Toward Circular Economy: Potentials of Spent Coffee Grounds in Bioproducts and Chemical Production

Abstract

1. Introduction

Composition and Characteristics of SCG

2. Creation of Value-Added Products from Spent Coffee Grounds

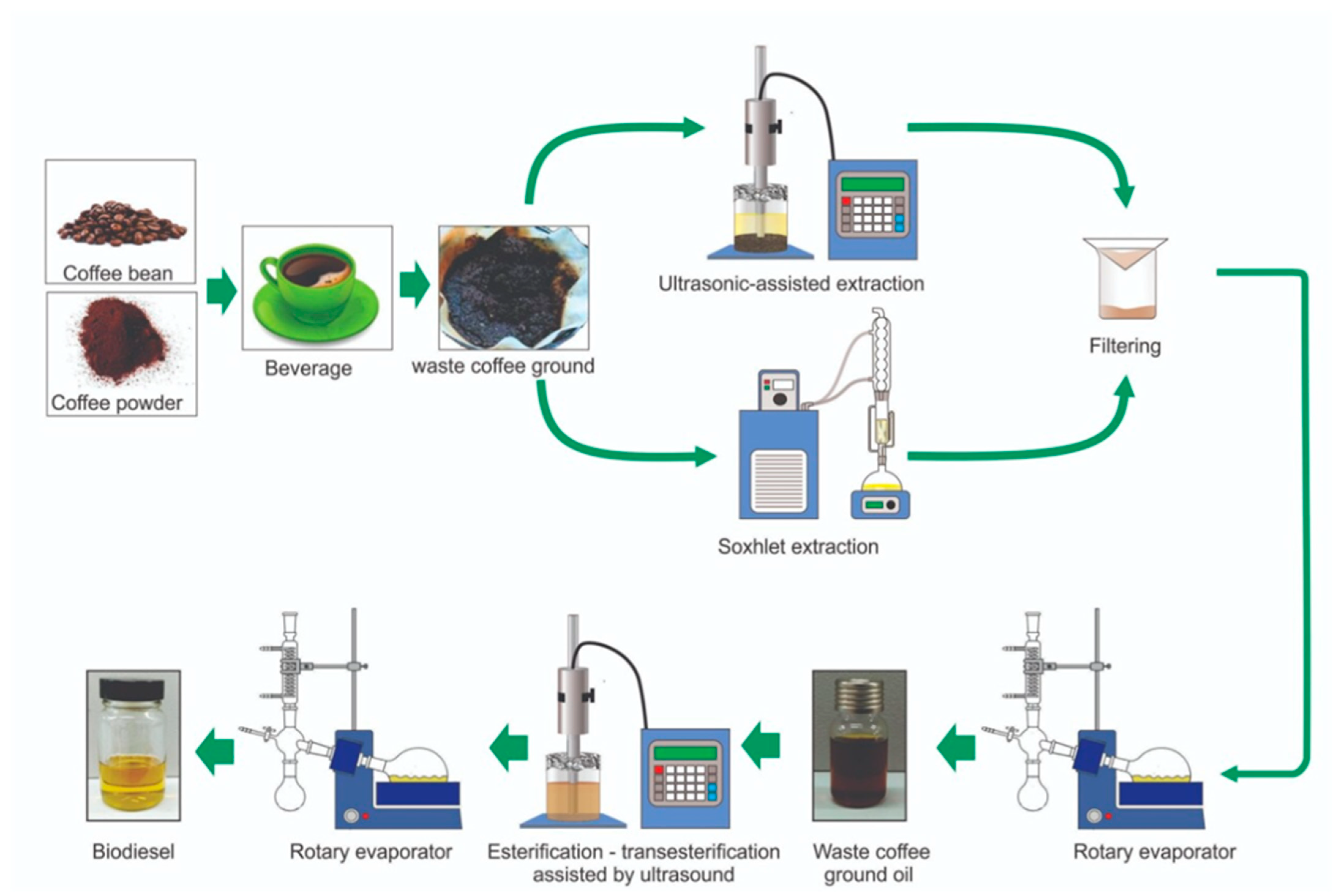

2.1. Biodiesel Production from Spent Coffee Grounds

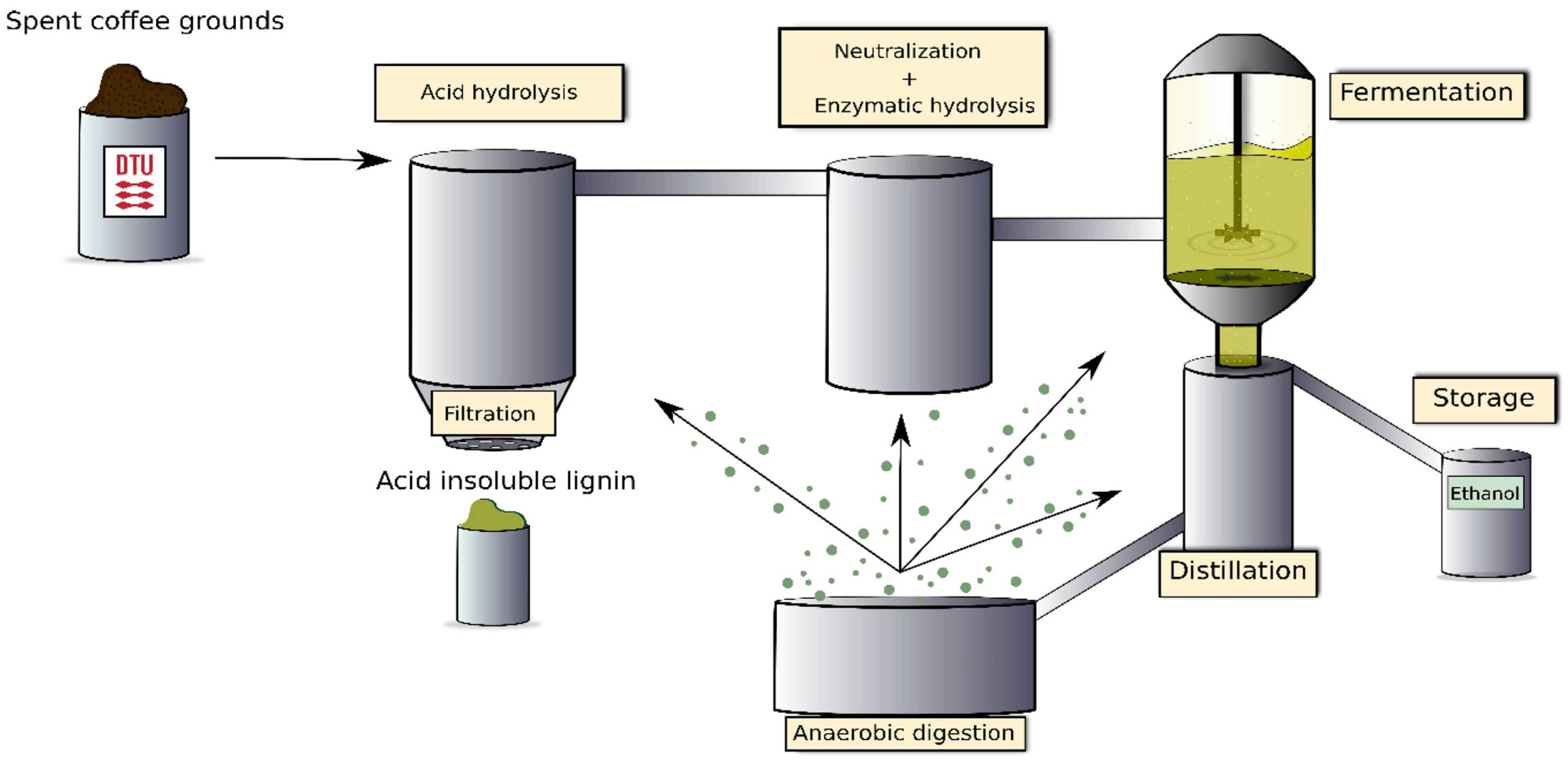

2.2. Bioethanol Production from Spent Coffee Grounds

2.3. Production of Biopolymers and Biocomposites from Spent Coffee Grounds

2.4. Extraction of Phenolic Compounds from Spent Coffee Grounds

2.5. SCG Is a Source of Biochar and Activated Carbon

2.6. Other Applications of Spent Coffee Grounds

2.6.1. Soil Amendment and Agriculture

2.6.2. Carbon Sequestration

2.6.3. Energy Production

2.6.4. Biodiversity and Ecosystem Impacts

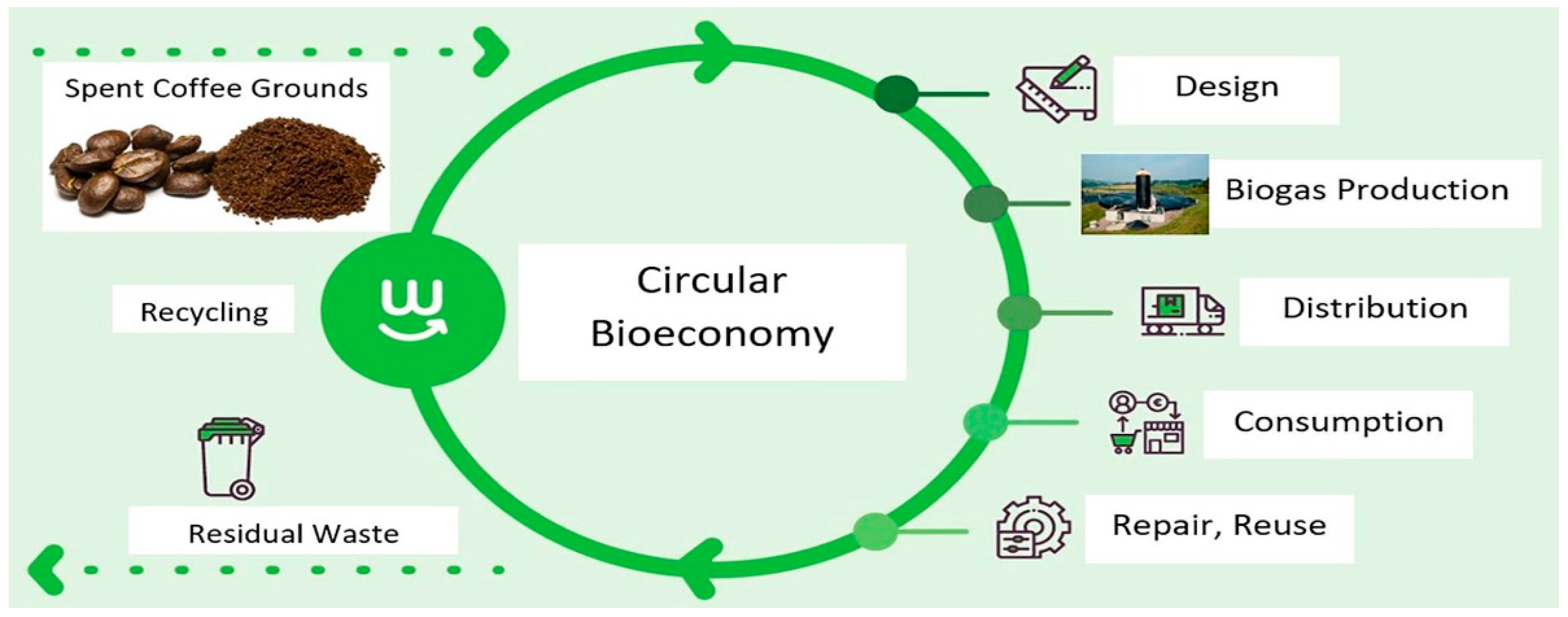

3. Role of the Valorisation of Spent Coffee Grounds in the Circular Economy

3.1. Economic and Social Implications

3.2. Challenges and Future Perspectives

| Institute/Organisation/Company/Body | Findings | City/Country | References |

|---|---|---|---|

| Imbibe—Coffee Roasters |

| Ireland | [175] |

| Coffee 4 Planet Ark—The Council of the City of Sydney |

| Syndey, Australia | [176] |

| ANDRITZ |

| Operating in: Austria, Brazil, Canada, China, Finland, Germany, United States.

| [169] |

| Bio-Bean Ltd., Nafigate, and WaysTUP! |

|

| [177,178,179] |

| Agricultores De La Vega Valencia and WaysTUP! Project |

| Valencia, Spain. | [180,181] |

| Coffeefrom |

| Italy | [182] |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Johnson, K.; Liu, Y.; Lu, M. A Review of Recent Advances in Spent Coffee Grounds Upcycle Technologies and Practices. Front. Chem. Eng. 2022, 4, 2. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, Composition, and Application of Coffee and Its Industrial Residues. Food Bioprocess Technol. 2011, 4, 661–672. [Google Scholar] [CrossRef]

- Kondamudi, N.; Mohapatra, S.K.; Misra, M. Spent Coffee Grounds as a Versatile Source of Green Energy. J. Agric. Food Chem. 2008, 56, 11757–11760. [Google Scholar] [CrossRef]

- Taifouris, M.; Corazza, M.L.; Martín, M. Integrated Design of Biorefineries Based on Spent Coffee Grounds. Ind. Eng. Chem. Res. 2021, 60, 494–506. [Google Scholar] [CrossRef]

- Johnson, K.; Karmee, S.K. A Spent Coffee Grounds Based Biorefinery for the Production of Biofuels, Biopolymers, Antioxidants and Biocomposites. Waste Manag. 2018, 72, 240–254. [Google Scholar] [CrossRef]

- Dattatraya Saratale, G.; Bhosale, R.; Shobana, S.; Banu, J.R.; Pugazhendhi, A.; Mahmoud, E.; Sirohi, R.; Kant Bhatia, S.; Atabani, A.E.; Mulone, V.; et al. A Review on Valorization of Spent Coffee Grounds (SCG) towards Biopolymers and Biocatalysts Production. Bioresour. Technol. 2020, 314, 123800. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, L.M.; Machado, S.; Segundo, M.A.; Lopes, J.A.; Páscoa, R.N.M.J. Rapid Assessment of Bioactive Phenolics and Methylxanthines in Spent Coffee Grounds by FT-NIR Spectroscopy. Talanta 2016, 147, 460–467. [Google Scholar] [CrossRef] [PubMed]

- Vitale, E.; Motta, C.M.; Avallone, B.; Amoresano, A.; Fontanarosa, C.; Battaglia, G.; Spinelli, M.; Fogliano, C.; Paradiso, R.; Arena, C. Sustainable Reuse of Expresso Coffee By-Products as a Natural Fertilizer to Improve Growth and Photosynthesis in Cucumber (Cucumis Sativus L.) Plants. Waste Biomass Valorization 2024, 15, 543–559. [Google Scholar] [CrossRef]

- Padma Ishwarya, S.; Nisha, P. Foaming Agents from Spent Coffee Grounds: A Mechanistic Understanding of the Modes of Foaming and the Role of Coffee Oil as Antifoam. Food Hydrocoll. 2021, 112, 106354. [Google Scholar] [CrossRef]

- Alonazi, M.; Al-Diahan, S.K.; Alzahrani, Z.R.A.; Ben Bacha, A. Combined Immobilized Lipases for Effective Biodiesel Production from Spent Coffee Grounds. Saudi J. Biol. Sci. 2023, 30, 103772. [Google Scholar] [CrossRef]

- Bhaskar, T.; Pandey, A.; Mohan, S.V.; Lee, D.J.; Khanal, S.K. Waste Biorefinery: Potential and Perspectives. In Waste Biorefinery: Potential and Perspectives; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–870. [Google Scholar] [CrossRef]

- Rajesh Banu, J.; Kavitha, S.; Yukesh Kannah, R.; Dinesh Kumar, M.; Preethi; Atabani, A.E.; Kumar, G. Biorefinery of Spent Coffee Grounds Waste: Viable Pathway towards Circular Bioeconomy. Bioresour. Technol. 2020, 302, 122821. [Google Scholar] [CrossRef] [PubMed]

- Bomfim, A.S.C.D.; Colantoni, A.; Paris, E.; Bianchini, L.; Ferri, S.; Marcantonio, V.; Carnevale, M.; Palma, A.; Civitarese, V.; Gallucci, F. Spent Coffee Ground Characterization, Pelletization Test and Emissions Assessment in the Combustion Process. Sci. Rep. 2021, 11, 5119. [Google Scholar] [CrossRef]

- Tapangnoi, P.; Obruca, S.; Benesova, P.; Kucera, D.; Petrik, S.; Marova, I. Biotechnological Conversion of Spent Coffee Grounds into Polyhydroxyalkanoates and Carotenoids. New Biotechnol. 2015, 32, 569–574. [Google Scholar] [CrossRef]

- Pujol, D.; Sharma, H.; Sharma, H. A Detail Chemistry of Coffee and Its Analysis. In Coffee-Production and Research; IntechOpen: London, UK, 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; de Melo Pereira, G.V.; de Carvalho Neto, D.P.; Magalhães Júnior, A.I.; do Prado, F.G.; Pagnoncelli, M.G.B.; Karp, S.G.; Soccol, C.R. Chemical Composition and Health Properties of Coffee and Coffee By-Products. Adv. Food Nutr. Res. 2020, 91, 65–96. [Google Scholar] [CrossRef]

- Singh, T.A.; Pal, N.; Sharma, P.; Passari, A.K. Spent Coffee Ground: Transformation from Environmental Burden into Valuable Bioactive Metabolites. Rev. Environ. Sci. Biotechnol. 2023, 22, 887–898. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Brekalo, M.; Rajs, B.B.; Aladić, K.; Jakobek, L.; Šereš, Z.; Krstović, S.; Jokić, S.; Budžaki, S.; Strelec, I. Multistep Extraction Transformation of Spent Coffee Grounds to the Cellulose-Based Enzyme Immobilization Carrier. Sustainability 2023, 15, 13142. [Google Scholar] [CrossRef]

- Muthukumar, G.; Mahadevan, A. Microbial Degradation of Lignin: Conversion, Application, and Challenges. J. Sci. Ind. Res. (India) 2022, 42, 195–219. [Google Scholar] [CrossRef]

- Afriliana, A.; Hidayat, E.; Yoshiharu, M.; Taizo, M.; Harada, H. Evaluation of Potency Spent Coffee Grounds for Make Black Compost. In Proceedings of the E3S Web of Conferences, Virtual, 23–24 November 2020; Volume 142, pp. 3–4. [Google Scholar] [CrossRef]

- Nhuchhen, D.R.; Basu, P.; Acharya, B. A comprehensive review on biomass torrefaction. Int. J. Renew. Energy Biofuels 2014, 2014, 506376. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Vergara-Castañeda, H.A.; Oomah, B.D. Spent Coffee Grounds: A Review on Current Research and Future Prospects. Trends Food Sci. Technol. 2015, 45, 24–36. [Google Scholar] [CrossRef]

- Behr, M.; El Jaziri, M.; Baucher, M. Glycobiology of the Plant Secondary Cell Wall Dynamics. Adv. Bot. Res. 2022, 104, 97–131. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Spent Grain: A Functional Ingredient for Food Applications. Foods 2023, 12, 1533. [Google Scholar] [CrossRef]

- Ramos-Andrés, M.; Andrés-Iglesias, C.; García-Serna, J. Production of Molecular Weight Fractionated Hemicelluloses Hydrolyzates from Spent Coffee Grounds Combining Hydrothermal Extraction and a Multistep Ultrafiltration/Diafiltration. Bioresour. Technol. 2019, 292, 121940. [Google Scholar] [CrossRef]

- Caetano, N.S.; Silva, V.F.; Mata, T.M. Valorization of Coffee Grounds for Biodiesel Production. Chem. Eng. Trans. 2012, 26, 1–6. [Google Scholar] [CrossRef]

- Mota, D.A.; Santos, J.C.B.; Faria, D.; Lima, Á.S.; Krause, L.C.; Soares, C.M.F.; Ferreira-Dias, S. Synthesis of Dietetic Structured Lipids from Spent Coffee Grounds Crude Oil Catalyzed by Commercial Immobilized Lipases and Immobilized Rhizopus oryzae Lipase on Biochar and Hybrid Support. Processes 2020, 8, 1542. [Google Scholar] [CrossRef]

- Ahmed, S.; Shah, P.; Ahmed, O. Biochemistry, Lipids. In StatPearls; StatPearls Publishing: Treasure Island, FL, USA, 2023. [Google Scholar]

- Figueroa Campos, G.A.; Kruizenga, J.G.K.T.; Sagu, S.T.; Schwarz, S.; Homann, T.; Taubert, A.; Rawel, H.M. Effect of the Post-Harvest Processing on Protein Modification in Green Coffee Beans by Phenolic Compounds. Foods 2022, 11, 159. [Google Scholar] [CrossRef] [PubMed]

- Arya, S.S.; Venkatram, R.; More, P.R.; Vijayan, P. The Wastes of Coffee Bean Processing for Utilization in Food: A Review. J. Food Sci. Technol. 2022, 59, 429–444. [Google Scholar] [CrossRef] [PubMed]

- Samsalee, N.; Sothornvit, R. Physicochemical, Functional Properties and Antioxidant Activity of Protein Extract from Spent Coffee Grounds Using Ultrasonic-Assisted Extraction. AIMS Agric. Food 2021, 6, 864–878. [Google Scholar] [CrossRef]

- Bhattarai, R.R.; Al-Ali, H.; Johnson, S.K. Extraction, Isolation and Nutritional Quality of Coffee Protein. Foods 2022, 11, 3244. [Google Scholar] [CrossRef] [PubMed]

- Moccand, C.; Manchala, A.D.; Sauvageat, J.L.; Lima, A.; FleuryRey, Y.; Glabasnia, A. Improvement of Robusta Coffee Aroma by Modulating Flavor Precursors in the Green Coffee Bean with Enzymatically Treated Spent Coffee Grounds: A Circular Approach. Food Res. Int. 2023, 170, 112987. [Google Scholar] [CrossRef]

- Fischer, H.; Romano, N.; Sinha, A.K. Conversion of Spent Coffee and Donuts by Black Soldier Fly (Hermetia illucens) Larvae into Potential Resources for Animal and Plant Farming. Insects 2021, 12, 332. [Google Scholar] [CrossRef] [PubMed]

- Sousa, C.; Gabriel, C.; Cerqueira, F.; Conceição Manso, M.; Vinha, A.F. Coffee Industrial Waste as a Natural Source of Bioactive Compounds with Antibacterial and Antifungal Activities. The Battle Against Microbial Pathogens: Basic Science, Technological Advances and Educational Programs, Formatex Research Center: Badajoz, Spain, 2015; Volume 1, 131–136. [Google Scholar]

- Hwang, H.S.; Winkler-Moser, J.K.; Kim, Y.; Liu, S.X. Antioxidant Activity of Spent Coffee Ground Extracts Toward Soybean Oil and Fish Oil. Eur. J. Lipid Sci. Technol. 2019, 121, 1800372. [Google Scholar] [CrossRef]

- Daniel, T. Use of Spent Coffee Ground (Scg) as Ingredient in Bread Formulation. Agri. Food Sci. 2018, 1, 17–19. [Google Scholar]

- Pujol, D.; Liu, C.; Gominho, J.; Olivella, M.À.; Fiol, N.; Villaescusa, I.; Pereira, H. The Chemical Composition of Exhausted Coffee Waste. Ind. Crops Prod. 2013, 50, 423–429. [Google Scholar] [CrossRef]

- Prihadi, A.R.; Maimulyanti, A. Chemical Compounds of Coffee Ground and Spent Coffee Ground for Pharmaceutical Products. Pharm. Biomed. Sci. J. (PBSJ) 2021, 2, 49–52. [Google Scholar] [CrossRef]

- Van Nguyen, D.; Duong, C.T.T.; Vu, C.N.M.; Nguyen, H.M.; Pham, T.T.; Tran-Thuy, T.-M.; Nguyen, L.Q. Data on Chemical Composition of Coffee Husks and Lignin Microparticles as Their Extracted Product. Data Brief 2023, 51, 109781. [Google Scholar] [CrossRef] [PubMed]

- Machado, M.; Espírito Santo, L.; Machado, S.; Lobo, J.C.; Costa, A.S.G.; Oliveira, M.B.P.P.; Ferreira, H.; Alves, R.C. Bioactive Potential and Chemical Composition of Coffee By-Products: From Pulp to Silverskin. Foods 2023, 12, 2354. [Google Scholar] [CrossRef] [PubMed]

- Nolasco, A.; Squillante, J.; Velotto, S.; D’Auria, G.; Ferranti, P.; Mamone, G.; Errico, M.E.; Avolio, R.; Castaldo, R.; Cirillo, T.; et al. Valorization of Coffee Industry Wastes: Comprehensive Physicochemical Characterization of Coffee Silverskin and Multipurpose Recycling Applications. J. Clean. Prod. 2022, 370, 133520. [Google Scholar] [CrossRef]

- Kanauchi, O.; Mitsuyama, K.; Araki, Y. Development of a Functional Germinated Barley Foodstuff from Brewer’s Spent Grain for the Treatment of Ulcerative Colitis. J. Am. Soc. Brew. Chem. 2001, 59, 59–62. [Google Scholar] [CrossRef]

- Neylon, E.; Arendt, E.K.; Zannini, E.; Sahin, A.W. Fundamental Study of the Application of Brewers Spent Grain and Fermented Brewers Spent Grain on the Quality of Pasta. Food Struct. 2021, 30, 100225. [Google Scholar] [CrossRef]

- Mensah, M.B.; Jumpah, H.; Boadi, N.O.; Awudza, J.A.M. Assessment of Quantities and Composition of Corn Stover in Ghana and Their Conversion into Bioethanol. Sci. Afr. 2021, 12, e00731. [Google Scholar] [CrossRef]

- Rainey, T.J. A Study into the Permeability and Compressibility of Australian Bagasse Pulp. Doctoral Dissertation, Queensland University of Technology, Brisbane, QDL, Australia, 2009. [Google Scholar]

- Da Silva, A.S.A.; Inoue, H.; Endo, T.; Yano, S.; Bon, E.P.S. Milling Pretreatment of Sugarcane Bagasse and Straw for Enzymatic Hydrolysis and Ethanol Fermentation. Bioresour. Technol. 2010, 101, 7402–7409. [Google Scholar] [CrossRef]

- Jackson de Moraes Rocha, G.; Martin, C.; Soares, I.B.; Souto Maior, A.M.; Baudel, H.M.; Moraes de Abreu, C.A. Dilute Mixed-Acid Pretreatment of Sugarcane Bagasse for Ethanol Production. Biomass Bioenergy 2011, 35, 663–670. [Google Scholar] [CrossRef]

- Rabelo, S.C.; Carrere, H.; Maciel Filho, R.; Costa, A.C. Production of Bioethanol, Methane and Heat from Sugarcane Bagasse in a Biorefinery Concept. Bioresour. Technol. 2011, 102, 7887–7895. [Google Scholar] [CrossRef]

- Canilha, L.; Chandel, A.K.; Suzane Dos Santos Milessi, T.; Antunes, F.A.F.; Luiz Da Costa Freitas, W.; Das Graças Almeida Felipe, M.; Da Silva, S.S. Bioconversion of Sugarcane Biomass into Ethanol: An Overview about Composition, Pretreatment Methods, Detoxification of Hydrolysates, Enzymatic Saccharification, and Ethanol Fermentation. J. Biomed. Biotechnol. 2012, 2012, 989572. [Google Scholar] [CrossRef]

- Chandel, A.K.; Antunes, F.A.F.; Anjos, V.; Bell, M.J.V.; Rodrigues, L.N.; Polikarpov, I.; De Azevedo, E.R.; Bernardinelli, O.D.; Rosa, C.A.; Pagnocca, F.C.; et al. Multi-Scale Structural and Chemical Analysis of Sugarcane Bagasse in the Process of Sequential Acid-Base Pretreatment and Ethanol Production by Scheffersomyces shehatae and Saccharomyces cerevisiae. Biotechnol. Biofuels 2014, 7, 63. [Google Scholar] [CrossRef] [PubMed]

- Ugheoke, B.; Mamat, O. A Critical Assessment and New Research Directions of Rice Husk Silica Processing Methods and Properties. Maejo Int. J. Sci. Technol. 2012, 6, 430–448. [Google Scholar]

- Gao, Y.; Guo, X.; Liu, Y.; Fang, Z.; Zhang, M.; Zhang, R.; You, L.; Li, T.; Liu, R.H. A Full Utilization of Rice Husk to Evaluate Phytochemical Bioactivities and Prepare Cellulose Nanocrystals. Sci. Rep. 2018, 8, 10482. [Google Scholar] [CrossRef]

- Shoaib, A.M.; El-Adly, R.A.; Hassanean, M.H.M.; Youssry, A.; Bhran, A.A. Developing a Free-Fall Reactor for Rice Straw Fast Pyrolysis to Produce Bio-Products. Egypt. J. Pet. 2018, 27, 1305–1311. [Google Scholar] [CrossRef]

- Sareena, C.; Sreejith, M.P.; Ramesan, M.T.; Purushothaman, E. Biodegradation Behaviour of Natural Rubber Composites Reinforced with Natural Resource Fillers—Monitoring by Soil Burial Test. J. Reinf. Plast. Compos. 2013, 33, 412–429. [Google Scholar] [CrossRef]

- Tozluoğlu, A.; Özyürek, Ö.; Çöpür, Y.; Özdemir, H. Integrated Production of Biofilm, Bioethanol, and Papermaking Pulp from Wheat Straw. Bioresources 2015, 10, 7834–7853. [Google Scholar] [CrossRef]

- Rebollo-Hernanz, M.; Aguilera, Y.; Gil-Ramírez, A.; Benítez, V.; Cañas, S.; Braojos, C.; Martin-Cabrejas, M.A. Biorefinery and Stepwise Strategies for Valorizing Coffee By-Products as Bioactive Food Ingredients and Nutraceuticals. Appl. Sci. 2023, 13, 8326. [Google Scholar] [CrossRef]

- Schwarz, S.; Peluso, M. Coffee By-Products: Economic Opportunities for Sustainability and Innovation in the Coffee Industry. Proceedings 2023, 89, 6. [Google Scholar] [CrossRef]

- Preethi; Gunasekaran, M.; Kumar, G.; Karthikeyan, O.P.; Varjani, S.; Rajesh Banu, J. Lignocellulosic Biomass as an Optimistic Feedstock for the Production of Biofuels as Valuable Energy Source: Techno-Economic Analysis, Environmental Impact Analysis, Breakthrough and Perspectives. Environ. Technol. Innov. 2021, 24, 102080. [Google Scholar] [CrossRef]

- Franca, A.S.; Oliveira, L.S. Potential Uses of Spent Coffee Grounds in the Food Industry. Foods 2022, 11, 2064. [Google Scholar] [CrossRef]

- Lee, Y.G.; Cho, E.J.; Maskey, S.; Nguyen, D.T.; Bae, H.J. Value-Added Products from Coffee Waste: A Review. Molecules 2023, 28, 3562. [Google Scholar] [CrossRef]

- Go, A.W.; Pham, T.Y.N.; Ju, Y.H.; Agapay, R.C.; Angkawijaya, A.E.; Quijote, K.L. Extraction of Lipids from Post-Hydrolysis Spent Coffee Grounds for Biodiesel Production with Hexane as Solvent: Kinetic and Equilibrium Data. Biomass Bioenergy 2020, 140, 105704. [Google Scholar] [CrossRef]

- Yao, Y.; You, Q.; Duan, G.; Ren, J.; Chu, S.; Zhao, J.; Li, X.; Zhou, X.; Jiao, Y. Quantitative Trait Loci Analysis of Seed Oil Content and Composition of Wild and Cultivated Soybean. BMC Plant Biol. 2020, 20, 51. [Google Scholar] [CrossRef]

- Tuntiwiwattanapun, N.; Tongcumpou, C. Sequential Extraction and Reactive Extraction Processing of Spent Coffee Grounds: An Alternative Approach for Pretreatment of Biodiesel Feedstocks and Biodiesel Production. Ind. Crops Prod. 2018, 117, 359–365. [Google Scholar] [CrossRef]

- Uwineza, P.A.; Waśkiewicz, A. Recent Advances in Supercritical Fluid Extraction of Natural Bioactive Compounds from Natural Plant Materials. Molecules 2020, 25, 3847. [Google Scholar] [CrossRef] [PubMed]

- Coelho, J.P.; Filipe, R.M.; Paula Robalo, M.; Boyadzhieva, S.; Cholakov, G.S.; Stateva, R.P. Supercritical CO2 Extraction of Spent Coffee Grounds. Influence of Co-Solvents and Characterization of the Extracts. J. Supercrit. Fluids 2020, 161, 104825. [Google Scholar] [CrossRef]

- Mahato, N.; Sharma, K.; Sinha, M.; Dhyani, A.; Pathak, B.; Jang, H.; Park, S.; Pashikanti, S.; Cho, S. Biotransformation of Citrus Waste-I: Production of Biofuel and Valuable Compounds by Fermentation. Processes 2021, 9, 220. [Google Scholar] [CrossRef]

- Kasirajan, R. Biodiesel Production by Two Step Process from an Energy Source of Chrysophyllum Albidum Oil Using Homogeneous Catalyst. S. Afr. J. Chem. Eng. 2021, 37, 161–166. [Google Scholar] [CrossRef]

- Neumann, K.; Werth, K.; Martín, A.; Górak, A. Biodiesel Production from Waste Cooking Oils through Esterification: Catalyst Screening, Chemical Equilibrium and Reaction Kinetics. Chem. Eng. Res. Des. 2016, 107, 52–62. [Google Scholar] [CrossRef]

- Kim, J.Y.; Yeom, S.H. Optimization of Biodiesel Production from Waste Coffee Grounds by Simultaneous Lipid Extraction and Transesterification. Biotechnol. Bioprocess Eng. 2020, 25, 320–326. [Google Scholar] [CrossRef]

- Narwal, S.K.; Gupta, R. Biodiesel Production by Transesterification Using Immobilized Lipase. Biotechnol. Lett. 2013, 35, 479–490. [Google Scholar] [CrossRef]

- Hundie, K.B.; Akuma, D.A. Optimization of Biodiesel Production Parameters from Prosopisjuliferaseed Using Definitive Screening Design. Heliyon 2022, 8, e08965. [Google Scholar] [CrossRef]

- Olagunju, O.A.; Musonge, P.; Kiambi, S.L. Production and Optimization of Biodiesel in a Membrane Reactor, Using a Solid Base Catalyst. Membranes 2022, 12, 674. [Google Scholar] [CrossRef]

- Yang, F.; Hanna, M.A.; Sun, R. Value-Added Uses for Crude Glycerol—A Byproduct of Biodiesel Production. Biotechnol. Biofuels 2012, 5, 13. [Google Scholar] [CrossRef]

- Mabona, N.; Aboyade, W.; Mollagee, M.; Mguni, L.L. Effect of Moisture Content on Oil Extraction from Spent Coffee Grounds. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 501–509. [Google Scholar] [CrossRef]

- Gigliobianco, M.R.; Campisi, B.; Peregrina, D.V.; Censi, R.; Khamitova, G.; Angeloni, S.; Caprioli, G.; Zannotti, M.; Ferraro, S.; Giovannetti, R.; et al. Optimization of the Extraction from Spent Coffee Grounds Using the Desirability Approach. Antioxidants 2020, 9, 370. [Google Scholar] [CrossRef]

- Leal Vieira Cubas, A.; Medeiros Machado, M.; Tayane Bianchet, R.; Alexandra da Costa Hermann, K.; Alexsander Bork, J.; Angelo Debacher, N.; Flores Lins, E.; Maraschin, M.; Sousa Coelho, D.; Helena Siegel Moecke, E. Oil Extraction from Spent Coffee Grounds Assisted by Non-Thermal Plasma. Sep. Purif. Technol. 2020, 250, 117171. [Google Scholar] [CrossRef]

- Akula, S.; Sahu, A.K.; Dana Permana, A.; Esther Ramadhani Eka Putra, J.N.; Dianhar, H.; Khairunnisa, H. Effect of Pretreatment Spent Coffee Ground with Natural Deep Eutectic Solvent (NADES) on Coffee Oil Yield. J. Phys. Conf. Ser. 2022, 2309, 12002. [Google Scholar] [CrossRef]

- Atabani, A.E.; Al-Muhtaseb, A.H.; Kumar, G.; Saratale, G.D.; Aslam, M.; Khan, H.A.; Said, Z.; Mahmoud, E. Valorization of Spent Coffee Grounds into Biofuels and Value-Added Products: Pathway towards Integrated Bio-Refinery. Fuel 2019, 254, 115640. [Google Scholar] [CrossRef]

- Tuntiwiwattanapun, N.; Usapein, P.; Tongcumpou, C. The Energy Usage and Environmental Impact Assessment of Spent Coffee Grounds Biodiesel Production by an In-Situ Transesterification Process. Energy Sustain. Dev. 2017, 40, 50–58. [Google Scholar] [CrossRef]

- Mofijur, M.; Kusumo, F.; Rizwanul Fattah, I.M.; Mahmudul, H.M.; Rasul, M.G.; Shamsuddin, A.H.; Mahlia, T.M.I. Resource Recovery from Waste Coffee Grounds Using Ultrasonic-Assisted Technology for Bioenergy Production. Energies 2020, 13, 1770. [Google Scholar] [CrossRef]

- Burniol-Figols, A.; Cenian, K.; Skiadas, I.V.; Gavala, H.N. Integration of Chlorogenic Acid Recovery and Bioethanol Production from Spent Coffee Grounds. Biochem. Eng. J. 2016, 116, 54–64. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D.J. Lignocellulosic Biomass Pretreatment by Deep Eutectic Solvents on Lignin Extraction and Saccharification Enhancement: A Review. Bioresour. Technol. 2021, 339, 125587. [Google Scholar] [CrossRef] [PubMed]

- Solarte-Toro, J.C.; Romero-García, J.M.; Martínez-Patiño, J.C.; Ruiz-Ramos, E.; Castro-Galiano, E.; Cardona-Alzate, C.A. Acid Pretreatment of Lignocellulosic Biomass for Energy Vectors Production: A Review Focused on Operational Conditions and Techno-Economic Assessment for Bioethanol Production. Renew. Sustain. Energy Rev. 2019, 107, 587–601. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A Review on Alkaline Pretreatment Technology for Bioconversion of Lignocellulosic Biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Tzani, A.; Lymperopoulou, T.; Pitterou, I.; Karetta, I.; Belfquih, F.; Detsi, A. Development and Optimization of Green Extraction Process of Spent Coffee Grounds Using Natural Deep Eutectic Solvents. Sustain. Chem. Pharm. 2023, 34, 101144. [Google Scholar] [CrossRef]

- Chiyanzy, I.; Brienzo, M.; García-Aparicio, M.; Agudelo, R.; Görgens, J. Spent Coffee Ground Mass Solubilisation by Steam Explosion and Enzymatic Hydrolysis. J. Chem. Technol. Biotechnol. 2015, 90, 449–458. [Google Scholar] [CrossRef]

- Vasić, K.; Knez, Ž.; Leitgeb, M. Bioethanol Production by Enzymatic Hydrolysis from Different Lignocellulosic Sources. Molecules 2021, 26, 753. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, X.; Wang, W.; Yu, Q.; Qi, W.; Wang, Q.; Tan, X.; Zhou, G.; Yuan, Z. Liquid Hot Water Pretreatment of Lignocellulosic Biomass for Bioethanol Production Accompanying with High Valuable Products. Bioresour. Technol. 2016, 199, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Fahmy, M.; Sohel, M.I.; Vaidya, A.A.; Jack, M.W.; Suckling, I.D. Does Sugar Yield Drive Lignocellulosic Sugar Cost? Case Study for Enzymatic Hydrolysis of Softwood with Added Polyethylene Glycol. Process Biochem. 2019, 80, 103–111. [Google Scholar] [CrossRef]

- Sriariyanun, M.; Gundupalli, M.P.; Phakeenuya, V.; Phusamtisampan, T.; Cheng, Y.S.; Venkatachalam, P. Biorefinery Approaches for Production of Cellulosic Ethanol Fuel Using Recombinant Engineered Microorganisms. J. Appl. Sci. Eng. 2023, 27, 1985–2005. [Google Scholar] [CrossRef]

- Kovalcik, A.; Obruca, S.; Marova, I. Valorization of Spent Coffee Grounds: A Review. Food Bioprod. Process. 2018, 110, 104–119. [Google Scholar] [CrossRef]

- Hashem, M.; Alamri, S.A.; Asseri, T.A.Y.; Moustafa, Y.S.; Lyberatos, G.; Ntaikou, I. On the Optimization of Fermentation Conditions for Enhanced Bioethanol Yields from Starchy Biowaste via Yeast Co-Cultures. Sustainability 2021, 13, 1890. [Google Scholar] [CrossRef]

- Moremi, M.E.; Jansen Van Rensburg, E.L.; La Grange, D.C. The Improvement of Bioethanol Production by Pentose-Fermenting Yeasts Isolated from Herbal Preparations, the Gut of Dung Beetles, and Marula Wine. Int. J. Microbiol. 2020, 2020, 5670936. [Google Scholar] [CrossRef]

- Derman, E.; Abdulla, R.; Marbawi, H.; Sabullah, M.K.; Gansau, J.A.; Ravindra, P. Simultaneous Saccharification and Fermentation of Empty Fruit Bunches of Palm for Bioethanol Production Using a Microbial Consortium of S. cerevisiae and T. harzianum. Fermentation 2022, 8, 295. [Google Scholar] [CrossRef]

- Park, E.Y.; Naruse, K.; Kato, T. One-Pot Bioethanol Production from Cellulose by Co-Culture of Acremonium cellulolyticus and Saccharomyces cerevisiae. Biotechnol. Biofuels 2012, 5, 64. [Google Scholar] [CrossRef] [PubMed]

- Ire, F.S.; Ezebuiro, V.; Ogugbue, C.J. Production of Bioethanol by Bacterial Co-Culture from Agro-Waste-Impacted Soil through Simultaneous Saccharification and Co-Fermentation of Steam-Exploded Bagasse. Bioresour. Bioprocess 2016, 3, 26. [Google Scholar] [CrossRef]

- Kwon, E.E.; Yi, H.; Jeon, Y.J. Sequential Co-Production of Biodiesel and Bioethanol with Spent Coffee Grounds. Bioresour. Technol. 2013, 136, 475–480. [Google Scholar] [CrossRef] [PubMed]

- Pereira, J.; de Melo, M.M.R.; Silva, C.M.; Lemos, P.C.; Serafim, L.S. Impact of a Pretreatment Step on the Acidogenic Fermentation of Spent Coffee Grounds. Bioengineering 2022, 9, 362. [Google Scholar] [CrossRef] [PubMed]

- Kaae Kirk, N.; Navarrete, C.; Ellegaard Juhl, J.; Martínez, J.L.; Procentese, A. The “Zero Miles Product” Concept Applied to Biofuel Production: A Case Study. Energies 2021, 14, 565. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R. Spent Coffee Grounds as a Valuable Source of Phenolic Compounds and Bioenergy. J. Clean. Prod. 2012, 34, 49–56. [Google Scholar] [CrossRef]

- Chaari, R.; Khlif, M.; Mallek, H.; Bradai, C.; Lacoste, C.; Belguith, H.; Tounsi, H.; Dony, P. Enzymatic Treatments Effect on the Poly (Butylene Succinate)/Date Palm Fibers Properties for Bio-Composite Applications. Ind. Crops Prod. 2020, 148, 112270. [Google Scholar] [CrossRef]

- de Bomfim, A.S.C.; Challa, A.A.; Saha, N.; Szewczyk, P.K.; Karbowniczek, J.E.; Stachewicz, U.; Ngwabebhoh, F.A.; Saha, P. Graphene Oxide Produced from Spent Coffee Grounds in Electrospun Cellulose Acetate Scaffolds for Tissue Engineering Applications. Mater. Today Commun. 2023, 35, 105974. [Google Scholar] [CrossRef]

- Emenike, E.C.; Iwuozor, K.O.; Saliu, O.D.; Ramontja, J.; Adeniyi, A.G. Advances in the Extraction, Classification, Modification, Emerging and Advanced Applications of Crystalline Cellulose: A Review. Carbohydr. Polym. Technol. Appl. 2023, 6, 100337. [Google Scholar] [CrossRef]

- Jiang, Z.; To, N. Recent Advances in Chemically Modified Cellulose and Its Derivatives for Food Packaging Applications: A Review. Polymers 2022, 14, 1533. [Google Scholar] [CrossRef] [PubMed]

- Shojaeiarani, J.; Bajwa, D.S.; Chanda, S. Cellulose Nanocrystal Based Composites: A Review. Compos. Part C Open Access 2021, 5, 100164. [Google Scholar] [CrossRef]

- Kulkarni, V.S.; Shaw, C. Use of Polymers and Thickeners in Semisolid and Liquid Formulations. Essent. Chem. Formul. Semisolid Liq. Dos. 2016, 1, 43–69. [Google Scholar] [CrossRef]

- Fang, Y.; Jiang, Z.; Zhao, X.; Dong, J.; Li, X.; Zhang, Q. Spent Coffee Grounds/Poly(Butylene Succinate) Biocomposites with Robust Mechanical Property and Heat Resistance via Reactive Compatibilization. Compos. Commun. 2022, 29, 101003. [Google Scholar] [CrossRef]

- Gaidukova, G.; Platnieks, O.; Aunins, A.; Barkane, A.; Ingrao, C.; Gaidukovs, S. Spent Coffee Waste as a Renewable Source for the Production of Sustainable Poly(Butylene Succinate) Biocomposites from a Circular Economy Perspective. RSC Adv. 2021, 11, 18580–18589. [Google Scholar] [CrossRef] [PubMed]

- T, S.M.; Yorseng, K.; Rajini, N.; Siengchin, S.; Ayrilmis, N.; Rajulu, V. Mechanical and Thermal Properties of Spent Coffee Bean Filler/Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Biocomposites: Effect of Recycling. Process Saf. Environ. Prot. 2019, 124, 187–195. [Google Scholar] [CrossRef]

- Tuntiwiwattanapun, N.; Arias, A.; Ioannidou, S.M.; Giannakis, N.; Feijoo, G.; Moreira, M.T.; Koutinas, A. Review of Potential and Prospective Strategies for the Valorization of Coffee Grounds within the Framework of a Sustainable and Circular Bioeconomy. Ind. Crops Prod. 2023, 205, 117504. [Google Scholar] [CrossRef]

- Boey, J.Y.; Lee, C.K.; Tay, G.S. Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers 2022, 14, 3737. [Google Scholar] [CrossRef] [PubMed]

- Cristofoli, N.L.; Lima, A.R.; Tchonkouang, R.D.N.; Quintino, A.C.; Vieira, M.C. Advances in the Food Packaging Production from Agri-Food Waste and By-Products: Market Trends for a Sustainable Development. Sustainability 2023, 15, 6153. [Google Scholar] [CrossRef]

- Mendes, J.F.; Martins, J.T.; Manrich, A.; Sena Neto, A.R.; Pinheiro, A.C.M.; Mattoso, L.H.C.; Martins, M.A. Development and Physical-Chemical Properties of Pectin Film Reinforced with Spent Coffee Grounds by Continuous Casting. Carbohydr. Polym. 2019, 210, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Essabir, H.; Raji, M.; Laaziz, S.A.; Rodrique, D.; Bouhfid, R.; Qaiss, A.e.k. Thermo-Mechanical Performances of Polypropylene Biocomposites Based on Untreated, Treated and Compatibilized Spent Coffee Grounds. Compos. B Eng. 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Tomić, A.; Šovljanski, O.; Erceg, T. Insight on Incorporation of Essential Oils as Antimicrobial Substances in Biopolymer-Based Active Packaging. Antibiotics 2023, 12, 1473. [Google Scholar] [CrossRef]

- Mestanza, M.; Mori-Culqui, P.L.; Chavez, S.G. Changes of Polyphenols and Antioxidants of Arabica Coffee Varieties during Roasting. Front. Nutr. 2023, 10, 1078701. [Google Scholar] [CrossRef] [PubMed]

- Tungmunnithum, D.; Thongboonyou, A.; Pholboon, A.; Yangsabai, A. Flavonoids and Other Phenolic Compounds from Medicinal Plants for Pharmaceutical and Medical Aspects: An Overview. Medicines 2018, 5, 93. [Google Scholar] [CrossRef] [PubMed]

- Arancibia-Díaz, A.; Astudillo-Castro, C.; Altamirano, C.; Soto-Maldonado, C.; Vergara-Castro, M.; Córdova, A.; Zúñiga-Hansen, M.E. Development of Solid-State Fermentation Process of Spent Coffee Grounds for the Differentiated Obtaining of Chlorogenic, Quinic, and Caffeic Acids. J. Sci. Food Agric. 2023, 103, 420–427. [Google Scholar] [CrossRef] [PubMed]

- Moya-Ramírez, I.; Pegalajar-Robles, M.E.; Debiasi Alberton, M.; Rufián-Henares, J.A.; Fernández-Arteaga, A.; Garcia-Roman, M.; Altmajer-Vaz, D. Spent Coffee Grounds as Feedstock for the Production of Biosurfactants and the Improved Recovery of Melanoidins. World J. Microbiol. Biotechnol. 2023, 39, 254. [Google Scholar] [CrossRef]

- Iriondo-DeHond, A.; Rodríguez Casas, A.; del Castillo, M.D. Interest of Coffee Melanoidins as Sustainable Healthier Food Ingredients. Front. Nutr. 2021, 8, 730343. [Google Scholar] [CrossRef]

- Bondam, A.F.; Diolinda da Silveira, D.; Pozzada dos Santos, J.; Hoffmann, J.F. Phenolic Compounds from Coffee By-Products: Extraction and Application in the Food and Pharmaceutical Industries. Trends Food Sci. Technol. 2022, 123, 172–186. [Google Scholar] [CrossRef]

- Rodrigues, R.; Oliveira, M.B.P.P.; Alves, R.C. Chlorogenic Acids and Caffeine from Coffee By-Products: A Review on Skincare Applications. Cosmetics 2023, 10, 12. [Google Scholar] [CrossRef]

- Bouhzam, I.; Cantero, R.; Balcells, M.; Margallo, M.; Aldaco, R.; Bala, A.; Fullana-i-Palmer, P.; Puig, R. Environmental and Yield Comparison of Quick Extraction Methods for Caffeine and Chlorogenic Acid from Spent Coffee Grounds. Foods 2023, 12, 779. [Google Scholar] [CrossRef]

- Okur, I.; Soyler, B.; Sezer, P.; Oztop, M.H.; Alpas, H. Improving the Recovery of Phenolic Compounds from Spent Coffee Grounds (SCG) by Environmentally Friendly Extraction Techniques. Molecules 2021, 26, 613. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.A.; Kim, Y.; Lee, J.; Yi, H.; Fai Tsang, Y.; Kwon, E.E. Investigation into Role of CO2 in Two-Stage Pyrolysis of Spent Coffee Grounds. Bioresour. Technol. 2019, 272, 48–53. [Google Scholar] [CrossRef]

- Kim, M.S.; Min, H.G.; Koo, N.; Park, J.; Lee, S.H.; Bak, G.I.; Kim, J.G. The Effectiveness of Spent Coffee Grounds and Its Biochar on the Amelioration of Heavy Metals-Contaminated Water and Soil Using Chemical and Biological Assessments. J. Environ. Manag. 2014, 146, 124–130. [Google Scholar] [CrossRef]

- Picca, G.; Goñi-Urtiaga, A.; Gomez-Ruano, C.; Plaza, C.; Panettieri, M. Suitability of Co-Composted Biochar with Spent Coffee Grounds Substrate for Tomato (Solanum lycopersicum) Fruiting Stage. Horticulturae 2023, 9, 89. [Google Scholar] [CrossRef]

- Hu, T.; Wei, J.; Du, L.; Chen, J.; Zhang, J. The Effect of Biochar on Nitrogen Availability and Bacterial Community in Farmland. Ann. Microbiol. 2023, 73, 4. [Google Scholar] [CrossRef]

- Ahmad, W.; Nepal, J.; Zou, Z.; Munsif, F.; Khan, A.; Ahmad, I.; Zaheer, S.; Khan, M.S.; Jadoon, S.A.; Tang, D. Biochar Particle Size Coupled with Biofertilizer Enhances Soil Carbon-Nitrogen Microbial Pools and CO2 Sequestration in Lentil. Front. Environ. Sci. 2023, 11, 1114728. [Google Scholar] [CrossRef]

- Islam, M.A.; Parvin, M.I.; Dada, T.K.; Kumar, R.; Antunes, E. Silver Adsorption on Biochar Produced from Spent Coffee Grounds: Validation by Kinetic and Isothermal Modelling. Biomass Convers. Biorefin. 2022, 1, 1–15. [Google Scholar] [CrossRef]

- Ma, W.; Fan, J.; Cui, X.; Wang, Y.; Yan, Y.; Meng, Z.; Gao, H.; Lu, R.; Zhou, W. Pyrolyzing Spent Coffee Ground to Biochar Treated with H3PO4 for the Efficient Removal of 2,4-Dichlorophenoxyacetic Acid Herbicide: Adsorptive Behaviors and Mechanism. J. Environ. Chem. Eng. 2023, 11, 109165. [Google Scholar] [CrossRef]

- Figueroa Campos, G.A.; Perez, J.P.H.; Block, I.; Sagu, S.T.; Saravia Celis, P.; Taubert, A.; Rawel, H.M. Preparation of Activated Carbons from Spent Coffee Grounds and Coffee Parchment and Assessment of Their Adsorbent Efficiency. Processes 2021, 9, 1396. [Google Scholar] [CrossRef]

- Sklepova, S.V.; Ivanichok, N.; Kolkovskyi, P.; Kotsyubynsky, V.; Boychuk, V.; Rachiy, B.; Uhryński, A.; Bembenek, M.; Ropyak, L. Porous Structure and Fractal Dimensions of Activated Carbon Prepared from Waste Coffee Grounds. Materials 2023, 16, 6127. [Google Scholar] [CrossRef]

- Ngueabouo, A.M.S.; Tagne, R.F.T.; Tchuifon, D.R.T.; Fotsop, C.G.; Tamo, A.K.; Anagho, S.G. Strategy for Optimizing the Synthesis and Characterization of Activated Carbons Obtained by Chemical Activation of Coffee Husk. Mater. Adv. 2022, 3, 8361–8374. [Google Scholar] [CrossRef]

- Alves, A.T.; Lasmar, D.J.; de Andrade Miranda, I.P.; da Silva Chaar, J.; dos Santos Reis, J. The Potential of Activated Carbon in the Treatment of Water for Human Consumption, a Study of the State of the Art and Its Techniques Used for Its Development. Adv. Biosci. Biotechnol. 2021, 12, 143–153. [Google Scholar] [CrossRef]

- Sukhbaatar, B.; Yoo, B.; Lim, J.H. Metal-Free High-Adsorption-Capacity Adsorbent Derived from Spent Coffee Grounds for Methylene Blue. RSC Adv. 2021, 11, 5118–5127. [Google Scholar] [CrossRef] [PubMed]

- Jjagwe, J.; Olupot, P.W.; Menya, E.; Kalibbala, H.M. Synthesis and Application of Granular Activated Carbon from Biomass Waste Materials for Water Treatment: A Review. J. Bioresour. Bioprod. 2021, 6, 292–322. [Google Scholar] [CrossRef]

- Guy, M.; Mathieu, M.; Anastopoulos, I.P.; Martínez, M.G.; Rousseau, F.; Dotto, G.L.; de Oliveira, H.P.; Lima, E.C.; Thyrel, M.; Larsson, S.H.; et al. Process Parameters Optimization, Characterization, and Application of KOH-Activated Norway Spruce Bark Graphitic Biochars for Efficient Azo Dye Adsorption. Molecules 2022, 27, 456. [Google Scholar] [CrossRef] [PubMed]

- Marzeddu, S.; Décima, M.A.; Camilli, L.; Bracciale, M.P.; Genova, V.; Paglia, L.; Marra, F.; Damizia, M.; Stoller, M.; Chiavola, A.; et al. Physical-Chemical Characterization of Different Carbon-Based Sorbents for Environmental Applications. Materials 2022, 15, 7162. [Google Scholar] [CrossRef] [PubMed]

- Matović, B.; Gorshkova, Y.E.; Kottsov, S.Y.; Kopitsa, G.P.; Butulija, S.; Minović Arsić, T.; Cvijović-Alagić, I. Carbon Cryogel Preparation and Characterization. Diam. Relat. Mater. 2022, 121, 108727. [Google Scholar] [CrossRef]

- Stylianou, M.; Christou, A.; Dalias, P.; Polycarpou, P.; Michael, C.; Agapiou, A.; Papanastasiou, P.; Fatta-Kassinos, D. Physicochemical and Structural Characterization of Biochar Derived from the Pyrolysis of Biosolids, Cattle Manure and Spent Coffee Grounds. J. Energy Inst. 2020, 93, 2063–2073. [Google Scholar] [CrossRef]

- Dima, A.A.; Zewge, F.; Chebude, Y.; Adamu, A. Adsorption Activity of Spent Coffee Ground Biochar for the Removal of Vivizole Red 3BS Dye from Aqueous Solution. Int. J. Environ. Res. 2023, 17, 46. [Google Scholar] [CrossRef]

- Mehdi, R.; Naqvi, S.R.; Khoja, A.H.; Hussain, R. Biomass Derived Activated Carbon by Chemical Surface Modification as a Source of Clean Energy for Supercapacitor Application. Fuel 2023, 348, 128529. [Google Scholar] [CrossRef]

- Low, Y.W.; Yee, K.F. A Review on Lignocellulosic Biomass Waste into Biochar-Derived Catalyst: Current Conversion Techniques, Sustainable Applications and Challenges. Biomass Bioenergy 2021, 154, 106245. [Google Scholar] [CrossRef]

- Das, C.; Tamrakar, S.; Kiziltas, A.; Xie, X. Incorporation of Biochar to Improve Mechanical, Thermal and Electrical Properties of Polymer Composites. Polymers 2021, 13, 2663. [Google Scholar] [CrossRef]

- Roychand, R.; Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Zhang, G.; Li, C.Q. Transforming Spent Coffee Grounds into a Valuable Resource for the Enhancement of Concrete Strength. J. Clean. Prod. 2023, 419, 138205. [Google Scholar] [CrossRef]

- Bhattarai, S.; Janaswamy, S. Biodegradable, UV-Blocking, and Antioxidant Films from Lignocellulosic Fibers of Spent Coffee Grounds. Int. J. Biol. Macromol. 2023, 253, 126798. [Google Scholar] [CrossRef]

- Oliva, A.; Papirio, S.; Esposito, G.; Lens, P.N.L. Ultrasounds Application for Nut and Coffee Wastes Valorisation via Biomolecules Solubilisation and Methane Production. Waste Manag. 2022, 150, 373–382. [Google Scholar] [CrossRef] [PubMed]

- Touil, M.; Lachheb, A.; Saadani, R.; Sanbi, M.; Talidi, A.; Rahmoune, M. Experimental Investigation on the Combined Effect of the Water Mixing Ratio and the Addition of Spent Coffee Grounds on Plaster’s Thermo-Mechanical Properties. Therm. Sci. Eng. Prog. 2022, 36, 101488. [Google Scholar] [CrossRef]

- de Bomfim, A.S.C.; de Oliveira, D.M.; Voorwald, H.J.C.; de Carvalho Benini, K.C.C.; Dumont, M.J.; Rodrigue, D. Valorization of Spent Coffee Grounds as Precursors for Biopolymers and Composite Production. Polymers 2022, 14, 437. [Google Scholar] [CrossRef] [PubMed]

- Lee, X.J.; Ong, H.C.; Gao, W.; Ok, Y.S.; Chen, W.H.; Goh, B.H.H.; Chong, C.T. Solid Biofuel Production from Spent Coffee Ground Wastes: Process Optimisation, Characterisation and Kinetic Studies. Fuel 2021, 292, 120309. [Google Scholar] [CrossRef]

- Xia, W.; Li, Z.; Tang, Y.; Li, Q. Sustainable Recycling of Café Waste as Natural Bio Resource and Its Value Adding Applications in Green and Effective Dyeing/Bio Finishing of Textile. Sep. Purif. Technol. 2023, 309, 123091. [Google Scholar] [CrossRef]

- Tapangnoi, P.; Sae-Oui, P.; Naebpetch, W.; Siriwong, C. Preparation of Purified Spent Coffee Ground and Its Reinforcement in Natural Rubber Composite. Arab. J. Chem. 2022, 15, 103917. [Google Scholar] [CrossRef]

- Nguyen, Q.A.; Cho, E.J.; Lee, D.S.; Bae, H.J. Development of an Advanced Integrative Process to Create Valuable Biosugars Including Manno-Oligosaccharides and Mannose from Spent Coffee Grounds. Bioresour. Technol. 2019, 272, 209–216. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Chen, N.; Wan, L.; Li, G.; Chen, T.; Yang, F.; Sun, S. Preparation of High-Performance Activated Carbon from Coffee Grounds after Extraction of Bio-Oil. Molecules 2021, 26, 257. [Google Scholar] [CrossRef] [PubMed]

- Bomfim, A.S.C.D.; de Oliveira, D.M.; Walling, E.; Babin, A.; Hersant, G.; Vaneeckhaute, C.; Dumont, M.-J.; Rodrigue, D. Spent Coffee Grounds Characterization and Reuse in Composting and Soil Amendment. Waste 2022, 1, 2–20. [Google Scholar] [CrossRef]

- Cervera-Mata, A.; Delgado, G.; Fernández-Arteaga, A.; Fornasier, F.; Mondini, C. Spent Coffee Grounds By-Products and Their Influence on Soil C–N Dynamics. J. Environ. Manag. 2022, 302, 114075. [Google Scholar] [CrossRef]

- Khan, M.O.; Klamerus-Iwan, A.; Kupka, D.; Słowik-Opoka, E. Short-Term Impact of Different Doses of Spent Coffee Grounds, Salt, and Sand on Soil Chemical and Hydrological Properties in an Urban Soil. Environ. Sci. Pollut. Res. 2023, 30, 86218–86231. [Google Scholar] [CrossRef]

- Horgan, F.G.; Floyd, D.; Mundaca, E.A.; Crisol-Martínez, E. Spent Coffee Grounds Applied as a Top-Dressing or Incorporated into the Soil Can Improve Plant Growth While Reducing Slug Herbivory. Agriculture 2023, 13, 257. [Google Scholar] [CrossRef]

- Hemati, S.; Udayakumar, S.; Wesley, C.; Biswal, S.; Nur-A-Tomal, M.S.; Sarmadi, N.; Pahlevani, F.; Sahajwalla, V. Thermal Transformation of Secondary Resources of Carbon-Rich Wastes into Valuable Industrial Applications. J. Compos. Sci. 2023, 7, 8. [Google Scholar] [CrossRef]

- Plaza, M.G.; González, A.S.; Pevida, C.; Pis, J.J.; Rubiera, F. Valorisation of Spent Coffee Grounds as CO2 Adsorbents for Postcombustion Capture Applications. Appl. Energy 2012, 99, 272–279. [Google Scholar] [CrossRef]

- Czekała, W.; Łukomska, A.; Pulka, J.; Bojarski, W.; Pochwatka, P.; Kowalczyk-Juśko, A.; Oniszczuk, A.; Dach, J. Waste-to-Energy: Biogas Potential of Waste from Coffee Production and Consumption. Energy 2023, 276, 127604. [Google Scholar] [CrossRef]

- Gu, J.; Lee, A.; Choe, C.; Lim, H. Comparative Study of Biofuel Production Based on Spent Coffee Grounds Transesterification and Pyrolysis: Process Simulation, Techno-Economic, and Life Cycle Assessment. J. Clean. Prod. 2023, 428, 139308. [Google Scholar] [CrossRef]

- Kamil, M.; Ramadan, K.M.; Olabi, A.G.; Al-Ali, E.I.; Ma, X.; Awad, O.I. Economic, Technical, and Environmental Viability of Biodiesel Blends Derived from Coffee Waste. Renew. Energy 2020, 147, 1880–1894. [Google Scholar] [CrossRef]

- Gaidukova, G.; Mayson, S.; Williams, I.D. Applying a Circular Economy Approach to Valorize Spent Coffee Grounds. Resour. Conserv. Recycl. 2021, 172, 105659. [Google Scholar] [CrossRef]

- Mahmoud, E.; Atabani, A.E.; Badruddin, I.A. Valorization of Spent Coffee Grounds for Biogas Production: A Circular Bioeconomy Approach for a Biorefinery. Fuel 2022, 328, 125296. [Google Scholar] [CrossRef]

- ANDRITZ Spent Coffee Grounds for Biofuel. Available online: https://www.andritz.com/separation-en/industries/food/spent-coffee-grounds-for-biofuel (accessed on 4 February 2024).

- KafsimoProject Use of Coffee Waste to Produce Biofuels|Interreg Europe—Sharing Solutions for Better Policy. Available online: https://www.interregeurope.eu/good-practices/use-of-coffee-waste-to-produce-biofuels (accessed on 4 February 2024).

- Matrapazi, V.K.; Zabaniotou, A. Experimental and Feasibility Study of Spent Coffee Grounds Upscaling via Pyrolysis towards Proposing an Eco-Social Innovation Circular Economy Solution. Sci. Total Environ. 2020, 718, 137316. [Google Scholar] [CrossRef] [PubMed]

- Pablo-Romero, P.; Pozo-Barajas, R.; Sánchez, J.; García, R.; Holechek, J.L.; Geli, H.M.E.; Sawalhah, M.N.; Valdez, R. A Global Assessment: Can Renewable Energy Replace Fossil Fuels by 2050? Sustainability 2022, 14, 4792. [Google Scholar] [CrossRef]

- Carpentieri, S.; Soltanipour, F.; Ferrari, G.; Pataro, G.; Donsì, F. Emerging Green Techniques for the Extraction of Antioxidants from Agri-Food By-Products as Promising Ingredients for the Food Industry. Antioxidants 2021, 10, 1417. [Google Scholar] [CrossRef] [PubMed]

- Lauberts, M.; Mierina, I.; Pals, M.; Latheef, M.A.A.; Shishkin, A. Spent Coffee Grounds Valorization in Biorefinery Context to Obtain Valuable Products Using Different Extraction Approaches and Solvents. Plants 2022, 12, 30. [Google Scholar] [CrossRef]

- ImbibeCoffeeRoasters Zero Waste Coffee—Imbibe Coffee Roasters. Available online: https://imbibe.ie/wholesale/zero-waste/ (accessed on 18 February 2024).

- Cameron, A.; O’malley, S. Coffee 4 Planet Ark; The Council of the City of Sydney: Sydney, NSW, Australia, 2016; Volume 1, pp. 1–21. Available online: https://assets.ctfassets.net/fqjwh0badmlx/7Jb4U4q1tH8awgNl51E31m/44cb75f992f1a414fb468e1dd844a0a9/doc-1793-cos-final-report-2016--5-.pdf (accessed on 4 December 2023).

- Biobean Welcome to Bio Bean: A Fusion of Biology and Caffeine for Your Fitness Goals—Bio Bean. Available online: https://www.bio-bean.com/ (accessed on 18 February 2024).

- WaysTUP! Cambridgeshire (UK)—WaysTUP! Available online: https://waystup.eu/cases/london-uk/ (accessed on 18 February 2024).

- Nafigate Nafigate Corporation. Available online: https://www.nafigate.com/ (accessed on 18 February 2024).

- AgricultoresDeLavegaDeValencia R&D&i European Projects|SAV—Agricultores de La Vega de Valencia. Available online: https://www.sav.es/en/idi-europe-projects/ (accessed on 18 February 2024).

- WaysTUP! VALENCIA (SPA)—WaysTUP! Available online: https://waystup.eu/cases/valencia-spa/ (accessed on 18 February 2024).

- CoffeeFrom Products|Bio-Based Materials|Coffeefrom®. Available online: https://coffeefrom.it/en/products/ (accessed on 18 February 2024).

| Components | Cellulose | Hemicellulose | Lignin | Total Extractives | Ash | Protein | Lipids | Total Phenolics | Caffeine | Chlorogenic Acid | Dietary Fibre | References |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCGs | - | - | - | - | 6.2 | 11.5–16.5 | 15.3–15.9 | - | - | - | [38] | |

| SCGs | - | 37.06–40.80 | 19.84–26.51 | 51.43–55.78 | - | - | - | 0.17–4.54 | - | - | - | [39] |

| SCGs | - | - | - | - | - | - | - | - | 1.41 | 1.50 | - | [40] |

| SCGs | 12.40 ± 0.79 | 39.10 ± 1.94 | 23.90 ± 1.70 | - | 1–21 | 17.44 ± 0.10 | 2.29 ± 0.30 | - | - | - | 60.46 ± 2.19 | [18] |

| Biomass Type | Cellulose % | Hemicellulose % | Lignin % | Protein % | Lipids % | Ash % | Total Phenolic Compounds (mg GAE/g) | References |

|---|---|---|---|---|---|---|---|---|

| Spent Coffee Grounds (SCGs) | 12.40 ± 0.79 | 37.06–40.80 | 19.84–26.51 | 11.5–16.5 | 15.3–15.9 | 1.5 | 0.17–4.54 | [18,38,39,40] |

| Coffee Husk | 39.2 | 12.6 | 26.2 | 8.77 | 1.06 | 7.86–9.5 | 2.12 | [41,42] |

| Coffee Silver skin | N/D | N/D | N/D | 16.31–18.9 | 2.91–3.0 | 9.47 | 1.28 | [42,43] |

| Coffee Parchment | N/D | N/D | N/D | 1.66 | 0.18 | 0.65 | 0.18 | [42] |

| Brewers Spent Grains (BSGs) | 25.4 | 21.8 | 11.9 | 24.0–31.4 | 10.3–10.6 | 2.4–3.7 | N/D | [44,45] |

| Whole Corn Stover (Combined Stalks, Leaves, Cobs, and Flower) | 37.72 | 20.62 | 34.25 | N/D | N/D | 5.03 | N/D | [46] |

| Sugar Cane Bagasse (SCB) | 38.4–47.0 | 23.2–27.0 | 19.1–32.4 | N/D | N/D | 1.0–2.8 | N/D | [47,48,49,50,51,52] |

| Rice Husk | 35.0–35.23 | 24.39–25.0 | 12.92–20.0 | 3–3.75 | N/D | 17 | 14.90 ± 0.70 | [53,54] |

| Rice Straw | 34 | 36.06 | 14.5 | N/D | N/D | 19.5 | N/D | [55] |

| Peanut Shells | 44.8 | 5.6 | 36.1 | 5.4 | 0.1 | N/D | N/D | [56] |

| Wheat Straw | 34.9 ± 1.52 | 25.17 | 18.5 | N/D | N/D | 7.56 ± 0.03 | N/D | [57] |

| Coffee Waste Type | Methods/Parameters | Research Findings | Product/Potential Applications | Reference |

|---|---|---|---|---|

| SCGs |

|

| Biochar for concrete strength enhancement | [148] |

| SCGs |

|

| Cellulose fibre is used to produce biodegradable, UV-blocking, and antioxidant films | [149] |

| SCGs |

|

| Methane Production for Organic Chemicals | [150] |

| SCGs |

|

| Plastering Composite | [151,152] |

| Spent Coffee Ground Wastes |

|

| Solid Biofuel | [153] |

| SCGs |

|

| Textiles Dyes—Natural bio-colorant, improved UV protection. | [154] |

| Spent Coffee Grounds |

|

| Reinforcement in a Natural Rubber Composite | [155] |

| Spent Coffee Grounds. |

|

| Oligosaccharides (OSs), manno-oligosaccharides (MOSs), mannose, and bioethanol | [156] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, H.; Abolore, R.S.; Jaiswal, S.; Jaiswal, A.K. Toward Circular Economy: Potentials of Spent Coffee Grounds in Bioproducts and Chemical Production. Biomass 2024, 4, 286-312. https://doi.org/10.3390/biomass4020014

Ahmed H, Abolore RS, Jaiswal S, Jaiswal AK. Toward Circular Economy: Potentials of Spent Coffee Grounds in Bioproducts and Chemical Production. Biomass. 2024; 4(2):286-312. https://doi.org/10.3390/biomass4020014

Chicago/Turabian StyleAhmed, Hisham, Rasaq S. Abolore, Swarna Jaiswal, and Amit K. Jaiswal. 2024. "Toward Circular Economy: Potentials of Spent Coffee Grounds in Bioproducts and Chemical Production" Biomass 4, no. 2: 286-312. https://doi.org/10.3390/biomass4020014

APA StyleAhmed, H., Abolore, R. S., Jaiswal, S., & Jaiswal, A. K. (2024). Toward Circular Economy: Potentials of Spent Coffee Grounds in Bioproducts and Chemical Production. Biomass, 4(2), 286-312. https://doi.org/10.3390/biomass4020014