Wood Gasification: A Promising Strategy to Extend Fuel Reserves after Global Catastrophic Electricity Loss

Abstract

1. Introduction

1.1. Agriculture’s Dependence on Fossil Fuels

1.2. Global Catastrophic Infrastructure Loss

1.3. Global EMP Damages

1.4. Gasification Devices

2. Methodology

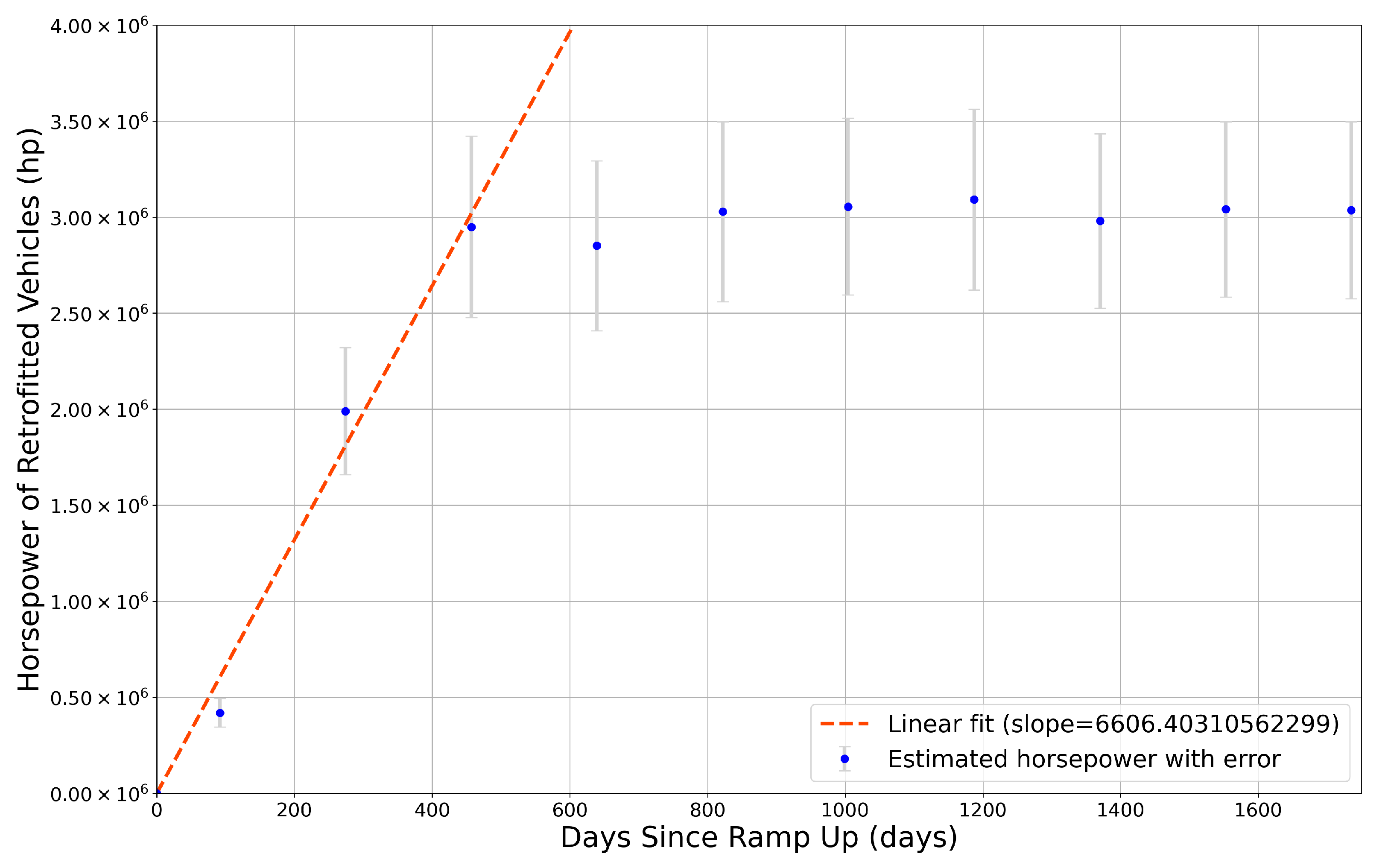

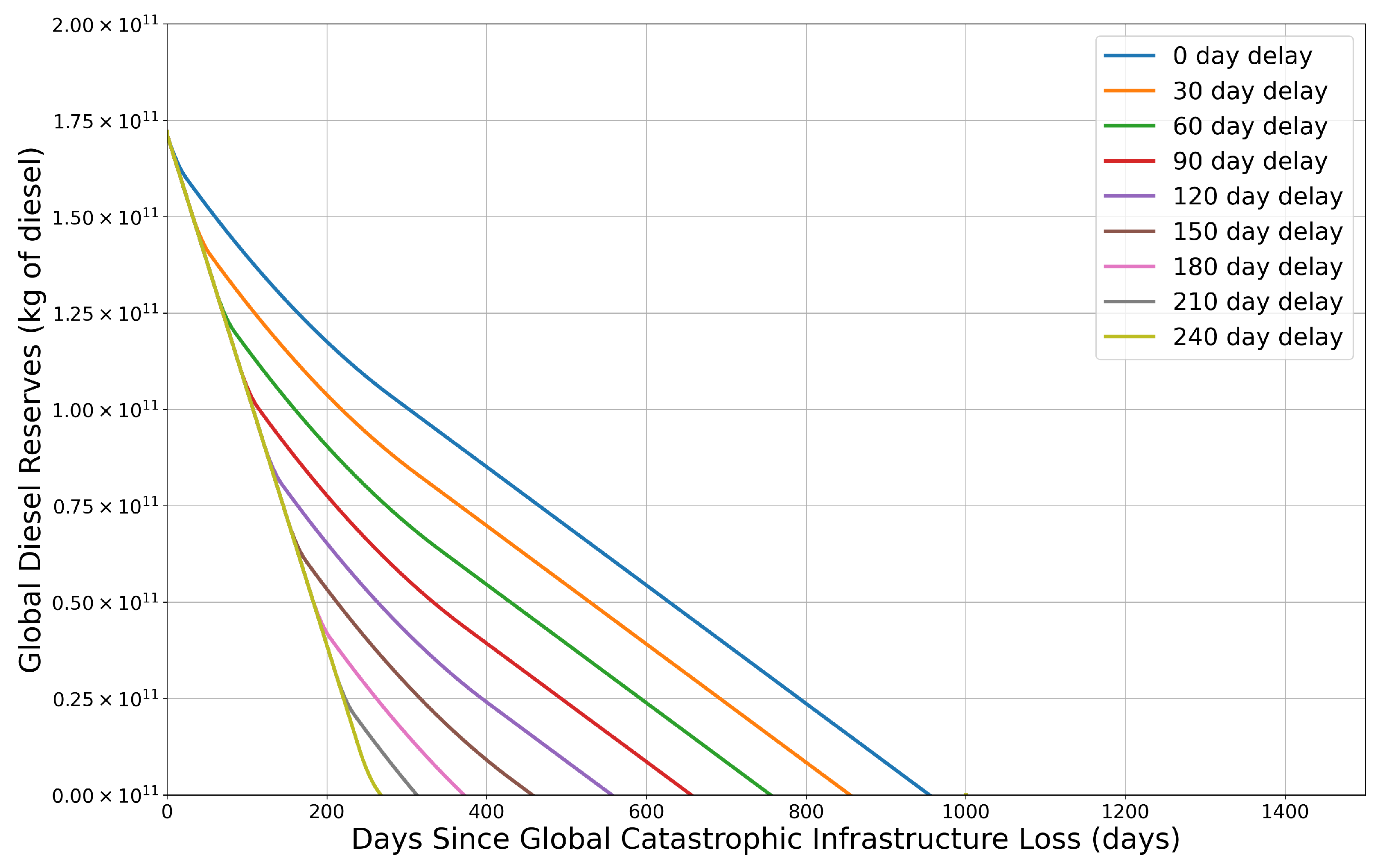

2.1. Gasification Device Installation Rate

2.2. Fuel Reserves

2.2.1. Stockpiled Fuels

2.2.2. Wood

2.2.3. Coal

2.3. Fuel Demand

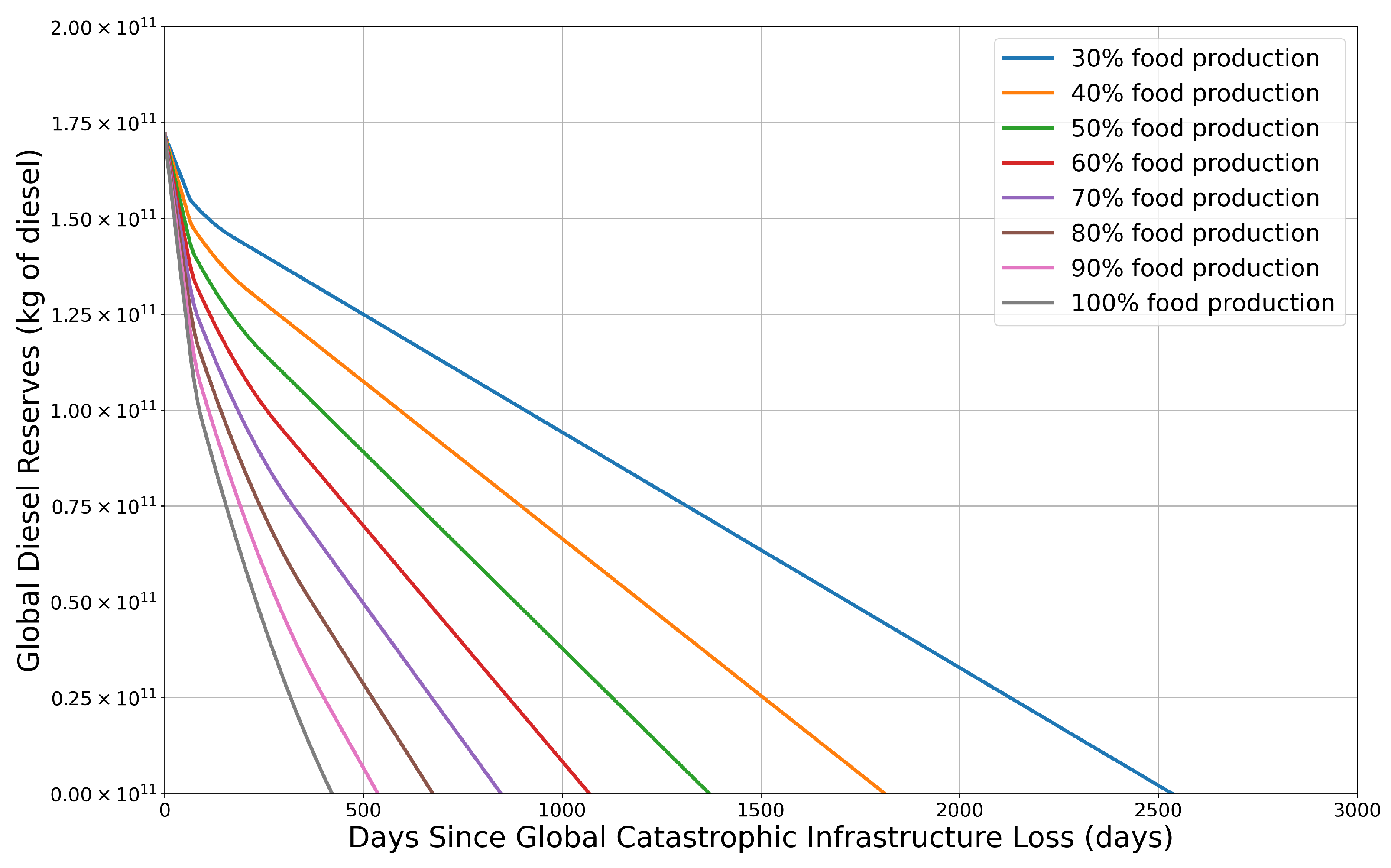

2.3.1. Food Production

2.3.2. Food Transportation

2.3.3. Rationing

2.4. Converting Diesel Engines

2.5. The Main Scenario

2.6. Statistical Analysis

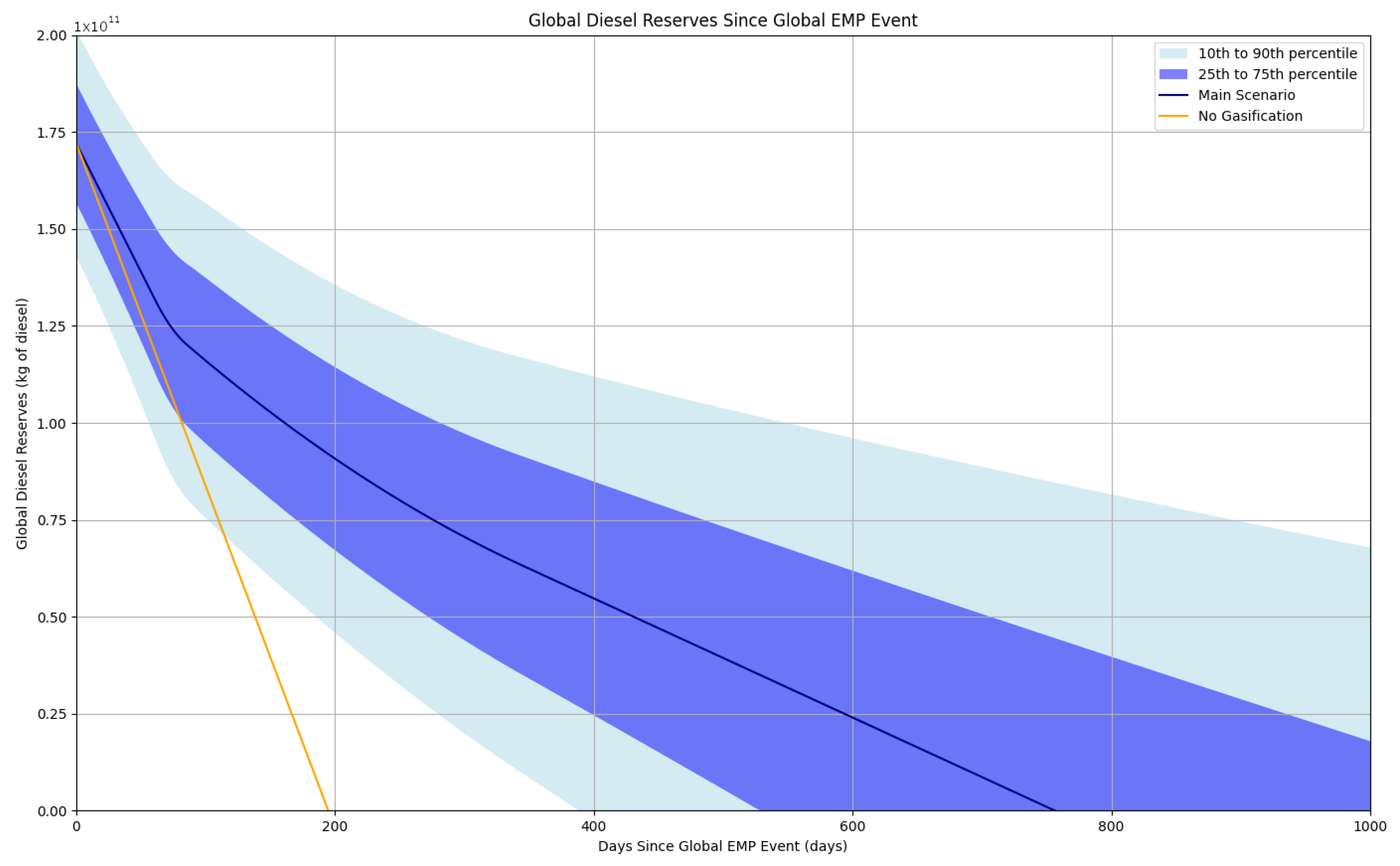

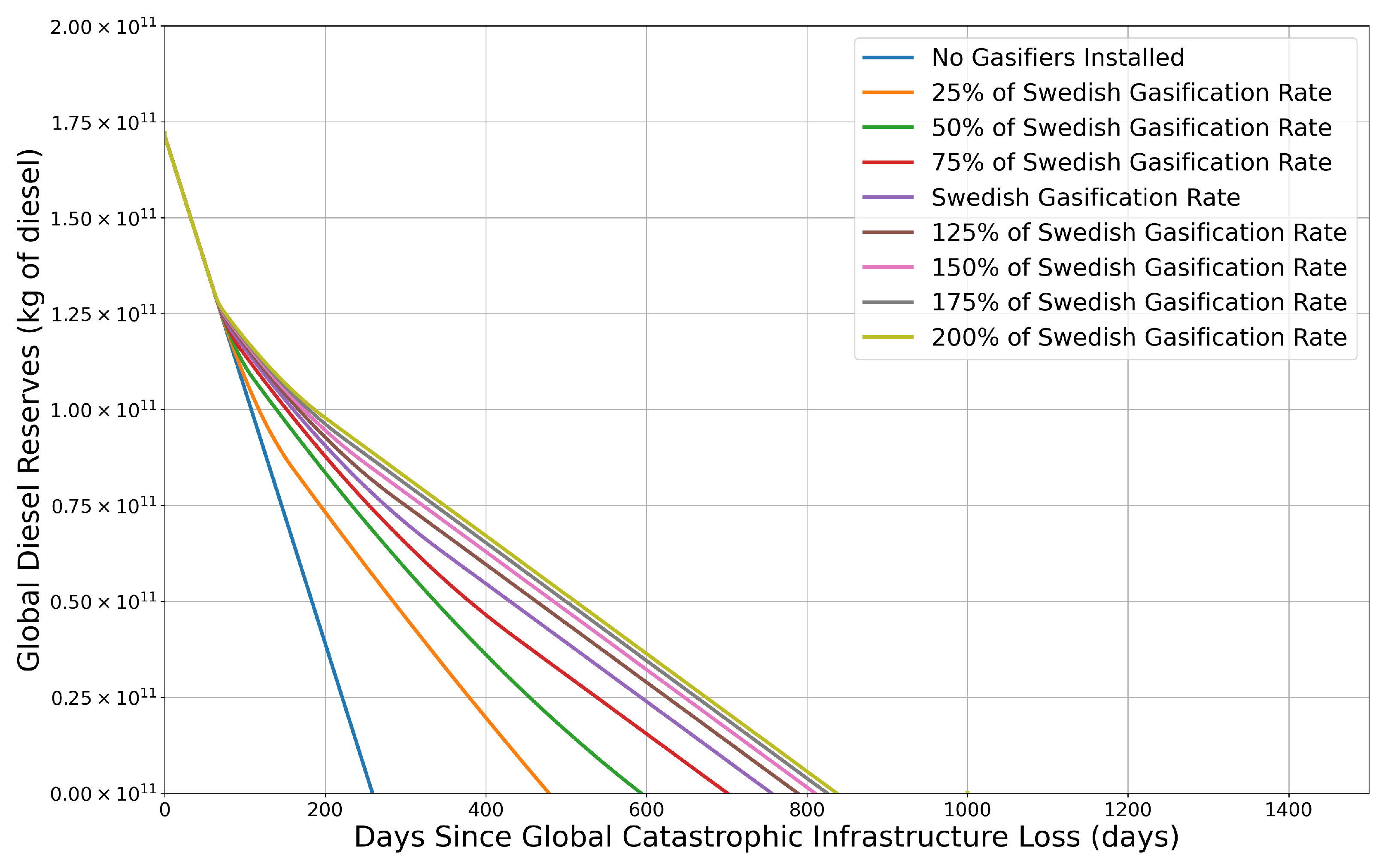

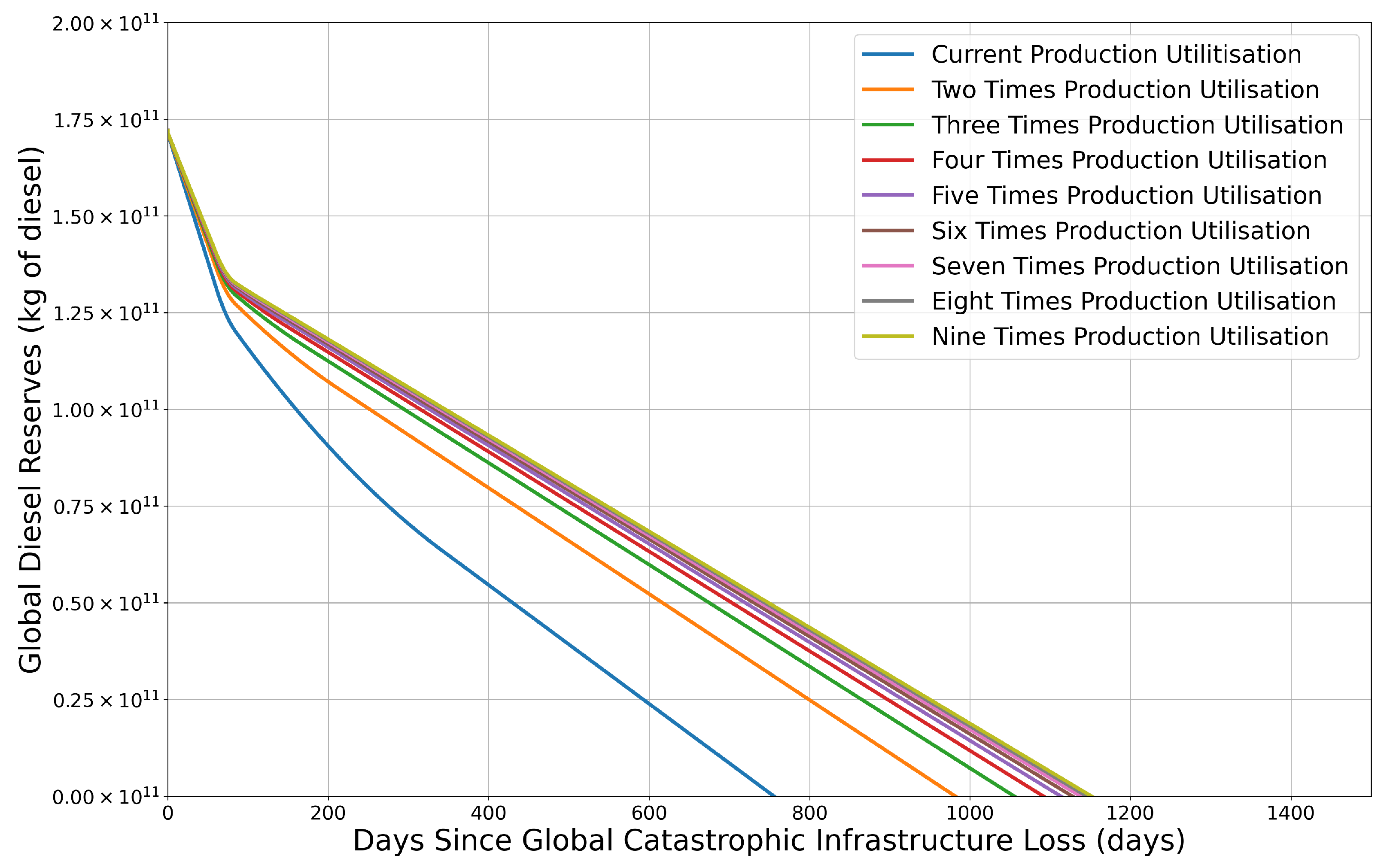

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Foster, J.; Graham, W.; Gjelde, E.; Hermann, R.; Kluepfel, H.; Lawson, R.; Soper, G. Report of the Commission to Assess the Threat to the United States from Electromagnetic Pulse (EMP) Attack; Critical National Infrastructures: Washington, DC, USA, 2008; Available online: https://apps.dtic.mil/sti/pdfs/ADA484672.pdf (accessed on 23 January 2024).

- Foti, N.; Pauls, S.; Rockmore, D.N. Stability of the World Trade Web Over Time—An Extinction Analysis. J. Econ. Dyn. Control 2013, 37, 1889–1910. [Google Scholar] [CrossRef]

- Ma, J.; Li, M.; Li, H.-J. Robustness of the International Wheat Trade Network. IEEE Trans. Netw. Sci. Eng. 2024, 11, 14–23. [Google Scholar] [CrossRef]

- Williams, A.; Hughes, J.; Black, M.; Murphy, R. Energy and the Food System. Philos. Trans. R. Soc. B 2010, 365, 2991–3006. [Google Scholar] [CrossRef]

- Pfeiffer, D. Eating Fossil Fuels: Oil, Food and the Coming Crisis in Agriculture; New Society Publishers: Gabriola Island, BC, Canada, 2006; ISBN 0865715653. [Google Scholar]

- Li, M.; Jia, N.; Lenzen, M.; Malik, A.; Raubenheimer, D. Global Food-Miles Account for Nearly 20% of Total Food-Systems Emissions. Nat. Food 2022, 3, 445–453. [Google Scholar] [CrossRef]

- Janssens-Maenhout, G.; Crippa, M.; Guizzardi, D.; Muntean, M.; Schaaf, E.; Dentener, F.; Bergamaschi, P.; Pagliari, V.; Olivier, J.; Peters, J.; et al. EDGAR v4.3.2 Global Atlas of the three major greenhouse gas emissions for the period 1970–2012. Earth Syst. Sci. Data 2019, 11, 959–1002. [Google Scholar] [CrossRef]

- Cole, D.D.; Denkenberger, D.; Griswold, M.; Abdelkhaliq, M.; Pearce, J. Feeding Everyone if Industry is Disabled. In Proceedings of the IDRC DAVOS 2016 Integrative Risk Management—Towards Resilient Cities, Davos, Switzerland, 28 August–1 September 2016. [Google Scholar]

- Moersdorf, J.; Rivers, M.; Denkenberger, D.; Breuer, L.; Jehn, F.U. The Fragile State of Industrial Agriculture: Estimating Crop Yield Reductions in a Global Catastrophic Infrastructure Loss Scenario. Glob. Challenges 2023, 8, 2300206. [Google Scholar] [CrossRef] [PubMed]

- Layton, L. Electromagnetic Pulse and Its Impact on the Electric Power Industry. PDHonline Course E402. 2020. Available online: https://pdhonline.com/courses/e402/e402content.pdf (accessed on 22 February 2024).

- Toon, O.B.; Turco, R.P.; Robock, A.; Bardeen, C.; Oman, L.; Stenchikov, G.L. Atmospheric Effects and Societal Consequences of Regional Scale Nuclear Conflicts and Acts of Individual Nuclear Terrorism. Atmos. Chem. Phys. 2007, 7, 1973–2002. [Google Scholar] [CrossRef]

- Pearce, J.; Denkenberger, D. A National Pragmatic Safety Limit for Nuclear Weapon Quantities. Safety 2018, 4, 25. [Google Scholar] [CrossRef]

- Norris, R.S.; Kristensen, H.M. Global Nuclear Stockpiles, 1945–2006. Bull. At. Sci. 2006, 62, 64–66. [Google Scholar] [CrossRef]

- Kakad, B.; Kakad, A.; Srivastava, A. Study of Particle Dynamics in Presence of Ring Current Driven Magnetic Field Variations. Adv. Space Res. 2024, 73, 2374–2386. [Google Scholar] [CrossRef]

- Crockett, C. Are We Ready? Understanding Just How Big Solar Flares Can Get. Knowable Magazine, 2021. Available online: https://knowablemagazine.org/content/article/physical-world/2021/understanding-just-how-big-solar-flares-can-get (accessed on 17 September 2021). [CrossRef]

- Ruhl, C. Global Catastrophic Biological Risks: A Guide for Philanthropists; Founders Pledge: New York, NY, USA, 2023; Available online: https://www.founderspledge.com/research/global-catastrophic-biological-risks-a-guide-for-philanthropists (accessed on 22 February 2024).

- Skov, N.A.; Papworth, M.L. DRIVING ON WOOD: The Lost Art of Driving without Gasoline; Revised 2006, with Plans for Building a WWII Gasifier; Biomass Energy Foundation Press: Franktown, CO, USA, 2006. [Google Scholar]

- The Swedish Academy of Engineering Sciences. Generator Gas: The Swedish Experience from 1939–1945; Solar Energy Research Institute: Golden, CO, USA, 1979; ISBN 1-890607-01-0. Available online: https://www.drtlud.com/?resource=prs79100 (accessed on 22 February 2024).

- Kaijser, A. Driving on wood: The Swedish transition to wood gas during World War Two. Hist. Technol. 2021, 37, 468–486. [Google Scholar] [CrossRef]

- Părăian, M.; Magyari, M.; Jurca, A.-M.; Păun, F.; Gabor, D. The Risk of Fires and Explosions during the Transport, Storage and Distribution of Diesel Fuel. Int. Multidiscip. Sci. GeoConf. SGEM 2021, 21, 124. [Google Scholar] [CrossRef]

- International Energy Agency. Oil Market Report. 16 May 2023. Available online: https://iea.blob.core.windows.net/assets/c00d5f19-f52f-47c1-82aa-6a464a688593/-16MAY2023_OilMarketReport.pdf (accessed on 25 January 2024).

- U.S. Energy Information Administration. Demand for OECD Crude Oil. 2023. Available online: https://www.eia.gov/finance/markets/crudeoil/demand-oecd.php (accessed on 22 February 2024).

- Denkenberger, D.C.; Cole, D.D.; Abdelkhaliq, M.; Griswold, M.; Hundley, A.B.; Pearce, J.M. Feeding Everyone if the Sun Is Obscured and Industry Is Disabled. Int. J. Disaster Risk Reduct. 2017, 21, 284–290. [Google Scholar] [CrossRef]

- Pan, Y.; Birdsey, R.A.; Fang, J.; Houghton, R.; Kauppi, P.E.; Kurz, W.A.; Phillips, O.L.; Shvidenko, A.; Lewis, S.L.; Canadell, J.G.; et al. A Large and Persistent Carbon Sink in the World’s Forests. Science 2011, 333, 988–993. [Google Scholar] [CrossRef] [PubMed]

- Throup, J.; García Martínez, J.B.; Bals, B.; Cates, J.; Pearce, J.M.; Denkenberger, D.C. Rapid repurposing of pulp and paper mills, biorefineries, and breweries for lignocellulosic sugar production in global food catastrophes. Food Bioprod. Process. 2022, 131, 22–39. [Google Scholar] [CrossRef]

- Martin, A.R.; Thomas, S.C. A Reassessment of Carbon Content in Tropical Trees. PLoS ONE 2011, 6, e23533. [Google Scholar] [CrossRef]

- Nurmi, J.; Hillebrand, K. The Characteristics of Whole-Tree Fuel Stocks from Silvicultural Cleanings and Thinnings. Biomass Bioenergy 2007, 31, 381–392. [Google Scholar] [CrossRef]

- Suárez-Ruiz, I.; Diez, M.A.; Rubiera, F. 1—Coal. In New Trends in Coal Conversion: Combustion, Gasification, Emissions, and Coking; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–30. [Google Scholar] [CrossRef]

- Worldometer. Coal Reserves in the World. Available online: https://www.worldometers.info/coal/#:~:text=World%20Coal%20Reserves (accessed on 25 January 2024).

- NS Energy. Coal Reserves in Australia and Other Leading Asia Pacific Producers Profiled. Available online: https://www.nsenergybusiness.com/features/australia-coal-reserves-asia-pacific/ (accessed on 25 January 2024).

- Schreiber, R. Rolling [Gasified] Coal: Gas Bag Vehicles. Available online: https://www.thetruthaboutcars.com/2014/07/rolling-gasified-coal-gas-bag-vehicles/ (accessed on 25 January 2024).

- Mansur, F.Z.; Faizal, C.K.M.; Monir, M.U.; Samad, N.A.F.A.; Atnaw, S.M.; Sulaiman, S.A. Performance Studies on Co-Gasification Between Coal/Sawdust and Coal/Wood Pellet Using RSM. IOP Conf. Ser. Mater. Sci. Eng. 2020, 736, 022085. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. FAO Statistical Database. Available online: https://www.fao.org/faostat/en/ (accessed on 25 January 2024).

- Flammini, A.; Pan, X.; Tubiello, F.N.; Qiu, S.Y.; Souza, L.R.; Quadrelli, R.; Bracco, S.; Benoit, P.; Sims, R. Emissions of Greenhouse Gases from Energy Use in Agriculture, Forestry and Fisheries: 1970–2019. Earth Syst. Sci. Data 2022, 14, 811–821. [Google Scholar] [CrossRef]

- The Engineering Toolbox. Fossil Fuels—Energy Content. Available online: https://www.engineeringtoolbox.com/fossil-fuels-energy-content-d_1298.html (accessed on 25 January 2024).

- Fuglie, K.O. Productivity Growth and Technology Capital in the Global Agricultural Economy. In Productivity Growth in Agriculture: An International Perspective; Fuglie, K.O., Ed.; CAB International: Wallingford, UK, 2012; Chapter 16; pp. 335–368. [Google Scholar] [CrossRef]

- Shi, Y. Reducing Greenhouse Gas Emissions from International Shipping: Is It Time to Consider Market-Based Measures? Mar. Policy 2016, 64, 123–134. [Google Scholar] [CrossRef]

- Statista. Amount of Fuel Consumed by Ships Worldwide by Fuel Type. Available online: https://www.statista.com/statistics/1266963/amount-of-fuel-consumed-by-ships-worldwide-by-fuel-type/ (accessed on 25 January 2024).

- Sonnek Engineering GmbH. Primary Recovery. 2023. Available online: https://sonnek.com/en/systems/modular-plants-for-enhanced-oil-recovery/phases-of-oil-production/primary-recovery/ (accessed on 13 February 2024).

- Stenger, B.; Pham, T.; Al-Afaleg, N.; Lawrence, P. Tilted Original Oil/Water Contact in the Arab-D Reservoir, Ghawar Field, Saudi Arabia. GeoArabia 2003, 8, 9–42. [Google Scholar] [CrossRef]

- Airseas. Available online: https://airseas.com/en/ (accessed on 25 January 2024).

- SkySails Marine. Available online: https://skysails-marine.com/ (accessed on 25 January 2024).

- Howitt, O.J.A.; Carruthers, M.A.; Smith, I.J.; Rodger, C.J. Carbon Dioxide Emissions from International Air Freight. Atmos. Environ. 2011, 45, 7036–7045. [Google Scholar] [CrossRef]

- Suzan, S.; Earl, T.; Frongia, T.; Mathieu, L.; Unterlohner, F. Easy Ride: Why the EU Truck CO2 Targets Are Unfit for the 2020s; Transport & Environment: Paris, France, 2021. [Google Scholar]

- Ministry for the Environment. Measuring Emissions: A Guide for Organisations: 2022 Detailed Guide; Ministry for the Environment: Wellington, New Zealand, 2022. [Google Scholar]

- Faw Jiefang Automotive Co., Ltd. Facts About Semi-Truck Engines. Available online: https://www.fawde.com/news/facts-about-semi-truck-engines.html (accessed on 25 January 2024).

- TCS Fuel. A Guide to Truck Weight, Classification, and Uses. Available online: https://www.tcsfuel.com/blog/truck-weight-classification/ (accessed on 25 January 2024).

- Walnum, H.J.; Simonsen, M. Does driving behavior matter? An analysis of fuel consumption data from heavy-duty trucks. Transp. Res. Part D Transp. Environ. 2015, 36, 107–120. [Google Scholar] [CrossRef]

- Forest Industries Division, FAO Forestry Department. The Designations Employed and the Presentation of Material in This Publication; Food and Agriculture Organization of the United Nations: Rome, Italy, 1986; ISBN 92-5-102436-7. [Google Scholar]

- Vintage Road Haulage. Frequently Asked Questions—Vintage Road Haulage. Available online: https://vrh.net.au/faq/#b3fae7090c2c35f48 (accessed on 25 January 2024).

- Our World in Data. Daily Supply of Calories per Person, 1961 to 2018. Available online: https://ourworldindata.org/grapher/daily-per-capita-caloric-supply?tab=chart&country=OWID_ASI~OWID_EUR~OWID_NAM~OWID_SAM~OWID_AFR~OWID_WRL (accessed on 25 January 2024).

- UNHCR; UNICEF; WFP; WHO. Food and Nutrition Needs in Emergencies; WHO: Geneva, Switzerland; New York, NY, USA; Rome, Italy, 2002. [Google Scholar]

- Manceron, S.; Ben-Ari, T.; Dumas, P. Feeding proteins to livestock: Global land use and food vs. feed competition. OCL 2014, 21, D408. [Google Scholar] [CrossRef]

- Alexandratos, N.; Bruinsma, J. World Agriculture Towards 2030/2050: The 2012 Revision; Food and Agriculture Organization of the United Nations: Rome, Italy, 2012; ESA Working Paper No. 12-03; Available online: https://www.fao.org/3/ap106e/ap106e.pdf (accessed on 21 February 2024).

- Andrade, T.A.; Ramírez-Márquez, C.; Ambye-Jensen, M. Process Simulation of an Integrated Green Protein Biorefinery Using Nanofiltration Membrane and Ethanol Fermentation. Sep. Purif. Technol. 2023, 327, 124887. [Google Scholar] [CrossRef]

- Davys, M.N.G.; Richardier, F.C.; Kennedy, D.; de Mathan, O.; Collin, S.M.; Subtil, J.; Bertin, E.; Davys, M.J. Leaf Concentrate and Other Benefits of Leaf Fractionation. In Combating Micronutrient Deficiencies: Food-Based Approaches; CAB International: Wallingford, UK, 2010; pp. 338–350. [Google Scholar] [CrossRef]

- Brameld, J.M.; Parr, T. Improving efficiency in meat production. Proc. Nutr. Soc. 2016, 75, 242–246. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nelson, D.; Turchin, A.; Denkenberger, D. Wood Gasification: A Promising Strategy to Extend Fuel Reserves after Global Catastrophic Electricity Loss. Biomass 2024, 4, 610-624. https://doi.org/10.3390/biomass4020033

Nelson D, Turchin A, Denkenberger D. Wood Gasification: A Promising Strategy to Extend Fuel Reserves after Global Catastrophic Electricity Loss. Biomass. 2024; 4(2):610-624. https://doi.org/10.3390/biomass4020033

Chicago/Turabian StyleNelson, David, Alexey Turchin, and David Denkenberger. 2024. "Wood Gasification: A Promising Strategy to Extend Fuel Reserves after Global Catastrophic Electricity Loss" Biomass 4, no. 2: 610-624. https://doi.org/10.3390/biomass4020033

APA StyleNelson, D., Turchin, A., & Denkenberger, D. (2024). Wood Gasification: A Promising Strategy to Extend Fuel Reserves after Global Catastrophic Electricity Loss. Biomass, 4(2), 610-624. https://doi.org/10.3390/biomass4020033