Abstract

This article touches upon the development of dispersed-reinforced concrete components and the improvement of their physical and mechanical properties. They can be used in road and defense structures, bridges, and takeoff and landing zones. Multifunctional micro-reinforced fine-grained concrete compositions have been developed based on basalt fiber, where the limit of compression strength varies from 65.6 to 78.35 MPa, flexural strength from 6.4 to 9.1 MPa, and water permeability from 3.7 to 1.8%. Among the compositions of micro-reinforced concrete with basalt fiber, the best strength result was recorded in the case of 2% basalt fiber and 10% microsilica, with compression and flexural strengths of 78.35 and 9.1 MPa, respectively. The best water absorption result of 1.8% was obtained only with basalt fiber concrete when the fiber content was increased to 3.2%. As a result, the water absorption was reduced by 62% compared to the initial concrete. The increases in flexural and compression strengths were 42.19% and 13.8%, respectively.

1. Introduction

Modern construction demands strict requirements for the physical and mechanical properties of the concrete used: crack resistance, high resistance to dynamic strokes, and durability. Dispersed-reinforced concrete can fully meet the mentioned requirements, the application rates of which are currently increasing. In the West, this composite has proven itself for a long time [1,2,3,4,5,6,7,8], and it is used in road and airport construction [9,10,11,12,13]. Among the materials used for dispersed-reinforced concrete, basalt fiber is singled out; the effectiveness of its use is determined by the availability and distribution of the raw material base necessary for its eco-friendly production, as well as its high physical, mechanical, and operational properties. The technical challenges in achieving a basalt fiber uniform distribution in a concrete cement matrix and engineering methods for calculating fiber–concrete structures [9,14,15,16,17] contribute to the difficulties in using the mentioned material for dispersed reinforcement.

Fiber-reinforced concrete has limited use in our country. Meanwhile, the RA has a rich raw material base and extensive experience in basalt fiber production. It has been determined by theoretical and experimental studies [1,4,18,19,20] that concrete reinforced with basalt fibers has high values for its physical and mechanical characteristics. We can increase cement activity by selecting the filler composition and grain size, enhancing the filler’s physical and mechanical qualities, using chemical methods, and using other techniques to produce a high dynamic strength index.

However, the concrete composites produced by this method cannot meet the requirements for the safe operation of defensive structures when using modern striking methods, which cause high exposure of the supporting and enclosing structures. In this regard, fiber concrete can be an effective material for defense structure construction, as it has a high potential for impact resistance [21,22,23].

In this research, basalt fibers were used due to the availability of raw materials and local production, and due to their properties, which include a significantly smaller fiber diameter (17 microns), which ensures adhesion with cement stone.

2. Materials and Methodology

2.1. Raw Materials

The investigated fiber concrete was made using 42.5-grade Portland cement. The strength increase at the macro level was ensured by introducing basalt fibers with a diameter of 17 microns, a length of 10–12 mm, and a tensile strength of 2000 MPa.

The main physical, mechanical, and chemical characteristics of the above-mentioned Portland cement were determined according to GOST EN 196-1-2002, 196-2-2002, and 196-3-2002 standards, and the data are given in Table 1 and Table 2.

Table 1.

Physical and chemical characteristics of the cement.

Table 2.

Physical and chemical characteristics of river sand.

River sand with grain sizes ranging from 0.16 to 5.0 mm and a size modulus of Mk = 3.1 was used as fine aggregate, the main characteristics of which are given in Table 2 (GOST 8735-88).

The characteristics of the basalt fibers are shown in Table 3.

Table 3.

Characteristics of the basalt fiber and microsilica.

2.2. Specimen Preparation

The fiber concrete mixture was prepared in an E-905 Matest-type mixer by adding pre-sieved and proportioned river sand and 42.5-grade Portland cement. After mixing the components, water and a chemical additive known as “Mapefluid N200” were added to improve the mixture’s operating characteristics. Then, basalt fiber of 10–12 mm in length and 17 µm in diameter was gradually added in small portions. When using a mineral additive, which was 10% by weight of Portland cement, it was pre-mixed with cement, after which the process continued in the same sequence. After homogenization, the mixtures were molded into 40 × 40 × 160 mm molds. After 24 h, they were removed from the molds and transferred to a cell (C 302-12 Matest type) for hardening under normal conditions (GOST EN 196-1, at a temperature of 20 ± 10 °C in water). The samples’ flexural and compressive strength limits were determined on Matest S337 and C089 compression machines according to the standards.

2.3. Analytical Methods

The water absorption of the samples was determined according to the GOST 12730.3-2020 standard (Concrete. Method for determining water absorption).

The flexural strength (F) of the 4 × 4 × 160 mm specimens was tested by a 50 kN Unitronic compression testing machine within the limits of its max. 50 kN capacity using the standard test method for flexural strength of cement-based materials. Prism specimens were subjected to three-point bending at a loading rate of 0.05 kN/s. The load was applied by a hydraulic testing machine that was driven by a brushless motor with a closed loop through an optic encoder and was controlled by a microprocessor. Stroke electric end switches were applied to the load piston to save the machine from accidental handling.

Compressive strength (Rcom) was determined for the specimen in accordance with EN 196-1 (Methods of Testing Cement Part 1: Determination of Strength). Compressive tests were carried out on an automatic testing machine (Concrete compression machine 2000 kN automatic, Servo-Plus Progress C089, Matest) with a loading rate of 0.6 kN/s at the age of 7 days and 28 days.

3. Results and Discussion

3.1. Flexural and Compressive Strength and Water Absorption Testing

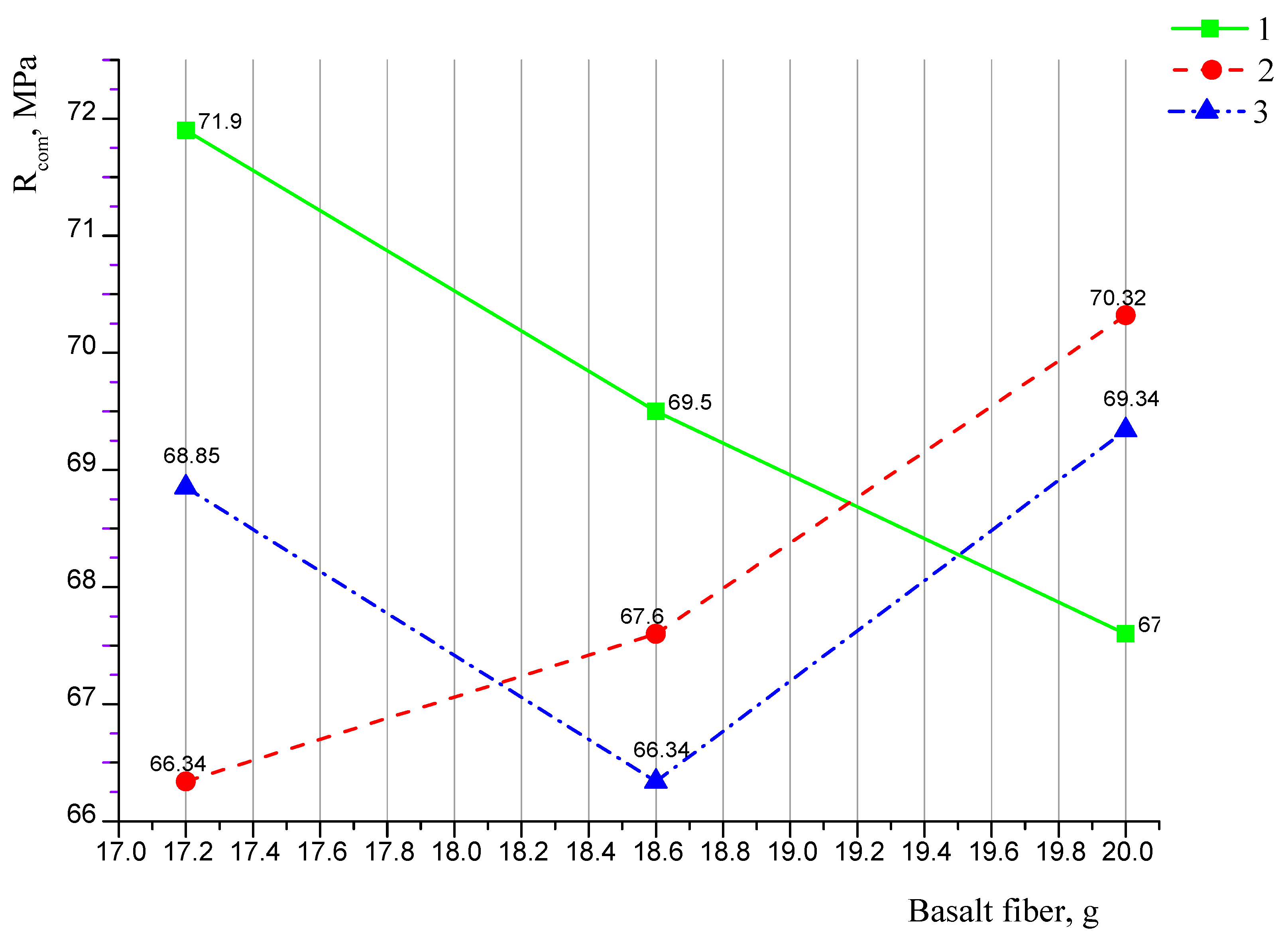

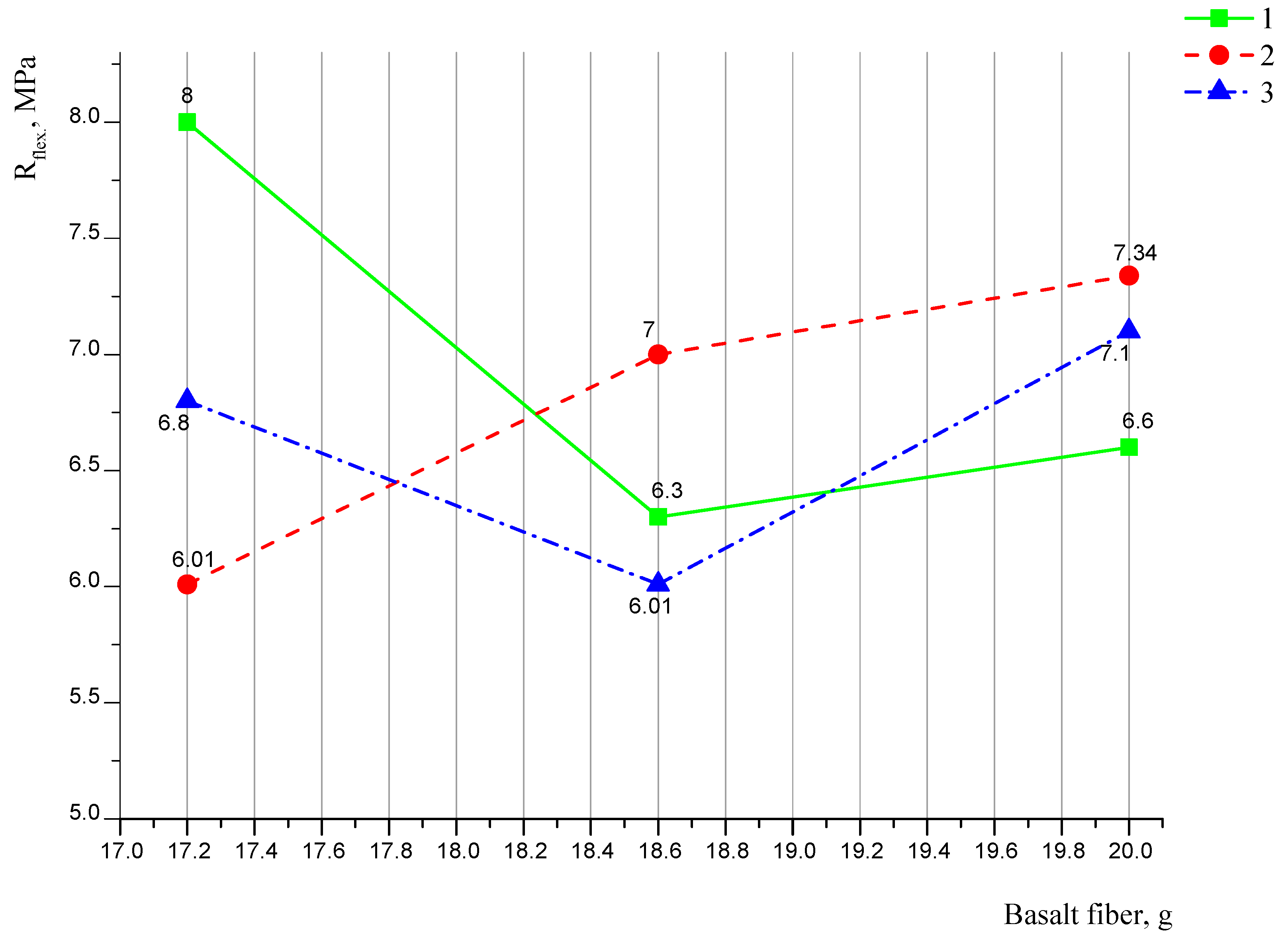

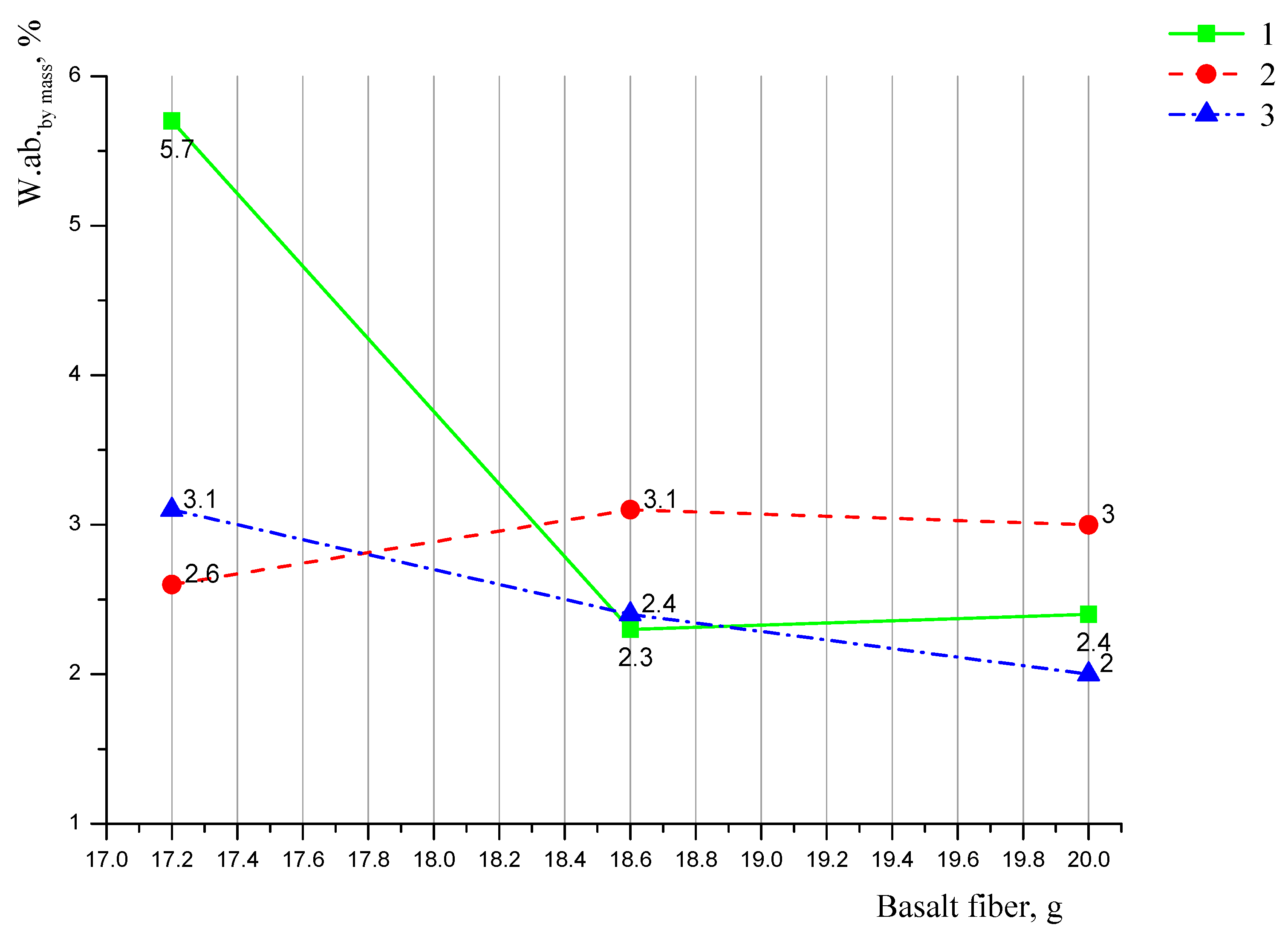

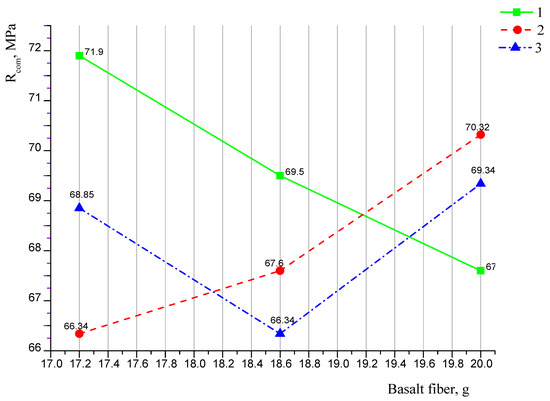

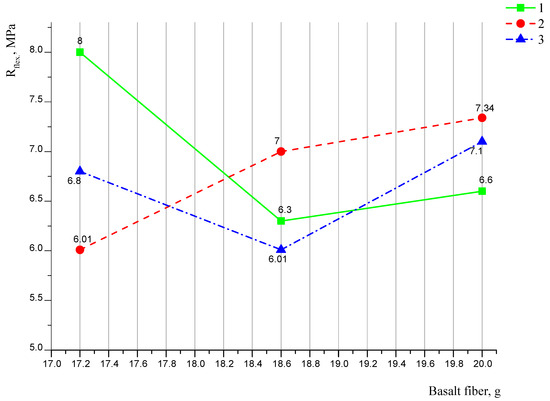

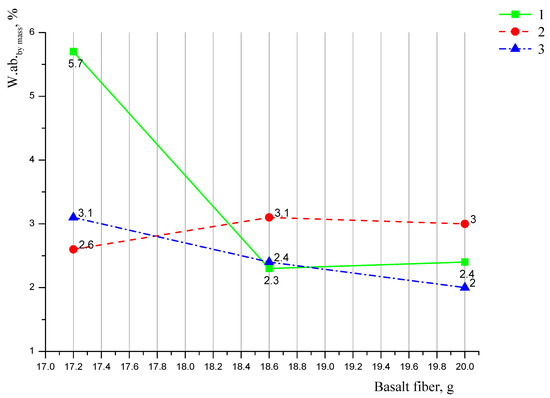

Fiber–concrete compositions were made with 1.8 to 2.15% fiber content by cement mass, 1.17 to 1.23% superplasticizer, and a 0.379 to 0.395 w/c ratio (Figure 1, Figure 2 and Figure 3).

Figure 1.

The relationship between the compressive strength and the amount of basalt fiber at maximum (1), average (2), and minimum (3) values of superplasticizer and w/c.

Figure 2.

The relationship between the flexural strength and the amount of basalt fiber at maximum (1), average (2), and minimum (3) values of superplasticizer and w/c.

Figure 3.

The relationship of water absorption with the amount of basalt fiber at maximum (1), average (2) and minimum (3) values of superplasticizer and w/c.

For micro-reinforced and non-micro-reinforced concrete samples, with and without additives, the test results are presented in Table 1. By analyzing the test results, it was found that, during micro reinforcement, an increase in the concrete’s compressive strength by 9% and flexural strength by 14% was observed compared to the initial concrete (composition 1). After introducing a superplasticizer into the concrete mixture, the compressive strength of the concrete increased by 6% and the flexural strength by 12.5% (Table 4).

Table 4.

The composition, physical, and mechanical properties of the concrete mixes.

3.2. Discussion

By introducing an active pozzolanic component into the mortar, such as microsilica, it is possible to bind the Ca(OH)2 generated by cement hydration and thereby reduce the decomposition of basalt fiber in the hardening cement. Thus, 10% of the 930 g of Portland cement was replaced with microsilica. The test samples were prepared with pozzolanic Portland cement (the 930 g initial dosage of the binder was preserved). Meanwhile, the pozzolanic reaction of microsilica increased the hydration process of calcium silicate and caused a distinct change in porosity in the concrete structure, reducing the capillary porosity and increasing gel formation, as a result of which the concrete acquired two main properties: increased strength and increased impermeability.

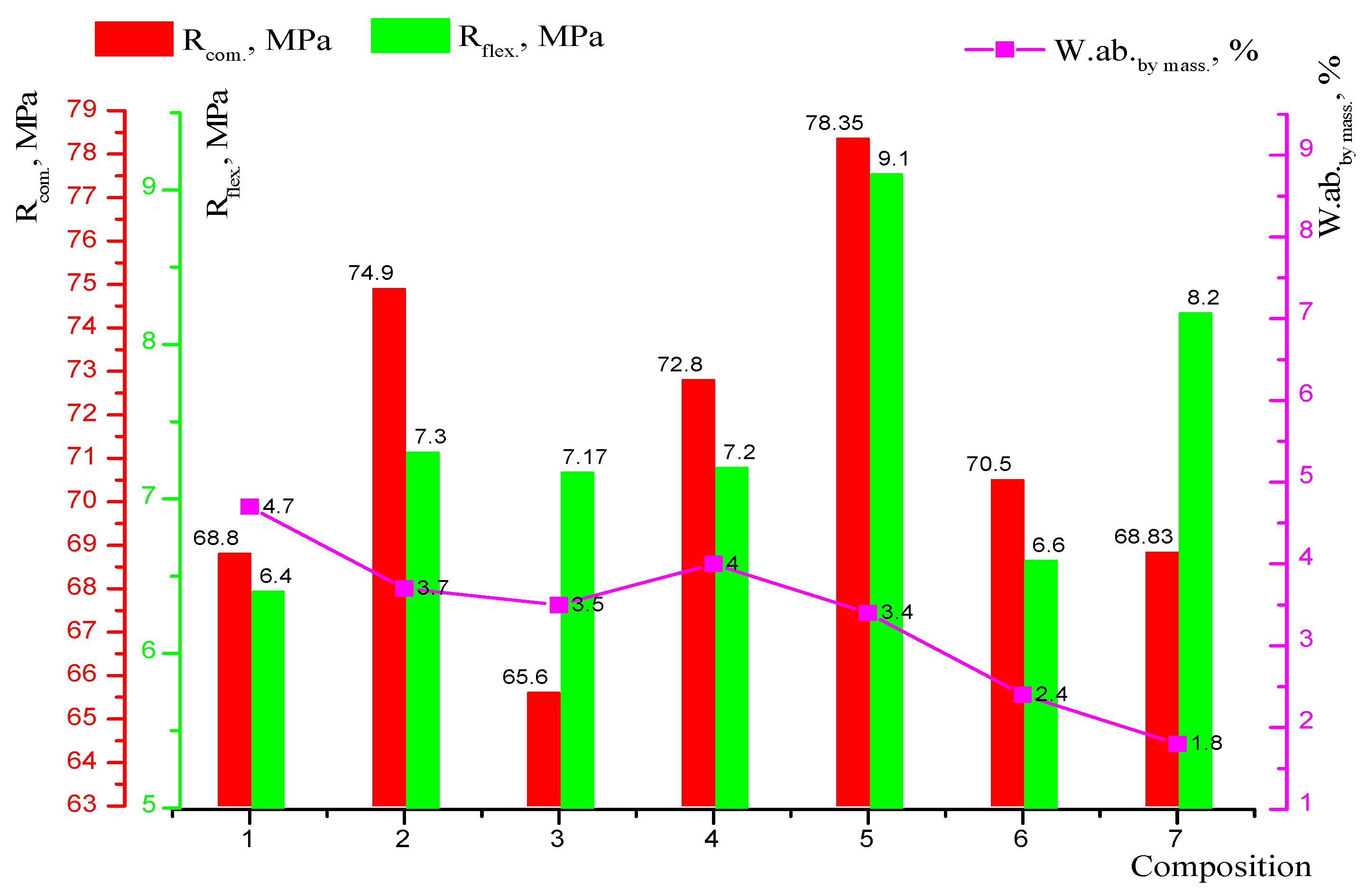

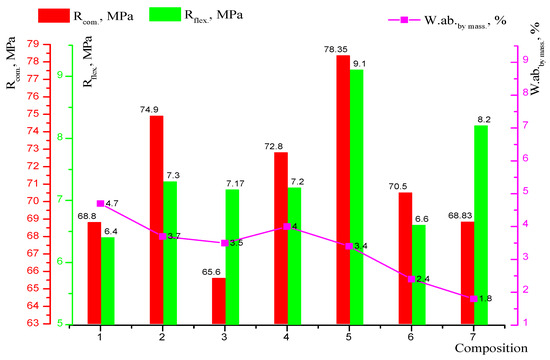

As an active mineral additive, the positive effect of microsilica on the properties of concrete is shown in Figure 4. The best results were obtained by adding 10% microsilica to the 2% basalt fiber-reinforced concrete mix.

Figure 4.

Dependence of the properties of fiber-reinforced concrete on the composition.

The best compressive and flexural strengths of 78.35 MPa and 9.1 Mpa, respectively, were reached by using a microsilica–basalt–fiber combination. Compared to microsilica concrete, there was a 38% increase in flexural strength and a 11.14% increase in compressive strength. The best water absorption rate of 1.8% was obtained in the initial mix with 3.2% basalt fiber, providing a 62% reduction in water absorption.

4. Conclusions

Because RA has a rich raw material base and extensive experience in basalt fiber production, the objective was to develop micro-reinforced, fine-grained composite components with high physical and mechanical properties using local raw materials. For the problem solution, fine-grained dense fiber concretes were developed based on basalt fibers with a compressive strength of 78.35 MPa, a flexural strength of 9.1 MPa, and a water permeability of 1.8%.

If we choose a basic concrete mixture, the addition of 10% microsilica to the initial concrete mix increases the compressive strength by 2.47% and the flexural strength by 3.13%. Then, the same concrete mixture, as a result of the introduction of basalt fibers, records an increase of 38% in flexural and 11.14% in compression strengths and an increase of 42.19% and 13.88%, respectively, over the initial concrete.

Author Contributions

Conceptualization, A.K., M.B. and A.A.; methodology, N.M. and A.G.; validation, A.K. and M.B.; formal analysis, M.B.; investigation, A.K., A.A., N.M. and A.G.; resources, M.B.; data curation, A.G.; writing—original draft preparation, A.K., M.B. and A.A.; writing—review and editing, A.K.; visualization, M.B.; supervision, A.A.; project administration, M.B.; funding acquisition, A.K. and M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Higher Education and Science Committee of RA.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

All individuals included in this section have consented to the acknowledgment.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Puharenko, Y.V.; Panteleev, D.A.; Zhavoronkov, M.I. Deformation diagrams of cement composites reinforced with steel wire fiber. Acad. Archit. Constr. 2018, 2, 143–147. [Google Scholar]

- Rozina, V.E.; Urkhanova, L.A.; Lkhasaranov, S.A.; Buyantuyev, S.L. Fiber Concrete with Basalt Fiber and Nanosilicon. Nanotechnol. Constr. 2015, 6, 53–57. (In Russian) [Google Scholar]

- Urkhanova, L.; Lkhasaranov, S.; Buiantuev, S. Fiber-reinforced Concrete with Mineral Fibers and Nanosilica. Procedia Eng. 2017, 19, 147–154. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Pimentel, M.; Nunes, S. Influence of fibre orientation on the tensile behaviour of ultrahigh performance fibre reinforced cementitious composites. Cem. Concr. Res. 2017, 97, 28–40. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Khezhev, T.A.; Pukharenko, Y.V. Fiber Concrete on the basis of compocite binder and technogenic raw materials. Mater. Sci. Forum 2018, N931, 603–607. [Google Scholar] [CrossRef]

- Fedyuk, R.S.; Mochalov, A.V.; Lesovik, V.S.; Gridchin, A.M.; Fisher, K.H.B. Composite Bonding And Self-Fitting Fibrobetons For Protective Facilities. Bull. Belgorod State Technol. Univ. Named After. V. G. Shukhov 2018, 3, 77–85. [Google Scholar] [CrossRef]

- Kim, J.-J.; Yoo, D.-Y. Effects of fiber shape and distance on the pullout behavior of steel fibers embed-ded in ultra-high- performance concrete. Cem. Concr. Compos. 2019, 103, 213–223. [Google Scholar] [CrossRef]

- Rabinovich, F.N. Composites Based on Dispersed Reinforced Concrete. Issues of Theory and Design, Technology, Structures; Izdatel’stvo ASV: Moscow, Russia, 2011. (In Russian) [Google Scholar]

- Efimov, B.; Isachenko, S.; Kodzoev, M.B.; Dosanova, G.; Bobrova, E. Dispersed reinforcement in concrete technology. E3S Web Conf. 2019, 110, 01032. [Google Scholar] [CrossRef]

- AL-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Alogla, S.M.; Hakamy, A.; Ahmad, J.; Deifalla, A.F. Basalt Fibers Reinforced Concrete: Strength and Failure Modes. Materials 2022, 15, 7350. [Google Scholar] [CrossRef]

- Babayev, V.B. Fine-Grained Cement Concrete Using Basalt Fiber for Road Construction. Ph.D. Thesis, Belgorod State Technological University, Belgorod Oblast, Russia, 2013; p. 179. (In Russian). [Google Scholar]

- Chen, Y.Z.; Li, Z.X. Study of Road Property of Basalt Fiber Asphalt Concrete. Appl. Mech. Mater. 2012, 238, 22–25. [Google Scholar] [CrossRef]

- Kudyakov, A.I.; Plevkov, V.S.; Kudyakov, K.L.; Nevskiy, A.V.; Ushakova, A. Improvement in manufacturing technology of basalt fiber concrete with increased uniformity. Constr. Mater. 2015, 10, 44–47. (In Russian) [Google Scholar]

- Voylokov, I.A. Basalt fiber reinforced concrete. Eng. Constr. J. 2009, 4, 26–31. (In Russian) [Google Scholar]

- Plevkov, V.S.; Yugov, A.A.; Shashkov, V.V.; Kudyakov, K.L.; Ustinov, A.M. Model of dynamic destruction of fiber-reinforced concrete. Вестник ТГАСУ 2014, N5, 63–76. (In Russian) [Google Scholar]

- Ren, W. Dynamic compressive behavior of basalt fiber reinforced concrete after exposure to elevated temperatures. Fire Mater. 2015, 40, 738–755. [Google Scholar] [CrossRef]

- Roman, F.; Yu, L.; Andrei, T.; Timohin, R.; Sergey, K.; Sezar, K. Increasing in impact viscosity of fiber-ash-concrete. Constr. Mater. Prod. 2021, 3, 5–16. [Google Scholar] [CrossRef]

- Lesovik, V.S. Construction materials. Present and Future. Vestnik MGSU 2017, 1, 9–16. [Google Scholar] [CrossRef]

- Lesovik, V.S.; Zagorodnyuk, L.K.H.; Chulkova, I.L.; Tolstoy, A.D.; Volodchenko, A.A. Affinity of structures as a theoretical basis for designing composites of the future. Constr. Mater. 2015, 9, 18–22. [Google Scholar]

- Morgun, L.V. Analysis of the Patterns of Formation of Optimal Structures of Disperse Reinforced Concrete. News High. Educ. Inst. Constr. 2003, 8, 58–62. (In Russian) [Google Scholar]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Engineering 2005, 36, 6–7. [Google Scholar] [CrossRef]

- Roman, F.; Aleksey, S.; Andrey, C.; Vladislav, G.; Andrey, B.; Yuriy, L. Increasing the Dynamic Strength of Fiber Concretes. Constr. Mater. Prod. 2019, 39, 90–99. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).