Smart Production Operations Management and Industry 4.0

A topical collection in Sustainability (ISSN 2071-1050). This collection belongs to the section "Sustainable Management".

Viewed by 220650Editors

Interests: industrial systems engineering; operations

Special Issues, Collections and Topics in MDPI journals

Interests: operations management; smart manufacturing; digitalization; sustainability

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

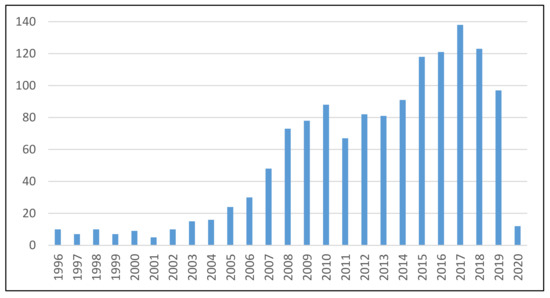

This Special Issue aims to investigate and advance our understanding of the impacts of recent technological developments based on the fourth industrial revolution (also known as Industry 4.0) on the evolution of operations and supply chain management.

In this context, the Special Issue focuses on novel theories, researches, case studies, and literature reviews exploring the changes in business models, strategies, and management modus operandi of firms fostering sustainability principles in the new digital era.

This Special Issue will investigate these emerging challenges across multiple sectors and different industries.

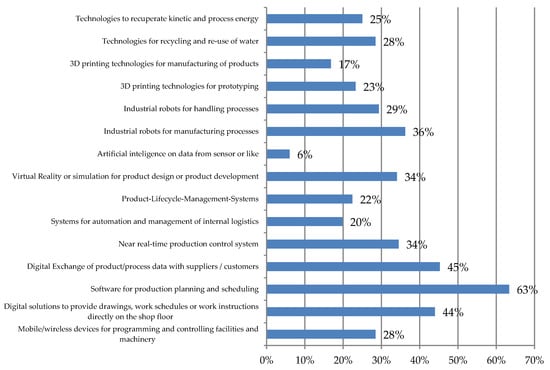

The smart technologies for operations and supply chain management—in both the domains of information technology (IT) and operational technology (OT)—that will be considered in the Special Issue may include:

- Industrial Internet-of-Things;

- Industrial analytics;

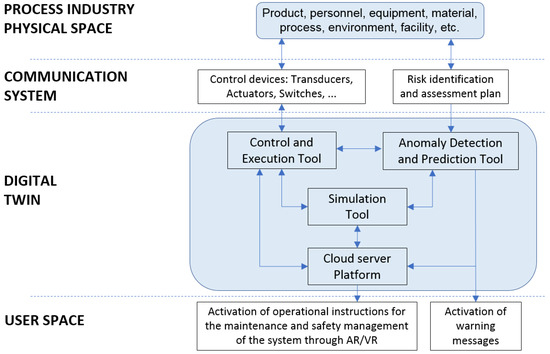

- Cyberphysical systems and digital twin;

- Smart manufacturing;

- Augmented reality, virtual reality, and mixed reality immersive technologies;

- Additive manufacturing;

- Autonomous vehicles and drones.

Topics to be covered include, but are not restricted to, the following aspects of smart and sustainable product lifecycles, smart and sustainable supply chains, and smart and sustainable factories:

- Challenges, visions, and concepts for Industry 4.0;

- New business models from smart manufacturing and services;

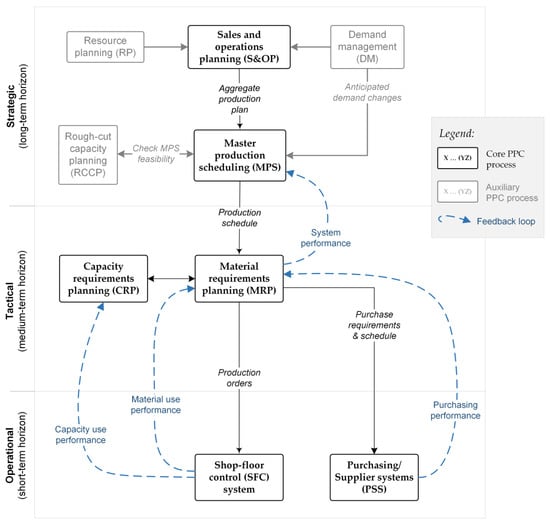

- Innovative digital manufacturing/service/supply chain models for Industry 4.0;

- Industry 4.0 standards for operations and supply chain management;

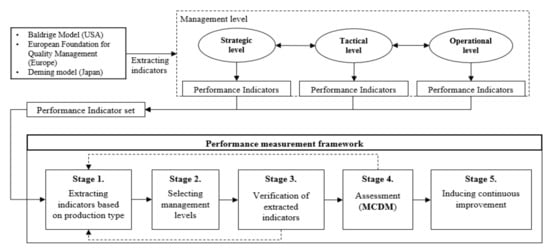

- KPIs and performance evaluation of smart production systems;

- Resource efficiency and sustainability in operations and supply chains with Industry 4.0;

- Environmental impacts of operations and supply chains from Industry 4.0;

- Cyberphysical systems for operation of smart production systems;

- Modeling and simulation of smart production systems;

- Multi-criteria decision making and decision analysis in smart production systems;

- Manufacturing data analysis;

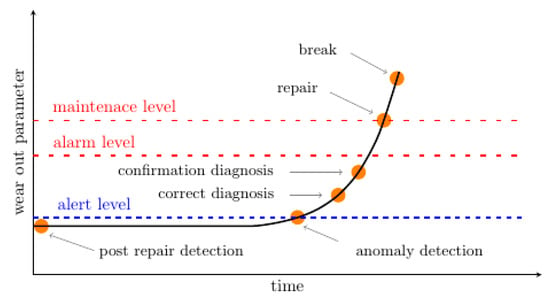

- Real-time diagnostics for quality, reliability, and maintenance;

- Advanced human–machine interface;

- Human factors, industrial ergonomics, and safety in smart factories;

- Integration of additive manufacturing in smart factories.

Prof. Dr. Giorgio Mossa

Prof. Dr. Fabio De Felice

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Sustainability is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- Industry 4.0

- Digital transformation of production systems

- Cyberphysical production systems

- Smart manufacturing

- Smart supply chains