Development of a Flexible Piezoelectric Biosensor That Integrates BaTiO3–Poly(Dimethylsiloxane) for Posture Correction Applications †

Abstract

1. Introduction

2. Materials and Methods

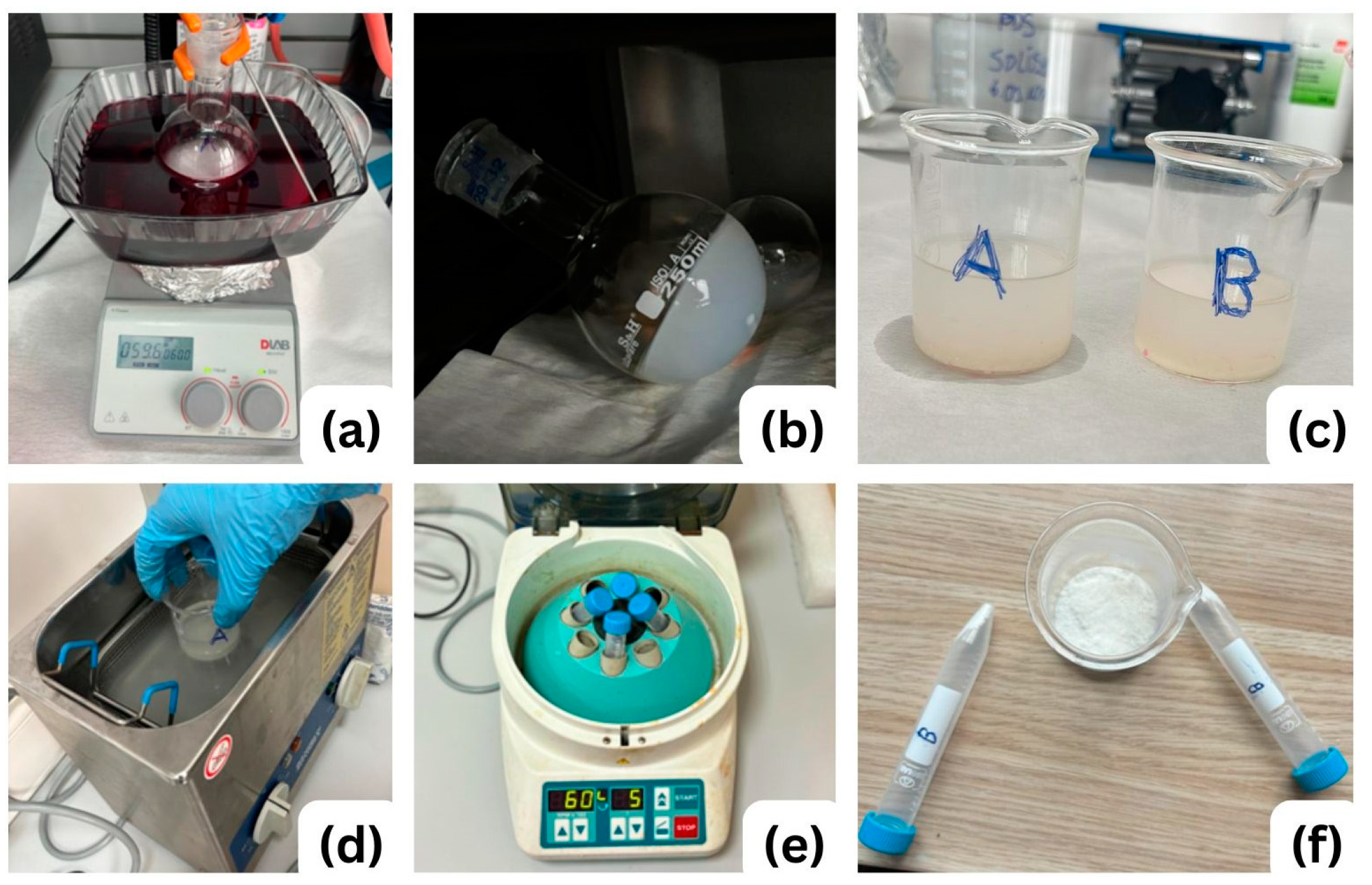

2.1. Synthesis of BaTiO3 Nanoparticles

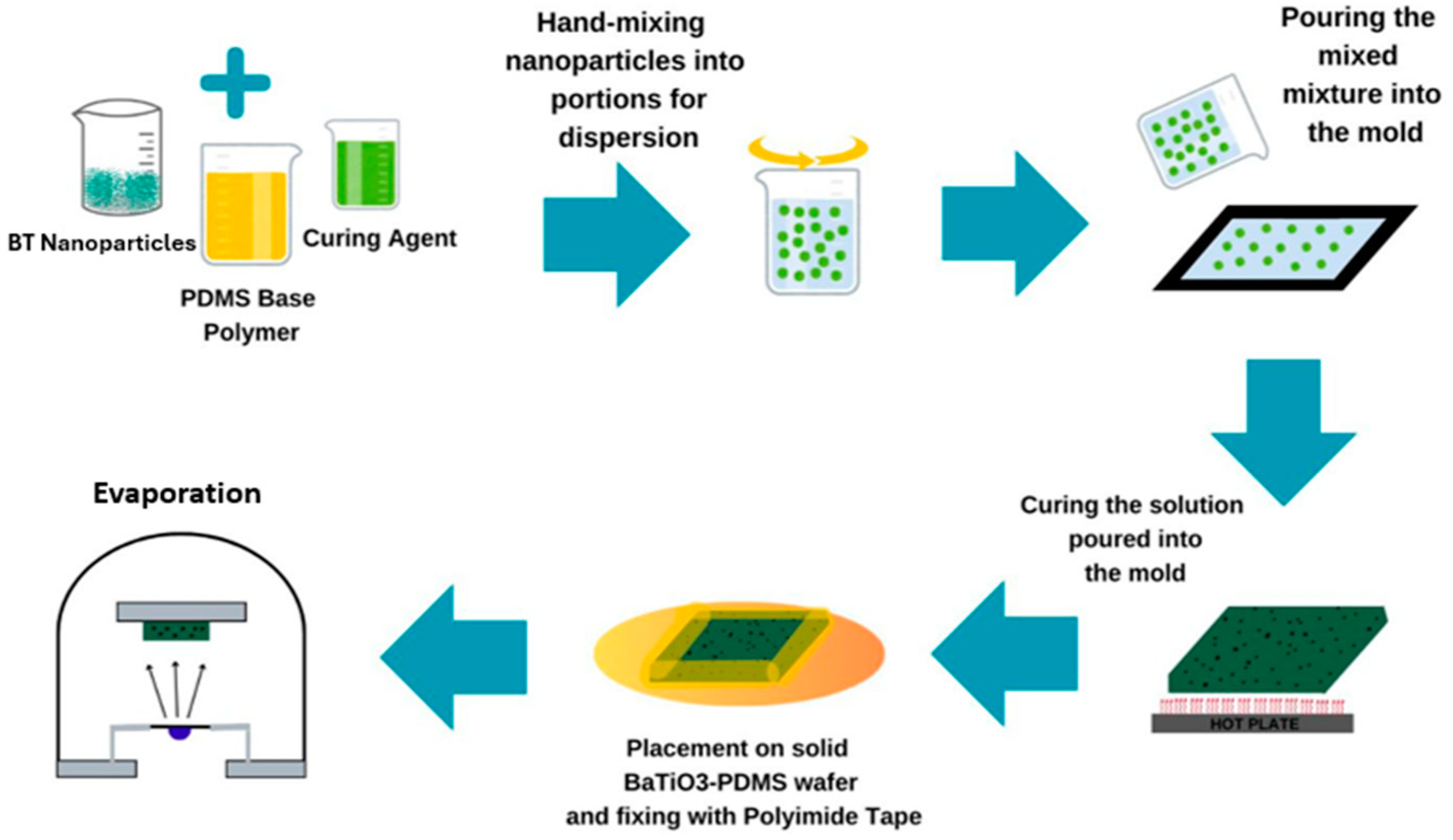

2.2. Fabrication of BaTiO3/PDMS Composite

3. Results and Discussion

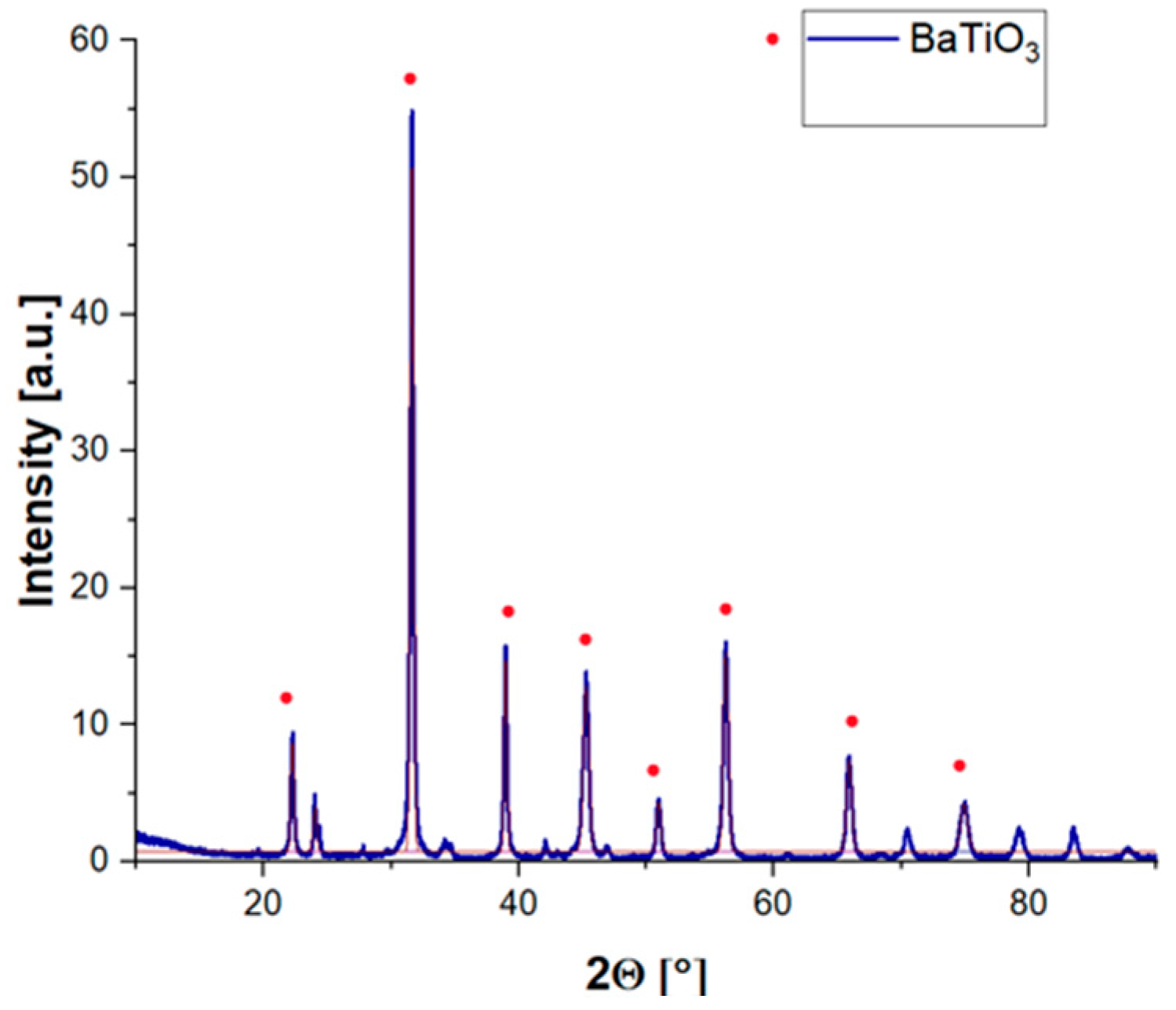

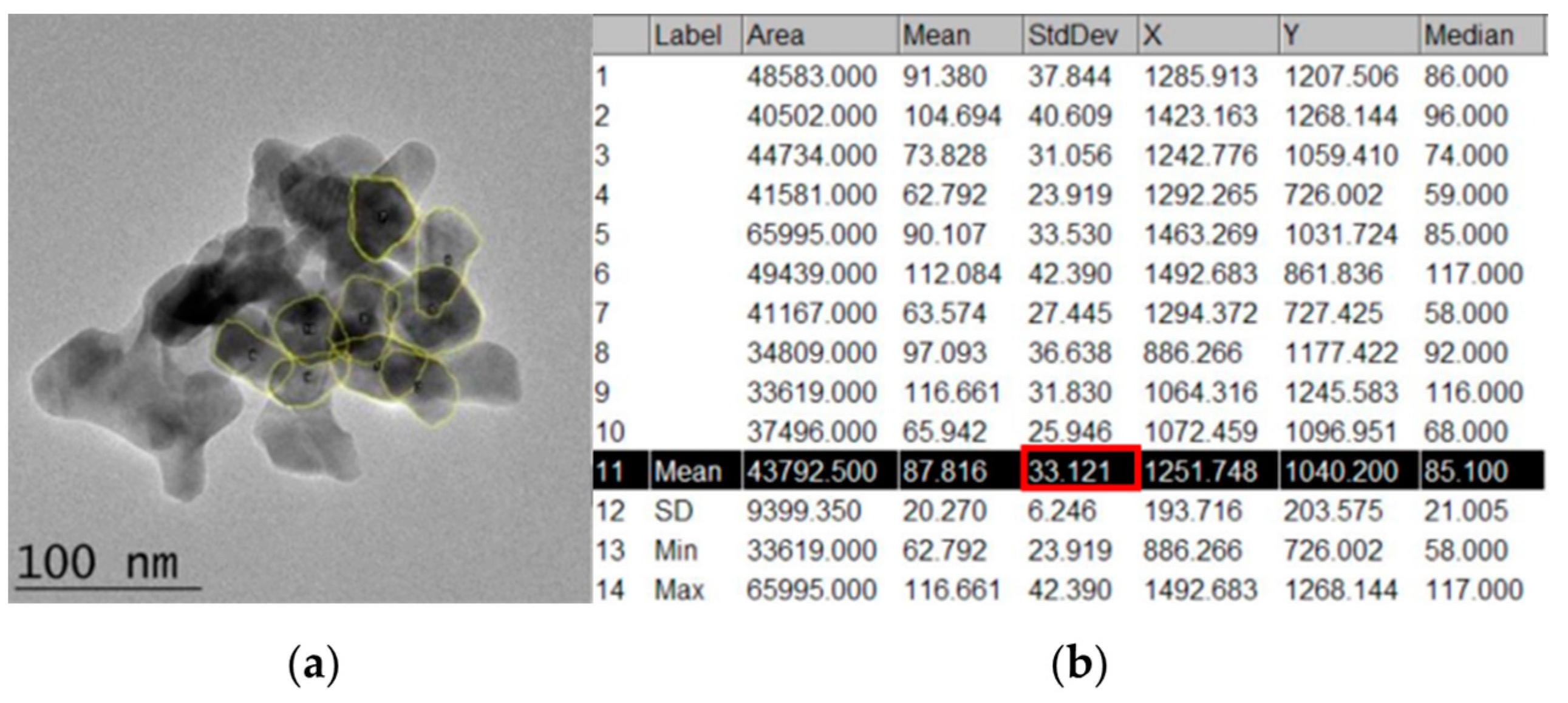

3.1. Structural Characterization

3.1.1. X-ray Diffraction (XRD) Analysis

3.1.2. Transmission Electron Microscopy (TEM) Analysis

3.2. Electrical Characterization

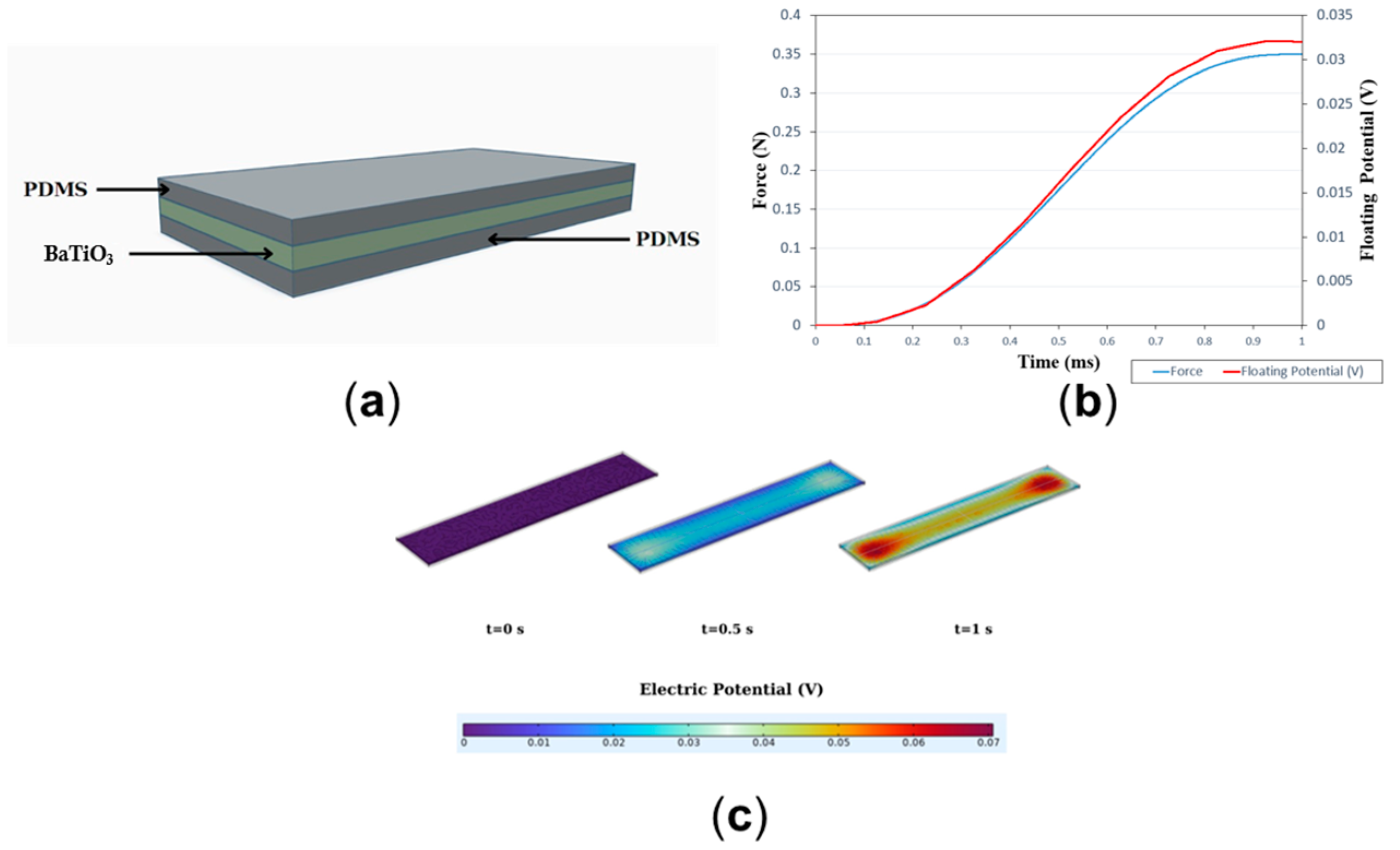

3.2.1. COMSOL Multiphysics Simulations

3.2.2. Electrical Response Testing and Final Product

4. Conclusions

Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Nakhli, H.H.; Bakheet, H.G. The Impact of Improper Body Posture on Office Workers’ Health. Int. J. Innov. Res. Med. Sci. 2020, 5, 147–151. [Google Scholar] [CrossRef]

- Kett, A.R.; Sichting, F.; Milani, T.L. The Effect of Sitting Posture and Postural Activity on Low Back Muscle Stiffness. Biomechanics 2021, 1, 214–224. [Google Scholar] [CrossRef]

- Kripa, S.; Kaur, H. Identifying relations between posture and pain in lower back pain patients: A narrative review. Bull. Fac. Phys. Ther. 2021, 26, 34. [Google Scholar] [CrossRef]

- Bowen, C.R.; Kim, H.A.; Weaver, P.M.; Dunn, S. Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energy Environ. Sci. 2014, 7, 25–44. [Google Scholar] [CrossRef]

- Ju, M.; Dou, Z.; Li, J.-W.; Qiu, X.; Shen, B.; Zhang, D.; Yao, F.-Z.; Gong, W.; Wang, K. Piezoelectric Materials and Sensors for Structural Health Monitoring: Fundamental Aspects, Current Status, and Future Perspectives. Sensors 2023, 23, 543. [Google Scholar] [CrossRef]

- Momin, R.T. Piezoelectric sensors for real-time monitoring and quality control in additive manufacturing. arXiv 2023, arXiv:2310.14321. [Google Scholar] [CrossRef]

- Pohanka, M. The Piezoelectric Biosensors: Principles and Applications, a review. Int. J. Electrochem. Sci. 2017, 12, 496–506. [Google Scholar] [CrossRef]

- Naresh, V.; Lee, N. A Review on Biosensors and Recent Development of Nanostructured Materials-Enabled Biosensors. Sensors 2021, 21, 1109. [Google Scholar] [CrossRef] [PubMed]

- Kaushal, J.B.; Raut, P.; Kumar, S. Organic Electronics in Biosensing: A Promising Frontier for Medical and Environmental Applications. Biosensors 2023, 13, 976. [Google Scholar] [CrossRef]

- Yoong, N.K.M.; Perring, J.; Mobbs, R.J. Commercial Postural Devices: A review. Sensors 2019, 19, 5128. [Google Scholar] [CrossRef]

- Senf, B.; Yeo, W.-H.; Kim, J.-H. Recent Advances in Portable Biosensors for Biomarker Detection in Body Fluids. Biosensors 2020, 10, 127. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, P.; Soares, A.R.; Girão, R.; Neto, M.; Cardoso, S. Spine Cop: Posture Correction Monitor and Assistant. Sensors 2020, 20, 5376. [Google Scholar] [CrossRef] [PubMed]

- Pereira, L.; Plácido da Silva, H. A Novel Smart Chair System for Posture Classification and Invisible ECG Monitoring. Sensors 2023, 23, 719. [Google Scholar] [CrossRef]

- Luo, H.; Jin, T.; Zhang, Y.; Tian, B.; Zhang, Y.; Wang, D. A skin-integrated device for neck posture monitoring and correction. Microsyst. Nanoeng. 2023, 9, 150. [Google Scholar] [CrossRef]

- Suo, G.; Yu, Y.; Zhang, Z.; Wang, S.; Zhao, P.; Li, J.; Wang, X. Piezoelectric and Triboelectric Dual Effects in Mechanical Energy Harvesting Using BaTiO3/Polydimethylsiloxane Composite Film. ACS Appl. Mater. Interfaces 2016, 8, 34335–34341. [Google Scholar] [CrossRef]

- Wei, X.; Xu, K.; Wang, Y.; Zhang, Z.; Chen, Z. 3D Printing of Flexible BaTiO3/Polydimethylsiloxane Piezocomposite with Aligned Particles for Enhanced Energy Harvesting. ACS Appl. Mater. Interfaces 2024, 16, 11740–11748. [Google Scholar] [CrossRef]

- Yousuf, M.; Beigh, N.T.; Arya, D.S.; Garg, M.; Mallick, D.; Singh, P. A sensitive and flexible poroelastic barium titanate matrix for pressure sensing applications. IEEE Sens. Lett. 2023, 7, 1–4. [Google Scholar] [CrossRef]

- Meisak, D.; Kinka, M.; Plyushch, A.; Macutkevic, J.; Zarkov, A.; Schaefer, S.; Selskis, A.; Samulionis, V.; Kuzhir, P.; Banys, J.; et al. Piezoelectric Nanogenerators Based on BaTiO3/PDMS Composites for High-Frequency Applications. ACS Omega 2023, 8, 13911–13919. [Google Scholar] [CrossRef] [PubMed]

- Sappati, K.K.; Bhadra, S. 0-3 Barium Titanate-PDMS Flexible Film for Tactile Sensing. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Fernandez, F.; Kim, M.; Yoon, S.; Kim, J. Capacitive BaTiO3-PDMS hand-gesture sensor: Insights into sensing mechanisms and signal classification with machine learning. Compos. Sci. Technol. 2024, 251, 110581. [Google Scholar] [CrossRef]

- Xue, F.; Zhang, J.; Hu, W.; Hsu, W.T.; Han, A.; Leung, S.F.; Huang, J.K.; Wan, Y.; Liu, S.; Zhang, J.; et al. Multidirection Piezoelectricity in Mono- and Multilayered Hexagonal α-In2Se3. ACS Nano 2018, 12, 4976–4983. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, S.; Su, C.; Zheng, Y.; Qin, Y.; Xu, C.; Wang, Z.L. A High-Reliability Kevlar Fiber-ZnO Nanowires Hybrid Nanogenerator and its Application on Self-Powered UV Detection. Adv. Funct. Mater. 2015, 25, 5794–5798. [Google Scholar] [CrossRef]

- Xu, S.; Qin, Y.; Xu, C.; Wei, Y.; Yang, R.; Wang, Z.L. Self-powered nanowire devices. Nat. Nanotechnol. 2010, 5, 366–373. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Bae, S.; Lin, L.; Yang, Y.; Park, C.; Kim, S.; Cha, S.N.; Kim, H.; Park, Y.J.; Wang, Z.L. Super-Flexible Nanogenerator for Energy Harvesting from Gentle Wind and as an Active Deformation Sensor. Adv. Funct. Mater. 2012, 23, 2445–2449. [Google Scholar] [CrossRef]

- Choi, M.; Murillo, G.; Hwang, S.; Kim, J.W.; Jung, J.H.; Chen, C.; Lee, M. Mechanical and electrical characterization of PVDF-ZnO hybrid structure for application to nanogenerator. Nano Energy 2017, 33, 462–468. [Google Scholar] [CrossRef]

- Ashiri, R.; Nemati, A.; Ghamsari, M.S.; Sanjabi, S.; Aalipour, M. A modified method for barium titanate nanoparticles synthesis. Mater. Res. Bull. 2011, 46, 2291–2295. [Google Scholar] [CrossRef]

- Biglar, M.; Gromada, M.; Stachowicz, F.; Trzepieciński, T. Synthesis of barium titanate piezoelectric ceramics for multilayer actuators (MLAs). Acta Mech. Et Autom. 2017, 11, 275–279. [Google Scholar] [CrossRef]

- Ayadi, M.D.; Hammami, D.G.; Naifar, S.; Bouhamed, A.; Bradai, C.; Kanoun, O. Electromechanical performance and figure of merit optimization for flexible Lead-Free PDMS–BATIO3 piezocomposites. ACS Omega 2024, 9, 28951–28960. [Google Scholar] [CrossRef]

- Mourched, B.; Hoxha, M.; Abdelgalil, A.; Ferko, N.; Abdallah, M.; Potams, A.; Lushi, A.; Turan, H.I.; Vrtagic, S. Piezoelectric-Based Sensor Concept and Design with Machine Learning-Enabled Using COMSOL Multiphysics. Appl. Sci. 2022, 12, 9798. [Google Scholar] [CrossRef]

- Naresh-Babu, J.; Arun-Kumar, V.; Raju, D.G.S. Surgeon’s Neck Posture during Spine Surgeries: “The Unrecognised Potential Occupational Hazard”. Indian J. Orthop. 2019, 53, 758–762. [Google Scholar] [CrossRef]

- Obeid, H.; Khettab, H.; Boutouyrie, P.; Laurent, S.; Hallab, M. 10.5 Comparison of Arterial Stiffness Assessed by Popmètre® With Arterial Stiffness Assessed by Applanation Tonometry: A Clinical Study. Artery Res. 2016, 16, 72. [Google Scholar] [CrossRef]

| Material | Synthesis Technique | Electrode | Voltage Output | Applications | References |

|---|---|---|---|---|---|

| BaTiO3/PDMS | Simple dispersion | Silver | 35 mV | High-Frequency Nanogenerators, Energy Harvesting | [18] |

| 2D α-In2Se3 | PVD | Silver | 35.7 mV | Body Motion Sensor | [21] |

| Kevlar Fiber/ZnO Nanowires | PVD | Palladium | 1.8 mV | UV Detector | [22] |

| ZnO Nanowire | PVD | Platinum | 0.243 mV | pH Sensor, UV Sensor | [23] |

| ZnO Nanowire Arrays | PVD | Aluminum | 50 mV | Skin Motion Sensor | [24] |

| ZnO/PVDF | Spin coating | Gold/Chromium | 410 mV | - | [25] |

| BaTiO3/PDMS | Sol–gel | Copper | 870 mV | Posture Correction | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aslan, M.F.; Özbek, C.; Yiğit, G.; Tosun, M.; Demirel Topel, S. Development of a Flexible Piezoelectric Biosensor That Integrates BaTiO3–Poly(Dimethylsiloxane) for Posture Correction Applications. Eng. Proc. 2024, 73, 2. https://doi.org/10.3390/engproc2024073002

Aslan MF, Özbek C, Yiğit G, Tosun M, Demirel Topel S. Development of a Flexible Piezoelectric Biosensor That Integrates BaTiO3–Poly(Dimethylsiloxane) for Posture Correction Applications. Engineering Proceedings. 2024; 73(1):2. https://doi.org/10.3390/engproc2024073002

Chicago/Turabian StyleAslan, Menduh Furkan, Cem Özbek, Gökhan Yiğit, Mehmet Tosun, and Seda Demirel Topel. 2024. "Development of a Flexible Piezoelectric Biosensor That Integrates BaTiO3–Poly(Dimethylsiloxane) for Posture Correction Applications" Engineering Proceedings 73, no. 1: 2. https://doi.org/10.3390/engproc2024073002

APA StyleAslan, M. F., Özbek, C., Yiğit, G., Tosun, M., & Demirel Topel, S. (2024). Development of a Flexible Piezoelectric Biosensor That Integrates BaTiO3–Poly(Dimethylsiloxane) for Posture Correction Applications. Engineering Proceedings, 73(1), 2. https://doi.org/10.3390/engproc2024073002