Use of Neural Networks to Identify Safety Prevention Priorities in Agro-Manufacturing Operations within Commercial Grain Elevators

Abstract

:1. Introduction

2. Literature Review

2.1. Artificial Neural Networks

2.2. Artificial Neural Networks in Occupational Safety

3. Materials and Methods

3.1. Variable Importance

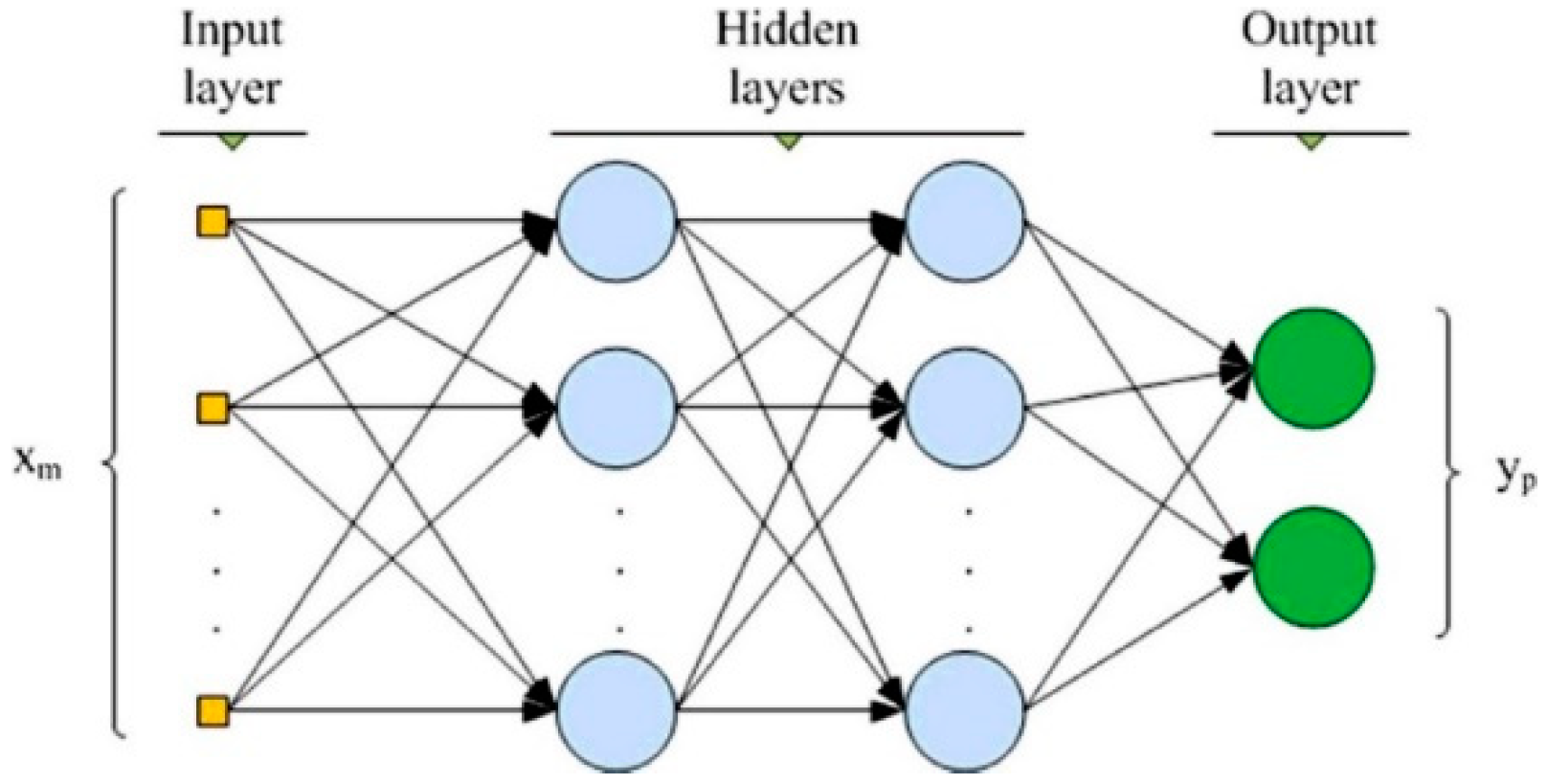

3.2. Architecture of ANNs

3.3. Model Assessment Criteria

4. Results

4.1. Model Performance

4.2. ROC and AUC Results

4.3. Sensitivity Analysis

4.4. Model Intepretation and Application in Safety

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mohammadfam, I.; Soltanzadeh, A.; Moghimbeigi, A.; Alizadeh Savareh, B. Use of Artificial Neural Networks (ANNs) for the Analysis and Modeling of Factors That Affect Occupational Injuries in Large Construction Industries. Electron. Physician 2015, 7, 1515. [Google Scholar] [CrossRef] [PubMed]

- Mekkodathil, A.; El-Menyar, A.; Al-Thani, H. Occupational Injuries in Workers from Different Ethnicities. Int. J. Crit. Illn. Inj. Sci. 2016, 6, 25. [Google Scholar] [CrossRef] [PubMed]

- Argilés-Bosch, J.M.; Martí, J.; Monllau, T.; Garcia-Blandón, J.; Urgell, T. Empirical Analysis of the Incidence of Accidents in the Workplace on Firms’ Financial Performance. Saf. Sci. 2014, 7, 123–132. [Google Scholar] [CrossRef]

- Gavious, A.; Mizrahi, S.; Shani, Y.; Minchuk, Y. The Costs of Industrial Accidents for the Organization: Developing Methods and Tools for Evaluation and Cost-Benefit Analysis of Investment in Safety. J. Loss Prev. Process Ind. 2009, 22, 434–438. [Google Scholar] [CrossRef]

- Altunkaynak, B. A Statistical Study of Occupational Accidents in the Manufacturing Industry in Turkey. Int. J. Ind. Ergon. 2018, 66, 101–109. [Google Scholar] [CrossRef]

- Amiri, M.; Ardeshir, A.; Fazel Zarandi, M.H.; Soltanaghaei, E. Pattern Extraction for High-Risk Accidents in the Construction Industry: A Data-Mining Approach. Int. J. Inj. Control Saf. Promot. 2016, 23, 264–276. [Google Scholar] [CrossRef]

- Hoła, A.; Sawicki, M.; Szóstak, M. Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis. Appl. Sci. 2018, 8, 48. [Google Scholar] [CrossRef]

- Field, W.E.; Heber, D.J.; Riedel, S.M.; Wettschurack, S.W.; Roberts, M.J.; Grafft, L.M.J. Worker Hazards Associated with the Use of Grain Vacuum Systems. J. Agric. Saf. Health 2014, 20, 147–163. [Google Scholar] [CrossRef]

- Jacinto, C.; Canoa, M.; Guedes Soares, C. Workplace and Organisational Factors in Accident Analysis within the Food Industry. Saf. Sci. 2009, 47, 626–635. [Google Scholar] [CrossRef]

- Shafique, M.; Rafiq, M. An Overview of Construction Occupational Accidents in Hong Kong: A Recent Trend and Future Perspectives. Appl. Sci. 2019, 9, 2069. [Google Scholar] [CrossRef]

- Geng, Y.; Dee Jepsen, S. Current Grain Storage and Safety Practices of Ohio Cash Grain Operators. J. Agric. Saf. Health 2018, 24, 127–139. [Google Scholar] [CrossRef] [PubMed]

- Douphrate, D.I.; Rosecrance, J.C.; Wahl, G. Workers’ Compensation Experience of Colorado Agriculture Workers, 2000–2004. Am. J. Ind. Med. 2006, 49, 900–910. [Google Scholar] [CrossRef] [PubMed]

- Williams, G.D.; Rosentrater, K.A. Design Considerations for the Construction and Operation of Flour Milling Facilities. Part I: Planning, Structural, and Life Safety Considerations. In 2007 ASABE Annual International Meeting, Technical Papers; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007. [Google Scholar]

- Ramaswamy, S.K.; Mosher, G.A. Using Workers’ Compensation Claims Data to Characterize Occupational Injuries in the Commercial Grain Elevator Industry. J. Agric. Saf. Health 2017, 23, 203–217. [Google Scholar] [CrossRef] [PubMed]

- Davoudi Kakhki, F.; Freeman, S.A.; Mosher, G.A. Use of Logistic Regression to Identify Factors Influencing the Post-Incident State of Occupational Injuries in Agribusiness Operations. Appl. Sci. 2019, 9, 3449. [Google Scholar] [CrossRef]

- Davoudi Kakhki, F.; Freeman, S.; Mosher, G. Segmentation of Severe Occupational Incidents in Agribusiness Industries Using Latent Class Clustering. Appl. Sci. 2019, 9, 3641. [Google Scholar] [CrossRef]

- Davoudi Kakhki, F.; Freeman, S.; Mosher, G. Analyzing Large Workers’ Compensation Claims Using Generalized Linear Models and Monte Carlo Simulation. Safety 2018, 4, 57. [Google Scholar] [CrossRef]

- Mosher, G.A.; Keren, N.; Freeman, S.A.; Hurburgh, C.R. Development of a Safety Decision-Making Scenario to Measure Worker Safety in Agriculture. J. Agric. Saf. Health 2014, 20, 91–107. [Google Scholar] [CrossRef]

- Davoudi Kakhki, F.; Freeman, S.A.; Mosher, G.A. Evaluating Machine Learning Performance in Predicting Injury Severity in Agribusiness Industries. Saf. Sci. 2019, 117, 257–262. [Google Scholar] [CrossRef]

- Yao, J.T. Sensitivity Analysis for Data Mining. In Proceedings of the Annual Conference of the North American Fuzzy Information Processing Society—NAFIPS, Chicago, IL, USA, 24–26 July 2003. [Google Scholar] [CrossRef]

- Buscema, P.M.; Massini, G.; Breda, M.; Lodwick, W.A.; Newman, F.; Asadi-Zeydabadi, M. Artificial Neural Networks. In Studies in Systems, Decision and Control; PHI Learning Pvt. Ltd.: New Delhi, India, 2018. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Ebadi, M.; Hosseini, S.M. Prediction Breakthrough Time of Water Coning in the Fractured Reservoirs by Implementing Low Parameter Support Vector Machine Approach. Fuel 2014, 117, 579–589. [Google Scholar] [CrossRef]

- Santos, R.B.; Rupp, M.; Bonzi, S.J.; Fileti, A.M.F. Comparison between Multilayer Feedforward Neural Networks and a Radial Basis Function Network to Detect and Locate Leaks in Pipelines Transporting Gas. Chem. Eng. Trans. 2013, 32, e1380. [Google Scholar] [CrossRef]

- Dong, Y.; Hu, Z.; Uchimura, K.; Murayama, N. Driver Inattention Monitoring System for Intelligent Vehicles: A Review. IEEE Trans. Intell. Transp. Syst. 2011, 12, 596–614. [Google Scholar] [CrossRef]

- Jacobé de Naurois, C.; Bourdin, C.; Stratulat, A.; Diaz, E.; Vercher, J.L. Detection and Prediction of Driver Drowsiness Using Artificial Neural Network Models. Accid. Anal. Prev. 2019, 126, 96–104. [Google Scholar] [CrossRef] [PubMed]

- Patel, D.A.; Jha, K.N. Neural Network Model for the Prediction of Safe Work Behavior in Construction Projects. J. Constr. Eng. Manag. 2014, 114, 04014006. [Google Scholar] [CrossRef]

- IBM SPSS Neural Networks—Smit Consult. Available online: https://www.smitconsult.nl/en/products/ibm-spss-statistics/info/ibm-spss-neural-networks/ (accessed on 25 September 2019).

- Tatar, A.; Naseri, S.; Bahadori, M.; Hezave, A.Z.; Kashiwao, T.; Bahadori, A.; Darvish, H. Prediction of Carbon Dioxide Solubility in Ionic Liquids Using MLP and Radial Basis Function (RBF) Neural Networks. J. Taiwan Inst. Chem. Eng. 2016, 60, 151–164. [Google Scholar] [CrossRef]

- Tatar, A.; Shokrollahi, A.; Mesbah, M.; Rashid, S.; Arabloo, M.; Bahadori, A. Implementing Radial Basis Function Networks for Modeling CO2-Reservoir Oil Minimum Miscibility Pressure. J. Nat. Gas Sci. Eng. 2013, 15, 82–92. [Google Scholar] [CrossRef]

- Geronimo, T.M.; Cruz, C.E.; de Souza Campos, F.; Aguiar, P.R.; Bianchi, E.C. MLP and ANFIS Applied to the Prediction of Hole Diameters in the Drilling Process. Artificial Neural Networks—Architectures and Applications. 2013. Available online: https://www.intechopen.com/books/artificial-neural-networks-architectures-and-applications/mlp-and-anfis-applied-to-the-prediction-of-hole-diameters-in-the-drilling-process (accessed on 4 November 2019). [CrossRef] [Green Version]

- Du, K.L.; Swamy, M.N.S. Neural Networks in a Softcomputing Framework; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- Abdelwahab, H.T.; Abdel-Aty, M.A. Artificial Neural Networks and Logit Models for Traffic Safety Analysis of Toll Plazas. Transp. Res. Rec. 2002, 1784, 115–125. [Google Scholar] [CrossRef]

- Roh, S.B.; Oh, S.K.; Pedrycz, W.; Seo, K.; Fu, Z. Design Methodology for Radial Basis Function Neural Networks Classifier Based on Locally Linear Reconstruction and Conditional Fuzzy C-Means Clustering. Int. J. Approx. Reason. 2019, 116, 228–243. [Google Scholar] [CrossRef]

- Jed Frees, E.W.; Derrig, R.A.; Meyers, G. Predictive Modeling in Actuarial Science. In Predictive Modeling Applications in Actuarial Science: Volume I: Predictive Modeling Techniques; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- Parsaie, A.; Haghiabi, A.H.; Saneie, M.; Torabi, H. Applications of Soft Computing Techniques for Prediction of Energy Dissipation on Stepped Spillways. Neural Comput. Appl. 2018, 29, 1393–1409. [Google Scholar] [CrossRef]

- Ian, H.; Frank, E. Data Mining: Practical Machine Learning Tools and Techniques; Morgan Kaufmann: Burlington, MA, USA, 2011; ISBN 9780120884070. [Google Scholar]

- Mannering, F. Temporal Instability and the Analysis of Highway Accident Data. Anal. Methods Accid. Res. 2018, 17, 1–13. [Google Scholar] [CrossRef]

- Durán-Rosal, A.M.; Fernández, J.C.; Casanova-Mateo, C.; Sanz-Justo, J.; Salcedo-Sanz, S.; Hervás-Martínez, C. Efficient Fog Prediction with Multi-Objective Evolutionary Neural Networks. Appl. Soft Comput. J. 2018, 70, 347–358. [Google Scholar] [CrossRef]

- Carrillo-Castrillo, J.A.; Guadix Martín, J.; Grosso de la Vega, R.; Onieva, L. Neural Network Application for Risk Factors Estimation in Manufacturing Accidents; Springer: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Moghaddam, F.R.; Afandizadeh, S.; Ziyadi, M. Prediction of Accident Severity Using Artificial Neural Networks. Int. J. Civ. Eng. 2011, 9, 41. [Google Scholar]

- Delen, D.; Sharda, R.; Bessonov, M. Identifying Significant Predictors of Injury Severity in Traffic Accidents Using a Series of Artificial Neural Networks. Accid. Anal. Prev. 2006, 38, 434–444. [Google Scholar] [CrossRef] [PubMed]

- Asensio-Cuesta, S.; Diego-Mas, J.A.; Alcaide-Marzal, J. Applying Generalised Feedforward Neural Networks to Classifying Industrial Jobs in Terms of Risk of Low Back Disorders. Int. J. Ind. Ergon. 2010, 40, 629–635. [Google Scholar] [CrossRef]

- Zurada, J.; Karwowski, W.; Marras, W.S. A Neural Network-Based System for Classification of Industrial Jobs with Respect to Risk of Low Back Disorders Due to Workplace Design. Appl. Ergon. 1997, 28, 49–58. [Google Scholar] [CrossRef]

- Darvishi, E.; Khotanlou, H.; Khoubi, J.; Giahi, O.; Mahdavi, N. Prediction Effects of Personal, Psychosocial, and Occupational Risk Factors on Low Back Pain Severity Using Artificial Neural Networks Approach in Industrial Workers. J. Manip. Physiol. Ther. 2017, 40, 486–493. [Google Scholar] [CrossRef] [PubMed]

- Aliabadi, M.; Farhadian, M.; Darvishi, E. Prediction of Hearing Loss among the Noise-Exposed Workers in a Steel Factory Using Artificial Intelligence Approach. Int. Arch. Occup. Environ. Health 2015, 88, 779–787. [Google Scholar] [CrossRef]

- Shankar Beriha, G.; Patnaik, B.; Shankar Mahapatra, S. Assessment of Occupational Health Practices in Indian Industries: A Neural Network Approach. J. Model. Manag. 2012, 7, 180–200. [Google Scholar] [CrossRef]

- Liu, T.I.; Kumagai, A.; Lee, C. Enhancement of Drilling Safety and Quality Using Online Sensors and Artificial Neural Networks. Int. J. Occup. Saf. Ergon. 2003, 9, 37–56. [Google Scholar] [CrossRef]

- Lim, T.-K.; Park, S.-M.; Lee, H.-C.; Lee, D.-E. Artificial Neural Network—Based Slip-Trip Classifier Using Smart Sensor for Construction Workplace. J. Constr. Eng. Manag. 2015, 142, 04015065. [Google Scholar] [CrossRef]

- Bradley, A.P. The Use of the Area under the ROC Curve in the Evaluation of Machine Learning Algorithms. Pattern Recognit. 1997, 40, 1145–1159. [Google Scholar] [CrossRef]

- Swets, J.A. Measuring the Accuracy of Diagnostic Systems. Science 1988, 240, 1285–1295. [Google Scholar] [CrossRef] [PubMed]

- Tien Bui, D.; Pham, B.T.; Nguyen, Q.P.; Hoang, N.D. Spatial Prediction of Rainfall-Induced Shallow Landslides Using Hybrid Integration Approach of Least-Squares Support Vector Machines and Differential Evolution Optimization: A Case Study in Central Vietnam. Int. J. Digit. Earth 2016, 9, 1077–1097. [Google Scholar] [CrossRef]

- Tsangaratos, P.; Ilia, I. Landslide Susceptibility Mapping Using a Modified Decision Tree Classifier in the Xanthi Perfection, Greece. Landslides 2016, 13, 305–320. [Google Scholar] [CrossRef]

- Yesilnacar, E.; Topal, T. Landslide Susceptibility Mapping: A Comparison of Logistic Regression and Neural Networks Methods in a Medium Scale Study, Hendek Region (Turkey). Eng. Geol. 2005, 75, 251–266. [Google Scholar] [CrossRef]

- Choi, J.Y.; Yoo, T.K.; Seo, J.G.; Kwak, J.; Um, T.T.; Rim, T.H. Multi-Categorical Deep Learning Neural Network to Classify Retinal Images: A Pilot Study Employing Small Database. PLoS ONE 2017, 12, e0187336. [Google Scholar] [CrossRef]

- Deng, J.; Berg, A.C.; Li, K.; Fei-Fei, L. What Does Classifying More than 10,000 Image Categories Tell Us? In European Conference on Computer Vision; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Li, Z.; Liu, P.; Wang, W.; Xu, C. Using Support Vector Machine Models for Crash Injury Severity Analysis. Accid. Anal. Prev. 2012, 45, 478–486. [Google Scholar] [CrossRef]

- Pianosi, F.; Wagener, T. A Simple and Efficient Method for Global Sensitivity Analysis Based Oncumulative Distribution Functions. Environ. Model. Softw. 2015, 67, 1–11. [Google Scholar] [CrossRef]

- Harrington, P.D.B.; Wan, C. Sensitivity Analysis Applied to Artificial Neural Networks: What Has My Neural Network Actually Learned? Anal. Chem. 2002, 70, 2983–2990. [Google Scholar]

- Booth-Kewley, S.; Schmied, E.A.; Highfill-McRoy, R.M.; Sander, T.C.; Blivin, S.J.; Garland, C.F. A Prospective Study of Factors Affecting Recovery from Musculoskeletal Injuries. J. Occup. Rehabil. 2014, 24, 287–296. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, S. Musculoskeletal Risk Factors in Cleaning Occupation-A Literature Review. Int. J. Ind. Ergon. 2008, 38, 158–170. [Google Scholar] [CrossRef]

- Arocena, P.; Núñez, I.; Villanueva, M. The Impact of Prevention Measures and Organisational Factors on Occupational Injuries. Saf. Sci. 2008, 49, 1369–1384. [Google Scholar] [CrossRef]

- Mohammadfam, I.; Soltanzadeh, A.; Moghimbeigi, A.; Akbarzadeh, M. Factors Affecting Occupational Accidents in the Construction Industry (2009–2013). J. Occup. Health Epidemiol. 2014, 3, 88–95. [Google Scholar] [CrossRef]

- Bernacki, E.J. Factors Influencing the Costs of Workers’ Compensation. Clin. Occup. Environ. Med. 2004, 4, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Moradhaseli, S.; Farhadian, H.; Abbasi, E.; Ghofranipour, F. Factors Affecting the Incidence of Occupational Accidents among Farmers. Health Educ. Health Promot. 2017, 5, 39–56. [Google Scholar]

- Chercos, D.H.; Berhanu, D. Work Related Injury among Saudi Star Agro Industry Workers in Gambella Region, Ethiopia; a Cross-Sectional Study. J. Occup. Med. Toxicol. 2017, 12, 7. [Google Scholar] [CrossRef] [PubMed]

- Molineri, A.; Signorini, M.L.; Tarabla, H.D. Risk Factors for Work-Related Injury among Farm Workers: A 1-Year Study. Rural Remote Health 2015, 15, 1–8. [Google Scholar]

- Jadhav, R.; Achutan, C.; Haynatzki, G.; Rajaram, S.; Rautiainen, R. Injury Risk Factors to Farm and Ranch Operators in the Central United States. Am. J. Ind. Med. 2017, 60, 889–899. [Google Scholar] [CrossRef]

- Swaen, G.M.H.; Van Amelsvoort, L.G.P.M.; Bültmann, U.; Kant, I.J. Fatigue as a Risk Factor for Being Injured in an Occupational Accident: Results from the Maastricht Cohort Study. Occup. Environ. Med. 2003, 60, 88–92. [Google Scholar] [CrossRef]

- Ramaswamy, S.K.; Mosher, G.A. Using Workers’ Compensation Claims Data to Characterize Occupational Injuries in the Biofuels Industry. Saf. Sci. 2018, 103, 352–360. [Google Scholar] [CrossRef]

- Mehrdad, R.; Seifmanesh, S.; Chavoshi, F.; Aminian, O.; Izadi, N. Epidemiology of Occupational Accidents in Iran Based on Social Security Organization Database. Iran. Red Crescent Med. J. 2014, 16, e10359. [Google Scholar] [CrossRef] [Green Version]

| Independent Variable | Chi-Square (χ2) | p-Value |

|---|---|---|

| Type of injury | 316.077 | <0.0001 * |

| Nature of injury | 7544.33 | <0.0001 * |

| Class Description | 145.63 | <0.0001 * |

| Age | 253.07 | <0.0001 * |

| Experience | 60.78 | <0.0001 * |

| Gender | 7.97 | 0.1578 |

| Layer | Structure Criteria | MLP | RBF |

|---|---|---|---|

| Input Layer | Factors | Injury Nature | Injury Nature |

| Class Description | Class Description | ||

| Injury Type | Injury Type | ||

| Experience | Experience | ||

| Age | Age | ||

| Number of Units | 4688 | 4679 | |

| Hidden Layer(s) | Number of Hidden Layers | 2 | 1 |

| Number of Units in Hidden Layer | 12 | 10 * | |

| Activation Function | Hyperbolic tangent | Softmax | |

| Output Layer | Dependent Variables | Cause Group | Cause Group |

| Number of Units | 6 | 6 | |

| Activation Function | Softmax | Identity | |

| Error Function | Cross-entropy | Sum of Squares |

| Data Set | Criteria | MLP | RBF |

|---|---|---|---|

| Train | Sum of Squares Error | N/A | 1161.041 |

| Cross Entropy Error | 3867.614 | N/A | |

| Percent Incorrect Predictions | 35.2% | 39.4% | |

| Overall Accuracy | 64.8% | 60.6% | |

| Test | Sum of Squares Error | N/A | 236.173 |

| Cross Entropy Error | 819.830 | N/A | |

| Percent Incorrect Predictions | 38.6% | 40.5% | |

| Overall Accuracy | 61.4% | 59.5% |

| Classification | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Observed | Predicted | ||||||

| Caught In, Under, or Between | Cut, Puncture, Scrape | Fall, Slip, or Trip Injury | Heat or Cold Exposures | Strain or Injury by | Struck or Injured by | Percent Correct | ||

| Train | Caught In, Under, or Between | 4 | 46 | 69 | 2 | 12 | 53 | 2.2% |

| Cut, Puncture, Scrape | 0 | 473 | 24 | 1 | 1 | 24 | 90.4% | |

| Fall, Slip, or Trip Injury | 1 | 70 | 746 | 2 | 486 | 97 | 53.2% | |

| Heat or Cold Exposures | 0 | 1 | 12 | 177 | 3 | 18 | 83.9% | |

| Strain or Injury by | 0 | 2 | 159 | 3 | 1331 | 9 | 88.5% | |

| Struck or Injured by | 0 | 135 | 282 | 3 | 56 | 155 | 24.6% | |

| Overall Percent | 0.1% | 16.3% | 29.0% | 4.2% | 42.4% | 8.0% | 64.8% | |

| Test | Caught In, Under, or Between | 2 | 5 | 18 | 0 | 1 | 14 | 5.0% |

| Cut, Puncture, Scrape | 0 | 93 | 6 | 0 | 1 | 8 | 86.1% | |

| Fall, Slip, or Trip Injury | 0 | 12 | 143 | 1 | 98 | 30 | 50.4% | |

| Heat or Cold Exposures | 0 | 1 | 4 | 28 | 1 | 3 | 75.7% | |

| Strain or Injury by | 0 | 0 | 38 | 2 | 233 | 3 | 84.4% | |

| Struck or Injured by | 0 | 29 | 52 | 0 | 10 | 37 | 28.9% | |

| Overall Percent | 0.2% | 16.0% | 29.9% | 3.6% | 39.4% | 10.9% | 61.4% | |

| Classification | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Observed | Predicted | ||||||

| Caught In, Under, or Between | Cut, Puncture, Scrape | Fall, Slip, or Trip Injury | Heat or Cold Exposures | Strain or Injury by | Struck or Injured by | Percent Correct | ||

| Train | Caught In, Under, or Between | 0 | 30 | 126 | 0 | 8 | 9 | 0.0% |

| Cut, Puncture, Scrape | 0 | 438 | 104 | 0 | 0 | 4 | 80.2% | |

| Fall, Slip, or Trip Injury | 0 | 75 | 804 | 0 | 447 | 66 | 57.8% | |

| Heat or Cold Exposures | 0 | 0 | 44 | 167 | 0 | 0 | 79.1% | |

| Strain or Injury by | 0 | 1 | 266 | 0 | 1213 | 3 | 81.8% | |

| Struck or Injured by | 0 | 93 | 435 | 0 | 36 | 61 | 9.8% | |

| Overall Percent | 0.0% | 14.4% | 40.2% | 3.8% | 38.5% | 3.2% | 60.6% | |

| Test | Caught In, Under, or Between | 0 | 12 | 40 | 0 | 1 | 2 | 0.0% |

| Cut, Puncture, Scrape | 0 | 85 | 19 | 0 | 0 | 0 | 81.7% | |

| Fall, Slip, or Trip Injury | 0 | 7 | 167 | 0 | 80 | 13 | 62.5% | |

| Heat or Cold Exposures | 0 | 0 | 10 | 30 | 0 | 0 | 75.0% | |

| Strain or Injury by | 0 | 1 | 45 | 0 | 234 | 0 | 83.6% | |

| Struck or Injured by | 0 | 29 | 88 | 0 | 9 | 6 | 4.5% | |

| Overall Percent | 0.0% | 15.3% | 42.0% | 3.4% | 36.9% | 2.4% | 59.5% | |

| ANN Model | Cause Group | AUC |

|---|---|---|

| MLP | Caught In, Under, or Between | 0.822 |

| Cut, Puncture, Scrape | 0.961 | |

| Fall, Slip, or Trip Injury | 0.757 | |

| Heat or Cold Exposures | 0.992 | |

| Strain or Injury by | 0.900 | |

| Struck or Injured by | 0.825 | |

| RB | Caught In, Under, or Between | 0.739 |

| Cut, Puncture, Scrape | 0.952 | |

| Fall, Slip, or Trip Injury | 0.715 | |

| Heat or Cold Exposures | 0.987 | |

| Strain or Injury by | 0.887 | |

| Struck or Injured by | 0.792 |

| Variable | RFB | MLP | ||

|---|---|---|---|---|

| Importance | Normalized Importance | Importance | Normalized Importance | |

| Injury Nature | 0.699 | 100.0% | 0.464 | 100.0% |

| Class Description | 0.080 | 11.4% | 0.126 | 27.1% |

| Injury Type | 0.204 | 29.2% | 0.063 | 13.5% |

| Experience | 0.012 | 1.7% | 0.170 | 36.7% |

| Age | 0.005 | 0.8% | 0.178 | 38.3% |

| Nature | Age | Experience | Strain or Injury by | Fall, Slip, or Trip Injury | Struck or Injured by | Cut, Puncture, Scrap | Cut, Puncture, Scrap | Caught in, Under, or Between | Final Predicted Cause Group |

|---|---|---|---|---|---|---|---|---|---|

| amputation | 43 | 6.5 | 0.00 | 0.00 | 0.20 | 0.46 | 0.16 | 0.18 | cut, puncture, scrap |

| hernia | 43 | 6.5 | 0.88 | 0.12 | 0.00 | 0.00 | 0.00 | 0.00 | strain or injury by |

| crushing | 43 | 6.5 | 0.00 | 0.01 | 0.43 | 0.02 | 0.00 | 0.53 | caught in, under, or between |

| puncture | 53 | 16 | 0.00 | 0.14 | 0.43 | 0.31 | 0.00 | 0.11 | struck or injured by |

| hearing loss | 53 | 16 | 0.00 | 0.00 | 0.01 | 0.01 | 0.98 | 0.00 | heat or cold exposures |

| fracture | 53 | 9 | 0.03 | 0.78 | 0.15 | 0.00 | 0.00 | 0.03 | fall, slip, or trip injury |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Davoudi Kakhki, F.; Freeman, S.A.; Mosher, G.A. Use of Neural Networks to Identify Safety Prevention Priorities in Agro-Manufacturing Operations within Commercial Grain Elevators. Appl. Sci. 2019, 9, 4690. https://doi.org/10.3390/app9214690

Davoudi Kakhki F, Freeman SA, Mosher GA. Use of Neural Networks to Identify Safety Prevention Priorities in Agro-Manufacturing Operations within Commercial Grain Elevators. Applied Sciences. 2019; 9(21):4690. https://doi.org/10.3390/app9214690

Chicago/Turabian StyleDavoudi Kakhki, Fatemeh, Steven A. Freeman, and Gretchen A. Mosher. 2019. "Use of Neural Networks to Identify Safety Prevention Priorities in Agro-Manufacturing Operations within Commercial Grain Elevators" Applied Sciences 9, no. 21: 4690. https://doi.org/10.3390/app9214690