Natural Non-Mulberry Silk Nanoparticles for Potential-Controlled Drug Release

Abstract

:1. Introduction

2. Results

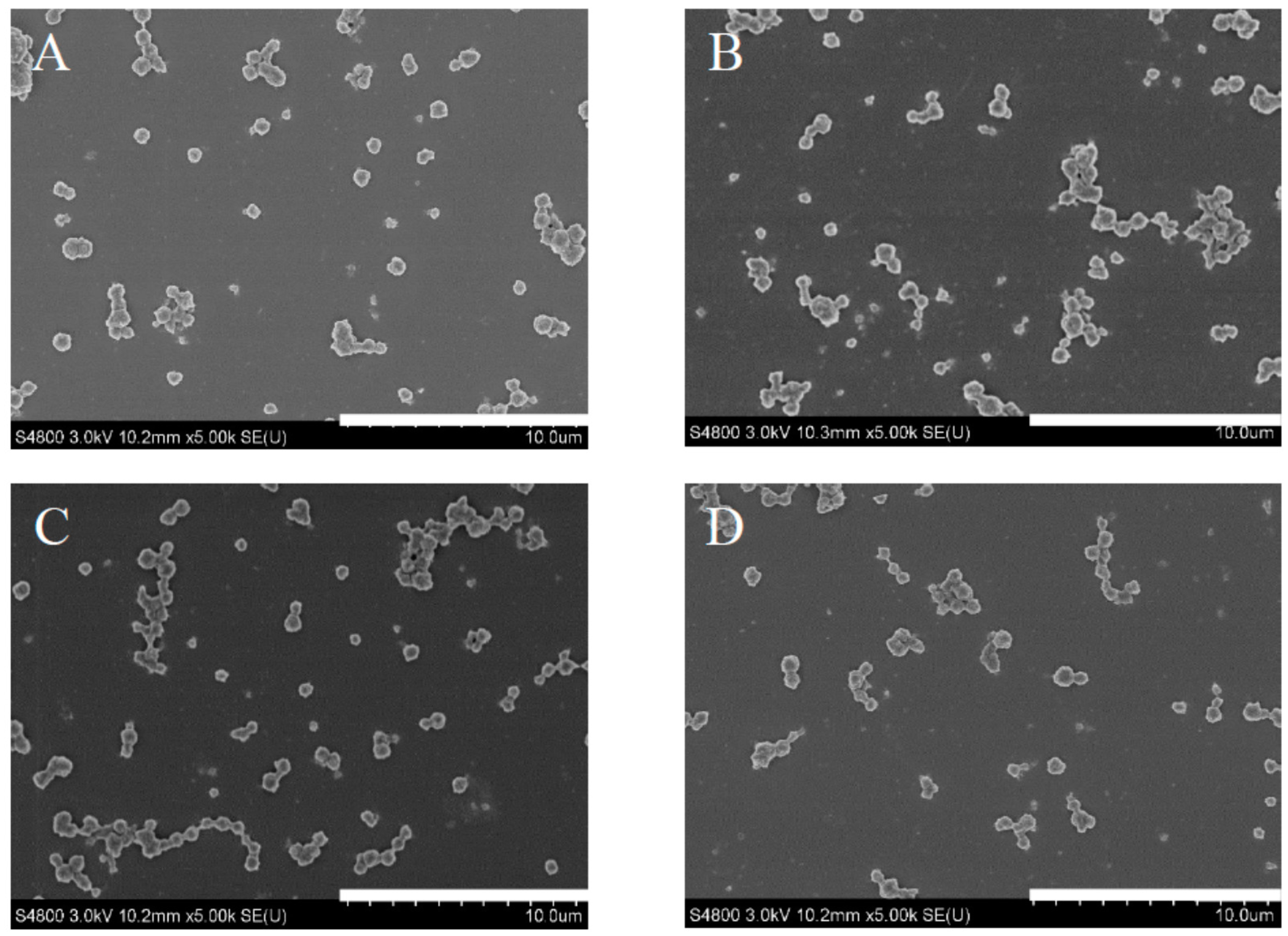

2.1. Morphology of Drug-Loaded ApF Nanoparticles

2.2. The Average Size and Brunauer-Emmett-Teller (BET) Surface Area of Particles

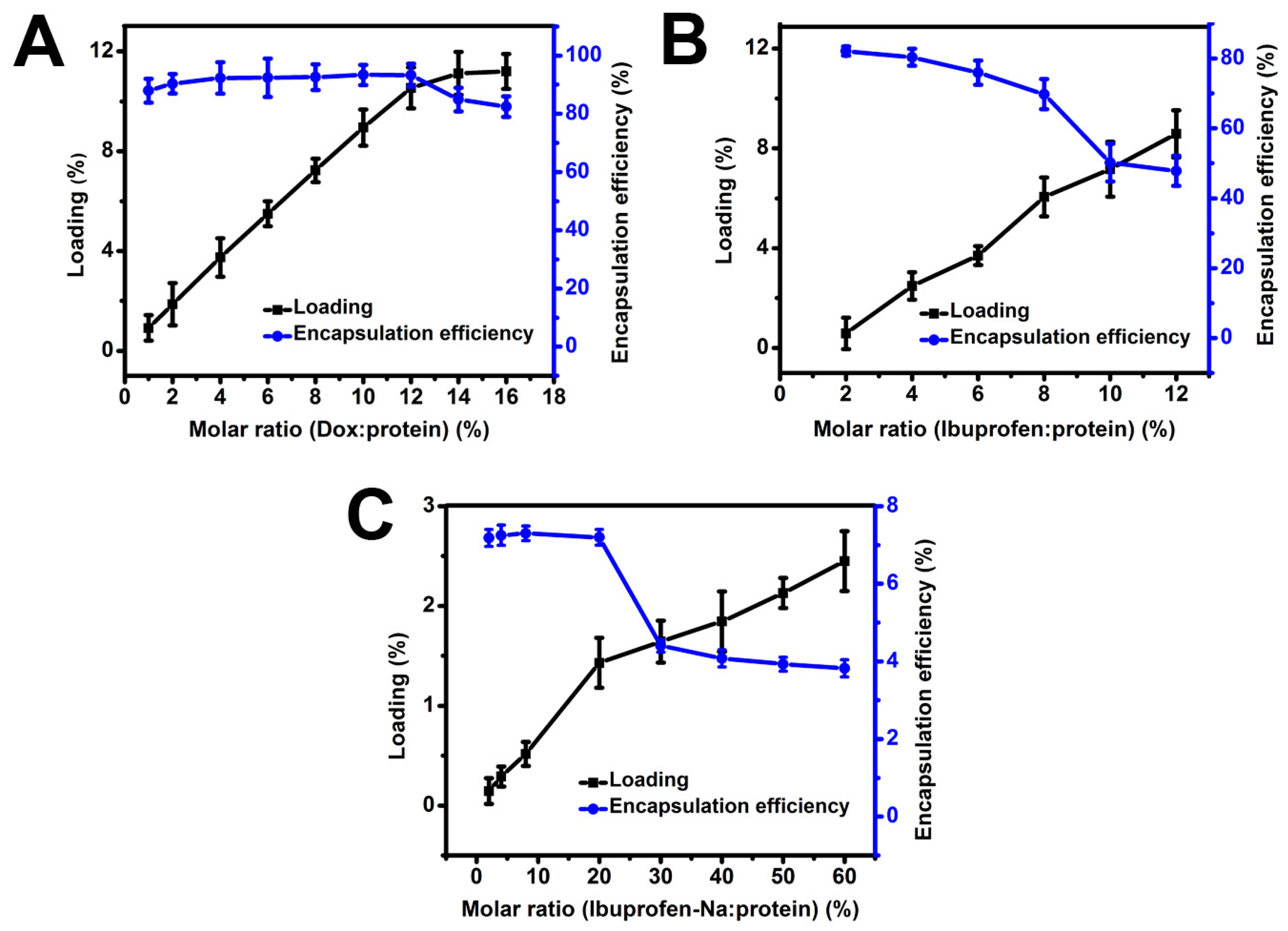

2.3. Drug Loading

2.4. Zeta Potential of Drug-Loaded ApF Nanoparticles

2.5. Drugs Release Rate

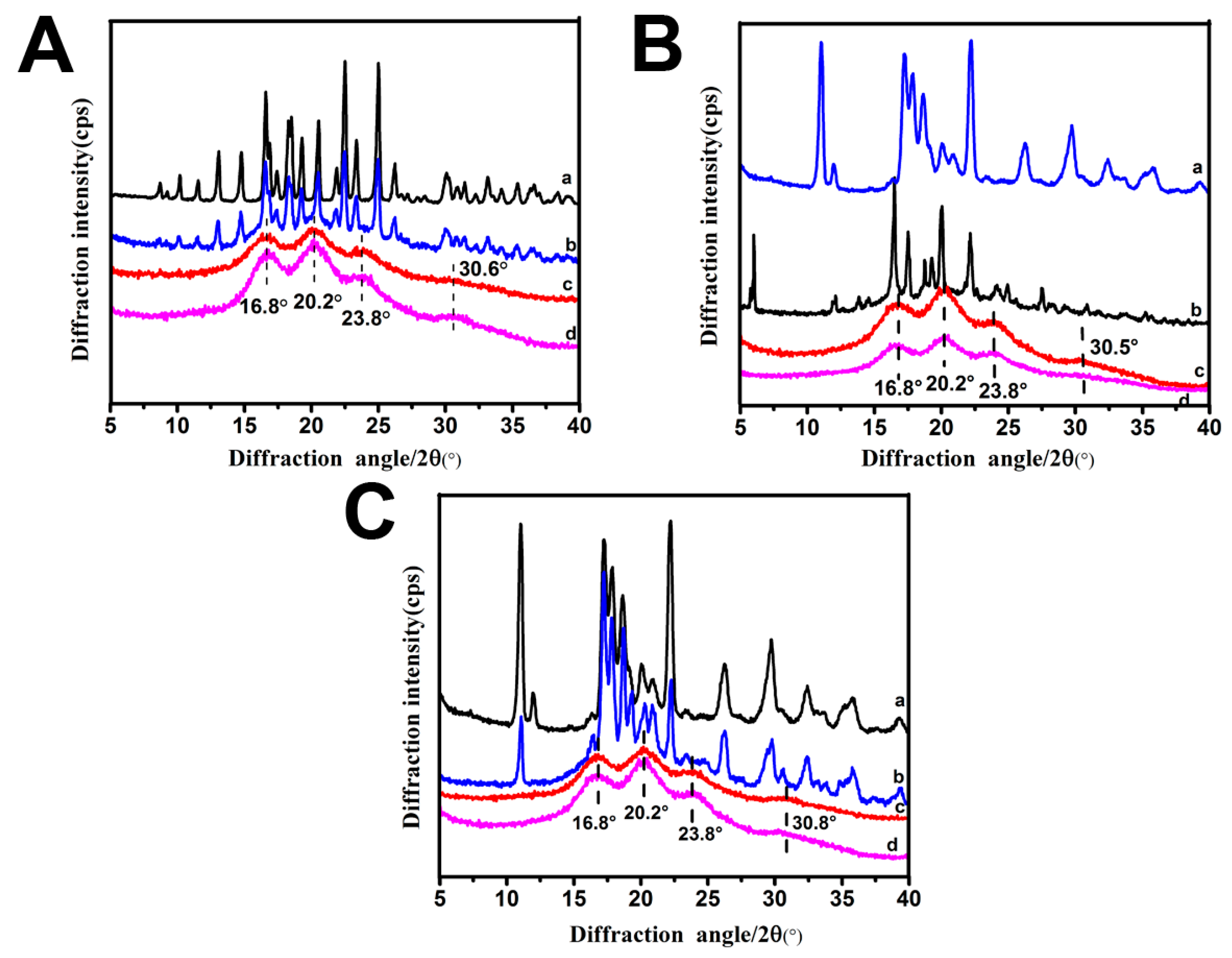

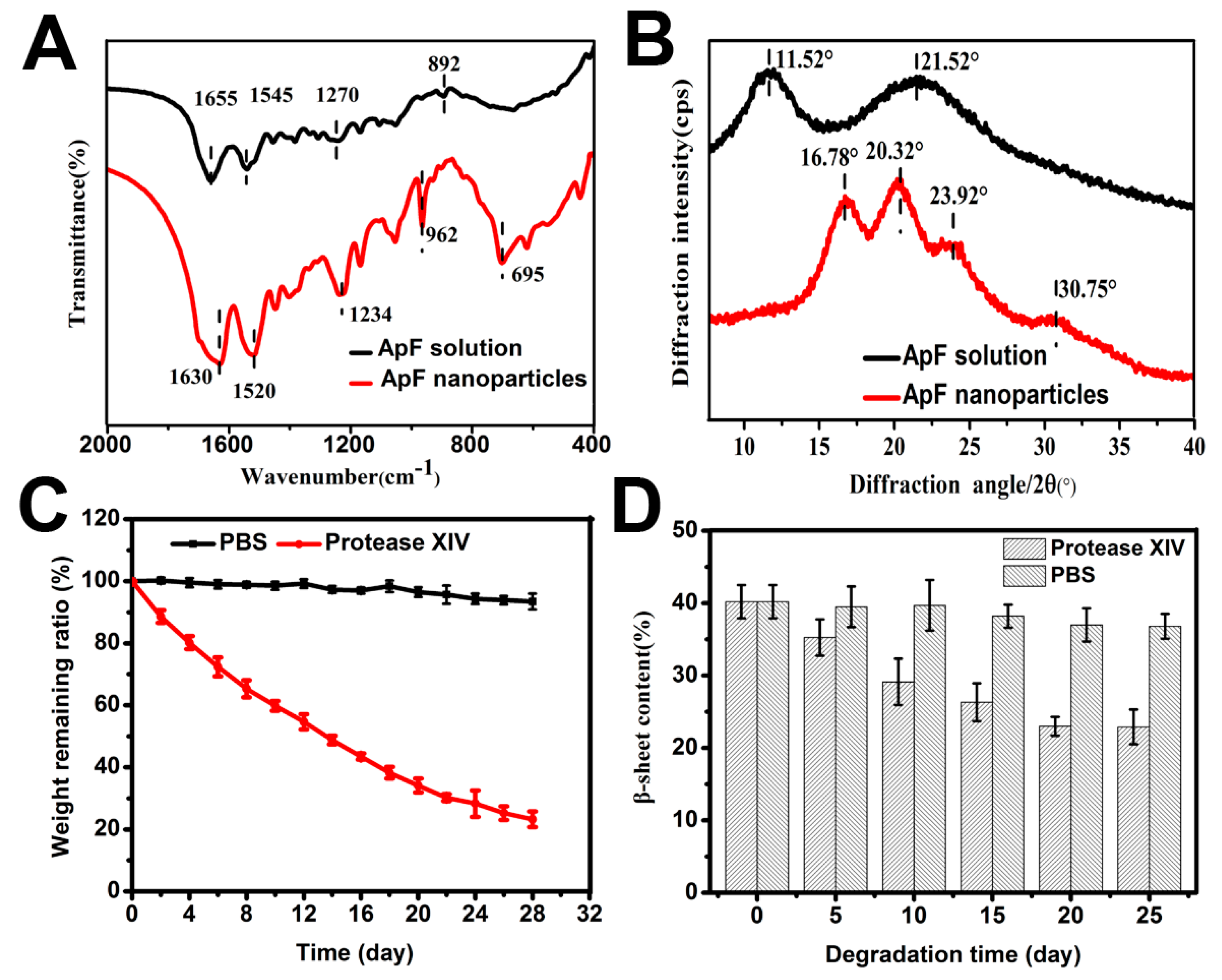

2.6. Structure of Drug-ApF Nanoparticles

2.7. In Vitro Degradation of ApF Nanoparticles

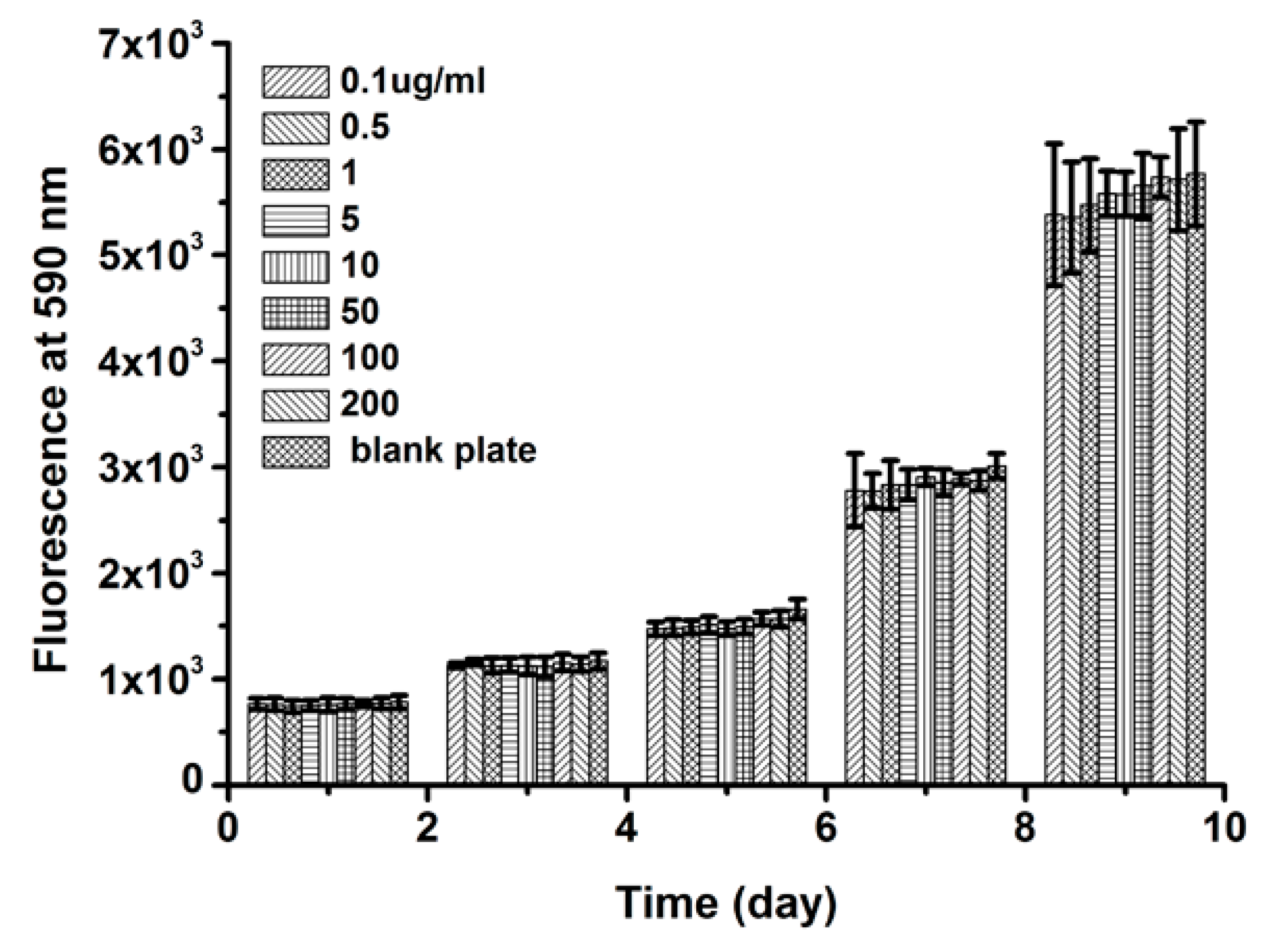

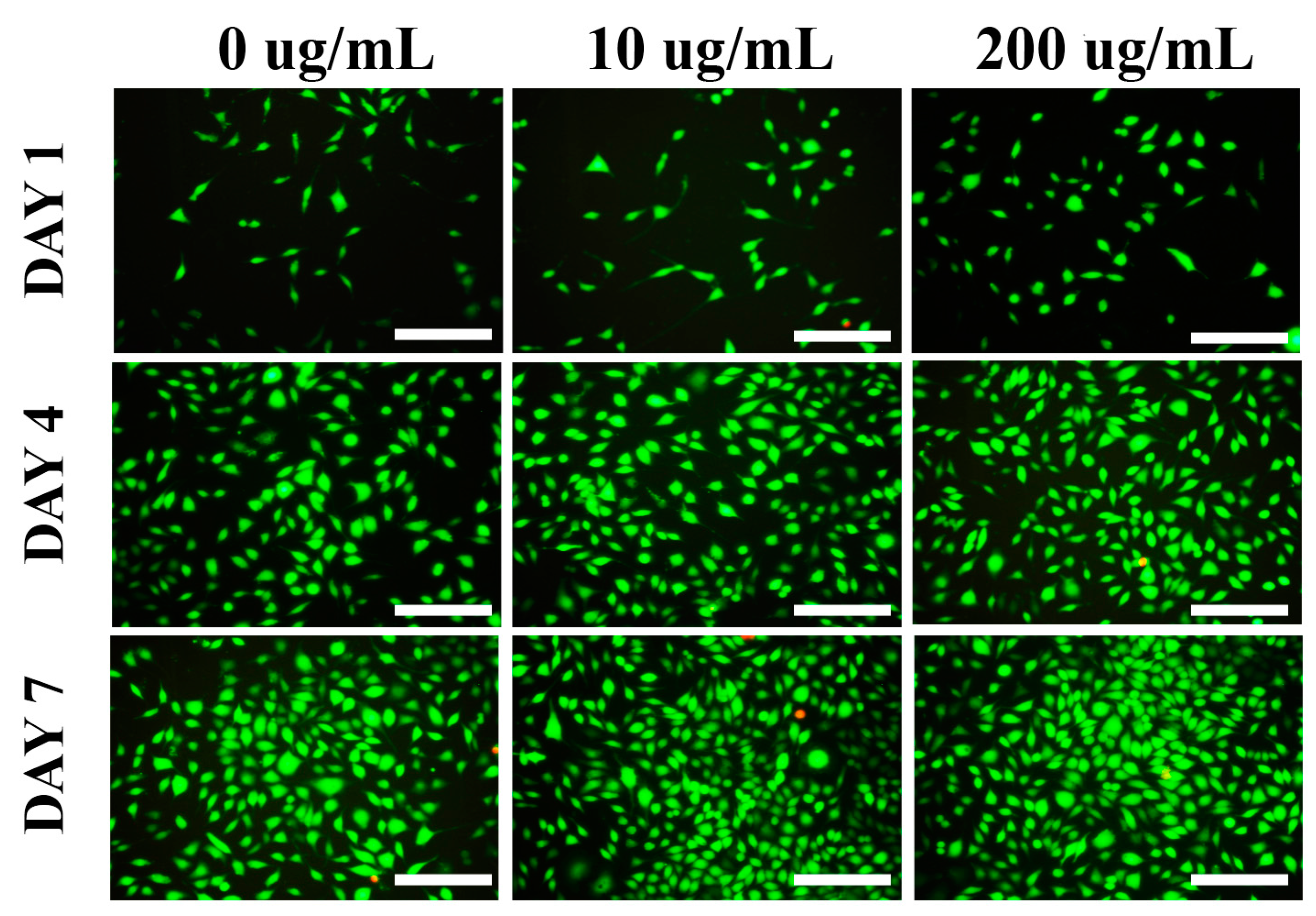

2.8. Cell Viability

3. Discussion

4. Materials and Methods

4.1. Preparation of ApF Solution

4.2. Preparation of ApF Nanoparticles

4.3. Drug Loading in ApF Nanoparticles

4.4. Zeta Potential and Surface Area Analysis

4.5. Release of Drugs from ApF Nanoparticles

4.6. Morphology and Particle Size of Drug-Loaded ApF Nanoparticles

4.7. Structure of ApF Nanoparticles

4.8. In Vitro Biodegradation of ApF Nanoparticles

4.9. Cell Culture

4.10. Statistical Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Langer, R. New methods of drug delivery. Science 1990, 249, 1527–1533. [Google Scholar] [CrossRef] [PubMed]

- Freiberg, S.; Zhu, X.X. Polymer microspheres for controlled drug release. Int. J. Pharm. 2004, 282, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Langer, R.; Peppas, N.A. Advances in biomaterials, drug delivery, and bionanotechnology. AIChE J. 2003, 49, 2990–3006. [Google Scholar] [CrossRef]

- George, M.; Abraham, T.E. Polyionic hydrocolloids for the intestinal delivery of protein drugs: Alginate and chitosan—A review. J. Control. Release 2006, 114, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Sun, Q.; Wang, H.; Wang, L.; Wang, J.Y. Microspheres of corn protein, zein, for an ivermectin drug delivery system. Biomaterials 2005, 26, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Won, Y.W.; Kim, Y.H. Recombinant human gelatin nanoparticles as a protein drug carrier. J. Control. Release 2008, 127, 154–161. [Google Scholar] [CrossRef] [PubMed]

- Sahin, S.; Selek, H.; Ponchel, G.; Ercan, M.T.; Sargon, M.; Hincal, A.A.; Kas, H.S. Preparation, characterization and in vivo distribution of terbutaline sulfate loaded albumin microspheres. J. Control. Release 2002, 82, 345–358. [Google Scholar] [CrossRef]

- Latha, M.S.; Rathinam, K.; Mohanan, P.V.; Jayakrishnan, A. Bioavailability of theophylline from glutaraldehyde cross-linked casein microspheres in rabbits following oral administration. J. Control. Release 1995, 34, 1–7. [Google Scholar] [CrossRef]

- Wenk, E.; Wandrey, A.J.; Merkle, H.P.; Meinel, L. Silk fibroin spheres as a platform for controlled drug delivery. J. Control. Release 2008, 132, 26–34. [Google Scholar] [CrossRef] [PubMed]

- Elzoghby, A.O.; Samy, W.M.; Elgindy, N.A. Protein-based nanocarriers as promising drug and gene delivery systems. J. Control. Release 2012, 161, 38–49. [Google Scholar] [CrossRef] [PubMed]

- Nanda, H.S.; Chen, S.; Zhang, Q.; Kawazoe, N.; Chen, G. Collagen scaffolds with controlled insulin release and controlled pore structure for cartilage tissue engineering. BioMed Res. Int. 2014, 2014, 623805. [Google Scholar] [CrossRef] [PubMed]

- Diab, T.; Pritchard, E.M.; Uhrig, B.A.; Boerckel, J.D.; Kaplan, D.L.; Guldberg, R.E. A silk hydrogel-based delivery system of bone morphogenetic protein for the treatment of large bone defects. J. Mech. Behav. Biomed. Mater 2012, 11, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Numata, K.; Cebe, P.; Kaplan, D.L. Mechanism of enzymatic degradation of β-sheet crystals. Biomaterials 2010, 10, 2926–2933. [Google Scholar] [CrossRef] [PubMed]

- Rajkhowa, R.; Hu, X.; Tsuzuki, T.; Kaplan, D.L.; Wang, X.Q. Structure and biodegradation mechanism of milled Bombyx mori silk particles. Biomacromolecules 2012, 13, 2503–2512. [Google Scholar] [CrossRef] [PubMed]

- Horan, R.L.; Bramono, D.S.; Stanley, J.R.L.; Simmons, Q.; Chen, J.; Boepple, H.E.; Altman, G.H. Biological and biomechanical assessment of a long-term bioresorbable silk-derived surgical mesh in an abdominal body wall defect model. Hernia 2009, 13, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Seib, F.P.; Maitz, M.F.; Hu, X.; Werner, C.; Kaplan, D.L. Impact of processing parameters on the haemocompatibility of Bombyx mori, silk films. Biomaterials 2012, 33, 1017–1023. [Google Scholar] [CrossRef] [PubMed]

- Wray, L.S.; Hu, X.; Gallego, J.; Georgakoudi, I.; Omenetto, F.G.; Schmidt, D.; Kaplan, D.L. Effect of processing on silk-based biomaterials: Reproducibility and biocompatibility. J. Biomed. Mater. Res. B Appl. Biomater. 2011, 99, 89–101. [Google Scholar] [CrossRef] [PubMed]

- Rockwood, D.N.; Preda, R.C.; Yücel, T.; Wang, X.; Lovett, M.L.; Kaplan, D.L. Materials fabrication from Bombyx mori silk fibroin. Nat. Protoc. 2011, 6, 1612–1631. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.Z.; Wang, X.Q.; Uppal, N.; Kaplan, D.L.; Li, M.Z. Stabilization of horseradish peroxidase in silk materials. Front. Mater. Sci. China 2009, 3, 367–373. [Google Scholar] [CrossRef]

- Zhang, J.; Pritchard, E.; Hu, X.; Valentin, T.; Panilaitis, B.; Omenetto, F.G.; Kaplan, D.L. Stabilization of vaccines and antibiotics in silk and eliminating the cold chain. Proc. Natl. Acad. Sci. USA 2012, 109, 11981–11986. [Google Scholar] [CrossRef] [PubMed]

- Kundu, S.C.; Kundu, B.; Talukdar, S.; Nayak, S.S.; Kundu, J.; Mandal, B.; Bhardwaj, N.; Botlagunta, M.; Dash, B.C.; Acharya, C.; et al. Invited review nonmulberry silk biopolymers. Biopolymers 2012, 97, 455–467. [Google Scholar] [CrossRef] [PubMed]

- Patra, C.; Talukdar, S.; Novoyatleva, T.; Velagala, S.R.; Mühlfeld, C.; Kundu, B.; Kundu, S.C.; Engel, F.B. Silk protein fibroin from Antheraea mylitta, for cardiac tissue engineering. Biomaterials 2012, 33, 2673–2680. [Google Scholar] [CrossRef] [PubMed]

- Yukuhiro, K.; Kanda, T.; Tamura, T. Preferential codon usage and two types of repetitive motifs in the fibroin gene of the Chinese oak silkworm, Antheraea pernyi. Insect Mol. Biol. 1997, 6, 89–95. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Lin, L.; Chen, J.; Chen, X.; Park, T.G.; Maruyama, A. RGD targeting hyaluronic acid coating system for PEI-PBLG polycation gene carriers. J. Control. Release 2011, 155, 47–53. [Google Scholar] [CrossRef] [PubMed]

- Minoura, N.; Aiba, S.; Higuchi, M.; Gotoh, Y.; Tsukada, M.; Imai, Y. Attachment and growth of fibroblast cells on silk fibroin. Biochem. Biophys. Res. Commun. 1995, 208, 511–516. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, S.; Foo, C.T.; Rossetti, F.; Textor, M.; Vunjak-Novakovic, G.; Kaplan, D.L. Silk fibroin as an organic polymer for controlled drug delivery. J. Control. Release 2006, 111, 219–227. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wenk, E.; Matsumoto, A.; Meinel, L.; Li, C.; Kaplan, D.L. Silk microspheres for encapsulation and controlled release. J. Control. Release 2007, 117, 360–370. [Google Scholar] [CrossRef] [PubMed]

- Lammel, A.S.; Hu, X.; Park, S.H.; Kaplan, D.L.; Scheibel, T.R. Controlling silk fibroin particle features for drug delivery. Biomaterials 2010, 31, 4583–4591. [Google Scholar] [CrossRef] [PubMed]

- Bessa, P.C.; Balmayor, E.R.; Azevedo, H.S.; Nürnberger, S.; Casal, M.; van Griensven, M.; Reis, R.L.; Redl, H. Silk fibroin microparticles as carriers for delivery of human recombinant BMPs. Physical characterization and drug release. J. Tissue Eng. Regen. Med. 2010, 4, 349–355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bessa, P.C.; Balmayor, E.R.; Hartinger, J.; Zanoni, G.; Dopler, D.; Meinl, A. Silk fibroin microparticles as carriers for delivery of human recombinant bone morphogenetic protein-2: In vitro and in vivo bioactivity. Tissue Eng. C 2009, 16, 937–945. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, P.; Goh, J.C. Release and cellular acceptance of multiple drugs loaded silk fibroin particles. Int. J. Pharm. 2011, 420, 282–289. [Google Scholar] [CrossRef] [PubMed]

- Rangam, R.; Radhika, N.; Wang, L.; Smith, S.V.; Wang, X. An investigation into transition metal ion binding properties of silk fibers and particles using radioisotopes. Appl. Polym. Sci. 2011, 119, 3630–3639. [Google Scholar]

- Kundu, B.; Eltohamy, M.; Yadavalli, V.K.; Kundu, S.C.; Kim, H.W. Biomimetic designing of functional silk nanotopography using self-assembly. ACS Appl. Mater. Interfaces 2016, 8, 28458–28467. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Bano, S.; Ghosh, A.S.; Mandal, M.; Kim, H.W.; Dey, T. Silk fibroin nanoparticles support in vitro sustained antibiotic release and osteogenesis on titanium surface. Nanomed. NBM 2016, 12, 1193–1204. [Google Scholar] [CrossRef] [PubMed]

- Hino, T.; Shimabayashi, S.; Nakai, A. Silk microspheres prepared by spray-drying of an aqueous system. Pharm. Pharmacol. Commun. 2010, 6, 335–339. [Google Scholar] [CrossRef]

- Wang, X.; Yucel, T.; Lu, Q.; Hu, X.; Kaplan, D.L. Silk nanospheres and microspheres from silk/PVA blend films for drug delivery. Biomaterials 2010, 31, 1025–1035. [Google Scholar] [CrossRef] [PubMed]

- Lammel, A.; Schwab, M.; Slotta, U.; Winter, G.; Scheibel, T. Processing conditions for the formation of spider silk microspheres. ChemSusChem 2008, 1, 413–416. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; You, R.; Liu, G.; Li, X.; Sheng, W.; Yang, J.; Li, M. Antheraea pernyi silk fibroin-coated PEI/DNA complexes for targeted gene delivery in HEK 293 and HCT 116 cells. Int. J. Mol. Sci. 2014, 15, 7049–7063. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.Z.; Wang, J.; Mao, L.; Li, G.J.; Jin, J. Antheraea pernyi silk fibroin nanoparticles for drug delivery. J. Nano Res. 2014, 27, 75–81. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, S.; Xing, T.; Kundu, B.; Li, M.; Kundu, S.C.; Lu, S.Z. Ion-induced fabrication of silk fibroin nanoparticles from Chinese oak tasar Antheraea pernyi. Int. J. Biol. Macromol. 2015, 79, 316–325. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, G.J.; Jiang, R.; Yin, Z.P.; Lu, S.Z. Antheraea pernyi silk fibroin microspheres carried lysozyme. Adv. Mater. Res. 2014, 915–916, 875–878. [Google Scholar] [CrossRef]

- Dalmark, M. Characteristics of doxorubicin transport in human red blood cells. Scand. J. Clin. Lab. Investig. 1981, 41, 633–639. [Google Scholar] [CrossRef]

- Lee, E.S.; Shin, H.; Na, K.; Bae, Y.H. Poly(l-histidine)-peg block copolymer micelles and pH-induced destabilization. J. Control. Release 2003, 90, 363–374. [Google Scholar] [CrossRef]

- Avdeef, A.; Box, K.J.; Comer, J.E.; Gilges, M.; Hadley, M.; Hibbert, C.; Patterson, W.; Tam, K.Y. PH-metric log P11. pKa determination of water-insoluble drugs in organic solvent-water mixtures. J. Pharm. Biomed. Anal. 1999, 20, 631–641. [Google Scholar] [CrossRef]

- Freddi, G.; Gotoh, Y.; Mori, T.; Tsutsui, I.; Tsukada, M. Chemical structure and physical properties of Antheraea assama silk. J. Appl. Polym. Sci. 1994, 52, 755–781. [Google Scholar] [CrossRef]

- Lins, L.; Brasseur, R. The hydrophobic effect in protein folding. FASEB J. 1995, 9, 535–540. [Google Scholar] [PubMed]

- Horan, R.L.; Antle, K.; Collette, A.L.; Wang, Y.; Huang, J.; Moreau, J.E.; ltman, G.H. In vitro degradation of silk fibroin. Biomaterials 2005, 26, 3385–3393. [Google Scholar] [CrossRef] [PubMed]

- Arai, T.; Freddi, G.; Innocenti, R.; Tsukada, M. Biodegradation of Bombyx mori, silk fibroin fibers and films. J. Appl. Polym. Sci. 2004, 91, 2383–2390. [Google Scholar] [CrossRef]

- Altman, G.H.; Diaz, F.; Jakuba, C.; Calabro, T.; Horan, R.L.; Chen, J. Silk-based biomaterials. Biomaterials 2003, 24, 401–416. [Google Scholar] [CrossRef]

- Subia, B.; Chandra, S.; Talukdar, S.; Kundu, S.C. Folate conjugated silk fibroin nanocarriers for targeted drug delivery. Integr. Biol. (Camb.) 2014, 6, 203–214. [Google Scholar] [CrossRef] [PubMed]

- Temming, K.; Schiffelers, R.M.; Molema, G.; Kok, R.J. RGD-based strategies for selective delivery of therapeutics and imaging agents to the tumour vasculature. Drug Resist. Updat. 2005, 8, 381–402. [Google Scholar] [CrossRef] [PubMed]

- Danhier, F.; Vroman, B.; Lecouturier, N.; Crokart, N.; Pourcelle, V.; Freichels, H. Targeting of tumor endothelium by RGD-grafted PLGA-nanoparticles loaded with paclitaxel. J. Control. Release 2009, 140, 157–175. [Google Scholar] [CrossRef] [PubMed]

- Miura, Y.; Takenaka, T.; Toh, K.; Wu, S.; Nishihara, H.; Kano, M.R. Cyclic RGD-linked polymeric micelles for targeted delivery of platinum anticancer drugs to glioblastoma through the blood-brain tumor barrier. ACS Nano 2013, 7, 8583–8592. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Chen, L.; Zhang, R.; Chen, Z.; Li, Z. RGD peptide conjugated liposomal drug delivery system for enhance therapeutic efficacy in treating bone metastasis from prostate cancer. J. Control. Release 2014, 196, 222–233. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.F.; Mäkilä, E.M.; Kaasalainen, M.H.; Liu, D.; Sarparanta, M.P.; Airaksinen, A.J. Copper-free azide-alkyne cycloaddition of targeting peptides to porous silicon nanoparticles for intracellular drug uptake. Biomaterials 2014, 35, 1257–1266. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.T.; Liu, C.H.; Yu, J.; Wu, K.C. Liver cancer cells: Targeting and prolonged-release drug carriers consisting of mesoporous silica nanoparticles and alginate microspheres. Int. J. Nanomed. 2014, 9, 2767–2778. [Google Scholar]

- Wang, J.L.; Xi, Y.; Liu, Y.L.; Wang, Z.H.; Zhang, Q. Combination of targeted PDT and anti-VEGF therapy for rat CNV by RGD-modified liposomal photocyanine and sorafenib. Investig. Ophthalmol. Vis. Sci. 2013, 54, 7983–7989. [Google Scholar] [CrossRef] [PubMed]

- Meinel, L.; Kaplan, D.L. Silk constructs for delivery of musculoskeletal therapeutics. Adv. Drug Deliv. Rev. 2012, 64, 1111–1122. [Google Scholar] [CrossRef] [PubMed]

- Numata, K.; Kaplan, D.L. Silk-based delivery systems of bioactive molecules. Adv. Drug Deliv. Rev. 2010, 62, 1497–1508. [Google Scholar] [CrossRef] [PubMed]

- Pritchard, E.M.; Kaplan, D.L. Silk fibroin biomaterials for controlled release drug delivery. Exp. Opin. Drug Deliv. 2011, 8, 797–811. [Google Scholar] [CrossRef] [PubMed]

- Wenk, E.; Merkle, H.P.; Meinel, L. Silk fibroin as a vehicle for drug delivery applications. J. Control. Release 2011, 150, 128–141. [Google Scholar] [CrossRef] [PubMed]

- Das, S.K.; Dey, T.; Kundu, S.C. Fabrication of sericin nanoparticles for controlled gene delivery. RSC Adv. 2014, 4, 2204–2209. [Google Scholar] [CrossRef]

- Gubernator, J.; Druliskawa, Z.; Kozubek, A. A simply and sensitive fluorometric method for determination of gentamicin in liposomal suspensions. Int. J. Pharm. 2006, 327, 104–109. [Google Scholar] [CrossRef] [PubMed]

- Kundu, J.; Chung, Y.I.; Kim, Y.H.; Tae, G.; Kundu, S.C. Silk fibroin nanoparticles for cellular uptake and control release. Int. J. Pharm. 2010, 388, 242–250. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.; Aseh, A.; Ríos, C.N.; Aggarwal, B.B.; Mathur, A.B. Fabrication and characterization of silk fibroin-derived curcumin nanoparticles for cancer therapy. Int. J. Nanomed. 2009, 4, 115–122. [Google Scholar] [CrossRef]

- Hermanson, K.D.; Harasim, M.B.; Scheibel, T.; Bausch, A.R. Permeability of silk microcapsules made by the interfacial adsorption of protein. Phys. Chem. Chen. Phys. 2007, 9, 6442–6446. [Google Scholar] [CrossRef] [PubMed]

| Samples | The Average Particle Size (nm) | BET Surface Area (m2/g) |

|---|---|---|

| ApF nanoparticles | 496 ± 53.45 | 38.95 |

| DOX-ApF nanoparticles | 522 ± 62.63 | 10.64 |

| Ibuprofen-ApF nanoparticles | 504 ± 48.43 | 19.32 |

| Ibuprofen-Na-ApF nanoparticles | 519 ± 36.98 | 32.96 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yin, Z.; Xue, X.; Kundu, S.C.; Mo, X.; Lu, S. Natural Non-Mulberry Silk Nanoparticles for Potential-Controlled Drug Release. Int. J. Mol. Sci. 2016, 17, 2012. https://doi.org/10.3390/ijms17122012

Wang J, Yin Z, Xue X, Kundu SC, Mo X, Lu S. Natural Non-Mulberry Silk Nanoparticles for Potential-Controlled Drug Release. International Journal of Molecular Sciences. 2016; 17(12):2012. https://doi.org/10.3390/ijms17122012

Chicago/Turabian StyleWang, Juan, Zhuping Yin, Xiang Xue, Subhas C. Kundu, Xiumei Mo, and Shenzhou Lu. 2016. "Natural Non-Mulberry Silk Nanoparticles for Potential-Controlled Drug Release" International Journal of Molecular Sciences 17, no. 12: 2012. https://doi.org/10.3390/ijms17122012