Exploring the Efficacy of Port Water Injection on Air–Fuel Ratios and NOx Emissions in Diesel Engines: An Experimental Study †

Abstract

:1. Introduction

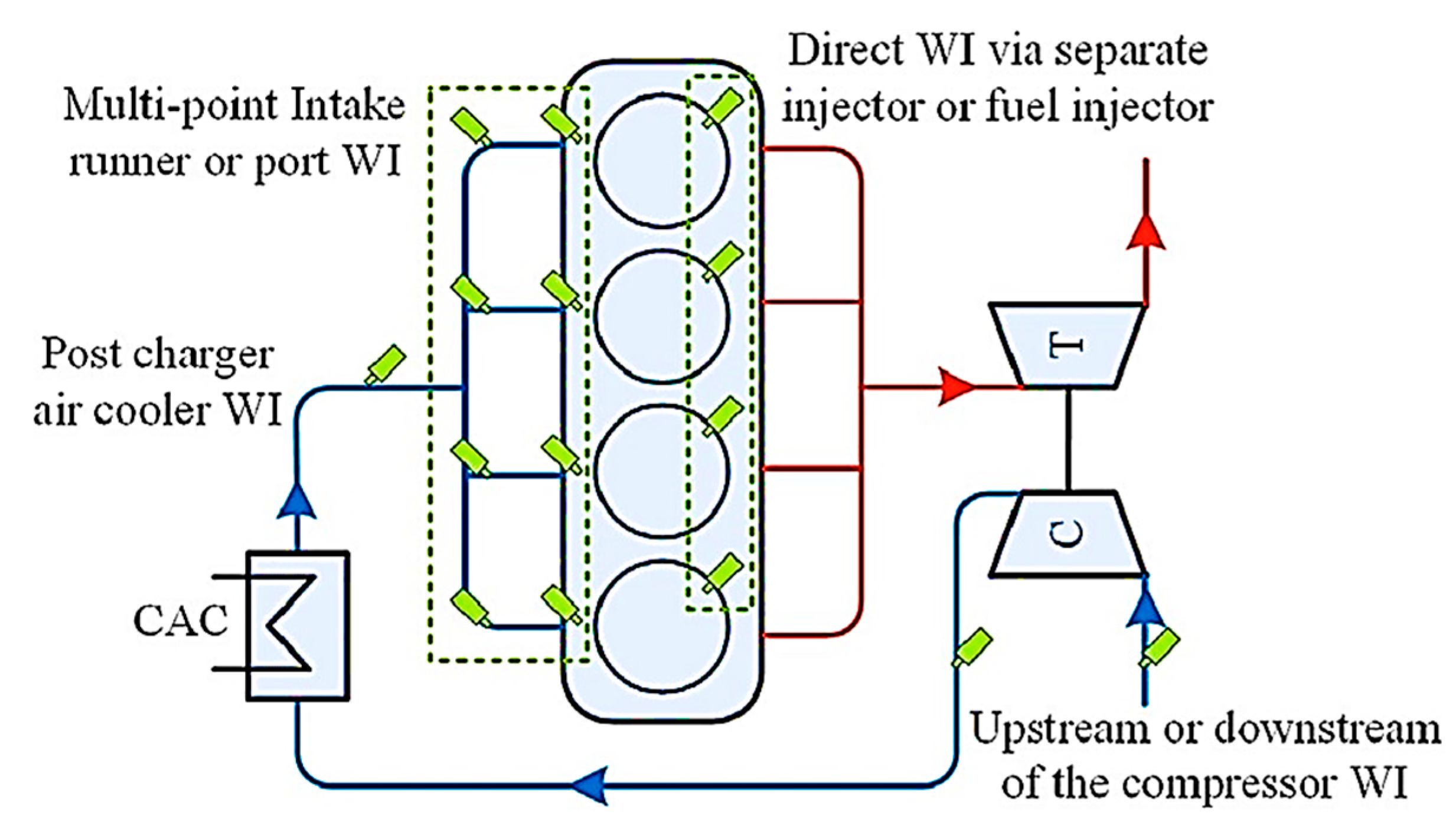

2. Methodology and Experimentation

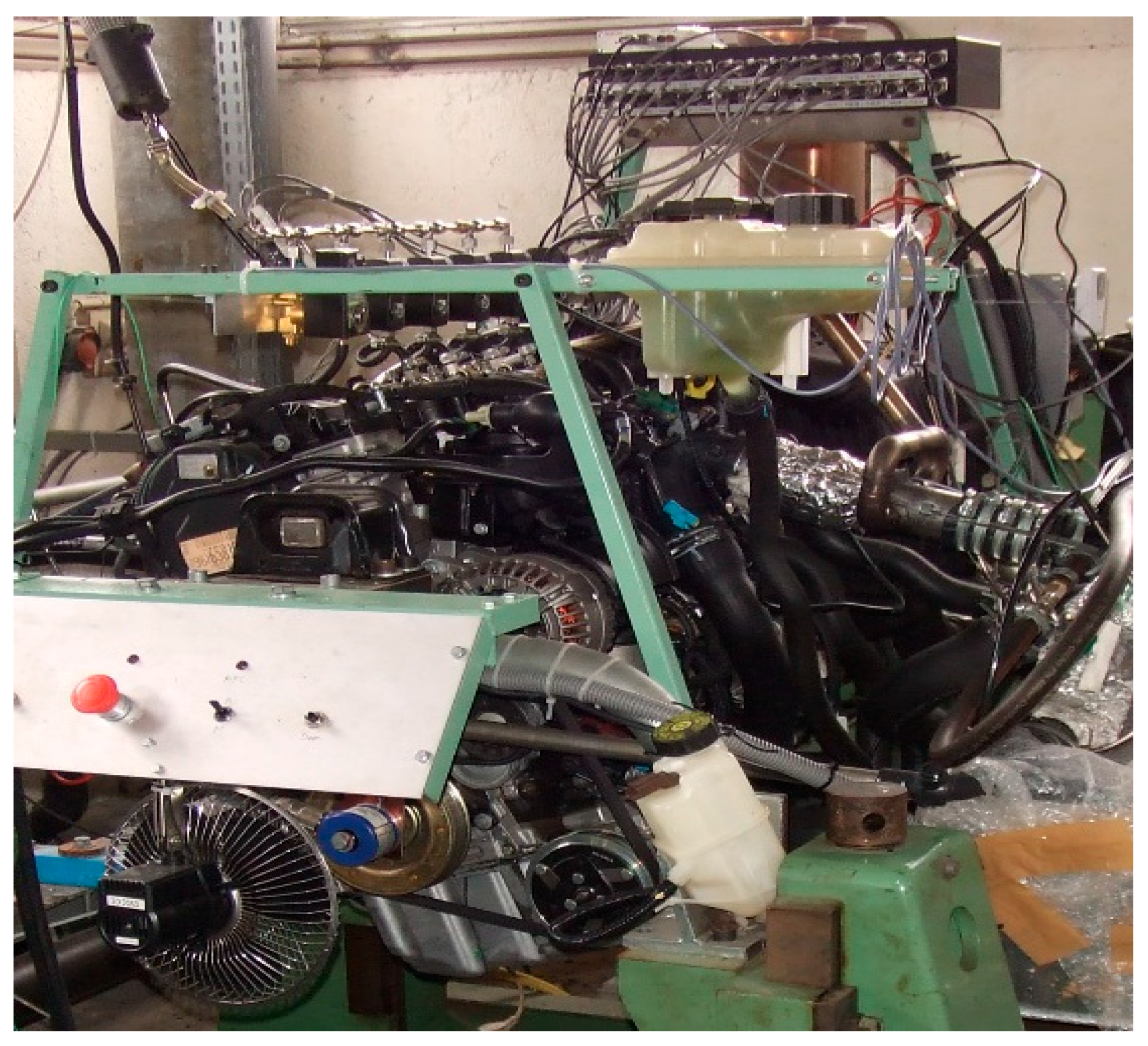

2.1. Engine Testbed

2.2. Instrumentation

2.3. Test Sets

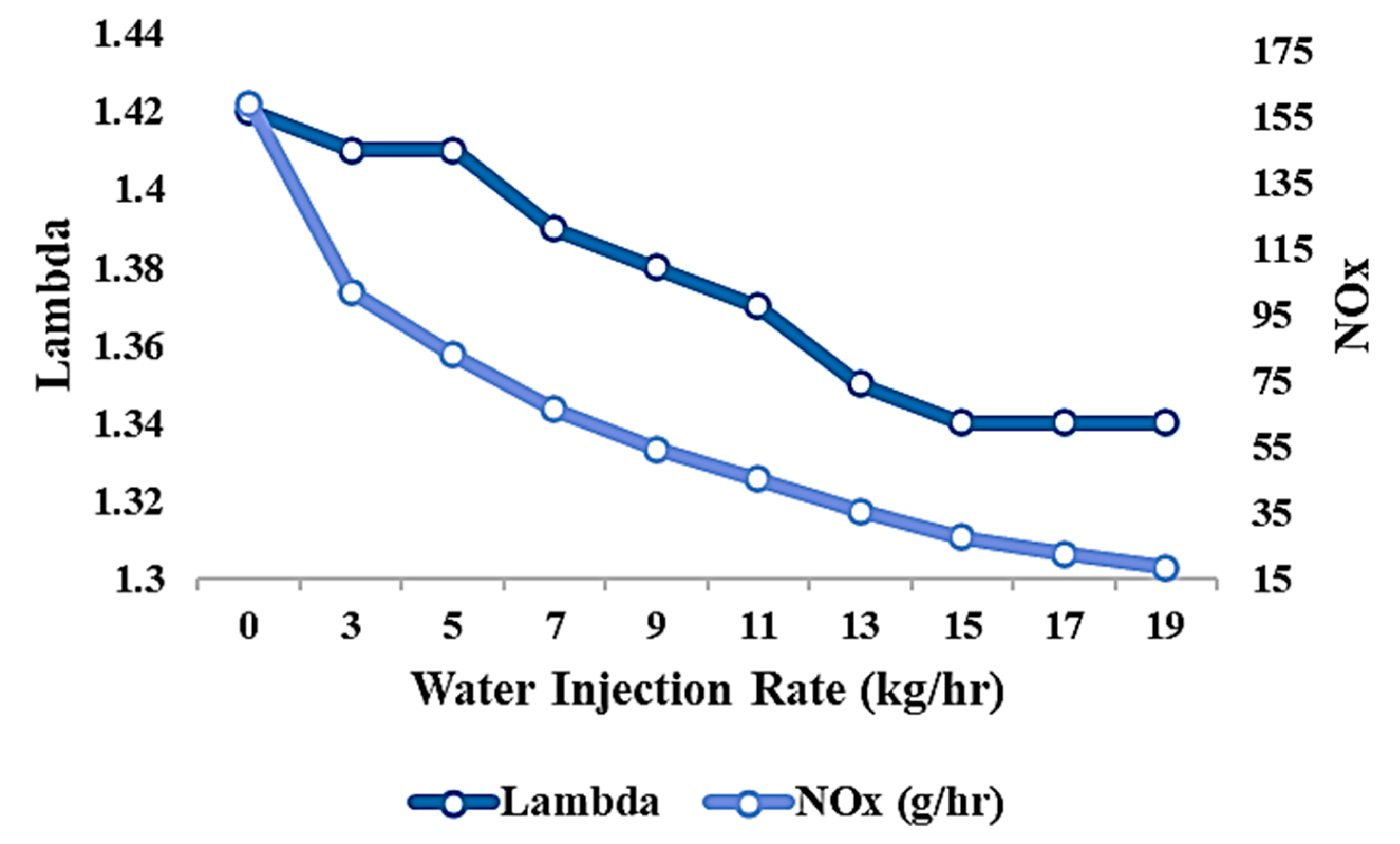

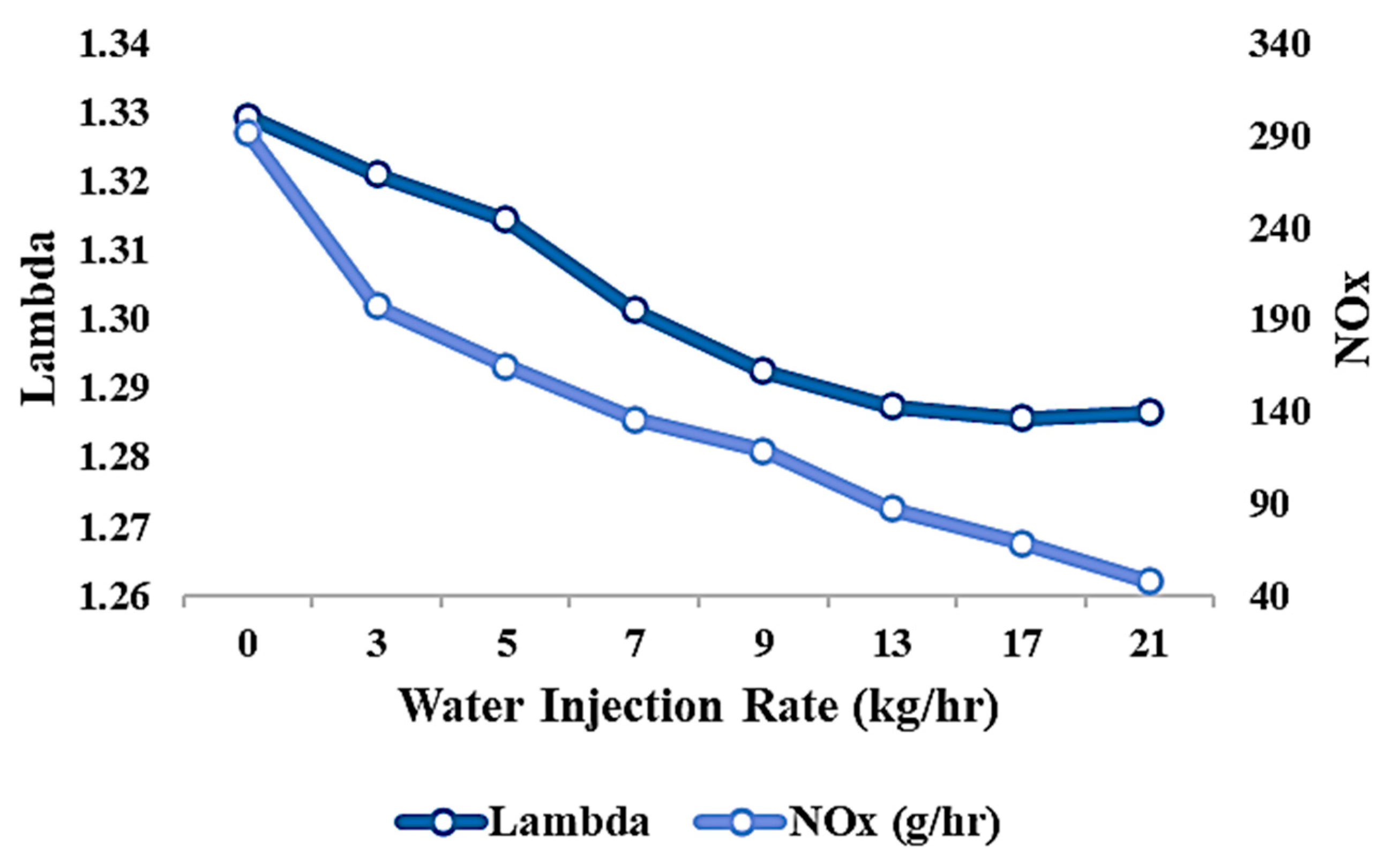

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghadikolaei, M.A.; Wong, P.K.; Cheung, C.S.; Zhao, J.; Ning, Z.; Yung, K.-F.; Wong, H.C.; Gali, N.K. Why is the world not yet ready to use alternative fuel vehicles? Heliyon 2021, 7, e07527. [Google Scholar] [CrossRef] [PubMed]

- Resitoglu, I.A.; Altinisik, K.; Keskin, A. The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems. Clean Technol. Environ. Policy 2015, 17, 15–27. [Google Scholar] [CrossRef]

- Yousaf, H.S.; Abbas, M.; Ghani, N.; Chaudhary, H.; Fatima, A.; Ahmad, Z.; Yasin, S.A. A comparative assessment of air pollutants of smog in Wagah border and other sites in Lahore, Pakistan. Braz. J. Biol. 2024, 84, e252471. [Google Scholar] [CrossRef] [PubMed]

- Rahman, S.M.A.; Fattah, I.M.R.; Ghani, N.; Ong, H.C.; Zamri, M.F.M.A. State-of-the-Art of Strategies to Reduce Exhaust Emissions from Diesel Engine Vehicles. Energies 2021, 14, 1766. [Google Scholar] [CrossRef]

- Singh, S.; Kulshrestha, M.J.; Rani, N.; Kumar, K.; Sharma, C.; Aswal, D.K. An Overview of Vehicular Emission Standards. Mapan-J. Metrol. Soc. India 2023, 38, 241–263. [Google Scholar] [CrossRef]

- Ramachander, J.; Gugulothu, S.K.; Sastry, G.R.; Bhsker, B. An experimental assessment on the influence of high fuel injection pressure with ternary fuel (diesel-mahua methyl ester-pentanol) on performance, combustion, and emission characteristics of common rail direct injection diesel engine. Environ. Sci. Pollut. Res. 2022, 29, 119–132. [Google Scholar] [CrossRef] [PubMed]

- Martinovic, F.; Castoldi, L.; Deorsola, F.A. Aftertreatment Technologies for Diesel Engines: An Overview of the Combined Systems. Catalysts 2021, 11, 653. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; He, Z.; Kosaka, H. Combustion and emission characteristics of a common rail diesel engine run with n-heptanol-methyl oleate mixtures. Energy 2021, 214, 118972. [Google Scholar] [CrossRef]

- Tesfa, B.; Mishra, R.; Gu, F.; Ball, A.D. Water injection effects on the performance and emission characteristics of a CI engine operating with biodiesel. Renew. Energy 2012, 37, 333–344. [Google Scholar] [CrossRef]

- Zhu, S.; Hu, B.; Akehurst, S.; Copeland, C.; Lewis, A.; Yuan, H.; Kennedy, I.; Bernard, J.; Branney, C. A review of water injection applied on the internal combustion engine. Energy Convers. Manag. 2019, 184, 139–158. [Google Scholar] [CrossRef]

- Janjua, A.A.; Shah, S.R.; Din, E.U.; Aslam, J.; Khan, M.Z.A.; Tauzia, X. Simplistic Comparative Analytical Methodology for Accuracy Determination of In-Cylinder Convective Heat Transfer Coefficient Models of Diesel Engine Operating with Water Injection using Experimental Pressure Signals. Arab. J. Sci. Eng. 2023, 48, 12177–12190. [Google Scholar] [CrossRef]

- Chen, Z.; Cai, Y.; Xu, G.; Duan, H.; Jia, M. Exploring the potential of water injection (WI) in a high-load diesel engine under different fuel injection strategies. Energy 2022, 243, 123074. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals, Indian ed.; McGraw Hill Education (India) Private Limited: New Delhi, India, 2011; pp. 68–72. [Google Scholar]

- Tsolakis, A.; Megaritis, A.; Wyszynski, M.L. Low temperature exhaust gas fuel reforming of diesel fuel. Fuel 2004, 83, 1837–1845. [Google Scholar] [CrossRef]

- Cameretti, M.C.; Robbio, R.D.; Mancaruso, E.; Palomba, M. CFD Study of Dual Fuel Combustion in a Research Diesel Engine Fueled by Hydrogen. Energies 2022, 15, 5521. [Google Scholar] [CrossRef]

- Shah, S. Experimental Study and Thermodynamical Analysis of Water Injection in the Intake Manifold of an Automotive Diesel Engine, for Pollutant Emission Reduction. Ph.D. Thesis, Ecole Centrale de Nantes, Nantes, France, 2011. [Google Scholar]

| Engine Parameters | Set 1 | Set 2 | Set 3 | Set 4 |

|---|---|---|---|---|

| Speed (rpm) | 1512 | 1664 | 2059 | 1997 |

| Torque (Nm) | 44 | 114 | 155 | 202 |

| Sets | Water Injection Rate (kg/h) | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Set 1 | 0 | 3 | 4 | 6 | 7 | 9 | |||||||||||||||||

| Set 2 | 0 | 3 | 5 | 7 | 9 | 11 | |||||||||||||||||

| Set 3 | 0 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 17 | 19 | |||||||||||||

| Set 4 | 0 | 3 | 5 | 7 | 9 | 13 | 17 | 21 | |||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janjua, A.A.; Khalid, W.; Shah, S.R.; Tauzia, X. Exploring the Efficacy of Port Water Injection on Air–Fuel Ratios and NOx Emissions in Diesel Engines: An Experimental Study. Eng. Proc. 2024, 75, 38. https://doi.org/10.3390/engproc2024075038

Janjua AA, Khalid W, Shah SR, Tauzia X. Exploring the Efficacy of Port Water Injection on Air–Fuel Ratios and NOx Emissions in Diesel Engines: An Experimental Study. Engineering Proceedings. 2024; 75(1):38. https://doi.org/10.3390/engproc2024075038

Chicago/Turabian StyleJanjua, Asad Asghar, Waqas Khalid, Samiur Rahman Shah, and Xavier Tauzia. 2024. "Exploring the Efficacy of Port Water Injection on Air–Fuel Ratios and NOx Emissions in Diesel Engines: An Experimental Study" Engineering Proceedings 75, no. 1: 38. https://doi.org/10.3390/engproc2024075038