Abstract

Sustainability is one of the main concerns of the aviation industry nowadays, as it strives to reduce emissions and noise, both from flight operations and in the airport environment. Batteries are a promising technology for meeting these challenges. From a sustainable aviation perspective, they can be used as the main power source for all-electric aircraft, but also to support other technologies in hybrid-electric aircraft. To scale up this technology, it is of great interest to classify and evaluate the different battery options, not only currently available, but also with a view to future developments. This work presents the main keywords related to the use of batteries in aviation. It then explains the classification of batteries developed in the framework of the Environmentally Friendly Aviation for All Classes of Aircraft (EFACA) project, together with the main results of an analysis of each battery type in terms of its current status and its potential for future development.

1. Introduction

Safety has always been a cornerstone in aviation. Nowadays, sustainability is another major concern for the industry. Traditionally, the aviation sector contribution to global CO2 levels has been analysed in detail. Although the COVID-19 pandemic dealt a severe impact to air traffic, the latest annual figures show that traffic in the sector has already recovered. This has also an impact on emissions. Despite the decrease in air traffic as a result of the pandemic, aviation accounted for 2% of global energy-related CO2 emissions in 2022. During that year, emissions in the sector reached almost 800 Mt CO2, around 80% of pre-pandemic levels [1]. Given that traffic has already recovered from the pandemic and, in some regions, even surpassed the pre-pandemic levels, the contribution of aviation emissions is expected to be more relevant as a result of increased traffic demand.

This fact explains why both regulators and all stakeholders in the aviation industry are developing strategies to reduce these emissions. In the European case in particular, 2050 is a key date in the decarbonisation process. This would be the milestone for achieving net CO2 emissions from aviation.

In addition, other emissions such as nitrogen oxides or the impact on local air quality and noise around airports have to be considered.

Aviation’s commitment to environmental efficiency is therefore justified. This can be achieved primarily through a dual approach: the pursuit of technological and operational efficiency. The first considers innovative technological developments in aircraft and fuels. The second takes into account other factors, such as optimising flight paths or surface movements at airports [2]. To achieve progress on a global scale, it is essential to innovate in both approaches and to combine their positive effects.

From the point of view of innovation in aircraft propulsion technologies, one technology of great relevance is batteries and their potential to be used as a source of propulsion for all-electric aircraft and in combination with other technologies for hybrid-electric aircraft.

The basic unit of a battery is the electrochemical cell. Several of these interconnected cells, together with other wiring systems, casing, etc., constitute the battery. Electrochemical cells are based on reduction–oxidation reactions, which convert stored chemical energy directly into electrical energy. During the reaction, the reduction takes place at the cathode (electron addition). On the other hand, the oxidation takes place at the anode (electron removal), and the movement of the electrodes generates a voltage inside the cell. This voltage is a function of the materials used in the cathode and anode. During the reaction, the two electrodes are connected by the electrolyte.

Among the main advantages of batteries are their growing importance in achieving net-zero emissions, as they help to reduce fuel consumption and aircraft noise. The authors of [3] developed an interesting review of the four main categories of alternative technologies for sustainable aviation. They considered biofuels, electrofuels, battery-based technology and hydrogen. As a result of their analysis, the authors highlighted the predicted lower environmental impact compared to electrofuels and low-to-zero dependence on carbon-based fuels as the main advantages of the battery technology.

Batteries, and other new technologies with which they can be used in combination, have the potential to reduce in-flight emissions. However, there is a risk that these impacts may occur earlier or later in the life cycle [4]. One of the most impactful stages is the battery manufacturing process.

During this and other stages, further improvements are needed to reduce the impacts associated with the emission of greenhouse gases during the extraction and manufacturing of raw materials, as well as the depletion of fossil fuels [5]. It is therefore essential to advance research to mitigate these impacts and improve the recyclability of batteries at the end of their operational life. It is of the utmost importance to assess the impact of batteries over their entire life cycle, not just during their in-flight operation.

This is particularly relevant when scaling up the technology. One of the main drivers to contribute to this scale-up is the potential of batteries to be used in electrical vertical take-off and landing (eVTOL) aircraft, which will be key elements of the new form of transport known as advanced air mobility (AAM). This new mode of transport may offer a solution to urban congestion.

The work developed in this study is part of the Environmentally Friendly Aviation for All Classes of Aircraft (EFACA) project. This project is co-funded by the European Commission under the Horizon Europe programme. Its aim is to promote research and development of new technologies and fuel alternatives to make the aviation sector more environmentally friendly. In particular, Work Package (WP) 6 focuses on the study of batteries and their potential application in the aviation sector.

This paper presents some of the results obtained during the research framed in WP6 of the EFACA project, focusing in particular on the classification of batteries defined in the project and the characterisation of each type. An analysis of the evolution of battery types and their expected future development is also presented. This analysis considers not only the technical performance metrics, but also other parameters related to the life cycle or safety of batteries. The results of this analysis are presented in detail in the following sections.

The remainder of this paper is structured as follows. Section 2 outlines the key concepts for understanding the role of batteries in aviation, presenting a word cloud of keywords. Section 3 presents the classification of batteries defined as part of the EFACA project. Once the different battery types have been presented, Section 4 summarises the results of the analysis on their use in electric aviation, considering their current status, and their main advantages and limitations for evolution and future prospects. Finally, Section 5 explains the conclusions of the study and lists future work for advancing research in the topic.

2. Word Cloud of Battery Technologies for Use in Aviation

The development of the AAM market represents a major opportunity to scale up the application of battery technology. This technology could make a significant contribution to reducing the carbon footprint of this new mode of transport.

Given the large number of concepts related to the application of batteries in aviation, it is essential to consider some basic ideas to understand the role of this technology and to select the most appropriate battery type for each application. Figure 1 presents a word cloud with some of the key concepts in the application of batteries in aviation.

Figure 1.

Word cloud of the main uses, parameters and applications for batteries in aviation.

Firstly, batteries can be used in three key concepts in aviation: more electric aircraft (MEA), all-electric aircraft and hybrid-electric aircraft.

- More Electric Aircraft (MEA) concept. In a large commercial aircraft, there are typically four sources of power derived from the engines: electrical, pneumatic, hydraulic and mechanical. The MEA concept proposes to use a single power system (electric power) for all systems. The aim is to increase flexibility and range [6]. Batteries play a very important role in this concept. However, this concept relates to the electrification of aircraft systems and not to the propulsion of the aircraft itself. For this reason, it is not considered further in this study;

- All-electric aircraft. To achieve an all-electric aircraft, it is not only necessary to re-place all subsystems with electric alternatives, but also to have an electric propulsion system to provide the necessary thrust for the aircraft to move forward [7]. Here, batteries can be a key technology. The EFACA project defines a proposal for technologies that can be used to power different classes of aircraft. Batteries are the technology proposed by the project to power aircraft carrying a small number of passengers for up to a few hundred kilometres. This is due to the weight and volume restrictions of current battery technologies;

- Hybrid-electric aircraft. In addition, batteries can support other technologies for the development of hybrid-electric systems. A very promising combination is the use of batteries together with hydrogen fuel cells in such hybrid configurations. Batteries could collaborate with fuel cells in the most power-demanding stages of flight. Based on the EFACA proposal, the use of these hybrid turbo-electric technologies using fuel cells is proposed for the regional aircraft segment.

The first step in selecting batteries is to characterise them properly. For this purpose, a number of key parameters should be considered, the so-called performance metrics. These are a series of qualitative and quantitative parameters such as: energy density, cycle life, nominal voltage, power density, C-rate, etc. One of the most important metrics is the energy density. This parameter is usually expressed in Wh/kg. It is defined as the amount of energy stored in a given volume or mass of the battery. Improving this parameter is one of the main challenges in the research and development stages of new batteries.

When selecting a battery, it is not enough to consider its performance metrics in isolation. It is necessary to develop a more detailed analysis of other parameters that consider the entire life cycle of the battery. For this reason, key parameters to consider have been included in the word cloud. These include materials used, battery safety, maintenance and recyclability.

Due to the high potential of batteries to be used in aviation, the word cloud in Figure 1 provides a basic introduction to the multitude of concepts used in the characterisation and evaluation of batteries for aviation applications, including their main uses, the performance metrics used to characterise them and other additional parameters of great importance in their life cycle assessment. Some of these parameters are common to sub-categories of batteries based on the same operating principle. The following section presents the battery classification proposed in the EFACA project to take this idea into account, considering the basic concepts of the word cloud.

3. EFACA Classification of Battery Technologies for Use in Aviation

Due to the complexity of battery characterisation, the EFACA project has developed a global battery classification structured in different levels. This section is divided into two subsections. The first presents the battery classification scheme. Additionally, the second subsection defines the different subgroups of batteries considered in the scheme.

3.1. Battery Classification Overview

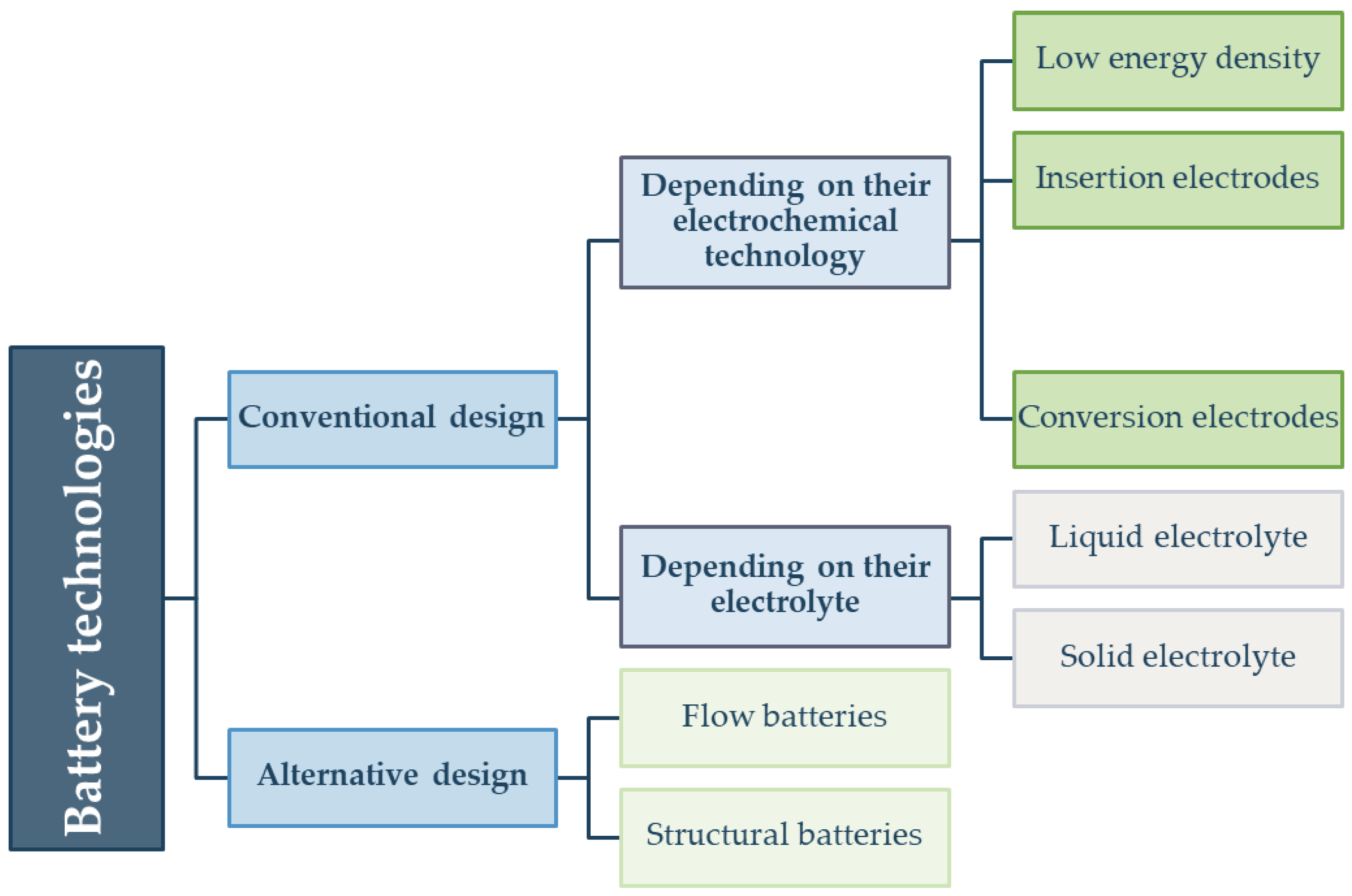

In order to select one type of battery over another for an aeronautical application, it is essential to have an overview of the classification of these batteries. Figure 2 presents the battery classification structured in levels and developed in the framework of the EFACA project.

Figure 2.

Battery classification scheme proposed in the framework of the EFACA project.

Firstly, it should be noted that to be used in sustainable aviation applications, batteries must be rechargeable, i.e., to be included in the secondary batteries category.

The first distinction made in Figure 2 is between batteries of conventional design and batteries of alternative design. Batteries in the conventional design category follow the typical electrochemical cell layout with two electrodes and an electrolyte. On the other hand, batteries in the alternative design category have more disruptive configurations, distinguishing between flow batteries and structural batteries.

Within the conventional design batteries, a sub-classification can be established: they can be classified according to their electrochemical technology and the type of electrolyte they use. In general, batteries can be classified according to their electrochemical technology as low energy density batteries, insertion electrode batteries and conversion electrode batteries. With regard to the electrolyte used, batteries can be classified as liquid electrolyte or solid electrolyte batteries. The classification according to the electrolyte used is complementary to the previous one. For example, batteries with liquid or solid electrolytes are included in the different subgroups of batteries according to the electrochemical technology used.

3.2. Definition of Each Battery Technology

The previous subsection presented the battery classification scheme. The aim of this subsection is to present the definitions of each of the battery subgroups.

Table 1 presents the definition of the main battery subgroups considered in the classification proposed by the EFACA project.

Table 1.

Definition of the main battery technologies considered in the EFACA classification.

It should be noted that the table above presents a general definition of each of the sub-categories. However, within each of these sub-categories there are a variety of different battery options with specific performance metrics and characteristics that are worth analysing in detail before selecting them for a specific aeronautical application.

4. Analysis of Batteries for Use in Aviation: Temporal Evolution and Future Prospects

After presenting the different categories of batteries, this section discusses some of the main results of the analysis on the current status of each type of battery and their main advantages and limitations with regard to their evolution and future development, considering previous reference works. Table 2 presents the main results grouped by battery category. The first column indicates the battery category analysed. The second column shows the current situation of each battery category. It highlights the current status (in operation, under development or in the early stages of research) as well as the alternatives under research. The third column presents the main possibilities for the development of each battery category. Finally, the fourth column presents the main constraints on their development. This last column identifies the main aspects on which research should be advanced for the category analysed to increase its application and scalability.

Table 2.

Main results of the analysis: current situation, main possibilities and challenges for the different battery categories researched for use in aviation.

Low energy density batteries (such as lead–acid or nickel–cadmium) were not included in the analysis as they do not have sufficient energy density for use in electric aviation.

Lithium-ion batteries are the dominant battery technology for aviation applications nowadays. The use of these batteries is also expected to increase in the coming years, as they are the most viable option for powering small eVTOLs. These aircraft are expected to play a key role in the development of Urban Air Mobility (UAM), integrated within the broader concept of AAM. Although the development of this mode of transport is innovative, research on lithium-ion batteries has been going on for several years, which explains its maturity. According to [10], the main development of this technology research took place in the late 1990s. These years saw a breakthrough in the state of the art, driven in particular by the development of new materials such as metal oxide cathode materials and the use of electrolytes compatible with them. Despite their great development, the main limitation of lithium-ion batteries is their low energy density, with typical ceiling values around 250 Wh/kg. Today, research continues into new electrode materials to improve cost constraints, energy density, power density, cycle life and safety [11]. In addition, the development of alternatives with solid-state electrolytes shows promising improvements in their properties.

Another problem with lithium-ion batteries is the use of lithium as the main material. Lithium cannot be found in its pure form in nature and the extraction process is very resource intensive. A first alternative is to use batteries with the same operating principle as lithium-ion batteries (i.e., insertion or removal of ions), but to look for an alternative to lithium. This requires the use of materials with similar chemical properties. Among the alternatives, magnesium and aluminium stand out because of their position in the periodic table, with theoretical energy densities second only to lithium. Other alternatives include sodium and zinc ions [12]. Of this subgroup, magnesium ion batteries may be the most promising option due to their lower tendency to form dendrites compared to other alternatives. They also have improved safety. On the downside, a passivation layer can be formed on the magnesium anode, and they present slower kinetics.

For the purpose of achieving even higher energy densities, the category of conversion electrode batteries is an interesting source of research. In general, the problem with batteries in this category is that there is a large gap between the theoretical parameters defined and those actually achieved. Within the metal–sulphur category, as in the case of insertion electrode batteries, the most promising option may be those based on magnesium. In general, metal–air batteries appear to have the most promising characteristics. However, many of these parameters (such as specific energy) remain theoretical. Further development is needed to confirm whether the actual values are as promising as expected.

In terms of alternative designs, flow batteries are still in the early stages of research and have a long way to go before they could actually be used in aviation applications. On the other hand, while there are interesting projects for the use of structural batteries, further research is needed to overcome the current problems with their integration into the aircraft structure.

5. Conclusions and Future Work

Nowadays, the development of new technologies and alternative fuels are priorities to move towards sustainable aviation with lower emissions and less dependence on fossil fuels. Batteries are one of the most promising technologies. Their benefits include helping to reduce dependence on fossil fuels, supporting net-zero emissions and reducing noise.

The EFACA project has proposed a classification of batteries for aviation applications. The classification is divided into levels. The first level distinguishes between batteries of conventional design (basic structure based on the electrochemical cell with two electrodes and an electrolyte) and alternative designs. Within the latter category, a distinction is made between flow batteries and structural batteries. Within the conventional design category, a second subdivision is made. Batteries can be classified according to their electrochemical technology into low energy density, insertion and conversion electrodes. They can also be classified based on their electrolyte, which can be either liquid or solid.

This study also analysed the current situation and the main opportunities and limitations of each type of battery in terms of their development and future prospects in aviation applications. At present and in the coming years, lithium-ion batteries will be the dominant technology. In particular, the development of UAM as part of AAM represents a major opportunity for the development of this technology. Additionally, new designs using solid electrolytes promise improvements in key parameters such as energy density.

To move away from the dependence on lithium, batteries with other insertion electrodes would be a good option. Although the advantages and limitations depend on the type of selected ion, the most promising technology in terms of performance metrics could be magnesium-ion batteries.

For higher energy densities, if the theoretical values are achieved, metal–air batteries would be the most promising category among the conversion electrode batteries.

This analysis has provided a starting point for an overview of battery classification and their application in aviation. As future steps, it is proposed to develop a more detailed analysis based on certain key performance metrics to further justify the viability of each battery type and systematically identify the most promising options within each subcategory. It is also proposed to further analyse the differences between the existing variants within each group and to work on the development of graphical elements for comparison.

Author Contributions

Conceptualisation, M.Z.S.: methodology, M.Z.S.; validation, R.D.-A.J., C.G.A. and V.F.G.C.; investigation, M.Z.S.; resources, V.F.G.C.; writing—original draft preparation, M.Z.S.; writing—review and editing, M.Z.S., F.P.M., R.D.-A.J., C.G.A. and V.F.G.C.; visualisation, M.Z.S. and F.P.M.; supervision, V.F.G.C.; project administration, V.F.G.C.; and funding acquisition, V.F.G.C. All authors have read and agreed to the published version of the manuscript.

Funding

The development of this work is framed in the Environmentally Friendly Aviation for All Classes of Aircraft (EFACA) project. This project is funded by the European Union Horizon Europe research and innovation programme (HORIZON-CL5-2021-D5-01-05) under grant agreement no.101056866.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tracking Clean Energy Progress 2023—Analysis. Available online: https://www.iea.org/reports/tracking-clean-energy-progress-2023 (accessed on 27 November 2024).

- Avogadro, N.; Redondi, R. Pathways toward Sustainable Aviation: Analyzing Emissions from Air Operations in Europe to Support Policy Initiatives. Transp. Res. Part A Policy Pract. 2024, 186, 104121. [Google Scholar] [CrossRef]

- Su-ungkavatin, P.; Tiruta-Barna, L.; Hamelin, L. Biofuels, Electrofuels, Electric or Hydrogen?: A Review of Current and Emerging Sustainable Aviation Systems. Prog. Energy Combust. Sci. 2023, 96, 101073. [Google Scholar] [CrossRef]

- Melo, S.P.; Cerdas, F.; Barke, A.; Thies, C.; Spengler, T.S.; Herrmann, C. Life Cycle Engineering of Future Aircraft Systems: The Case of eVTOL Vehicles. Procedia CIRP 2020, 90, 297–302. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Ayoub, M.; Khuri, S.; Alami, A.H.; Sayed, E.T.; Deepa, T.D.; Olabi, A.G. Environmental Aspects of Batteries. Sustain. Horiz. 2023, 8, 100074. [Google Scholar] [CrossRef]

- Wheeler, P.; Bozhko, S. The More Electric Aircraft: Technology and Challenges. IEEE Electrif. Mag. 2014, 2, 6–12. [Google Scholar] [CrossRef]

- Barzkar, A.; Ghassemi, M. Components of Electrical Power Systems in More and All-Electric Aircraft: A Review. IEEE Trans. Transp. Electrif. 2022, 8, 4037–4053. [Google Scholar] [CrossRef]

- Weber, A.Z.; Mench, M.M.; Meyers, J.P.; Ross, P.N.; Gostick, J.T.; Liu, Q. Redox Flow Batteries: A Review. J. Appl. Electrochem. 2011, 41, 1137–1164. [Google Scholar] [CrossRef]

- Di Mauro, G.; Corcione, S.; Cusati, V.; Marciello, V.; Guida, M.; Nicolosi, F. The Potential of Structural Batteries for Commuter Aircraft Hybridization. J. Mater. Eng. Perform. 2023, 32, 3871–3880. [Google Scholar] [CrossRef]

- Xu, K. Nonaqueous Liquid Electrolytes for Lithium-Based Rechargeable Batteries. Chem. Rev. 2004, 104, 4303–4418. [Google Scholar] [CrossRef] [PubMed]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-Ion Battery Materials: Present and Future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Gao, Y.; Pan, Z.; Sun, J.; Liu, Z.; Wang, J. High-Energy Batteries: Beyond Lithium-Ion and Their Long Road to Commercialisation. Nano-Micro Lett. 2022, 14, 94. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).