Abstract

Building envelopes can play a crucial role in building improvement efficiency, and the adoption of Phase Change Materials (PCMs), coupled with transparent elements, may: (i) allow a better control of the heat flows from/to the outdoor environment, (ii) increase the exploitation of solar energy at a building scale and (iii) modulate light transmission in order to prevent glare effects. Starting from a literature review, focused on experimental works, this research identifies the main possible integrations of PCMs in transparent/translucent building envelope components (in glazing, in shutters and in multilayer façade system) in order to draw a global picture of the potential and limitations of these technologies. Transparent envelopes with PCMs have been classified from the simplest “zero” technology, which integrates the PCM in a double glass unit (DGU), to more complex solutions—with a different number of glass cavities (triple glazed unit TGU), different positions of the PCM layer (internal/external shutter), and in combination with other materials (TIM, aerogel, prismatic solar reflector, PCM curtain controlled by an electric pump). The results of the analysis have been summarised in a Strengths, Weakness, Opportunities and Threats (SWOT) analysis table to underline the strengths and weaknesses of transparent building envelope components with PCMs, and to indicate opportunities and threats for future research and building applications.

1. Introduction

1.1. Background

Over the last few decades, research activities conducted to enhance the energy efficiency of buildings have led to the development of new functional strategies, technologies and materials. The façade, and the building envelope in general, are probably two of the most frequently investigated construction elements, as this is where most of the energy exchange between the indoor and the outdoor environment occurs, as well as where solar energy harvesting can take place.

Among the large variety of technologies and systems that can be used to increase the energy performance of a building, phase change materials (PCMs) are undoubtedly one of the key elements in R&D, and several applications of PCMs to the building envelope have been proposed (e.g., a commercially available transparent technology system with an integrated prismatic solar reflector and a cavity filled with PCM has been developed by GlassX (Zurich, Switzerland).

PCMs are materials that exhibit a phase change (usually a solid-to-liquid transition in building applications) over a desired temperature range, and which are able to exploit the latent heat of the phase change for thermal energy storage purposes. Different analyses on the state of the art of PCM in building applications were published between 1998 and 2016 [1,2,3,4,5,6,7,8]. PCMs are generally employed in opaque building envelope components [4]. However, applications of PCM to transparent building components have also been proposed, and have undergone a grown focus in the last few years [9,10].

The main aim of the adoption of PCMs in transparent systems is to increase the thermal inertia of glazed components and to improve the overall performance of glazed components, in terms of energy and comfort. In other words, the goal of this concept is to better manage the direct solar gain (which can cause overheating problems) and to minimize the heat loss, thanks to the buffer effect provided by the PCM layer, while still allowing the visible part of solar radiation to be exploited for daylighting. Such an effect is only possible because of the optical properties of many PCMs, which show partial transparency to electromagnetic radiation within the solar range. The PCM layer is used to absorb and store (thanks to latent heat) most of the short-wavelength infrared (SW-IR) radiation, near infrared (NIR) radiation and part of the visible (VIS) radiation, and to let part of the VIS radiation enter the indoor environment in order to provide daylighting.

However, the performance and effectiveness of the PCM glazing concept are somewhat complicated to predict, and may sometimes show positive aspects and sometimes negative ones. This depends on different features of the system (i.e., the technology of the assembly), on the material itself (i.e., the type of PCM) and, more in general, on how the system is related to the building energy concept, and how it is managed (i.e., whether the component acts as a fully passive system or is actively controlled through additional devices).

Furthermore, applications in different climates or in different building types might lead to substantially different outcomes. Moreover, complexity also arises from the fact that these systems influence different domains of the building energy and indoor environmental performance (i.e., both thermal and visual environment), and that a concept or solution that might be suitable for one domain might not perform so well as far as the other domain is concerned.

In terms of building energy performance, the PCM glazing concept (like other state-of-the-art transparent building envelope components) is called upon to assure a good performance in terms of reduction of transmission heat loss (i.e., to obtain low values of thermal transmittance), to offer a (possibly dynamic) control of solar irradiance transmission (i.e., to obtain variable values of solar factor), and to allow a good exploitation of daylight to be achieved (i.e., to contribute to high values of daylighting autonomy and the daylight uniformity ratio) [11]. Furthermore, when it comes to thermal and visual comfort, the integration of PCM in transparent components should be able to assure suitable surface temperature values (to avoid general and local thermal discomfort conditions), and reduce the risk of glare discomfort for the occupants.

1.2. Aim of the Paper

A review, classification and detailed analysis of different PCM glazing concepts that appeared in the scientific literature between 1998 and 2018 are presented in this paper. The first aim of this work is to provide an up-to-date classification and state of the art of PCM glazing concepts, and then to include the latest development in the field since the most recent reviews on these technologies [9,10] have been published. Moreover, on the basis of the first-hand experience of the authors, and on the findings from the search in the scientific literature, the paper presents a critical analysis of the performance of the different systems, adopting the structure of the well-known SWOT analysis (Strengths, Weaknesses Opportunities, Threats). The analysis of the state of the art is presented through tables, where each research activity on or technology for the integration of PCM in transparent envelope components is listed. The main achievements, strengths, weaknesses, opportunities, and threats of each research activity are highlighted synthetically.

The scope of this SWOT analysis in particular was to crystalize the knowledge so far achieved on PCM glazing concepts and to identify necessary developments in R&D in order to further improve the performance of the systems investigated so far.

2. Literature Review at a Glance

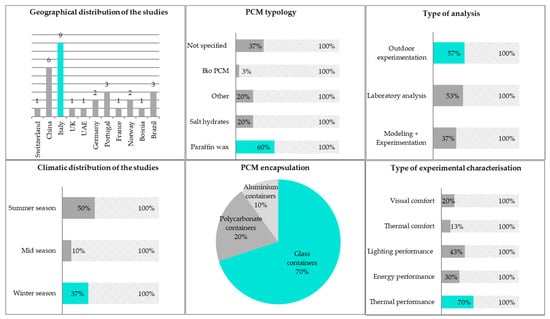

The literature review was based on a total of 30 papers, published between 1997 and 2018, related to experimental analyses of PCMs in transparent building envelope components. The analysed works were published in peer review journals and conference papers. The review analysis was restricted to only experimental research which presented the results of experimental in-field campaigns and to laboratory tests carried out on transparent technology prototypes with PCM. The investigated features are represented in Figure 1 and the percentages refer to the total number of studies, that is, 30 (thus representing 100%):

Figure 1.

Analysis of the papers that presented experimental activities on PCM glazing systems.

- -

- in the “Geographical distribution of the studies” chart, each bar expresses the number of studies conducted for each country;

- -

- in the “Climatic distribution of the studies”, “PCM typology”, “Type of analysis” and “Type of experimental characterisation” charts, each bar expresses, in percentage, the number of studies which considered the feature described in each row;

- -

- the “PCM encapsulation” pie chart reports, in percentage, the distribution of the analysed articles, according to the typology of the containers.

A simple analysis of the paper features has led to the following synthetic picture of PCMs in glazing (see also Figure 1):

- the geographical distribution of the studies, which also provides an indication of the climatic conditions of the study;

- the climatic/seasonal distribution of the studies: winter season (37%) [12,13,14,15,16,17,18,19,20,21,22], mid-season (10%) [14,15,20] and summer (50%) [13,14,15,16,17,20,23,24,25,26,27,28,29,30,31] season periods;

- the most investigated PCM typologies, that have been found to be paraffin wax (60%) [14,15,16,18,19,22,23,25,26,27,28,29,30,31,32,33,34,35] and salt hydrates (20%) [12,13,16,17,28,36,37], while only one study analysed the performance of bio PCMs (3%) [28];

- in all the papers, the PCM had been macro-encapsulated in containers, that is, glass containers (70%) [12,13,14,15,20,21,22,23,24,25,27,30,31,32,33,34,35,38,39,40,41], polycarbonate containers (20%) [16,17,19,28,36,42] and aluminium containers (10%) [18,26,29];

- the technologies had predominantly been characterised in outdoor test cells (57%) [14,15,17,18,19,20,21,22,24,25,26,27,29,31,35] and through laboratory analysis (53%) [12,13,17,20,23,32,33,34,35,36,37,38,39,40,41,42], while some other studies had been carried out by coupling a modelling activity with an experimental activity (37%) [12,13,14,16,21,23,29,30,32,34,37,40];

- the parameters investigated for the performance characterization of PCM transparent building envelope components have been found to be related above all to thermal performance (70%) [13,14,16,17,18,19,20,21,22,23,24,25,26,27,29,30,31,36,37,41,42] and lighting performance (43%) [12,20,21,22,31,32,33,34,35,38,39,40,41], while 30% of the studies evaluated energy performance [15,21,22,23,25,28,31,37,38];

- very few analysis had been carried out to evaluate the thermal (13%) [14,17,22,31,37] and visual (20%) [14,15,17,22,30] comfort performances related to the application of the technology at a room level;

- in all the papers, the analysis of the PCM transparent systems had been investigated at a component scale, while only a few works had extended the analysis to a building/system scale (13%) [14,17,20,35,37].

This synthetic analysis on the literature has made it possible to highlight the international interest in the subject of PCMs in glazing and to outline the main current research lines on the subject.

3. PCMs in Transparent Building Envelopes: A Technology Classification

The papers related to the integration of PCMs in transparent building envelopes have been classified according to the type of technology that had been considered. In order to improve the energy efficiency of the glazing areas and transparent/translucent areas, PCMs can be integrated in three main ways:

- (1)

- in the glazing, in order to directly enhance the heat capacity and thermal inertia of fenestration;

- (2)

- in the shutters, where they act as an energy buffer, and can be positioned either inside or outside a traditional window;

- (3)

- in façade systems, to interact with other insulating materials and solar control devices in a multilayer technology.

Each building application can be subdivided into different technological systems (Table 1), starting from the simplest “zero” technology, which integrates the PCM in a DGU, to more complex solutions, which can involve varying the number of glass cavities (TGU), the position of the PCM layer (internal/external shutter) and the interaction with other materials (TIM, aerogel, prismatic solar reflector, PCM curtain controlled by an electric pump). The technological systems have been analysed on the basis of the following classification (Table 1) in this paper:

Table 1.

Technologies integrating PCM in transparent envelopes.

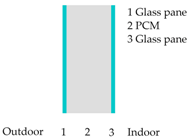

- Technology number 0, basic glazing technology: integration of the PCM in DGU glazing;

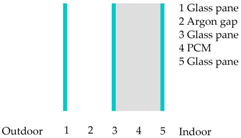

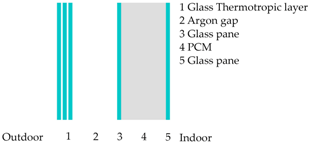

- Technology number 1, advanced glazing technology: integration of the PCM in TGU glazing;

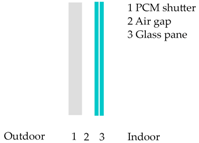

- Technology number 2, shutter technology: integration of the PCM in the shutter;

- Technology number 3, façade system: integration of the PCM in the façade.

Sub-categories have been identified for each category, and the working principle used to integrate the PCM in the glazing has been indicated (Table 1).

4. SWOT Analysis

4.1. Strenghts and Weaknesses of PCM Glazing Systems

A SWOT analysis has been developed from the review of the literature papers presented briefly in Section 2 and it is described in the following section. The potential and limitations of the following devices are presented hereafter on the basis of the classification of the transparent technologies given in Section 3:

- the basic glazing technology (Section 4.1.1);

- the advanced glazing technologies: integration of the PCM in TGU glazing (Section 4.1.2);

- the shutter technology: integration of the PCM in the shutter (Section 4.1.3);

- the façade system: integration of the PCM in the façade (Section 4.1.4).

It’s important to underline that the main outcomes (strengths, weaknesses, opportunities, and threats) for each solution are here synthetically summarised as found in the original paper, without any interpretation or added consideration by the Authors of this Review.

4.1.1. Basic Technology: Integration of the PCM in DGU Glazing

The basic technology in which the PCM is integrated in transparent building envelopes involves a double-glazing unit (DGU), where the cavity between the two glass panes is filled with PCM instead of a gas. This type of technology was first introduced about twenty years ago by Manz [12].

So far, the literature has presented different experimental studies on the integration of PCM in glazing units [13,23,24,30,32,33,34,41,43,44]. Real-scale prototypes of the technology (DGU + PCM) were used to collect data during measurements [25,26,28], and the assembly and the construction of these prototypes were carried out in house laboratories. Experimental tests were performed in outdoor test cells, and the energy performance of the PCM system were analysed and compared with a conventional fenestration. The surface temperatures, transmitted irradiances, heat fluxes and comfort performance of both the PCM glazing and the reference fenestration were measured during extensive experimental campaigns, in order to assess the energy performance of the technology under different boundary conditions. Starting from experimental results, the effects of thermo-physical parameters on the dynamic heat transfer performance of PCM were also investigated by means of numerical simulation softwares [13,23,30,43,44,45]. The semi-transparent property of a glazing roof containing PCM and the effect of zenith angle on the thermal performance were only analysed numerically by Liu et al. [46,47].

The effect of the PCM thickness and PCM melting temperatures on the thermal performance of double glazing units have been numerically and experimentally investigated by Liu et al. [21,41].

Furthermore, some results concerning laboratory characterizations [32,34,35,44] and numerical investigations [24] were published to determine the optical properties of the technologies for PCMs in solid and liquid states. The use of large integrating sphere equipment [33,35] has been necessary to obtain reliable results, due to the high scattering property of the system when the PCM is in a solid state. Transmittance, reflectance and absorbance spectra have been measured at different incident beam angles for components with different PCM layer thicknesses. Durakovic and Torlak [30] carried out laboratory and natural environment experimental activities to collect data and to validate a numerical model on a DGU with PCM in order to optimize the PCM layer thickness in the cavity.

The tested PCM typologies are commercially available paraffin-based ones with different nominal melting temperatures [15,23,30,32] and eutectics [13].

The results of the studies highlighted the potential of the technologies:

- to reduce the cooling load [13,15,23,30,43];

- to exploit the time shift of the cooling load—a well-designed project will ensure that the external temperature will start to decline before total melting of the enclosed PCM [15];

- to improve the poor thermal inertia of the glazing system [21,30,32,41];

- to collect and store solar energy at a building scale—a reduction in the “mismatch” between the heating demand and the availability of solar radiation during winter time-[15];

- to better control the visible solar radiation and reduce the glare risk—an improved exploitation of daylighting-[33,34,35];

- a “mitigation” of the internal glass surface temperatures, which leads to an improvement in the thermal comfort [14].

On one hand, the improvements, in terms of energy performance and visible control, that can be obtained using DGU + PCM were assessed during different seasons—summer, winter, mid-season [14,15,33,43], while, on the other hand, some threats and weaknesses were reported. However, further investigations of thermally massive glazed units and the optimization process used to control the transition of the PCM are still needed [14,15,32]. This can be achieved by choosing a proper melting temperature range on the basis of the considered boundary conditions in order to avoid too fast melting in summer or incomplete melting during winter.

Moving to the building scale, Bionda et al. [48] developed a simulation tool to evaluate the energy saving potentiality of translucent windows with PCM. The results showed that the application of the basic technology (DGU + PCM) can lead to both cooling and heating reductions, of between 1–9% and 7–10%, respectively. A further positive impact on thermal comfort was highlighted, with a reduction in the number of hours of overheating.

As a general comment, it is possible to state that the Technology Readiness Level (TRL) can be assessed as being between 4 and 6, which means that the technologies are in the validation phase in laboratories and in a significant environment. However, some steps still need to be taken to reach TRL 9.

The works concerning the basic technology DGU + PCM technology are reported in Table 2. The main achievements, strengths, weaknesses, opportunities and threats are synthetically highlighted.

Table 2.

SWOT analysis of PCM in DGU glazing.

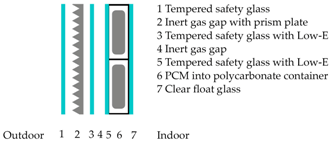

4.1.2. Advanced Technology: Integration of the PCM in TGU Glazing

The adoption of Phase Change Materials, in combination with advanced technologies, has been investigated in order to improve the weaknesses of the basic technology through the interaction of the PCM layer with more complex transparent envelopes through a multilayer structure.

The parameters investigated in order to assess the optimal configuration of a PCM transparent technology are:

- the location of the PCM compared to the position of the glazing;

- the PCM layer thickness;

- the interaction of the PCM with insulating materials;

- the interaction of the PCM with solar control devices in order to control daylighting.

The following research case studies analysed the potential and limitations of transparent advanced technologies containing phase change materials.

Goia et al. [25] and Bianco et al. [22,31] studied the technology that integrates Phase Change Material in triple glazing units (TGU) through experimental and a numerical analysis [49] in order to assess the thermo-physical behaviour of the components, by varying the position of the PCM layer in the inner or outer cavity of a triple glazing, and they obtained a better buffer performance—U value and thermal inertia—compared to the DGU technology.

They developed a physical-mathematical model to test the effect of variations in the position of a PCM layer in the inner-outer cavity of the TGU on the energy performance of the components, while real-scale prototypes were set up to analyse the influence of Thermotropic glass (TT) on solar energy transmission control. All the tested PCMs were paraffin based, with different melting temperatures of 25, 30 and 35 °C, in order to identify the best range during the summer period.

The results of this research highlight the potentials of this technology:

- solar gain reduction during daytime;

- heat storage within the paraffin layer;

- IR radiation absorption;

- heat flux peak shift;

- better control of the PCM melting process using a TT layer.

The main limitations are connected to the limited active control over the release of energy in summer and the drastic reduction in solar free gains during winter.

The experimental research of Li et al. [27] was focused on the dynamic thermal performance and energy saving performance of a triple-pane window with the outer cavity filled with PCM (paraffin type) during summer days. Compared to a DGU + PCM, the system effectively avoided overheating risks and reduced heat transfer to the room on sunny days, while the TGU + PCM component showed a good performance on reducing the temperature fluctuation of the interior surface and the heat entered the room on rainy days, but it was unsatisfactory in reducing the peak heat flux of the interior surface and delaying the peak temperature. The works concerning the advanced TGU + PCM technology are reported in Table 3.

Table 3.

SWOT analysis of PCM in TGU glazing.

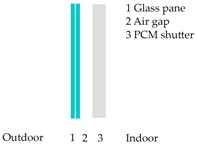

4.1.3. Shutter Technology: Integration of PCMs in Shutters

The concept of PCM integration in shutter systems was first developed in order to shift the potential of thermal storage and a surface temperature decrease-internal shutter-and solar-light control and a peak solar radiation reduction-external shutter-to another element positioned in front of the glazing.

Internal PCM sun protection studies [16,17,29,50] dealt with the problem of the overheating of a screen positioned on the inner side during the summer period: in the case of incoming solar radiation, the blind can only heat up to the melting temperature of the PCM, which then starts to absorb heat and store it as latent heat. A further increase in temperature cannot occur until the PCM has melted completely. The PCM thus decreases the blind surface temperature as well as the g-value of the system. Furthermore, the possibility of increasing the thermal inertia of the glazing during winter [16,17,18,26,51] could be achieved, thanks to the insulation properties of the PCM layer and to the possibility of taking advantage of the heat stored during the day for the release phase of the material.

The concept of moving the PCM layer to external shutters [19,28,52] was proposed to optimize the technology performance during the summer period, by absorbing incident solar radiation before it enters indoor spaces and exploiting the latent heat storage process of PCM to shift the peak values of heat fluxes and surface temperatures.

The experimental analysis carried out by Bianco et al. [28] verified the influence of the colour of the polycarbonate panel and the behaviour of different PCMs typologies on the performance of shading components; furthermore, a qualitative analysis of the PCM phase transition pointed out the strong discontinuity in appearance that can limit the application of transparent PCM-filled components in architecture.

The works concerning the technologies of PCM shutters are reported in Table 4. The tested PCMs are paraffin-based ones and salt hydrates.

Table 4.

SWOT analysis of PCM in shutters.

The results of the studies highlight the potential of the technologies:

- heat gain reduction;

- internal surface temperature reduction;

- thermal comfort enhancement;

- peak cooling load reduction;

- glare risk reduction;

- thermal inertia enhancement and heat loss reduction in winter.

The main limits of this technology are represented by the reduction of the incoming daylight and problems related to leakage; furthermore, the melting temperature range of PCM should be chosen carefully in order to prevent the material from melting too quickly in the external shutters as well as the incomplete melting of the PCM in the internal components.

Future improvements could be made concerning the visual appearance of the system to improve the architectural integration of the element, by enhancing the appearance quality of the shading during the melting phase and considering the possibility of integrating ventilation systems to improve the PCM discharging process.

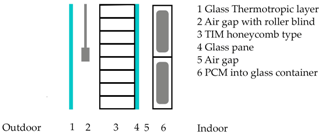

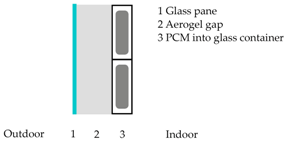

4.1.4. Façade System: Integration of the PCM in Façades

The development of façade systems containing PCM has been investigated to improve the thermal inertia of transparent envelope components in order to achieve the typical thermal performances of opaque building elements, but still preserving daylighting.

Manz [12] studied the heat storage capacity of hydrate salts, combined with the insulation property of Transparent Insulation Material (TIM), through an experimental investigation, and the storage capacity of this passive technology was found to be promising. Nevertheless, the solid phase of PCM leads to heat and light gain reductions, and encapsulation in glass containers could represent a threat from a safety point of view.

Berthou [20] prototyped a system in which PCM was combined with aerogel in order to achieve the aims of superinsulation, heat storage and daylighting. The results of laboratory and in situ experimentations showed that the translucent layer of silica aerogel played a filtering role on solar radiation and interacted with the PCM to reduce heat losses. This kind of façade system plays a positive role during the winter season, even though the PCM melting temperature should be chosen carefully in order to allow the phase change of the material to take place, even on low solar radiation days.

The novel Responsive Building Element concept proposed by Iennarella et al. [53] consists of three glazings that have been dynamically combined to minimize the energy consumption for lighting and HVAC systems: a low-E selective glass coupled with two active layers (with automated motion), one with aerogel, to increase the insulation in winter, and one with a PCM to increase the solar control in summer. The system was designed for a sample office room in Turin, and the annual energy consumption (for cooling, heating and lighting) was assessed numerically for different configurations, changing the orientation of the sample room and the thicknesses of the active layers. The obtained results showed that the module allowed a significant improvement to be made in the annual primary energy performances, compared to a traditional transparent façade, and that the advantage of using the RBE was particularly evident for south, west and east facing orientations, but less so for a north facing one because of the limited activation of the PCM in summer.

Commercially available façade systems with prismatic solar control were studied using large scale measurements [36,42] and simulation [37]. The purpose of thermal inertia enhancement, through PCM activation, can only be reached by choosing low melting temperatures of the PCM and by ensuring a long-time interval between consequent cycles. Further improvements still need to be made to enhance daylighting and to reduce artificial lighting.

The transparent façade system developed by Ismail et al. [38,39,40] is a double glass unit containing a moving PCM curtain controlled by an electric pump. They conducted experimental investigations using spectrophotometry, which indicated a considerable reduction in the infrared and ultraviolet radiations while preserving good visibility, and the use of coloured PCMs, in particular the green ones, seems to be more effective in reducing radiated energy gains.

The particular combination of a PCM layer and a semi-transparent PV module inside the cavity of a double skin façade (DSF) has recently been investigated numerically by Goia et al. [54] and the obtained results show that this technology can significantly reduce the indoor cooling load and increase conversion efficiency from solar energy to electrical energy.

The works concerning the technologies of PCM integrated in façade systems are reported in Table 5.

Table 5.

SWOT analysis of PCM in the façade.

4.2. Threats and Opportunities of PCM Glazing Systems

The main results of the SWOT analysis pertaining to all the typologies of technologies analysed in the paper i.e., glazing, shutter and façade with PCMs, are summarised in Table 6. The considerations reported in the table have been elaborated by the authors from the literature analysis presented in the previous sections.

Table 6.

Summary of the SWOT analyses.

It is possible to note that the integration of PCMs in transparent envelopes introduces some positive aspects to the performance of the technology from the energy, thermal and comfort points of view. Benefits have emerged as the thermal mass and the heat storage capacity of the building envelope have increased.

With regards to the weaknesses, most of the points, such as flammability, chemical compatibility and change in volume, are mainly related to the chemical and thermos-physical properties of the PCMs. An appropriate climate-based design of the transparent system with PCM needs to be introduced to define the correct nominal melting temperature of the PCMs in order to ensure the complete achievement of the PCM cycle. At the same time, since the benefit of integrating PCMs in glazing is achieved during its phase change, this phase can be considered the most critical from other points of view, such as those pertaining to visual transmission and the aesthetics of the system. In fact, the PCM is not homogeneous during the transition phase, and consequently influences the appearance of the technology. Furthermore, the external view and the transparency of a glazing system with PCM can only be achieved when the PCM has melted completely, and is therefore in a liquid state i.e., in an optimized design technology, in the late afternoon when the solar heat gains are lower. This means that the dynamic glazing is in a transition phase during the rest of the day and therefore not completely transparent, and the daylighting is consequently lower.

The main weaknesses that arise from the integration of PCMs in transparent envelopes are related to technological aspects, such as leakage risks and/or difficulty in sealing the PCMs as well as an increase in the weight of the transparent technologies.

As far as the opportunities are concerned, it is possible to highlight that PCMs in transparent envelopes present the possibility of several research paths for future development. It is also worth mentioning that the integration of PCMs still needs certain technological problems to be overcome and a technological readiness level to be reached which would make their integration in real scale buildings feasible. One of the most interesting opportunities is that of working on the regulation of PCM transition, in order to obtain homogenous behaviour of the system and also to be able to control the state of the material as well as its appearance, whether liquid or solid, transparent or translucent. This scenario could be envisaged considering the integration of other materials/systems in a more complex façade system. The most significant threat is the cost-effectiveness of the system, which needs to be justified by the enhanced performances of the façade system in order to encourage architects to use these kinds of solutions. The other identified threats can be considered technical ones, which can be overcome through research on the topic.

5. Conclusions and Suggestions for Future Research Activities

A complete critical picture of the experimental works on the transparent building envelopes that integrate PCMs has been given (between 1998 and 2017) in this work. The first step of the review activity involved categorizing the main possible integrations of PCMs in transparent building envelopes: in the cavity of double or triple glazing units, as an internal or external shutter system, or in a more complex system with other materials, such as on a façade. The research papers published on the subject, related to the experimental activity, have been analysed for each of the previously identified technology categories. The result is a series of SWOT analyses, which have pointed out the main strengths, weakness, opportunities and threats for each work.

The analysis has shown that the main strengths of integrating PCMs in transparent building envelopes are related to an enhancement, in terms of performance, of the technology from the energy, thermal, and comfort points of view. Benefits, which show an increase in the thermal mass and the heat storage capacity of the building envelope, have also been revealed. However, different weaknesses still need to be overcome, at both the technological and chemical level. In addition, the energy performance should also be evaluated accurately during winter i.e., if the PCMs stay solid, the reduction in solar heat gains could negatively influence the overall energy and thermal balance of a building. Another critical aspect pertains to the visual and thermal behaviour of the dynamic envelope during the transition phase of the material, when the PCM is not completed liquid.

In short, the present work has defined the opportunities and threats for future building applications of transparent building envelopes with PCMs, according the results achieved in the different researches. The main outcomes of the work highlight that some research on the subject still needs to be carried out in order to achieve cost-effective solutions and a higher technology readiness level. Moreover, opportunities for this dynamic transparent envelope have been identified and new research paths have been indicated. Finally, aside from some technological improvements aimed assuring full durability of some technologies (e.g., sealants) and design optimisation, the review activity has also highlighted the need to develop and/or integrate numerical models in building performance simulation tools, as well as performance metrics, and standardised test procedures.

Acknowledgments

The authors would like to thank EU Cost Action TU1403 “Adaptive Facades Network” for providing excellent research networking.

Author Contributions

F.G. and V.S. conceived and designed the review paper; I.V. and L.B. conducted the literature review; all the author contributed the SWOT analysis; I.V., L.B., and F.G. wrote the paper, V.S. coordinated the writing, reviewed the final paper, and contributed via fruitful scientific discussions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Zhang, Y. Review of thermal energy storage technologies based on PCM application in buildings. Energy Build. 2013, 67, 56–69. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Xiao, W.; Zeng, R.; Zhang, Q.; Di, H. Review on thermal performance of phase change energy storage building envelope. Sci. Bull. 2009, 54, 920–928. [Google Scholar] [CrossRef]

- Zhou, D.; Zhao, C.Y.; Tian, Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl. Energy 2012, 92, 593–605. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M.M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 2004, 45, 263–275. [Google Scholar] [CrossRef]

- Tatsidjodoung, P.; Le Pierrès, N.; Luo, L. A review of potential materials for thermal energy storage in building applications. Renew. Sustain. Energy Rev. 2013, 18, 327–349. [Google Scholar] [CrossRef]

- Hasnain, S.M. Review on sustainable thermal energy storage technologies, Part I: Heat storage materials and techniques. Energy Convers. Manag. 1998, 39, 1127–1138. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F. Literature review on the use of phase change materials in glazing and shading solutions. Renew. Sustain. Energy Rev. 2016, 53, 515–535. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Kylili, A.; Kalogirou, S.A. Phase change materials (PCMs) integrated into transparent building elements: A review. Mater. Renew. Sustain. Energy 2015, 4. [Google Scholar] [CrossRef]

- Rezaei, S.D.; Shannigrahi, S.; Ramakrishna, S. A review of conventional, advanced, and smart glazing technologies and materials for improving indoor environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Manz, H.; Egolf, P.; Suter, P.; Goetzberger, A. TIM–PCM external wall system for solar space heating and daylighting. Sol. Energy 1997, 61, 369–379. [Google Scholar] [CrossRef]

- Li, S.; Zhong, K.; Zhou, Y.; Zhang, X. Comparative study on the dynamic heat transfer characteristics of PCM-filled glass window and hollow glass window. Energy Build. 2014, 85, 483–492. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Improving thermal comfort conditions by means of PCM glazing systems. Energy Build. 2013, 60, 442–452. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Experimental analysis of the energy performance of a full-scale PCM glazing prototype. Sol. Energy 2014, 100, 217–233. [Google Scholar] [CrossRef]

- Weinläder, H.; Beck, A.; Fricke, J. PCM-facade-panel for daylighting and room heating. Sol. Energy 2005, 78, 177–186. [Google Scholar] [CrossRef]

- Weinlaeder, H.; Koerner, W.; Heidenfelder, M. Monitoring results of an interior sun protection system with integrated latent heat storage. Energy Build. 2011, 43, 2468–2475. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Development of a window shutter with phase change materials: Full scale outdoor experimental approach. Energy Build. 2015, 88, 110–121. [Google Scholar] [CrossRef]

- Komerska, A.; Bianco, L.; Serra, V.; Fantucci, S.; Rosiński, M. Experimental analysis of an external dynamic solar shading integrating PCMs: First results. Energy Procedia 2015, 78, 3452–3457. [Google Scholar] [CrossRef]

- Berthou, Y.; Biwole, P.H.; Achard, P.; Sallée, H.; Tantot-Neirac, M.; Jay, F. Full scale experimentation on a new translucent passive solar wall combining silica aerogels and phase change materials. Sol. Energy 2015, 115, 733–742. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Li, D.; Zhou, Y.; Wang, Z.; Liu, X. Effect of PCM thickness and melting temperature on thermal performance of double glazing units. J. Build. Eng. 2017, 11, 87–95. [Google Scholar] [CrossRef]

- Bianco, L.; Cascone, Y.; Goia, F.; Perino, M.; Serra, V. Responsive glazing systems: Characterisation methods and winter performance. Sol. Energy 2017, 155, 372–387. [Google Scholar] [CrossRef]

- Zhong, K.; Li, S.; Sun, G.; Li, S.; Zhang, X. Simulation study on dynamic heat transfer performance of PCM-filled glass window with different thermophysical parameters of phase change material. Energy Build. 2015, 106, 87–95. [Google Scholar] [CrossRef]

- Jain, L.; Sharma, S.D. Phase Change Materials for Day Lighting and Glazed Insulation in Buildings. J. Eng. Sci. Technol. 2009, 4, 322–327. [Google Scholar]

- Goia, F.; Bianco, L.; Cascone, Y.; Perino, M.; Serra, V. Experimental Analysis of an Advanced Dynamic Glazing Prototype Integrating PCM and Thermotropic Layers. Energy Procedia 2014, 48, 1272–1281. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Performance of a window shutter with phase change material under summer Mediterranean climate conditions. Appl. Therm. Eng. 2015, 84, 246–256. [Google Scholar] [CrossRef]

- Li, S.; Sun, G.; Zou, K.; Zhang, X. Experimental research on the dynamic thermal performance of a novel triple-pane building window filled with PCM. Sustain. Cities Soc. 2016, 27, 15–22. [Google Scholar] [CrossRef]

- Bianco, L.; Vigna, I.; Serra, V. Energy assessment of a novel dynamic PCMs based solar shading: Results from an experimental campaign. Energy Build. 2017, 150, 608–624. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Amaral, C.; Figueiredo, A. Thermal performance of a window shutter containing PCM: Numerical validation and experimental analysis. Appl. Energy 2016, 179, 64–84. [Google Scholar] [CrossRef]

- Durakovic, B.; Torlak, M. Experimental and numerical study of a PCM window model as a thermal energy storage unit. Int. J. Low-Carbon Technol. 2016. [Google Scholar] [CrossRef]

- Bianco, L.; Cascone, Y.; Goia, F.; Perino, M.; Serra, V. Responsive glazing systems: Characterisation methods, summer performance and implications on thermal comfort. Sol. Energy 2017, 158, 819–836. [Google Scholar] [CrossRef]

- Gowreesunker, B.L.; Stankovic, S.B.; Tassou, S.A.; Kyriacou, P.A. Experimental and numerical investigations of the optical and thermal aspects of a PCM-glazed unit. Energy Build. 2013, 61, 239–249. [Google Scholar] [CrossRef]

- Goia, F.; Zinzi, M.; Carnielo, E.; Serra, V. Characterization of the optical properties of a PCM glazing system. Energy Procedia 2012, 30, 428–437. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Li, Z.; Qi, H. Optical properties of a liquid paraffin-filled double glazing unit. Energy Build. 2015, 108, 381–386. [Google Scholar] [CrossRef]

- Goia, F.; Zinzi, M.; Carnielo, E.; Serra, V. Spectral and angular solar properties of a PCM-filled double glazing unit. Energy Build. 2015, 87, 302–312. [Google Scholar] [CrossRef]

- Grynning, S.; Goia, F.; Time, B. Dynamic Thermal Performance of a PCM Window System: Characterization Using Large Scale Measurements. Energy Procedia 2015, 78, 85–90. [Google Scholar] [CrossRef]

- Frontini, F.; Pfafferott, J.; Herkel, S.; Schwarz, D. Building simulation study of a residential double-row house with seasonal PCM-translucent façade. In Proceedings of the CleanTech for Sustainable Buildings: From Nano to Urban Scale, Lausanne, Switzerland, 14–16 September 2011; pp. 99–104. [Google Scholar]

- Ismail, K.A.; Henriquez, J. Thermally effective windows with moving phase change material curtains. Appl. Therm. Eng. 2001, 21, 1909–1923. [Google Scholar] [CrossRef]

- Ismail, K.A.; Henrı́quez, J. Parametric study on composite and PCM glass systems. Energy Convers. Manag. 2002, 43, 973–993. [Google Scholar] [CrossRef]

- Ismail, K.A.; Henriquez, J.R.; Te, D.D.E. PCM Glazing Systems. Int. J. Energy Res. 1997, 21, 1241–1255. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Zhu, Y.; Li, D.; Ma, L. Experimental investigation of optical and thermal performance of a PCM-glazed unit for building applications. Energy Build. 2018, 158, 794–800. [Google Scholar] [CrossRef]

- Grynning, S.; Goia, F.; Rognvik, E.; Time, B. Possibilities for characterization of a PCM window system using large scale measurements. Int. J. Sustain. Built Environ. 2013, 2, 56–64. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Y.; Zhong, K.; Zhang, X.; Jin, X. Thermal analysis of PCM-filled glass windows in hot summer and cold winter area. Int. J. Low-Carbon Technol. 2013, 1–8. [Google Scholar] [CrossRef]

- Li, D.; Ma, T.; Liu, C.; Zheng, Y.; Wang, Z.; Liu, X. Thermal performance of a PCM-filled double glazing unit with different optical properties of phase change material. Energy Build. 2016, 119, 143–152. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Zheng, Y.; Liu, C.; Hussein, A.K.; Liu, X. Thermal performance of a PCM-filled double-glazing unit with different thermophysical parameters of PCM. Sol. Energy 2016, 133, 207–220. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, Y.; Li, D.; Meng, F.; Zheng, Y.; Liu, X. Numerical analysis on thermal performance of a PCM-filled double glazing roof. Energy Build. 2016. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Li, D.; Ma, T.; Hussein, A.K.; Zhou, Y. Investigation of thermal and optical performance of a phase change material–filled double-glazing unit. J. Build. Phys. 2017, 174425911770873. [Google Scholar] [CrossRef]

- Bionda, D.; Kräuchi, P.; Plüss, I.; Schröcker, M. Simulation of the thermal performance of translucent phase change materials and whole-building energy implications. In Proceedings of the 10th Conference on Advanced Building Skins, Bern, Switzerland, 3–4 November 2015; pp. 673–680. [Google Scholar]

- Goia, F. Thermo-physical behaviour and energy performance assessment of PCM glazing system configurations: A numerical analysis. Front. Archit. Res. 2012, 1, 341–347. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, C.Y. Parametric investigations of using a PCM curtain for energy efficient buildings. Energy Build. 2015, 94, 33–42. [Google Scholar] [CrossRef]

- Soares, N.; Samagaio, A.; Vicente, R.; Costa, J. Numerical simulation of a PCM shutter for buildings space heating during the winter. In Proceedings of the World Renewable Energy Congress 2011 (WREC2011), Linköping, Sweden, 8–13 May 2011; pp. 1797–1804. [Google Scholar]

- Alawadhi, E.M. Using phase change materials in window shutter to reduce the solar heat gain. Energy Build. 2012, 47, 421–429. [Google Scholar] [CrossRef]

- Iennarella, S.; Serra, V.; Lo, V.R.M. A novel concept of a responsive transparent façade module: Optimization of energy performance through parametric design. Energy Procedia 2015, 78, 358–363. [Google Scholar] [CrossRef]

- Elarga, H.; Goia, F.; Zarrella, A.; Dal Monte, A.; Benini, E. Thermal and electrical performance of an integrated PV-PCM system in double skin façades: A numerical study. Sol. Energy 2016, 136, 112–124. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).