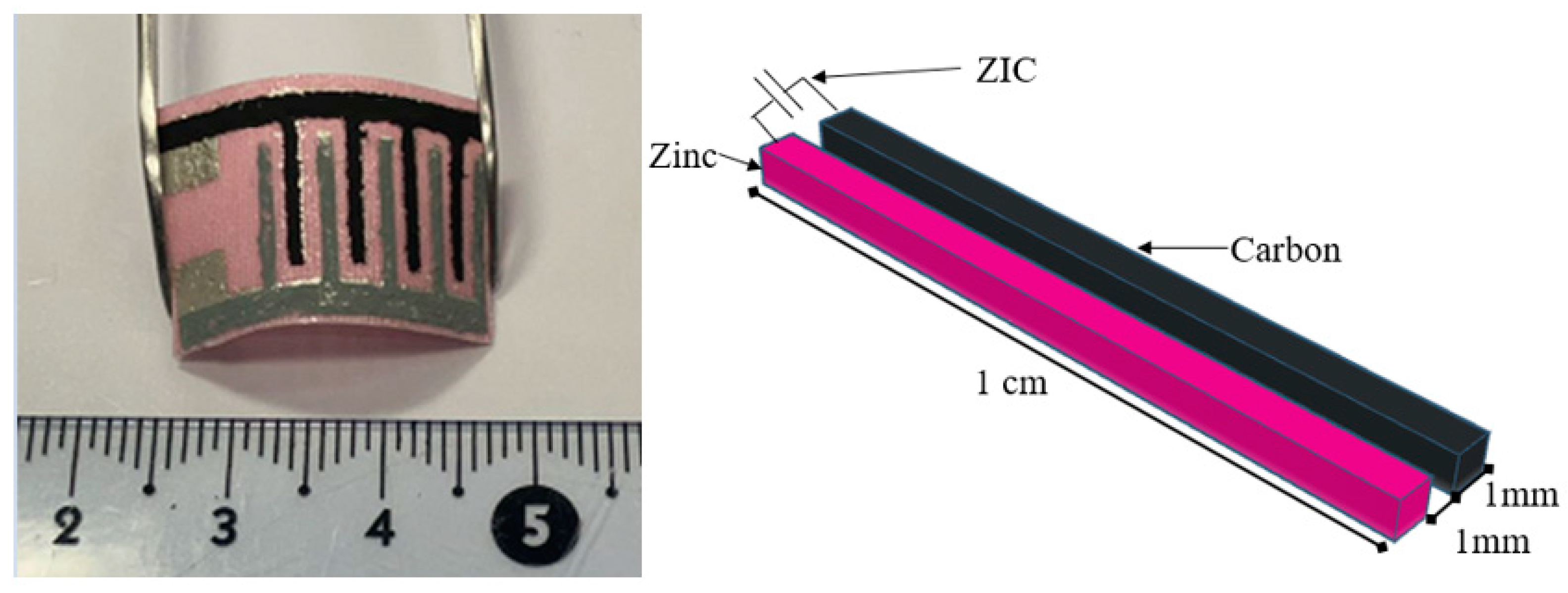

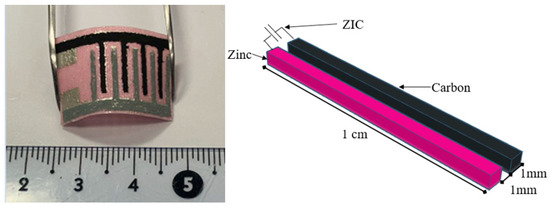

As shown in Figure 2, the flexible capacitor array consists of 8 ZICs and has a total active area of approximately 0.016 cm2 (total device area = 1.5 cm2). The ZIC array was covered by an organic gel electrolyte with zinc triflate (0.45 M) in ethylene carbonate and propylene carbonate and dried under vacuum for 30 min.

Figure 2.

(Left) Textile ZICs under bending. (Right) Schematic illustration of a single ZIC.

3. Results

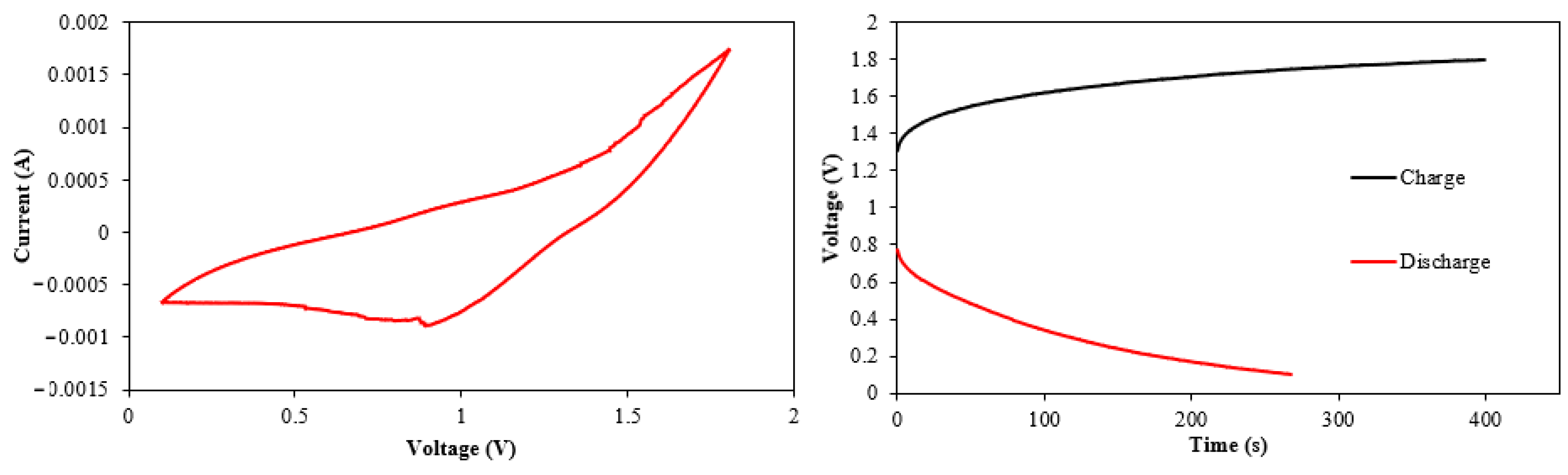

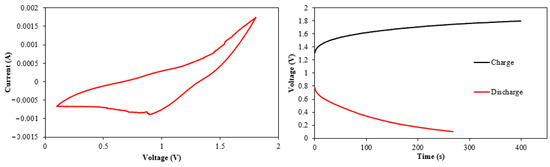

The electrochemical performance of the textile ZIC arrays was assessed using a potentiostat Autolab pgsatat101 (Metrohm Autolab, Utrecht, The Netherlands). Galvanostatic cycling (GC) results were obtained at a cycling current of 25 mA·cm−2 (per active material area), and a cyclic voltammetry (CV) test was performed at 50 mV·s−1 between 0.1 and 1.8 V.

Figure 3 (left) shows the CV test results after the first test cycle for the ZIC array on the textile. There was no oxidation peak when charging the device from 0.1 to 1.8 V, which shows the presence of the carbon cathode. The reduction (discharging) peak appears around 1 V. This is the typical voltage peak for the redox reactions in the zinc-ion energy storage system. The cycling test in Figure 3 (right) is derived from the GC test. This ZIC array demonstrated an areal energy density of 0.47 μWh·cm−2 (per device area) or 0.51 mWh·cm−2 (per active material area) between 1.8 and 0.1 V after three test cycles.

Figure 3.

(Left) CV test results. (Right) GC-derived voltage charge and discharge results of the zinc-ion capacitor.

4. Conclusions

This work presents an encapsulated flexible ZIC array on a polyester–cotton substrate. This energy storage device achieves an areal energy density of 0.47 μWh·cm−2 (per device area) or 0.51 mWh·cm−2 (per active material area) between 1.8 and 0.1 V, with good bending durability. In comparison with previous devices [3], the proposed zinc-ion capacitors are directly printed on the textile, encapsulated, and tested without tube fitting. Future work will include optimizing the formulation and fabrication method of the active materials based on the printing technique for better electrochemical performance and durability. The final device can be applied in a wide range of e-textile systems.

Author Contributions

Conceptualization, S.Y.; methodology, S.Y. and W.W.; validation, S.Y. and W.W.; formal analysis, S.Y.; investigation, S.Y.; resources, S.B.; data curation, S.Y.; writing—original draft preparation, S.Y.; writing—review and editing, S.B.; visualization, S.Y.; supervision, S.B.; project administration, S.B.; funding acquisition, S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Royal Academy of Engineering under the Chairs in Emerging Technologies scheme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data for this paper can be found at DOI: https//doi.org/10.5258/SOTON/D2828 (accessed on 1 January 2024).

Conflicts of Interest

Steve Beeby is the director of Smart Fabric Inks Ltd.

References

- Dias, T. Electronic Textiles Smart Fabrics and Wearable Technology; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Tie, D.; Huang, S.F.; Wang, J.; Ma, J.M.; Zhang, J.J.; Zhao, Y.F. Hybrid energy storage devices: Advanced electrode materials and matching principles. Energy Storage Mater. 2019, 21, 22–40. [Google Scholar] [CrossRef]

- Gibertini, E.; Lissandrello, F.; Bertoli, L.; Viviani, P.; Magagnin, L. All-Inkjet-Printed Ti3C2 MXene Capacitor for Tex-tile Energy Storage. Coatings 2023, 13, 230. [Google Scholar] [CrossRef]

- Zeng, J.; Dong, L.; Sun, L.; Wang, W.; Zhou, Y.; Wei, L.; Guo, X. Printable Zinc-Ion Hybrid Micro-Capacitors for Flexible Self-Powered Integrated Units. Nano-Micro Lett. 2021, 13, 19. [Google Scholar] [CrossRef] [PubMed]

- Yong, S.; Li, Y.; Beeby, S. Flexible Textile Zinc Ion Supercapacitor. In Proceedings of the 2023 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Boston, MA, USA, 9–12 July 2023; pp. 1–4. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).