Abstract

The present study deals with the reuse of agro-industrial waste with a specific focus on biochar (processed plant biomass or biochar) consisting of organic and inorganic waste biomass subjected to thermochemical processes. The objective of this work is to carry out a systematic review of the literature according to the Methodi Ordinatio methodology and select a bibliographic portfolio of high relevance to this study that makes it possible to present the concepts, applications and interest on the part of companies in including biochar in their processes, as well as addressing the environmental impacts linked to incorrect waste disposal. In this sense, biochar presents an interesting potential solution from both a waste management and environmental point of view. The current challenge is studies that prove economic viability.

1. Introduction

The generation of agro-industrial waste is a major concern related to sustainability. Currently, attention is focused on the sustainable disposal of this waste. Correct disposal and conscientious treatment are essential pillars for cooperation with the environment, as these activities generate major negative impacts on the ecosystem. Agro-industrial waste is generated through food processing, fibrous materials, wood, sugar production and alcohol, among others. Waste is classified as organic (from agro-industrial processes) and inorganic (solids that fall into agricultural and domestic inputs) [1].

Around a third of the world’s annual food production is agro-industrial waste, with Europe generating around 100 thousand tons of agro-industrial waste annually. Much of the waste is rich in nutritional properties, which attracts the attention of companies linked to agro-industrial waste management and has been highlighted in relation to the sustainable development objectives (SDGs) proposed by the United Nations 2030 [2].

The reuse of residual biomass discarded by industries would be an important contribution to sustainable and ecological benefits. In this context, an alternative would be the production of biochar. Biochar is a carbon-rich material that can be prepared from various organic waste feedstock, such as agricultural wastes and municipal sewage sludge [3].

The biochar manufacturing process, together with the characteristics of the residue or biomass used in the process, can change the properties and characteristics of biochar. According to [4], changes in the characteristics of biochar can occur because of several factors that include the following: type of biomass, particle size, reaction time, heating variation and type of catalyst, among others.

The main process for manufacturing biochar is pyrolysis, but according to [5], biochar can be produced through other thermochemical processes such as roasting, hydrothermal carbonization and gasification. Biochar is promising for carbon storage, energy transport with high energy density and increased water and nutrient retention capacity; thus, it is an important agent for the quality of the environment and responsible for minimizing emissions of greenhouse gases, in accordance with [6].

The objective of this work is to carry out a systematic review of the literature in order to present a quantitative and qualitative evolution of interest in biochar throughout the industrial sector.

2. Materials and Methods

This work was carried out in accordance with the PRISMA statement. The statement was applied to assist in the selection of articles, data extraction and analysis of results. This systematic review was carried out both quantitatively and qualitatively. Proximity operators were used to search the databases used (Scopus, Science Direct and Web of Science), and the search results were obtained based on the keyword combinations indicated in Table 1.

Table 1.

Result of the number of articles with keyword combinations.

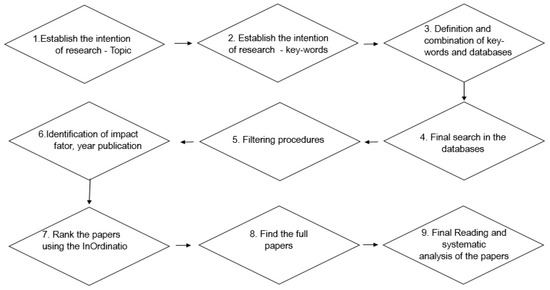

The methodology used to select articles relevant to the topic was the Methodi Ordinatio, which was used to construct the Systematic Review of Literature and State of the Art, consisting of the nine stages described in Figure 1. It is a multi-criteria decision-making methodology with the aim of selecting scientific articles to compose a bibliographic portfolio [7]. The methodology is based on the following three relevant factors when choosing an article: number of citations, metric or impact factor and year of publication.

Figure 1.

Flowchart of the steps for applying the research methodology.

The filtering process and identification of the impact factor and number of citations were carried out. Filtering, in particular, consists of applying procedures to eliminate duplicate works and works whose theme and keywords are unrelated to the original theme.

Equation (1), as proposed by [7], was used to find the ordering index of scientific relevance so that the research portfolio was as aligned as possible with the objective and topic of study. Updating the equation allowed us to consider the importance of the main methodology factors including the year of publication, number of citations and impact factor.

where IF = impact factor; α = value of alpha, varying from 1 to 10, to be defined by the researcher according to the importance of the novelty of the subject; ResearchYear = year in which the research was carried out; PubYear = year in which the article was published; and Ci = number of citations of the article.

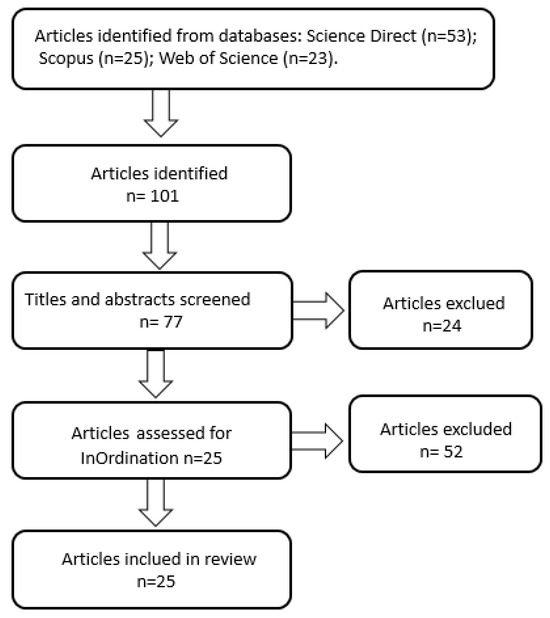

After searching the databases, we identified 101 articles to include in the research portfolio. After filtering procedures were carried out in reference management software (Mendeley v1.19.8 and JabRef v5.12), this number was reduced to 77 articles in the portfolio (Figure 2).

Figure 2.

Flowchart of the study selection process.

The portfolio of articles present in the reference management software was transferred to an Excel spreadsheet called the RankIn spreadsheet. After weighing the factors, the number of citations for each article was searched and, finally, the RankIn table automatically applied In Ordinatio2.0 Formula (1) and presented the ordering of the most relevant articles to this research according to the methodology. A total of 25 articles were selected to carry out this study. These articles are presented in Table S1 (Supplementary Material) according to the RankIn spreadsheet.

3. Results and Discussion

3.1. Bibliometric Study

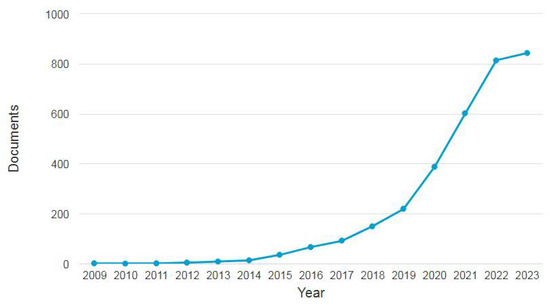

The number of articles published over the years according to the combination of keywords in this research and the Scopus database is shown in Figure 3.

Figure 3.

Number of articles published over the years.

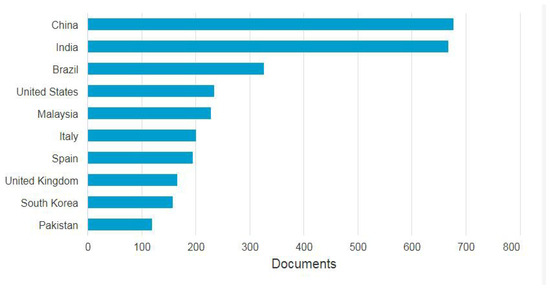

According to the Scopus database, the three countries with the highest volume of publications related to the research topic of this work are China, India and Brazil, in that order, as shown in Figure 4.

Figure 4.

Number of publications by countries.

The common points with the greatest relevance to the researched topic were listed within the final portfolio constructed. The most discussed points were the use of waste for sustainability, bioenergy production, adsorption processes and waste management. Table S2 presents the content of the articles addressing the method used, proposed solutions and suggestions for future work.

3.2. Agro-Industrial Waste

With the constant advancement in industrialization linked to global population growth, agricultural and industrial activities grow at the same pace in order to meet market demands. Therefore, the amount of waste coming from domestic, commercial and industrial food cultivation and processing areas is significant, making it necessary to study and discuss the generation of this waste [8].

Agro-industrial waste is generated through food processing, fibrous materials, wood, sugar production and alcohol, among others. Waste is classified as organic (from agro-industrial processes) and inorganic (solids that fall into agricultural and domestic inputs) [1].

Organic waste generated by agricultural industries is often rich in nutritional value; thus, it is of interest for reuse and serves as raw material for various purposes. Examples such as rice bran, barley bran, soy whey, soy bagasse and sugarcane molasses, among others, have been studied for this purpose [9].

As stated in the Introduction, around a third of the world’s annual food production is agro-industrial waste, with Europe generating around 100 thousand tons of agro-industrial waste annually. Companies linked to agro-industrial waste management are interested in the rich nutritional properties of this waste, which has also been highlighted in relation to the sustainable development objectives (SDGs) proposed by the United Nations 2030 Agenda [2].

3.3. Pyrolysis Process

Pyrolysis involves the chemical transformation (decomposition) of a sample after heating to a high temperature [10]. There are several studies on the application of the pyrolysis process in the chemical industry. According to [11], the pyrolysis process has been extensively addressed in the transformation of biomass into gaseous, liquid and solid components, where its conditions are related to the composition of the compound structure.

When subjected to low temperatures and long periods of steam residence, the process promotes the creation of solids or coal. In contrast, in the process that is subjected to high temperatures together with long steam residence, the biomass is transformed into gas, and when it is processed at medium temperatures and short vapor residence times, liquids are produced [11].

Studies focused on the pyrolysis process show considerable relevance in the context of sustainability, as the waste subjected to the process has a high potential to reduce greenhouse gas emissions indirectly. According to the authors of [12], pyrolysis in the waste tire recycling process has great relevance to environmental and economic aspects, as it completely degrades the waste generating gases, condensable oil and solid coal that can serve as raw material for formulation and usability in other processes, thus reducing pollutant emissions.

The various applications of pyrolysis in industry have been adopted as a new option for waste management in a more sustainable way. The high temperatures used in the process, together with the degradation of organic materials and oxidation of minerals, destroy pathogenic organisms that may be included in the residual compounds, as explained by [13]. In terms of sewage, when there is molecular structural degradation of sludge, the process reduces its volume and produces compounds such as biochar, which has been studied and used in various applications in the market and industry.

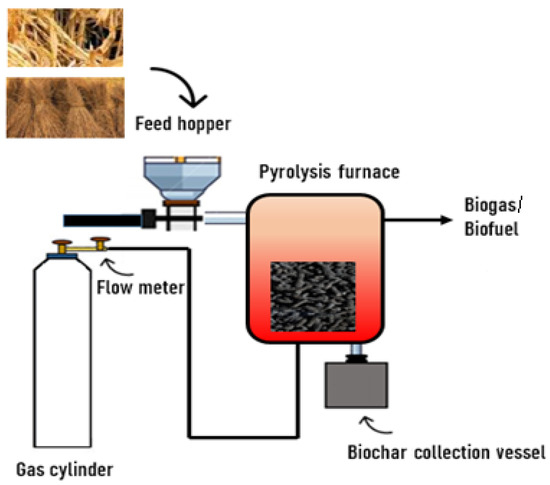

Compared with other existing thermochemical processes, pyrolysis stands out in terms of optimization and product varieties, that is, it has great adaptability to different types of raw materials and operating environments. With this easy adaptation to materials, pyrolysis is characterized as a process for producing valuable raw materials for the economic market [4]. A simplified scheme of the process is shown in Figure 5.

Figure 5.

Schematic representation of obtaining biochar by pyrolysis.

3.4. Aspects of Biochar Production

Biochar is a solid aromatic adsorbent compound highly rich in carbon, with a porous structure, consisting of around 70% carbon and 30% other nutrients and mineral components [6]. It is produced from organic and inorganic waste through the pyrolysis process. Being rich in nutrients such as nitrogen, phosphorus, sulfur and potassium, it is extracted from residual compounds such as waste from agricultural activities, wood production, plant tissue, animal waste, and urban, industrial and domestic solid waste. According to [14], biochar can be used as fertilizers and soil conditioners because of its properties that promote the enrichment of the physical and chemical conditions of the soil.

The main process for manufacturing biochar is pyrolysis. However, biochar can be produced through other thermochemical processes such as roasting, hydrothermal carbonization and gasification, as discussed in [5]. Hydrothermal carbonization (HTC) is used to develop surface-modified biochar. HTC is also called wet pyrolysis, where biomass is submerged in water in a Teflon-lined container and heated to a temperature ranging from 120 °C to 220 °C for hours. The biochar produced using this technique has numerous amounts of oxygenated functional groups that assist in holding the incoming pollutants [15].

Another point to consider is that the energy consumed in the production of biochar is highly sensitive to the characteristics of the biomass. Different biomasses result in a different net energy balance. The calorific value and yield directly affect viability because of profitability, which sometimes does not meet the requirements for large productions. Furthermore, other parameters must be considered in biochar production, such as temperature, pressure and residence time [16].

Among the characteristics already mentioned, biochar has shown potential in carbon storage and energy transport with high energy density as well as having increased water and nutrient retention capacity. Therefore, it can act as an important agent of responsible environmental quality by minimizing the emission of greenhouse gases [6].

Along with biochar, previous research has investigated biochar-based nanocomposites, which are formed through the union of nanomaterials present on their surface. Nanomaterials can be formed through changes in properties during the pyrolysis process, synthesis methods and variation in raw materials, according to [17].

Although the term biochar has seen an important rise in recent years, [18] emphasizes that biochar or biochar has been studied since before the 1990s, although the term biochar was not used. The term was first used in 1998 to refer to solid biomass manufactured from pyrolysis. There is written evidence of its application since the end of the 17th century, which leads us to believe that techniques were used at that time to enrich the soil in agricultural activities, as is proven in the black soils of the Amazon Basin called Terras Negras da Amazon or Terra Preta de Índio.

According to [4], the incorporation of biochar into the industrial market still needs to be explored since biochar is not used as the main raw material product of large companies. For them, life cycle assessment together with techno-economic analysis are fundamental to understanding the economic viability and incorporation of biochar into the industrial economy.

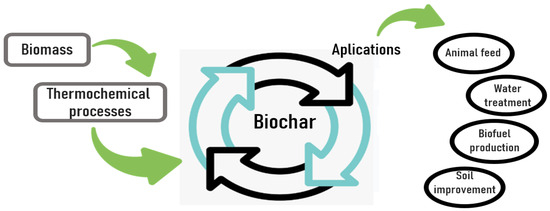

Mathematical models are also used to study biochar. These models use a database and make predictions of the properties of biochar produced from different types of raw materials [19]. Statistical methods such as Regression Modeling and Linear Regression have been applied to predict the composition of elements (carbon, nitrogen, oxygen and sulfur) of different biomasses produced from bark rice, sewage sludge, pine needles, orange peel and wood, for example. Figure 6 shows some applications of biochar.

Figure 6.

Graphic summary of biochar based on its composition, thermochemical processes and applications.

3.5. Biochar Applications

3.5.1. Treatment of Polluted Water

Because of the adsorption properties and structural characteristics of biochar, it is effective in eliminating wastewater pollutants such as heavy metals and organic contaminants, specifically antibiotics and dyes.

Heavy metals found in effluents are generally released by foundry, mining and electronic equipment production industries [5]. Organic contaminants also pose a high risk to sustainability and the environment because of their irrational use and improper disposal in wastewater.

According to the authors, the adsorption power of biochar shows significant results for the removal of antibiotics and dyes from effluents that are disposed of by paper and cellulose industries and that are present in textiles and wastewater from hospitals and domestic households.

Table 2 indicates the adsorption capacity/removal efficiency of biochar derived from biomass composed of different wastes to remediate contaminants found in wastewater, such as emerging pollutants and organic contaminants (Table 2).

Table 2.

Biochar applied for the remediation of contaminants in wastewater.

3.5.2. Biochar as an Additive for Cement Mortar

Biochar is also being explored in the construction industry as an additive to improve the properties of cement-based mortars. According to [25], silica used as an additive in cement bases has high drying shrinkage, which generates cracks on the cement surface in climatic conditions with high temperatures.

As stated in [26], the application of biochar based on rice husk and ash with a low silica content has been explored as an additive to replace the percentage of cement used in mortars. According to the authors, the additives provide better conditions for the material’s properties, such as greater resistance, durability and impermeability when compared with cementitious mortars.

Biochar produced from different types of waste can also be applied to modify the properties of cement-based mortars and explore the viability of different biomasses based on food and wood wastes. Here, the insertion of biochar derived from these compounds into cement mortars results in a significant increase in mechanical properties such as compression, tensile strength and impermeability [27].

3.5.3. Application of Biochar for Soil Improvement

Agricultural activities have always been prominent and growing in the global economy. Obtaining soil rich in nutrients and well-prepared for production is an essential requirement for small, medium and large-scale producers.

Biochar can bring many more benefits than conventional fertilizers used in the agricultural industry. Because it has a favorable structure for soil properties, biochar, when applied, improves the soil’s physical, chemical and biological properties. This makes the soil more suitable for planting because the application of biochar results in higher levels of nutrients, removes organic contaminating elements and heavy metals, and increases water retention and microbial activity, which directly increases soil health and quality [28].

In addition to helping to remove contaminants contained in the soil, biochar also contributes to nutrition and fertility through its properties. According to [29], the application of biochar in tea plantation soils brought significant benefits to the properties and condition of the soil. Conditions such as pollution, low use of fertilizers and acidification lead to a shortage of nutrients in the soil, making it ineffective for planting. With the addition of biochar derived from rice and bamboo biomass, plant growth levels related to fertility and nutrition increased by approximately 2.5% to 5.0% when compared with the control soil.

3.5.4. Application of Biochar in Animal Feed and Livestock Farming

Because of the beneficial conditions of biochar implemented in the agricultural sector, interest in its exploitation in the agricultural market has also increased. Biochar has been used as an additive in feed for different types of animals, bringing significant results in terms of nutrition and presenting itself as a beneficial agent in the ecosystem in which animals live.

Biochar incorporated in direct feeding of animals added positive results to the nutrition process combined with weight gain, better digestion, blood levels, increased immunity, adsorption of toxins and improvement in the health and productivity of animals [5].

Biochar used as a food input for broiler chickens is capable of bringing positive results in relation to the vital quality of the animal and its productivity. According to [30], the incorporation of biochar based on oak, corncob, canary seed, coconut shells and wood into the diet of broiler chickens results in higher levels of activation of intestinal flora, growth, performance, weight gain, absorption of nutrients and deactivation of intestinal toxins, which leads to a reduction in mortality and provides vitality to the animals.

Another application of biochar associated with animal feeding is highlighted by [30], who suggest that it is a beneficial addition to the diet of ruminants for fattening. As stated by the authors, biochar produced from walnut shells, pistachios and chicken manure is a low-cost food additive that brings significant results such as a higher rumen fermentation rate, better feed efficiency and better animal performance.

3.5.5. Application of Biochar in the Production of Biofuels

The constant concern on the part of industries to generate energy without the presence of pollutants harmful to human health and the environment has been increasingly discussed. Biochars can be important sources for the production of biofuels. For example, biochars derived from crop residues are efficient catalysts that support the production of biofuels. The inclusion of biochar in the production of catalysts is an economic investment that is easily accessible and ecologically sustainable [31].

Currently, the largest energy sources are derived from fossil fuels, which is a global concern when it comes to scarcity. Therefore, it is necessary to explore other non-conventional sources for energy generation. It is assumed that organic waste generated through various industrial activities can contribute to the production of gaseous biofuels. According to one study, the addition of biochar in the synthesis of biogas fuel increases its yield by 5% to 400% depending on the properties of the biochar [32].

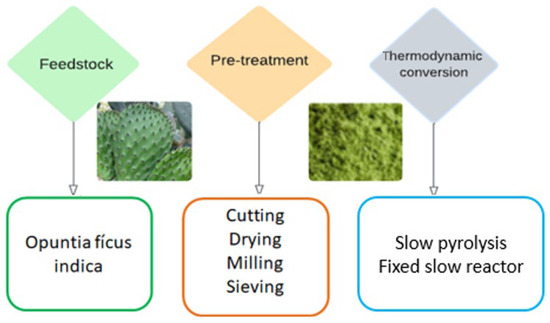

The article by [33] addresses the production of liquid biofuel through biochar from the biomass of a cactus in the cladode family. The study found that this resource is valuable in the production of value-added ecological biofuels.

Figure 7 illustrates the main feedstock for the biomass process as well as the thermodynamic conversion for biochar synthesis.

Figure 7.

Preparation of Opuntia Ficus Indica biomass for the pyrolysis process.

Thus, liquid and gaseous biofuels can be produced through biochar, which points out the importance of including biochar derived from citrus fruit peel residues in the solid biofuel production process as a renewable energy source [28]. According to the authors, biomass is not recommended for the synthesis of biofuel, as it has high moisture content, low grinding capacity and low energy density, making its use unfeasible. Therefore, it is converted into biochar that can serve as a potential derivative for the production of solid fuel.

4. Conclusions

This systematic literature review presents the importance and need for exploring agro-industrial waste, as well as its applications for generating bioproducts that add value to the market and reduce environmental impacts generated by the accumulation of waste and scarcity of natural resource sources. It is evident that the circular economy and sustainability are intrinsic pillars in waste management and concern for the environment; therefore, the reviewed works allowed us to present the evolution and growing demand for research related to the reuse of waste and transformation into products, specifically biochar. The transformation of agro-industrial waste into value-added products has been extensively studied over the years, but only in the research and experimentation phase. As of 2021, some industries have adopted and implemented the practice of new sustainable waste management methods, which allowed us to observe a subtle change in the temporal scenario, but these methods are still in the early stages. Currently, equipment such as the continuous biochar carbonization furnace is being developed for use and implementation in industries, which is facilitating the process of manufacturing and using biochar.

However, in the context of sustainability, some issues make the process difficult. Among these obstacles are the adoption and implementation of these methods by socioeconomic and industrial sectors that have a high investment in adequate infrastructure, logistical issues for the transport and storage of raw materials, scarcity of technological tools to assist the practice and a lack of guidance legal lines for implementing sustainable practices, among others. Regarding future studies, we provide some recommendations in Supplementary Material Table S2. Most studies indicate that another crucial point necessary for the adoption of the practice is the need for studies that prove the economic viability of implementation, that is, studies that prove the effectiveness of implementing sustainable investment systems as well as social awareness.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/biomass4020029/s1, Table S1: Portfolio of articles according to the methodology. Table S2. Qualitative content analysis.

Author Contributions

Conceptualization, L.H.S.A. and J.R.P.O.; methodology and investigation J.R.P.O., G.G.L., G.G. and L.H.S.A. writing—review and editing J.R.P.O., A.M.T. and G.G.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received external funding. The fourth author thanks CNPq for financial support (process: 310562/2021-0). The last author thanks CNPq for financial support (process: 304068/2022-5).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are included in this article.

Acknowledgments

The authors thank the Capes, Fundação Araucária, and CNPq agencies.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Phiri, R.; Rangappa, S.M.; Siengchin, S.; Oladijo, O.P.; Dhakal, H.N. Development of sustainable biopolymer-based composites for lightweight applications from agricultural waste biomass: A review. Adv. Ind. Eng. Polym. Res. 2003, 6, 436–450. [Google Scholar] [CrossRef]

- Lima, A.R.; Cristofoli, N.L.; da Costa, A.M.R.; Saraiva, J.A.; Vieira, M.C. Comparative study of the production of cellulose nanofibers from agro-industrial waste streams of Salicornia ramosissima by acid and enzymatic treatment. Food Bioprod. Process. 2023, 137, 214–225. [Google Scholar] [CrossRef]

- Yang, S.S.; Chen, Y.D.; Kang, J.H.; Xie, T.R.; He, L.; Xing, D.F.; Ren, N.Q.; Ho, S.H.; Wu, W.M. Generation of high-efficient biochar for dye adsorption using frass of yellow mealworms (larvae of Tenebrio molitor Linnaeus) fed with wheat straw for insect biomass production. J. Clean. Prod. 2019, 227, 33–47. [Google Scholar] [CrossRef]

- Mishra, R.K.; Kumar, D.J.P.; Narula, A.; Chistie, S.M.; Naik, S.U. Production and beneficial impact of biochar for environmental application: A review on types of raw materials, chemical compositions, operational parameters, technical-economic study and life cycle assessment. Fuel 2023, 343, 127968. [Google Scholar]

- Ding, Z.; Ge, Y.; Gowd, S.C.; Singh, E.; Kumar, V.; Chaurasia, D.; Kumar, V.; Rajendran, K.; Bhargava, P.C.; Wu, P.; et al. Production of biochar from tropical fruit tree residues and ecofriendly applications-A review. Bioresour. Technol. 2023, 376, 128903. [Google Scholar] [CrossRef]

- Safarian, S. Performance analysis of sustainable technologies for biochar production: A comprehensive review. Energy Rep. 2023, 9, 4574–4593. [Google Scholar] [CrossRef]

- Pagani, R.N.; Kovaleski, J.L.; Resende, L.M. Methodi Ordinatio: A proposed methodology to select and rank relevant scientific papers encompassing the impact factor, number of citation, and year of publication. Scientometrics 2015, 105, 2109–2135. [Google Scholar] [CrossRef]

- Yafetto, L.; Odamtten, G.T.; Kwagyan, M.W. Valorization of agro-industrial residues through microbial fermentation: A global and Ghanaian state review. Helyion 2023, 9, e14814. [Google Scholar]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial wastes and their utilization using solid state fermentation: A review. Bioresour. Bioprocess 2018, 5, 1. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, Y.; Chen, P.; Liu, S.; Zhou, N.; Ding, K.; Fan, L.; Peng, P.; Min, M.; Cheng, Y.; et al. Gasification Technologies and Their Energy Potentials. In Sustainable Resource Recovery and Zero Waste Approaches; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 14; pp. 193–206. [Google Scholar]

- Makepa, D.C.; Chihobo, C.H.; Ruziwa, W.R.; Musademba, D. Microwave-assisted pyrolysis of pine sawdust: Process modelling, performance optimization and economic evaluation for bioenergy recovery. Helyion 2023, 9, e14688. [Google Scholar] [CrossRef]

- Gao, N.; Wang, F.; Quan, C.; Santamaria, L.; Lopez, G.; Williams, P.T. Tire pyrolysis charcoal: Processes, properties, update and applications. Prog. Energy Combust. Sci. 2022, 93, 101022. [Google Scholar] [CrossRef]

- Xing, J.; Xu, G.; Li, G. Comparison of pyrolysis process, various fractions and potential soil applications between sewage sludge-based biochars and lignocellulose-based biochars. Ecotoxicol. Environ. Saf. 2021, 208, 111756. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Zhang, H. Influence of pyrolysis conditions on nitrogen speciation in a biochar ‘preparation-application’ process. J. Energy Inst. 2018, 91, 916–926. [Google Scholar] [CrossRef]

- Prasannamedha, G.; Kumar, P.S.; Mehala, R.; Sharumitha, T.J.; Surendhar, D. Enhanced adsorptive removal of sulfamethoxazole from water using biochar derived from hydrothermal carbonization of sugarcane bagasse. J. Hazard. Mater. 2021, 407, 124825. [Google Scholar] [CrossRef] [PubMed]

- Seow, Y.X.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Ibrahim, M.L.; Ghasemi, M. A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. J. Environ. Chem. Eng. 2022, 10, 107017. [Google Scholar] [CrossRef]

- Mazarji, M.; Bayero, M.T.; Minkina, T.; Sushkova, S.; Mandzhieva, S.; Bauer, T.V.; Soldatov, A.; Sillanpää, M.; Wong, M.H. Nanomaterials in biochar: Review of their effectiveness in remediating heavy metal-contaminated soils. Sci. Total Environ. 2023, 880, 163330. [Google Scholar] [CrossRef] [PubMed]

- Campion, L.; Bekchanova, M.; Malina, R.; Kuppens, T. The costs and benefits of biochar production and use: A systematic review. J. Clean. Prod. 2023, 408, 137138. [Google Scholar] [CrossRef]

- Ganesapillai, M.; Metha, R.; Tiwari, A.; Sinha, A.; Bakshi, H.S.; Chellappa, V.; Drewowoski, J. Waste to energy: A review of biochar production with emphasis on mathematical modelling and its applications. Heliyon 2023, 9, e14873. [Google Scholar] [CrossRef] [PubMed]

- Spath, J.; ArumugamII, P.; LindbergI, R.H.; AbafeIII, O.A.; JanssonI, S.; FickI, J.; BuckleyII, C.A. Biochar for the removal of detected micropollu-tants in South African domestic wastewater: A case study from a demonstration-scale decentralized wastewater treatment system in eThekwini. Water SA 2021, 47, 396–416. [Google Scholar]

- Li, X.; Shi, J. Simultaneous adsorption of tetracycline, ammonium and phosphate from wastewater by iron and nitrogen modified biochar: Kinetics, isotherm, thermodynamic and mechanism. Chemosphere 2022, 29, 3133574. [Google Scholar] [CrossRef]

- Fernandes, J.O.; Bernardino, C.A.R.; Mahler, C.F.; Santelli, R.E.; Braz, B.F.; Borges, R.C.; Veloso, M.C.C.; Romeiro, G.A.; Cincotto, F.H. Biochar generated from agro-industry sugar cane residue by low temperature pyrolysis utilized as an adsorption agent for the removal of thiamethoxam pesticide in wastewater. Water Air Soil Pollut. 2021, 232, 67. [Google Scholar] [CrossRef]

- Xu, L.; Wu, C.; Chai, C.; Cao, S.; Bai, X.; Ma, K.; Jin, X.; Shi, X.; Jin, P. Adsorption of micropollutants from wastewater using iron and nitrogen co-doped biochar: Performance, kinetics and mechanism studies. J. Hazard. Mater. Part C 2022, 424, 127606. [Google Scholar] [CrossRef] [PubMed]

- Steigerwald, J.M.; Ray, J.R. Adsorption behavior of perfluorooctanesulfonate (PFOS) onto activated spent coffee grounds biochar in synthetic wastewater effluent. J. Hazard. Mater. Lett. 2021, 2, 100025. [Google Scholar] [CrossRef]

- Gupta, S.; Krishnan, P.; Kashani, A.; Kua, H.W. Application of biochar from coconut and wood waste to reduce shrinkage and improve physical properties of silica fume-cement mortar. Constr. Build. Mater. 2020, 262, 120688. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Gupta, S.; Kua, H.W. Application of rice husk biochar and thermally treated low silica rice husk ash to improve physical properties of cement mortar. Theor. Appl. Fract. Mech. 2019, 104, 102376. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619–620, 419–435. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.P.S.; Bhandari, S.; Bhatta, D.; Poudel, A.; Bhattarai, S.; Yadav, P.; Ghimire, N.; Paudel, P.; Paudel, P.; Shrestha, J.; et al. Biochar application: A sustainable approach to improve soil health. J. Agric. Food Res. 2023, 11, 100498. [Google Scholar]

- Zou, Z.; Mi, W.; Li, X.; Hu, Q.; Zhang, L.; Zhang, L.; Fu, J.; Li, Z.; Han, W.; Yan, P. Biochar application method influences root growth of tea (Camellia sinensis L.) by altering soil biochemical properties. Sci. Hortic. 2023, 315, 111960. [Google Scholar]

- Mirheidari, A.; Torbatinejad, N.M.; Shakeri, P.; Mokhtarpour, A. Effects of biochar produced from different biomass sources on digestibility, ruminal fermentation, microbial protein synthesis and growth performance of male lambs. Small Rumin. Res. 2020, 183, 106042. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V. Application of biochar derived from crop residues for the production of biofuels. Fuel Commun. 2023, 15, 100088. [Google Scholar] [CrossRef]

- Sirohi, R.; Vivekanand, V.; Pandey, A.K.; Tarafdar, A.; Awasthi, M.K.; Shakya, A.; Kim, S.H.; Sim, S.J.; Tuan, H.A.; Pandey, A. Emerging trends in role and significance of biochar in gaseous biofuels production. Environ. Technol. Innov. 2023, 30, 103100. [Google Scholar] [CrossRef]

- Maaoui, A.; Trabelsi, A.B.H.; Hamdi, M.; Chagtmi, R.; Jamaaoui, F.; Lopez, G.; Cortazar, M.; Olazar, M. Towards local circular economy through Opuntia Ficus Indica cladodes conversion into renewable biofuels and biochars: Product distribution and kinetic modelling. Fuel 2023, 332, 126056. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).