Abstract

Every year, millions of tons of waste glass are generated all over the world and disposed in landfills. Utilization of this waste by substituting a certain share of cement in cement mortars can contribute to the reduction of environmental pollution in two aspects: the utilization of waste and the reduction of the cement content in cement-based mortars. The cement industry is responsible for approximately 6% of global CO2 emissions. Seven different mortar mixes, containing between 0% and 30% of waste glass powder added by weight of cement, were analyzed. The following physical and mechanical properties of the mortar mixes were measured: compressive strength, flexural strength, and density. The test results revealed that waste glass powder can be used in small amounts in cement-based mortars to reduce the amount of cement and to utilize waste glass. A higher performance, modified cement-based mortar can be produced for civil engineering applications by replacing 5% with waste glass powder. The linear regression equations obtained illustrate the relationships between the density and compressive strength, and between density and flexural strength at 28 days.

1. Introduction

In day-to-day life, glass is used in construction, soft drink bottles, medicinal bottles, vehicles, mirrors, windscreens, doors, windows, decorative items, tube lights, bulbs, and other electronics items. Glass has a limited life span, so after completion of its utility period, it is either stock piled or sent (non-recycled) to landfills. Non-degradable waste has been a major issue in the 21st century. The disposal of waste glass in landfills is not an environmentally friendly solution because glass is non-biodegradable waste [1].

Production of cement (the binder in concrete) is an energy-intensive and highly pollutive process, which contributes about 5–8% to the total global CO2 emissions. Recently, many studies have been focused on the use of waste glass in concrete as an aggregate replacement [2,3].

The main chemical component of waste glass is SiO2 [4,5,6,7,8,9]. High content of SiO2 is the inherent characteristic of pozzolanic materials. The properties that influence the pozzolanic behavior of waste glass (and most pozzolans in concrete) are the fineness, chemical composition, and the pore solution present for the reaction [10]. Finer glass particles in a concrete mix cause a non-expansive pozzolanic reaction where calcium silicate hydrate (C-S-H) with a low calcium–silicate ratio is produced [11].

The paper analyses the possibility of utilizing waste glass powder in a cement-based mortar. The part of cement replaced by waste glass powder ranged from 5 to 30%. The relationships between the density and compressive strength, flexural strength, ultrasonic pulse velocity, and water absorption were analyzed at 28 days.

2. Materials and Methods

The tested mortar mixes were made from Portland cement CEM I 42.5 R and waste glass powder of the following chemical composition: 68.7% of SiO2; 12.18% of Al2O3; 3.95% of CaO; 2.80% of K2O; 1.30% of Fe2O3; 0.90% of MgO; 0.75% of Na2O; 0.20% of TiO2; 9.77% of other elements. The tested waste glass powder has the particle size of 15.1 μm. 90% of the particles were smaller than 29 μm, 50% were smaller than 1385 μm, and 10% were smaller than 2.69 μm. 0/4 fraction sand was used for the tests, with particle density of 2488 kg/m3, and bulk density of 1643 kg/m3. Compositions of concrete mixes are presented in Table 1. Test specimens were made of the mixes where 0%–30% of cement was replaced by waste glass powder. W/C in all mixes was 0.46.

Table 1.

Compositions of the mixes, shown in %.

The mixed cement mortar was poured into standard 40 × 40 × 160 mm molds and left to set for 24 h. After 24 h, the specimens were de-molded and cured in water of 20 ± 1.0 °C for 28 days. The main physical and mechanical properties of the mortar were determined according to the applicable standards. The density of the specimens was determined according to EN 772-13, the compressive strength was determined according to EN 196-1. The microstructure of the cement mortar and waste glass powder was examined with the scanning electron microscopy (SEM) device SEM JEOL 7600F. The obtained test results were processed with STATISTICA software.

3. Results and Discussion

3.1. Physical and Mechanical Properties

Physical and mechanical properties—namely density, flexural strength, and compressive strength—of the control specimens of the cement mortar and the specimens modified with waste glass powder were tested after 28 days of curing in water. The test findings are presented in Table 2.

Table 2.

Physical and mechanical properties.

3.2. Relationship between Physical and Mechanical Properties and the Density of Hardened Mortar

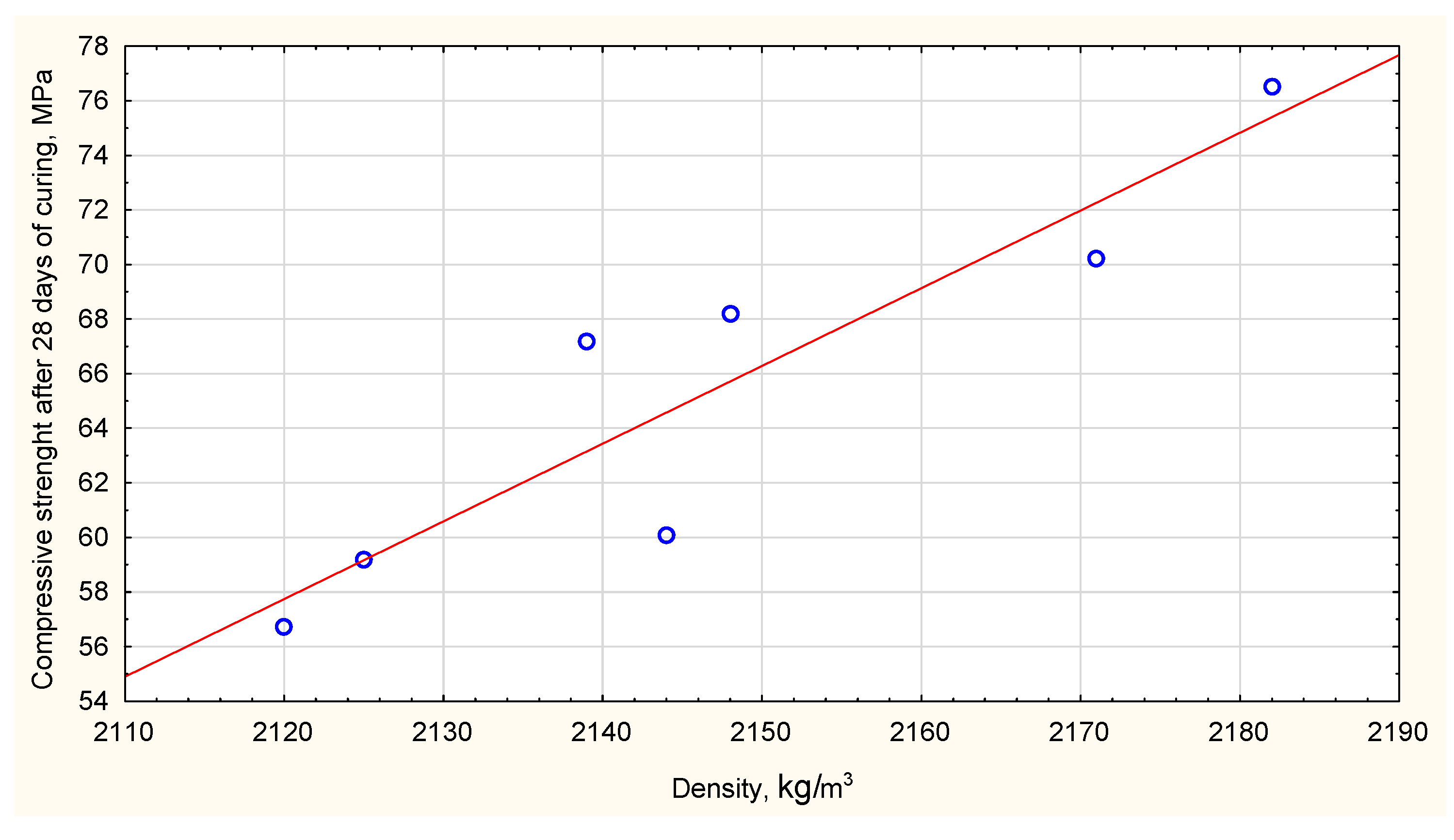

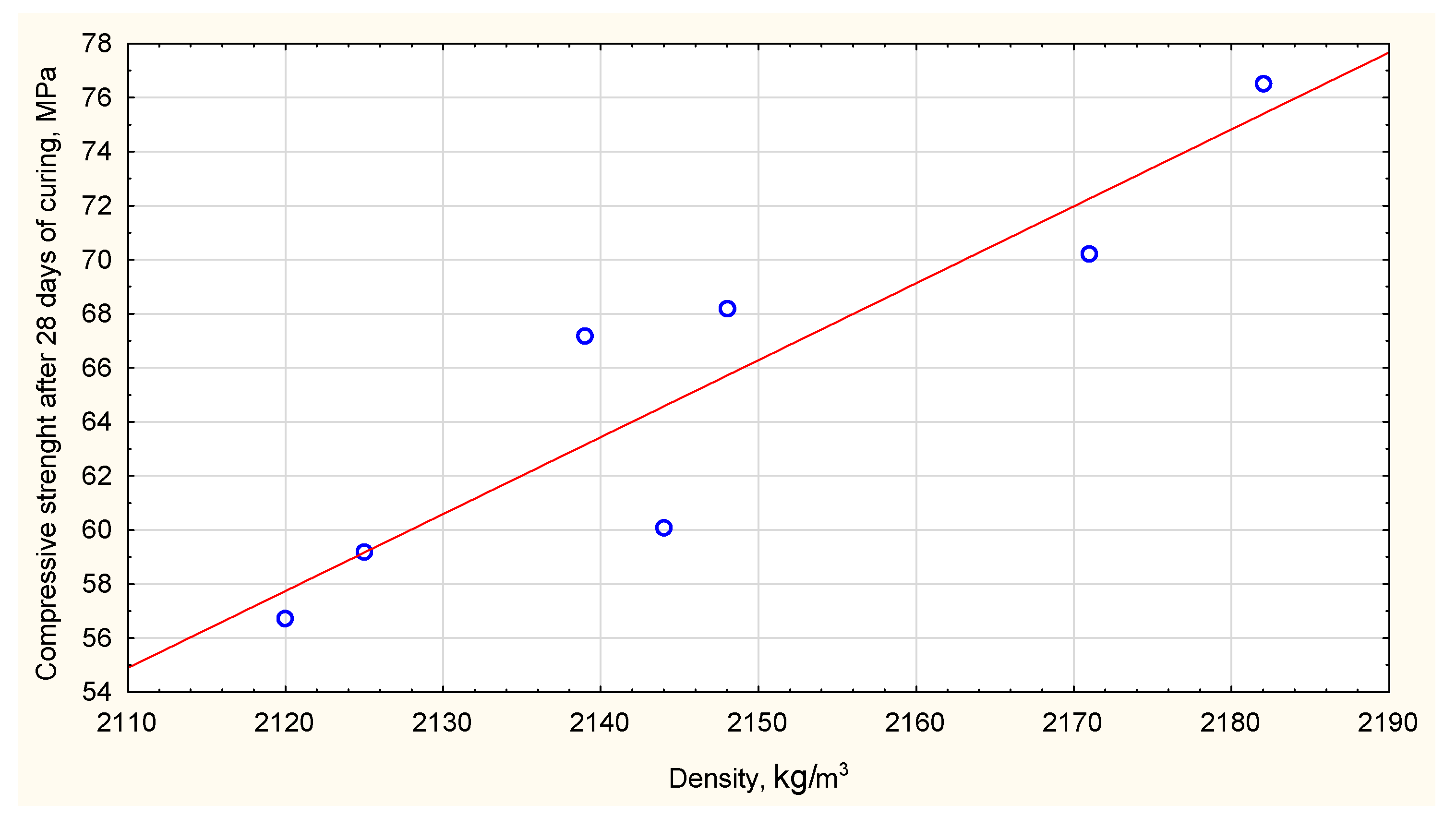

The analysis of test results with the software (Statistica) produced a linear regression equation, which describes the relationship between the density and compressive strength of concrete after 28 days of curing. The relationship between the strength and density after 28 days of curing is presented in Figure 1. The coefficient of determination is 0.835; it means that 83% of the change in compressive strength is affected by density. The coefficient of correlation r = 0.914 indicates a high correlation between the compressive strength and density after 28 days of curing. The regression in this case is positive. It was found that the compressive strength of concrete increased with the increase of density.

Figure 1.

Relationship between compressive strength and density.

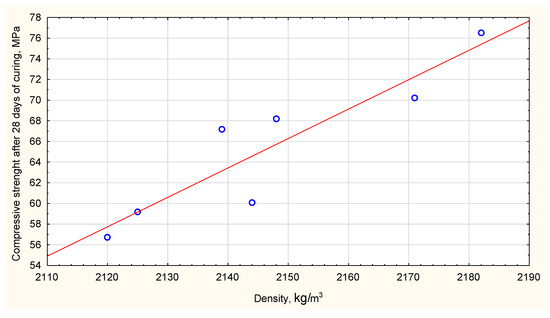

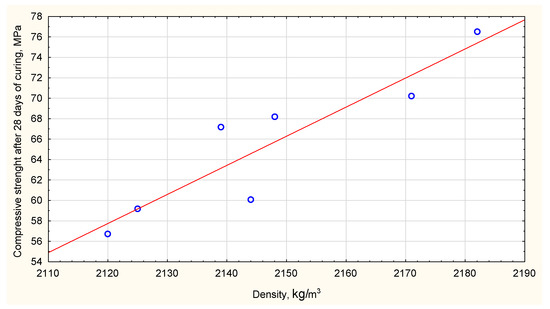

The highest flexural strength at 28 days was recorded in specimens containing 5 % of waste glass powder. The strength value was 76.5 MPa. The lowest flexural strength value of 4.6 MPa was found in mortar specimens where 30% cement was replaced by waste glass powder. After the statistical processing of the results, a linear regression equation describing the relationship between the density and flexural strength of the mortar was obtained. This relationship between the flexural strength and the density of the mortar is illustrated in Figure 2. The coefficient of determination is 0.853; meaning that 85% of the change in the flexural strength is affected by the density. The coefficient of correlation r = 0.923 indicates a high correlation between the flexural strength and the density. A positive regression was obtained. The flexural strength of the mortar was found to increase with the increasing density of the mortar.

Figure 2.

Relationship between flexural strength and density.

4. Conclusions

- 1.

- The obtained linear regression equations illustrate the relationships between the density and compressive strength, and between the density and flexural strength at 28 days. These relationships were expressed by linear regression equations with a correlation coefficient r > 0.914.

- 2.

- The test results revealed that waste glass powder can be used in small amounts of cement-based mortars to reduce the amount of cement and to utilize waste glass. A higher performance, modified cement-based mortar can be produced for civil engineering applications by replacing 5 % with waste glass powder.

Author Contributions

Conceptualization, D.N. and K.B.; methodology, D.N. and K.B.; formal analysis, D.N. and K.B.; investigation, D.N. and K.B.; resources, D.N. and K.B.; writing—original draft preparation, D.N. and K.B.; writing—review and editing, D.N. and K.B.; visualization, K.B.; supervision, D.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abhay, S.; Shashivendra, D. Mechanical performance of lean mortar mixes comprising glass powder as cement replacement. Compliance Eng. J. 2019, 10. Available online: https://www.researchgate.net/publication/343083546 (accessed on 13 March 2021).

- Aliabdo, A.A.; Elmoaty, M.A.; Elmoaty, A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Madandoust, R.; Ghavidel, R. Mechanical properties of concrete containing waste glass powder and rice husk ash. Biosyst. Eng. 2013, 116, 113–119. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zeng, H.; Wu, J.Y. A study on the macro and micro properties of concrete with LCD glass. Constr. Build. Mater. 2014, 50, 664–670. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical behaviour of ground waste glass when used as partial cement replacement in mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolinia, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Compos. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Calmona, J.L.; Sauera, A.S.; Vieiraa, G.L.; Teixeira, J.E.S.L. Effects of windshield waste glass on the properties of structural repair mortars. Cem. Concr. Compos 2014, 53, 88–96. [Google Scholar] [CrossRef]

- Madandousta, R.; Ranjbara, M.M.; Moghadamb, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Cassar, J.; Camilleri, J. Utilisation of imploded glass in structural concrete. Constr. Build. Mater. 2012, 29, 299–307. [Google Scholar] [CrossRef]

- Sadiqul Islam, G.M.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Tamanna, N.; Tuladhar, R. Sustainable Use of Recycled Glass Powder as Cement Replacement in Concrete. Open Waste Manag. J. 2020, 13, 1–13. Available online: https://openwastemanagementjournal.com/VOLUME/13/PAGE/1/ (accessed on 13 March 2021). [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).