Materials Containing Silicon, Its Inorganic Derivatives, Functional Silanes, and/or Organosilicon Polymers

A special issue of Materials (ISSN 1996-1944). This special issue belongs to the section "Materials Chemistry".

Deadline for manuscript submissions: 20 November 2024 | Viewed by 4238

Special Issue Editor

Interests: science and technology of polymers and plastics, with focus on chemistry and technology of organosilicon, organo-metallic and inorganic polymers (silicones, etc.); silane coupling agents (SCA); synthesis of functional silanes, polymers and their characterization; modification of inorganic fillers with functional silanes, silicates and silicones; modification of polymers and polymeric materials by chemical and physical methods; epoxy resins, polyurethane foams, fire resistant polymers and composites, nanocomposites; chemical and antimicrobial (antibacterial and antifungal) modifications of properties of textile materials, barrier protection of textiles and garments against UV radiation, preparation of polymeric membranes for water desalination and purification

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

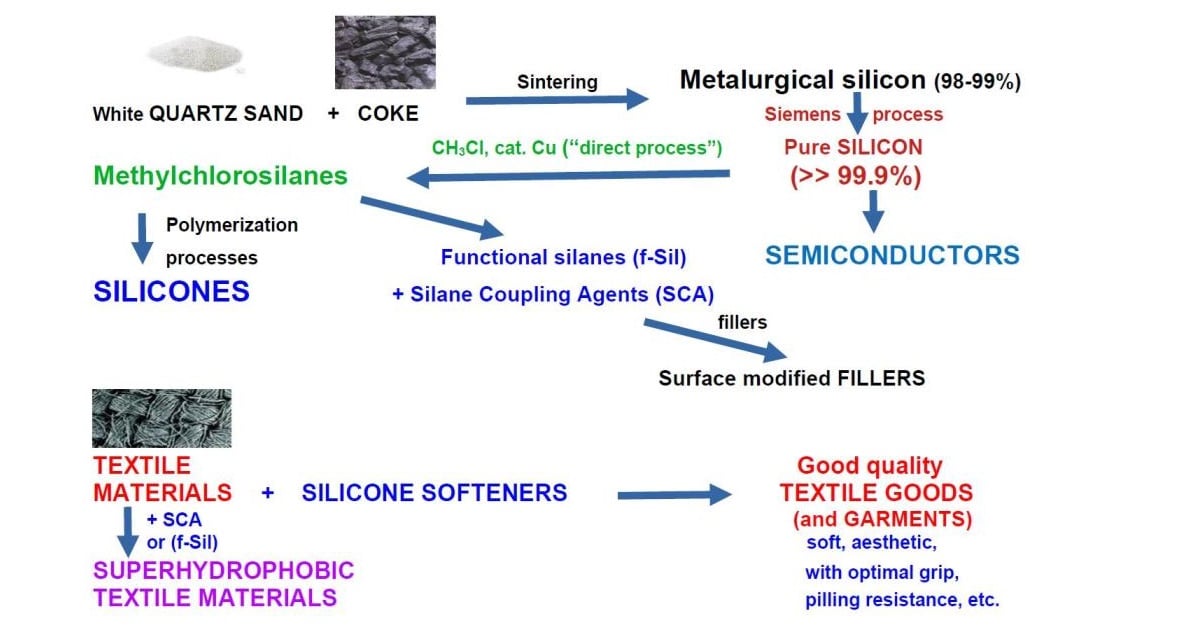

A semiconductive pure silicon is used as a basic electronic material for production of computer chips and other electronic devices.

Many functional silanes of different chemical structures containing reactive groups, mostly bound to silicon atom, but also quite often attached to carbon atom are applied for modification of surface properties of different polymeric and inorganic materials, e.g., fillers.

Silicones (polysiloxanes), containing silicon and oxygen atoms in their main chains and organic substituents bound to silicon, are a large and most important group of various inorganic-organic (hybrid) compounds and materials. Mainly poly(dimethylsiloxanes) (PDMS) are used. Silicones are applied as oils, rubbers, and resins (W. Noll, 1968; M.A. Brook, 2000). They have many unusual features - they exhibit excellent chemical, physical, and electrical properties. Even an addition of a very small amount of silicones causes a crucial improvement of properties of modified materials. Silicones increase hydrophobicity and improve water resistance and thermal stability of many materials.

Other organosilicon polymers, and especially, polysilanes, polycarbosilanes, and polysilazanes, are raw materials for fabrication of polymer-derived high-tech ceramic materials. Silicon-based polymers and polymeric materials as well as reactive silane coupling agents are used in many fields – from industry, through everyday life commodity goods and cosmetics, to medicine. Their universal properties decide that they are very useful and attractive materials and components in a very wide range of products.

A continuously growing interest in applications of reactive silanes, all kinds of silicones, chemically modified nanosilica, different composites, silicon photovoltaic cells, and silicon nanowires has been still observed in many different fields of science, the chemical technology, and especially in materials science. Original contributions and reviews are welcome.

Dr. Jerzy J. Chruściel

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- silica annd silicates - applications in materials science

- silicon containing polymers and materials

- chemistry, technology and applications of silicones

- applications of silane coupling agents (SCA)

- polysilsesquioxanes (POSS)

- modification of polymeric materials with silanes, silicates and silicones

- nanomaterials, composites and nanocomposites

- superhydrofobic materials

- medical applications of silicones

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.

Further information on MDPI's Special Issue polices can be found here.