Abstract

The main challenge in the field of water distribution systems (WDS) is (re)designing the network in order to achieve savings. In many water systems, there are pumping stations designed for much larger flows than what would be observed under normal operating conditions. On the other hand, reducing the diameter of the water pipes has become the main saving method. Designers very often forget to design the network so that it can be used for fire protection purposes. The computer modelling of water networks supports the decision-making process by identifying the optimal compromise between cost and performance (e.g., flow, velocity, pressure). Computer models help in the selection of optimal values of hydraulic pumps, preparation of the pump control method and selection of energy-optimized pumping systems, ensuring the efficiency and pressure of the WDS during normal operation and in fire conditions. The article presents the results of optimization of the pump station in terms of efficiency and pressure in the system, and optimization of pump energy consumption. Computer simulations of the water supply system, measurements of pressure and flow, hydrant flow tests, and model calibration were used in the research.

1. Introduction

Rising electricity prices force us to look for savings in every possible area. One of the ways is to use renewable energy sources, but what if we do not want to design such solutions [1]? One of the options is to optimize the operation of the pumping station. The optimization of the pumping station is multidimensional because it allows you to generate savings in electricity consumption, reduce the occurrence of failures, limit water outflow through network leaks, and secure the water supply to consumers [2,3,4]. The research described in the article consisted of making a model of the existing water supply system, carrying out measurements and tests to obtain data for calibrating a computer model, calibrating the model, simulating variants of changes in the network operation, and selecting devices, calculating the electricity consumption in a given variant, and comparing and results analysing the results.

2. Material and Methods

The field tests included pressure measurements and hydrant performance tests.

Mobile pressure recorders with a measuring range of 0–20 bar and an accuracy of 0.1 FS were used to measure the pressure. Above-ground and underground hydrants of the existing distribution system were used as measuring points.

The HYDRO-TEST measuring device was used to test the hydrant pressure efficiency. This device is characterized by the possibility of measuring the static pressure before the measurement and the dynamic pressure after opening of the hydrant. Specially designed measuring nozzles allow determination of the intensity of the outflow from the hydrant at the measured dynamic pressure [5,6].

Water distribution system operation simulations were made using EPANET software. The program is characterized by the possibility of simulating any size of a water supply system, manual calibration of the properties of the water supply system, and the possibility of calculating energy consumption by pumps [7]. It is important that the calibrated model meets the appropriate level of accuracy between the simulation results and the test data [8].

3. Results and Discussion

Based on the data from the water supply company, a computer model for simulating the operation of the water supply network (theoretical model) was created. The theoretical model was calibrated. As a result of calibrating the theoretical model, the following accuracy was obtained:

- +/−5.0% at pressure measurement points;

- +/−2.5 m H2O for hydrant tests.

The obtained accuracy of the model allows evaluation of the model as good. The calibration process and the obtained compliance of the simulated values with the actual measurement results allow the model to be used for conceptual work and optimization of the water system operation.

The results of the field measurements and the simulation of the system operation revealed problems in one of the sectors of the water supply network. Hydrant performance tests showed that, in sector No. 1, pressure is not reached at the critical point.

Several variants of the pumping station(water supply system operation were simulated based on changes in operating parameters):

- Connecting the sectors with a new pipe;

- Reduction in the outlet pressure from the pump station;

- Increasing the outlet pressure from the pump station;

- Adding an additional pump to the pump station.

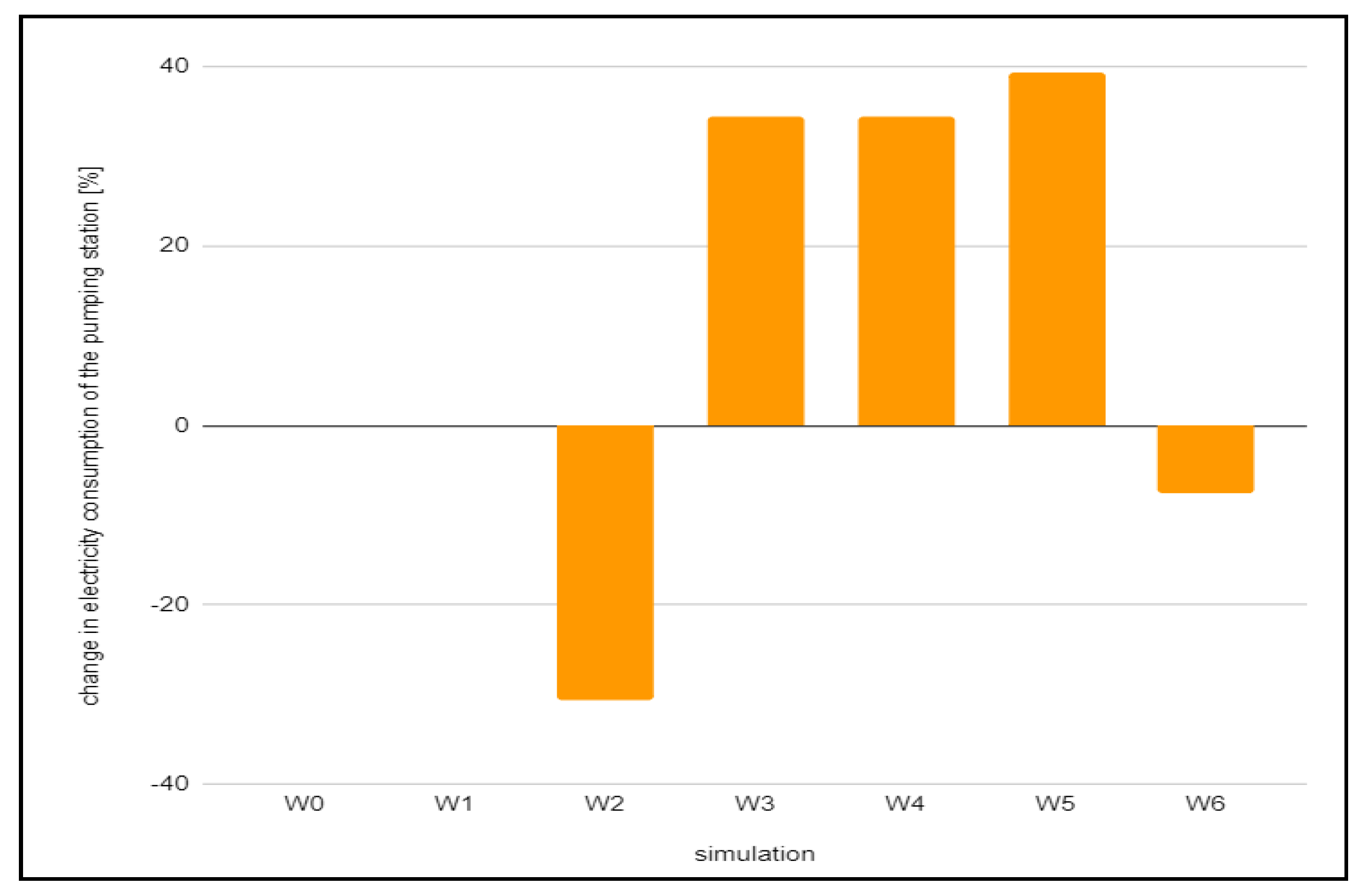

The changes in electricity consumption in the simulation variants are shown in Figure 1. The lowest electricity consumption for pumping station works occurred in variant W2, in which the sectors of the system were connected. This allowed reduce in the pressure by 5 mH2O. The decrease in electricity consumption to the base variant of the simulation was over 34%. The greatest increase in electricity consumption for pumping station works occurred in variant W5. In variant W5, the pressure at the outlet of the pumping station was increased by 5 m H2O. Leaving the pumping system in its basic configuration and connecting the zones did not reduce the electricity consumed by the pumping station.

Figure 1.

Percentage changes in electricity consumption in the pumping station in the analyzed variants of the water supply system operation.

4. Conclusions

Computer hydraulic models subjected to the calibration process are a very good tool for simulating the operation of the water supply network. Obtaining high accuracy of calibration of the theoretical model allows assessment with high probability of the effects of the proposed changes before their introduction to the implementation process.

The aim of the research and optimization of the pumping station’s operation was to find the optimal solution for the operation of the pumping station and to reduce the electricity consumption of the pumping station. As a result of the conducted research, it was found that:

- The value of the outlet pressure from the pumping stations had the greatest impact on the electricity consumption of the pumping station;

- The connection of the network sectors did not change the electricity consumption in the pumping station;

- Adding an additional pump resulted in an increase in electricity consumption by the pump set;

- Connecting the sectors with a new pipe allowed reduction in the pressure at the outlet of the pumping station.

The best solution in this case is to connect the sectors of the water supply network with a new conduit, which will reduce the pressure at the outlet of the pumping station and reduce electricity consumption.

Author Contributions

M.Ś., I.B. and J.G.-M. contributed to the design and implementation of the research, to the analysis of the results and to the writing of the manuscript. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Naval, N.; Yusta, J.M. Water-Energy Management for Demand Charges and Energy Cost Optimization of a Pumping Stations System under a Renewable Virtual Power Plant Model. Energies 2020, 13, 2900. [Google Scholar] [CrossRef]

- Cimorelli, L.; Covelli, C.; Molino, B.; Pianese, D. Optimal Regulation of Pumping Station in Water Distribution Networks Using Constant and Variable Speed Pumps: A Technical and Economical Comparison. Energies 2020, 13, 2530. [Google Scholar] [CrossRef]

- Luna, T.; Ribau, J.; Figueiredo, D.; Alves, R. Improving energy efficiency in water supply systems with pump scheduling optimization. J. Clean. Prod. 2019, 213, 342–356. [Google Scholar] [CrossRef]

- Świętochowski, K. Modelling of pressure management in reducing water losses. Technol. Wody 2020, 2, 8–13. [Google Scholar]

- Biatech Ltd. Hydro-Test: Users Manual; Biatech Ltd.: Zaścianki, Poland, 2020. [Google Scholar]

- Świętochowski, K. The impact of testing fire hydrants on water loss. Instal 2018, 11, 41–43. [Google Scholar]

- Rossman, L.A. EPANET 2: Users Manual; U.S. Environmental Protection Agency: Cincinnati, OH, USA, 2000.

- Walski, T.M.; Chase, D.V.; Savic, D.A.; Grayman, W.; Beckwith, S.; Koelle, E. Advanced Water Distribution Modelling and Management; Haestad Press: Waterbury, CT, USA, 2003. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).