Application and Modification of Clay Minerals

A special issue of Materials (ISSN 1996-1944).

Deadline for manuscript submissions: 1 December 2024 | Viewed by 4391

Special Issue Editor

Special Issue Information

Dear Colleagues,

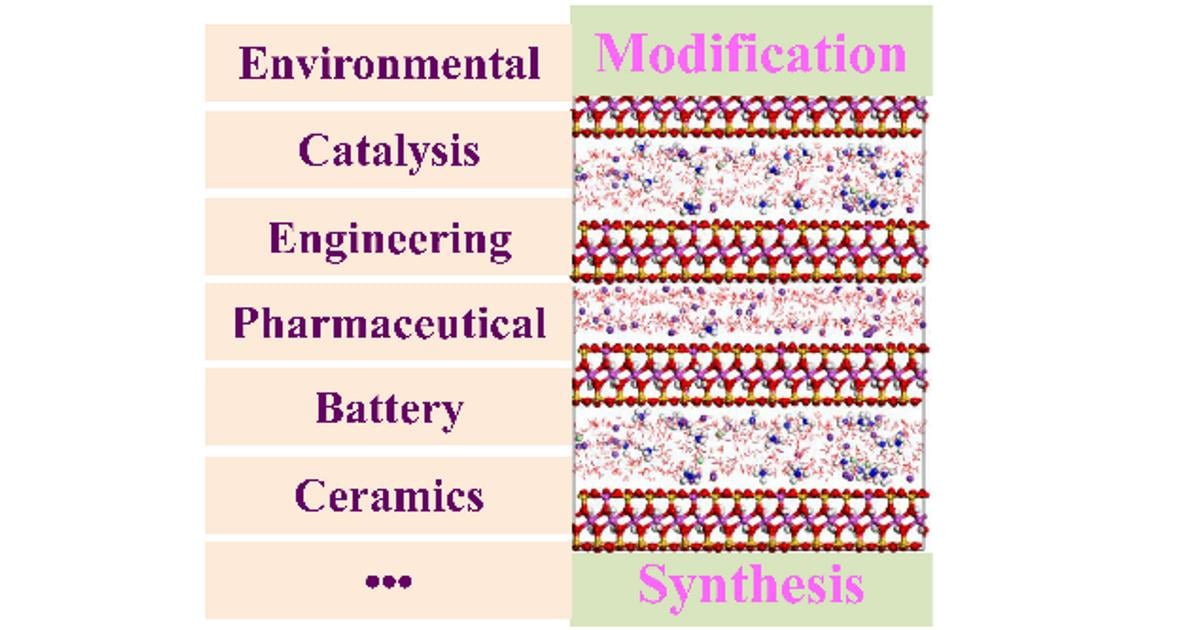

Clay minerals are a group of minerals that are ubiquitously found in soils, sediments, and rocks. Natural clay minerals are scavengers for heavy metals and organic contaminants, and catalysts for reactions such as the degradation of organic contaminants, oil and gas formation, and the condensation of amino acids. Modification and oriented synthesis broaden the applications of clay minerals and also enhance their adsorption and catalytic performances. Overall, clay minerals have a wide range of applications and can be modified to suit specific needs in various engineering and industrial processes. Their unique properties make them valuable materials for a variety of purposes.

This Special Issue of the journal Materials, entitled “Application and Modification of Clay Minerals”, focuses on recent advances in the application of modified and synthesized clay minerals in environmental, catalytic, engineering, pharmaceutical and other fields. As the Guest Editor of this Special Issue, I am inviting you to contribute your work on clay mineral materials to this Special Issue, whose scope includes, but is not limited to, the following topics: the modification/synthesis of clay mineral materials, and the adsorption/catalysis/characterization of clay mineral materials.

Your contributions are highly appreciated.

Dr. Gang Yang

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- adsorption

- catalysis

- characterization

- modeling

- modification

- synthesis

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.

Further information on MDPI's Special Issue polices can be found here.

Planned Papers

The below list represents only planned manuscripts. Some of these manuscripts have not been received by the Editorial Office yet. Papers submitted to MDPI journals are subject to peer-review.

Title: Preparation of mesoporous analcime/sodalite composite from natural Jordanian kaolin

Authors: Muayad Esaifan; Fayez Al Daboobi; Mohammed Khair Hourani

Affiliation: Department of Chemistry, Faculty of Art and Sciences, University of Petra, Amman 11196, Jordan

Abstract: In this work meso-macroporous analcime/sodalite zeolite composite was produced by hybrid synthesis process between complex template method and hydrothermal treatment at 220 °C of naturally abundant koalinitic rich clay using dodecyltrimethylammonium bromide as organic soft template to enhance the mesoporous structure. The chemical and morphological properties of the developed zeolites composite was characterized using powder X-ray diffraction (PXRD), attenuated total Reflectance-Fourier transform infrared spectroscopy (ATR-FTIR), thermogravimetric analysis (TGA), N2 adsorption/desorption and scanning electron microscopy with energy dispersive spectroscopy (SEM-EDS) methods were used to study the morphology, chemical composition and structure of the product. Two types of zeolite particles were obtained, (1) hollow microsphere with attached analcime icositetrahedron of 30 - 40 µm in size and (2) sodalite microsphere with ball-like morphology of 3-4 µm in size. Both N2 adsorption/desorption and surface area data confirmed the ability of the produced zeolite composite to act as excellent adsorbent to remove inorganic and organic pollutants from water and their high catalytic activity.