Abstract

The monitoring of machining has been the focus of widespread research in recent years because of its substantial contribution to manufacturing process automation. To maximise productivity, the spindle speed and feed have been increased, which has increased noise and temperature generation in the workpiece and tool. Such loud noise levels are uncomfortable for the operators, create stress, and have negative health effects, which reduces productivity. Controlling the temperature and noise produced during milling is crucial. Among its several series, the aluminium alloy 7075 (AA7075) is one of the strong alloys utilised in aircraft structural components. Hence, the present work examines the effect of spindle speed, feed, and depth of cut on noise and temperature generation during the end-milling of an AA7075 plate with 0.25-inch thickness. The sound and temperature were measured for both up- and down-milling processes and compared. In up-milling, the temperature and noise varied from 32.9 to 50.6 °C and 87.5 to 95 dB and the same were varied from 30.6 to 36.2 °C and 89.6 to 93.9 dB for down-milling. Finally, it was recommended that down-milling is the best process with low noise and temperature generation.

1. Introduction

Milling is referred to as an interrupted cutting process because the cutting force’s direction changes as the tool rotates, and the teeth enter and exit the workpiece with each cutting pass [1]. Among different milling processes, end mill cutting can be used to finish materials by removing huge amounts of material as well as to smooth the surface. Machining, especially end milling, is regarded as one of the crucial manufacturing processing to satisfy the need and expand the applications of AA7075. However, the amount of heat produced during the milling processes has a significant impact on tool wear and workpiece surface integrity and quality, and results in less dimensional accuracy and higher operating costs [2]. During milling processes, several factors contribute to the generation of heat and noise including cutting parameters such as depth of cut (ap), feed (f), and cutting speed (Vc), which have major effects on it [3]. When exposed to noise above 70 dB for an extended amount of time, your hearing may begin to suffer. During the milling processes, the noise can reach up to 100 dB which affects the operators’ health in the machine shop. Sampath, K et al. [4] attempt to reduce the noise in their experiments with the help of a microphone and verified with a modelling technique. Babu et al. and Ji et al. [5,6] also tried to reduce the noise by measuring the sound using a sound level meter to reduce noise during the milling process. Hence, from the literature, it was found that the measurement of temperature and sound in this type of dynamic process is still ongoing continuous research. As a result, the current study’s main objective is to analyse the temperature and sound produced while up and down end milling AA7075 material using a solid carbide end mill cutter with a range of feed, speed, and axial depth of cut combinations.

2. Experimental Details

The Al 7075-T6 alloy plate with a size of 150 × 70 × 6 mm (l × b × t) was employed in the experimental milling investigation. A vertical milling machine (Model: NAMMIL XL6026AV, BFW, Bangalore, KA, India) was used for the end milling; it has a 2 HP spindle power motor and can spin at a maximum speed of 1700 rpm when working in dry conditions. A solid carbide end mill cutter with a 10 mm diameter was used for end milling, and it is mostly used for cutting hard material used in aerospace, medical, mould and die, etc. A carbide end mill cutter was selected to increase the machinability of this chosen high-strength alloy rather than the HSS tool. To investigate the effect of end milling parameters on the tool–work interface’s temperature variation and the noise level reached, three milling parameters, including the cutting speed (S), feed (f), and depth of cut (d), were considered in the present study. The milling parameters were selected based on the literature [7,8], initial trial experiments to avoid the sticking of aluminium material on the milling cutter as well as too much side flow (flash) of the materials on the side of the channels, and available settings in the used milling machine.

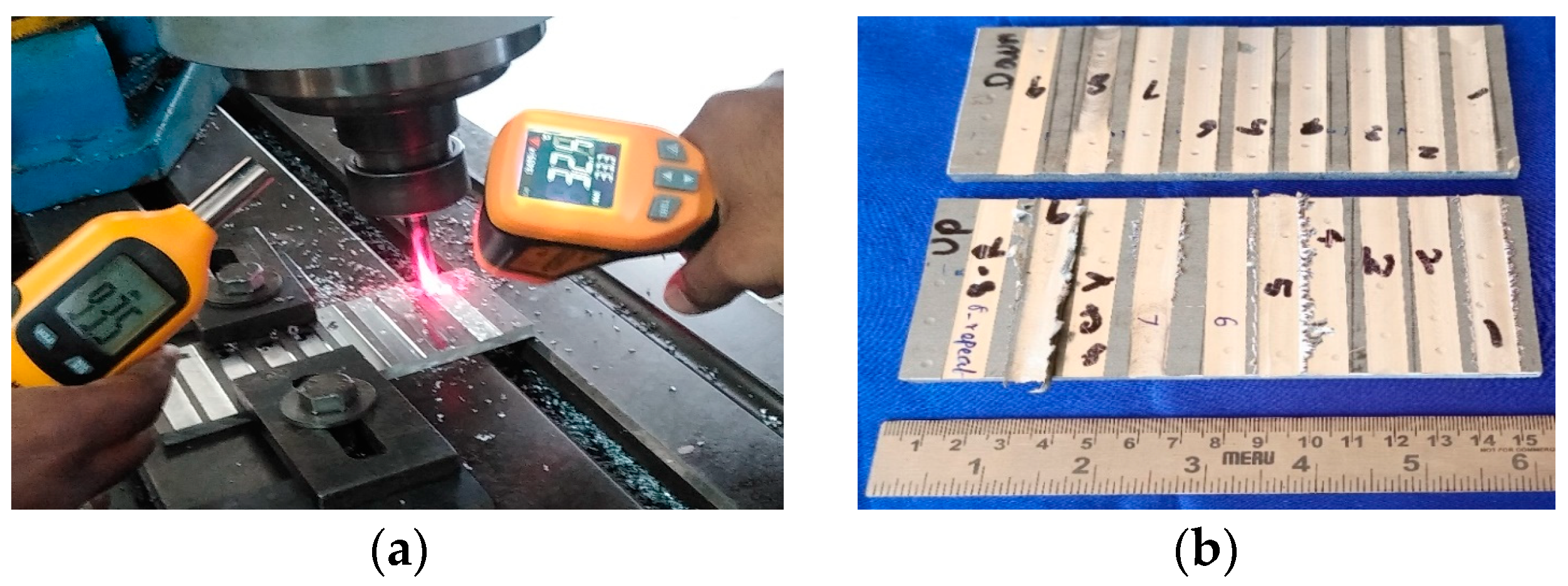

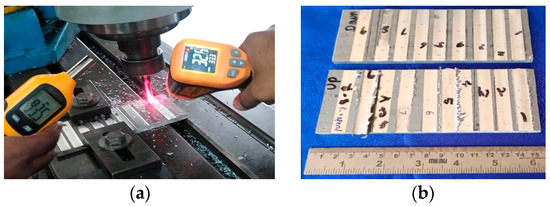

The milling parameter, their levels, and experimental runs given in Table 1 were carried out using the Taguchi L9 experimental design, and readings were gathered for both up- and down-milling operations. To reduce the number of studies, the L9 design was applied. For each experiment, a non-contact infrared radiation pyrometer is used to detect the temperature at the interface between the tool and the workpiece. It features a temperature range of −50 to 550 °C and a 2 °C precision. The noise generated by the grinding operation was measured using a sound level meter (HT-80 sound level meter). To capture the highest values during machining, the sound and temperature sensors were focused within a 15 cm radius of the interaction between the workpiece and the grinding wheel. Figure 1a indicates the close view of the experiment and arrangement for capturing the temperature and sound. Figure 1b shows the two workpieces after the up- and down-milling processes. The initial value of temperature and sound before the start of the machining from the surrounding environment is 28.8 °C and 54.9 dB, respectively.

Table 1.

Experimental condition and results.

Figure 1.

Experimental setup: (a) Close view of sound and temperature measurement for fifth exp. in down-milling; (b) workpieces after up- and down-milling process (150 × 70 × 6 mm-l × b × t).

3. Results and Discussion

3.1. Effect of Spindle Speed on Responses

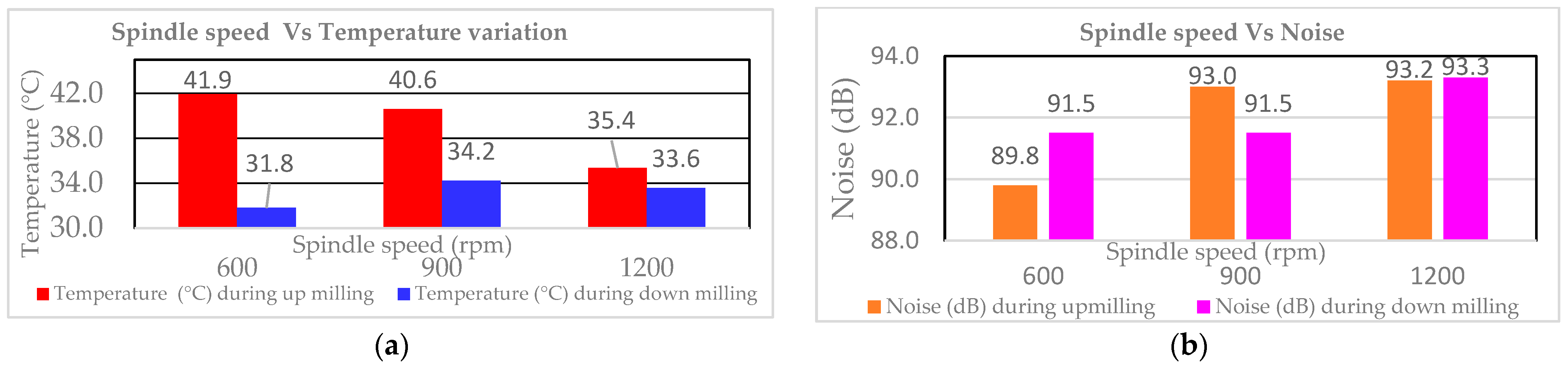

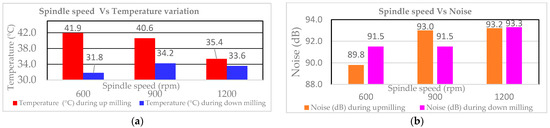

The surface feature and tool life in milling processes is influenced by the temperature generated at the tool–work interface or point of contact. The monitoring of temperature with a multipoint cutting tool at a restricted tool–work interface is a difficult one. Since the temperature was measured in the present study using a non-contact radiation pyrometer, that temperature is used in this analysis. Figure 2, Figure 3 and Figure 4 show the influence of the selected process parameters on temperature and noise generation for both milling processes.

Figure 2.

Effect of spindle speed (S): (a) S Vs Temperature (b) S Vs Noise generation.

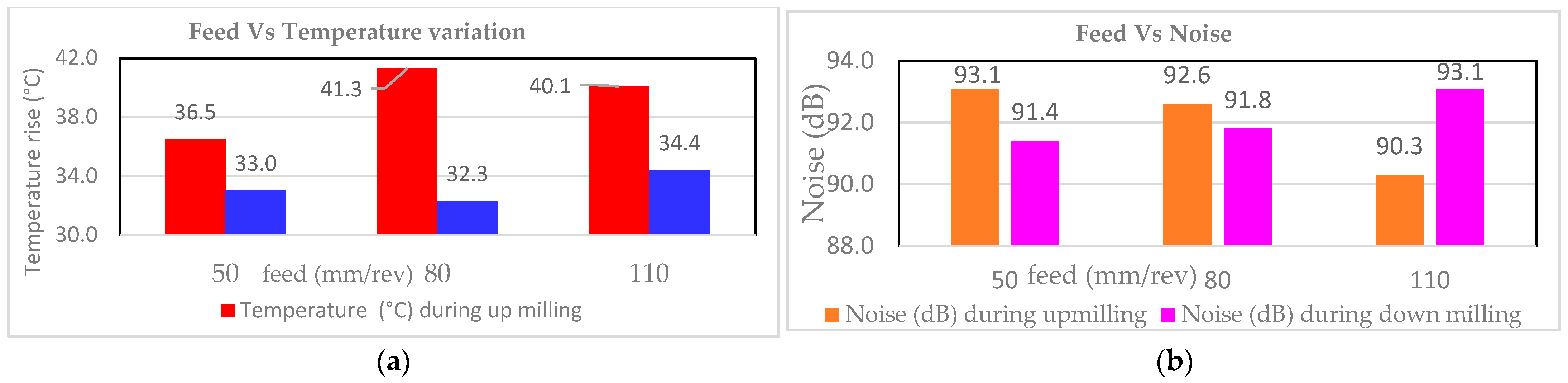

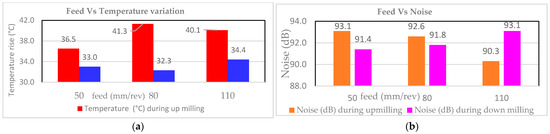

Figure 3.

Effect of feed: (a) Feed Vs Temperature variation (b) Feed Vs Noise generation.

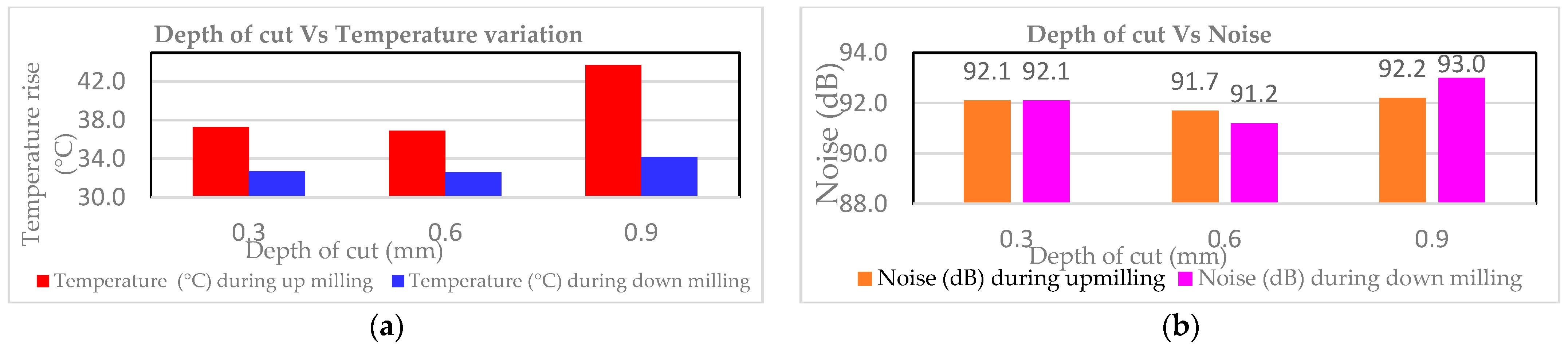

Figure 4.

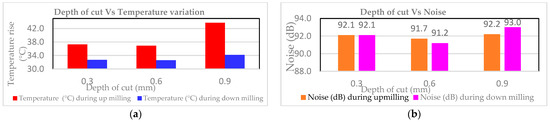

Effect of doc: (a) Depth of cut Vs Temperature variation (b) Depth of cut Vs Noise.

From Figure 2a, with the rise in “S”, the temperature generation decreases for up-milling and increases for down-milling due to the cutting process, becoming more adiabatic as the cutting speed increases. Compared with up-milling, the temperature generation is low in down-milling because the chips are easily disposed of compared with up-milling and do not interfere with machining, thus reducing the temperature. From Figure 2b, the noise increased with an increase in “S” for both up-milling, and down-milling. The down-milling produced lower noise than up-milling since the chip clogging is less frequent in down-milling.

3.2. Effect of Feed on Responses

For both milling processes, an increase in “f” (Figure 3a) and “d” (Figure 4a) caused the tool–work contact length to grow, causing friction between the workpiece and the tool and, as a result, increasing the milling force and temperature. Compared with up-milling, down-milling produced less temperature which is nearly 18% than up-milling.

3.3. Effect of Depth of Cut on Responses

From Figure 3b and Figure 4b, it can be seen that the average value of sound level is approximately equal for both milling processes, and it shows almost an increase in trends with an increase in feed and depth of cut for both up- and down-milling. Hence, overall, it is concluded that down-milling is the best in terms of low temperature rise with the same noise level while end milling the AA7075 plate. The optimum condition for minimising temperature and noise for up-milling was found to be 750 rpm, 110 mm/rev., and 0.8 mm doc. The speed of 615 rpm, 50 rev/min, and 0.8 mm depth of cut was attained as the optimum condition for down-milling. These conditions were found with the help of design expert 7.0 software.

3.4. Analysis of Machined Surfaces

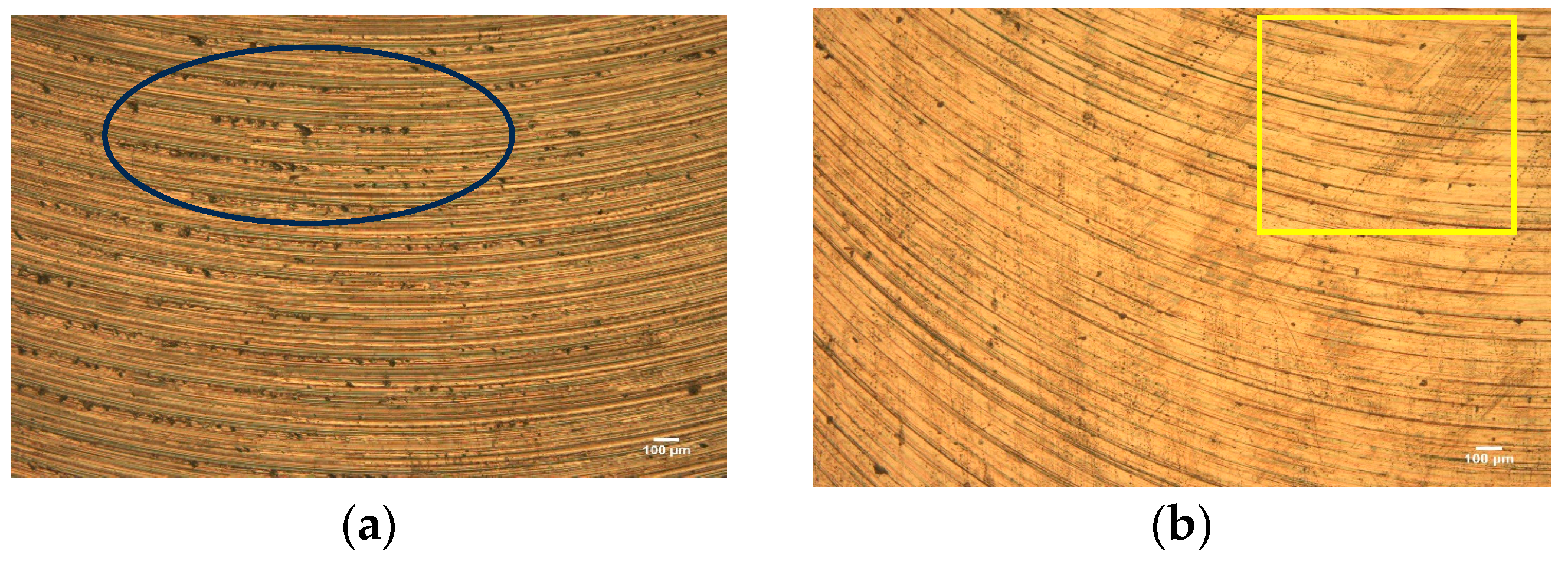

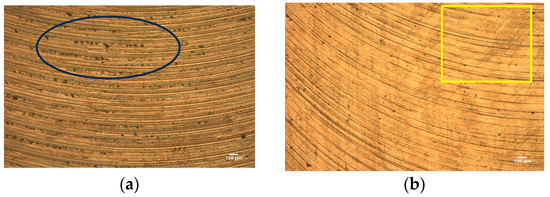

To analyse the appearance/features of the machined surfaces, microstructure images were taken. Figure 5a,b display the microscope images of machined surfaces with 100× magnification from an optical microscope for up- and down-milling, respectively, for the fourth experimental condition in which the temperature and noise values are near their average values. Figure 5a depicts the surface with prominent shearing marks in curved shape (marked with yellow square-shaped box), and deeper batches of ripping areas are marked with elliptical shape (marked using blue colour) from up-milling. Figure 5b displays a smoother surface than Figure 5a with a low level of these markings. As a result, down-milling created a smoother surface since chips may readily leave the workpiece.

Figure 5.

Microstructure of machined surfaces: (a) From up milling (b) From down milling.

4. Conclusions

From the end milling investigation, the impact of end milling parameters on the fluctuation of tool–work interface temperature and noise generation on an Al 7075 plate during both up- and down-milling processes was analysed. The temperature and sound were increased with an increase in spindle speed, feed, and axial depth of cut. Compared with up-milling, the down-milling produced low temperature (~18%) and noise generation (~1%). Machined surfaces with down-milling showed a better appearance than up-milling since chips tend to collect in the cutting region and can either be blocked or carried away by the cutting edge during up-milling, which affects the surface finish.

Author Contributions

K.J.: Writing—original draft, Conceptualization, Methodology, Investiga-tion. R.A.: Software, Validation, formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No data was used for the research described in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hadi, M.A.; Ghani, J.A.; Haron, C.C.; Kasim, M.S. Comparison between up-milling and down-milling operations on tool wear in milling Inconel 718. Procedia Eng. 2013, 68, 647–653. [Google Scholar] [CrossRef]

- Pereira Guimaraes, B.M.; da Silva Fernandes, C.M.; Amaral de Figueiredo, D.; Correia Pereira da Silva, F.S.; Macedo Miranda, M.G. Cutting temperature measurement and prediction in machining processes: Comprehensive review and future perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 2849–2878. [Google Scholar] [CrossRef]

- Jayakumar, K. Study of cutting force and surface roughness in Ball nose end milling of vacuum hot pressed A356 alloy/SiCp metal matrix composite. Mater. Today Proc. 2018, 5, 6526–6533. [Google Scholar] [CrossRef]

- Sampath, K.; Kapoor, S.G.; De Vor, R.E. Modeling and prediction of cutting noise in the face-milling process. J. Manuf. Sci. Eng. 2007, 129, 527–530. [Google Scholar] [CrossRef]

- Babu, P.S.; Kumar, A.; Shihab, S.K.; Siddiquee, A.N. An investigation on Effects of End Milling process on Noise during Machining of Copper. Innov. Prod. Des. Dev. 2017, 8, 119–124. [Google Scholar]

- Ji, C.; Liu, Z.; Ai, X. Effect of cutter geometric configuration on aerodynamic noise generation in face milling cutters. Appl. Acoust. 2014, 75, 43–51. [Google Scholar] [CrossRef]

- Jayakumar, K.; Rahman, P.A. Effect of end milling parameters on MRR and hardness variation of AA7075. Mater. Today Proc. 2023, 72, 2212–2216. [Google Scholar] [CrossRef]

- Vakondios, D.; Kyratsis, P.; Yaldiz, S.; Antoniadis, A. Influence of milling strategy on the surface roughness in ball end milling of the aluminum alloy Al7075-T6. Measurement 2012, 45, 1480–1488. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).