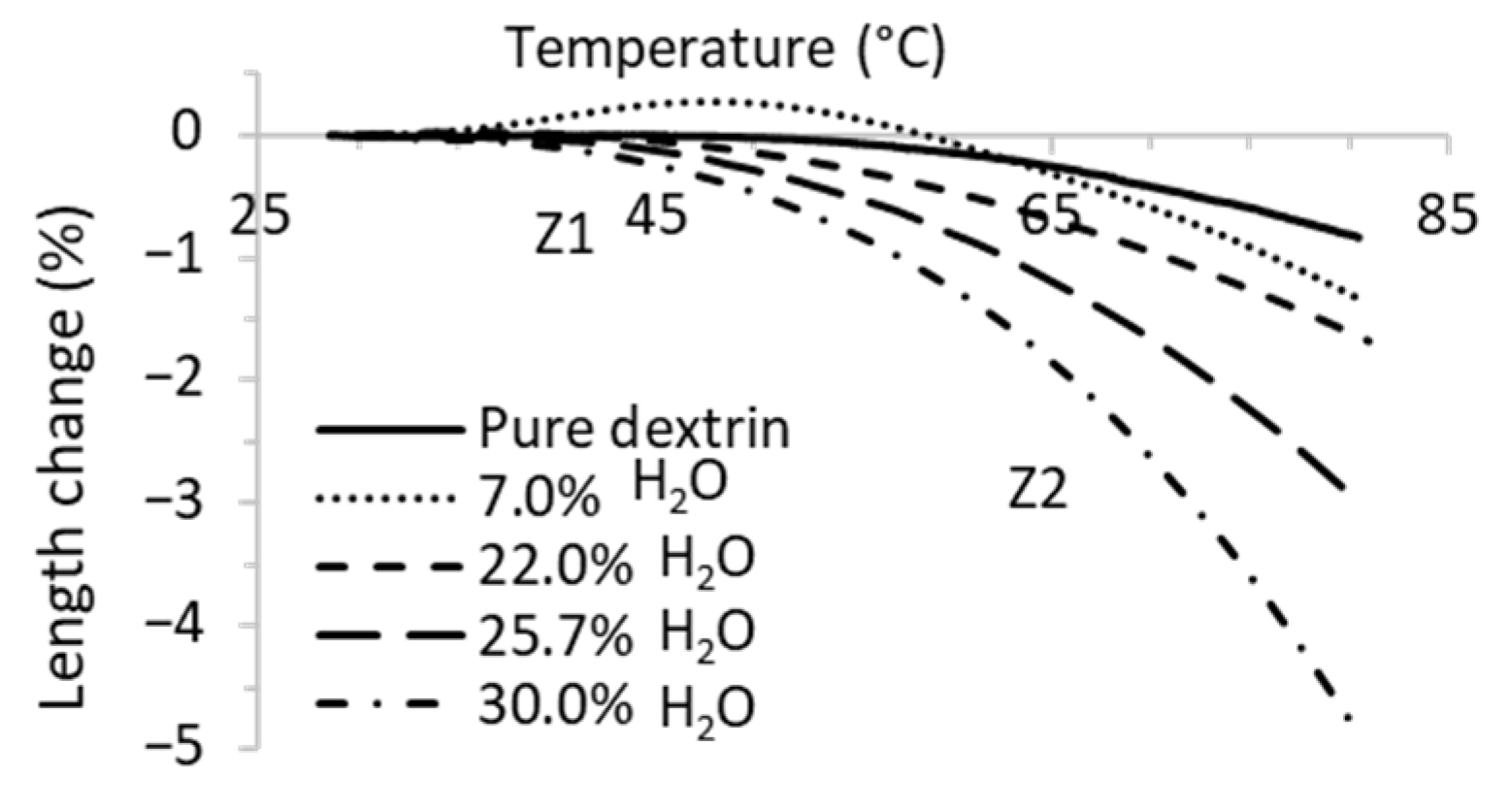

Abrasive wheels are composed of abrasive grains, vitreous bond precursors, and a temporary binder that, normally, includes a liquid part to give consistency and plasticity to the green body [1]. During the thermal drying cycle, there are length variations in the material caused by thermal expansion and water elimination. These can result in the formation of cracks in the composite. In this work, the effect of the amount of water added to the vitreous precursor and the organic additive (dextrin) was analyzed, up to 80 °C, via Thermomechanical Analysis and Dynamic Mechanical Analysis in compression mode. Firstly, it was observed that the vitreous bond precursor does not significantly contribute to the length variation of the composite (<0.05%) in the drying process. Figure 1 presents the dimensional variation for dextrin with different H2O contents. Initially, the added water is incorporated into the dextrin molecules as water for hydration (zone Z1). The sample with 7.0% H2O presents an expansion, up to ~47 °C, followed by a contraction. As the water content in the samples increases, free water begins to form and, therefore, the shrinkage generated by the water evaporation occurs (zone Z2) becoming the predominant effect. The trend lines of the samples with a water content in the range of 22–30% converge to a value of ~15 ± 1% of H2O as the transition zone to free water formation.

Figure 1.

Dextrin thermal expansion.

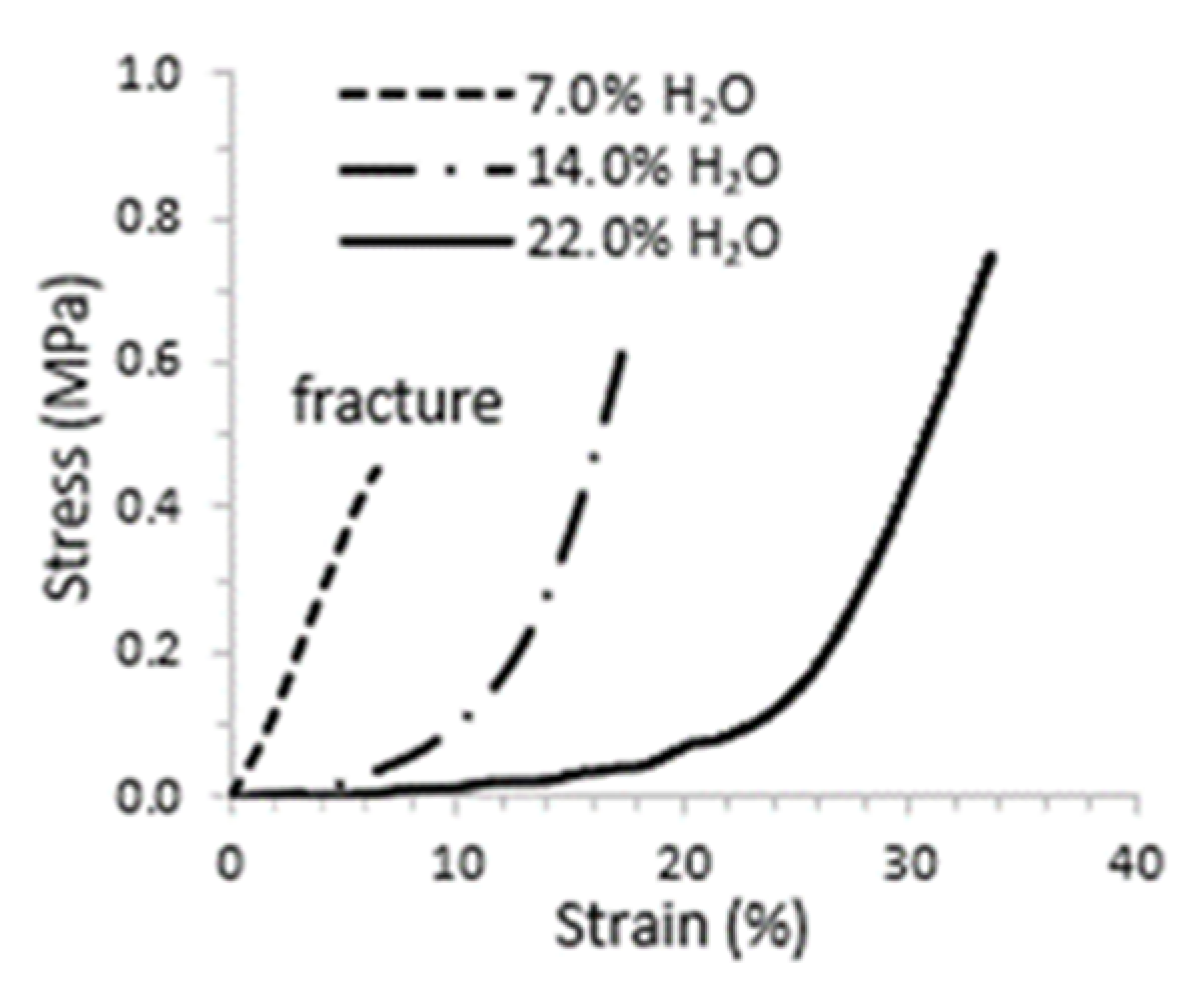

Compression tests (Figure 2) show that the two types of water incorporation in dextrin have a different effect, inducing a transition from a mainly elastic to a plastic deformation behavior. The necessary water content to guarantee the plasticity of the mixture without subjecting the composite to excessive dimensional variations during the drying step was determined. Excess water increases the global dimensional variation in drying and can induce the formation of cracks.

Figure 2.

Dextrin compression tests.

Author Contributions

Conceptualization, S.M.d.C., M.P. and P.C.; methodology, S.M.d.C. and J.R.; writing—original draft preparation, S.M.d.C.; writing—review and editing, P.C.; supervision, D.S. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by FCT national funds, under the national support to R&D units grant, through the reference project UIDB/04436/2020 and UIDP/04436/2020. This work is within the scope of the Sharlane Costa Ph.D. degree in progress, financially supported by the Portuguese Foundation for Science and Technology (FCT) through the PhD grant reference 2021.07352.BD.

Conflicts of Interest

The authors declare no conflict of interest.

Reference

- Capela, P.; Carvalho, S.F.; Guedes, A.; Pereira, M.; Carvalho, L.; Correia, J.; Soares, D.; Gomes, J.R. Effect of sintering temperature on mechanical and wear behavior of a ceramic composite. Tribol. Int. 2018, 120, 502–509. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).